A high-quality exhaust component designed for optimal performance and noise reduction in vehicles. It serves as a critical element within the exhaust system, channeling gases away from the engine while simultaneously diminishing unwanted sound emissions. For instance, a vehicle experiencing excessive engine noise might benefit from the installation of this particular component to restore a quieter and more comfortable driving experience.

The utilization of a well-engineered exhaust system element can significantly improve a vehicle’s overall efficiency. Benefits include enhanced fuel economy, reduced emissions, and a smoother engine operation. Historically, improvements in these types of components have played a significant role in minimizing environmental impact and improving driver satisfaction by creating a quieter cabin environment. Modern versions are often constructed from durable materials designed to withstand high temperatures and corrosive elements, ensuring longevity and consistent performance.

The following sections will delve into specific attributes of these components, including material composition, installation procedures, maintenance guidelines, and factors to consider when selecting the appropriate system element for a given vehicle application. This detailed analysis aims to provide a thorough understanding of how these systems contribute to a vehicles overall performance and longevity.

Essential Guidance

The following represents crucial information regarding exhaust system maintenance and optimization, leading to extended lifespan and optimal functionality.

Tip 1: Conduct Regular Inspections. Examine the exhaust system, paying close attention to the muffler, for any signs of corrosion, rust, or physical damage. Early detection of these issues can prevent more significant problems down the line.

Tip 2: Address Leaks Promptly. Exhaust leaks can compromise the system’s efficiency and may introduce harmful gases into the vehicle’s cabin. If a leak is suspected, have it professionally inspected and repaired immediately.

Tip 3: Select Quality Replacement Parts. When replacing a muffler or any other component of the exhaust system, opt for high-quality parts from reputable manufacturers to ensure durability and proper fitment.

Tip 4: Ensure Proper Installation. Incorrect installation can lead to premature wear, leaks, and reduced performance. Professional installation is recommended, particularly for complex exhaust systems.

Tip 5: Monitor Engine Performance. Changes in engine noise, fuel economy, or emissions levels can indicate problems within the exhaust system, including a failing muffler. Investigate any such changes promptly.

Tip 6: Protect Against Environmental Factors. Areas with heavy road salt usage during winter can accelerate corrosion. Regular washing of the vehicle’s undercarriage can help mitigate this effect.

Tip 7: Avoid Short Trips. Short trips do not allow the exhaust system to reach its optimal operating temperature, which can lead to moisture accumulation and accelerate internal corrosion.

Adhering to these guidelines will contribute significantly to the longevity and consistent performance of the vehicle’s exhaust system, mitigating the need for frequent replacements and ensuring regulatory compliance.

The subsequent sections will provide further insights into specific material considerations and advanced troubleshooting techniques.

1. Material Durability

Material durability represents a critical factor influencing the lifespan and performance of a muffler. The exhaust system endures extreme conditions, including high temperatures, corrosive gases, and physical stresses. Consequently, the choice of materials directly affects the muffler’s ability to withstand these challenges and maintain its functionality over time.

- Corrosion Resistance

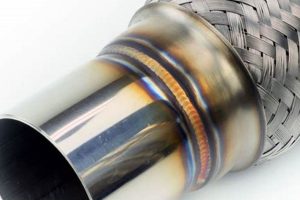

The materials used in a muffler must exhibit high resistance to corrosion from exhaust gases, moisture, and road salts. Stainless steel, aluminized steel, and specialized coatings are commonly employed to combat corrosion. The effectiveness of these materials dictates how long the muffler can withstand exposure to these elements before structural integrity is compromised.

- Thermal Stability

Mufflers operate in environments with fluctuating high temperatures. The chosen materials must maintain their strength and structural integrity under these conditions to prevent warping, cracking, or weakening. Materials with high thermal stability are essential for ensuring consistent performance and preventing premature failure due to thermal stress.

- Mechanical Strength

The muffler is subjected to physical stresses from vibration, impacts from road debris, and the weight of the exhaust system. The materials must possess adequate mechanical strength to withstand these forces without deformation or breakage. High-strength materials contribute to the muffler’s overall resilience and resistance to physical damage.

- Weld Integrity

The welding processes used to fabricate the muffler must create strong, durable joints that can withstand the same environmental stressors as the base materials. Weak or improperly executed welds can lead to premature failure and leaks. Maintaining weld integrity is crucial for ensuring the overall structural integrity and longevity of the muffler.

The selection of appropriate materials and manufacturing processes directly correlates with the long-term reliability and performance of mufflers. A muffler constructed from durable, corrosion-resistant materials will provide a longer service life, reduce the need for frequent replacements, and contribute to a more efficient and environmentally sound vehicle operation. Consequently, material durability is a primary factor considered when assessing the overall quality and value of such systems.

2. Noise Reduction

Noise reduction is a primary function of an exhaust system element, directly influencing the driving experience and regulatory compliance. It is achieved through specific design characteristics and internal structures engineered to attenuate sound waves generated by the engine. A properly functioning noise reduction system is essential for maintaining a comfortable and legally compliant vehicle operation.

- Acoustic Absorption

Acoustic absorption materials, such as fiberglass packing or specialized baffling, are used within the structure to dissipate sound energy. These materials convert sound waves into heat through friction and vibration, thereby reducing the overall noise level. The effectiveness of acoustic absorption depends on the type and amount of material used, as well as its placement within the system. The component with insufficient acoustic absorption can result in excessive noise levels, potentially violating local regulations.

- Resonance Chambers

Resonance chambers are carefully sized and shaped cavities within the muffler designed to cancel out specific frequencies of sound. By creating destructive interference patterns, these chambers effectively neutralize certain engine noises. The design of resonance chambers requires precise calculations and tuning to target the most problematic frequencies. Improperly designed or damaged resonance chambers can lead to increased noise levels and altered sound characteristics.

- Baffle Systems

Baffles are internal plates or partitions that redirect the flow of exhaust gases, forcing sound waves to travel through a more complex path. This increased path length and redirection cause sound waves to collide and cancel each other out, reducing noise levels. Baffle systems can be designed in various configurations to achieve different levels of noise reduction. Damaged or missing baffles significantly reduce the effectiveness of noise reduction, leading to louder exhaust sounds.

- Muffler Design and Volume

The overall design and volume of the muffler directly impact its ability to reduce noise. Larger mufflers generally offer greater noise reduction capabilities due to the increased space for sound waves to dissipate and cancel each other out. The internal configuration of the muffler, including the arrangement of baffles and resonance chambers, further influences its performance. A poorly designed or undersized unit may struggle to effectively reduce noise, particularly in high-performance vehicles.

Effective noise reduction is a key indicator of a well-engineered exhaust system element. It not only enhances the driving experience by minimizing unwanted noise but also ensures compliance with noise regulations, contributing to a quieter and more environmentally responsible operation. The combination of acoustic absorption, resonance chambers, baffle systems, and strategic muffler design ensures optimal sound attenuation, creating a balanced and compliant exhaust system.

3. Exhaust Flow

Exhaust flow, the movement of combustion gases from the engine through the exhaust system, is intrinsically linked to the performance and efficiency of the vehicle component under discussion. Its design directly influences the backpressure exerted on the engine, which in turn affects power output, fuel economy, and emissions. The effectiveness of the component relies heavily on its ability to manage exhaust flow optimally.

- Pipe Diameter and Configuration

The diameter and configuration of the piping within the component dictate the volume and velocity of exhaust gases that can pass through. A larger diameter generally reduces backpressure, potentially increasing power output, particularly in high-performance applications. However, an excessively large diameter can decrease exhaust gas velocity, leading to reduced scavenging and potentially lower torque at lower engine speeds. The component’s design must strike a balance between flow capacity and exhaust gas velocity to optimize performance across the engine’s operating range. Consideration is also needed for mandrel bending which is the folding point of the muffler.

- Internal Baffle Design

Internal baffles, used for noise reduction, inherently restrict exhaust flow. The design of these baffles significantly impacts the level of restriction. Straight-through designs, with minimal obstruction, offer the least resistance and are often preferred for performance applications. Chambered designs, with more complex gas pathways, provide greater noise reduction but at the expense of increased backpressure. A well-designed system utilizes baffles strategically to minimize flow restriction while achieving acceptable noise levels. Also with the strategic placement of chambered designed, this maximizes the performance for the exhaust flow.

- Surface Smoothness and Material

The smoothness of the internal surfaces and the material composition influence the friction encountered by exhaust gases as they flow through the component. Rough surfaces create turbulence, increasing backpressure and reducing flow efficiency. Smooth surfaces, achieved through careful manufacturing processes, minimize friction and promote laminar flow. Materials with low surface roughness, such as polished stainless steel, are often used in high-performance applications to maximize flow. Proper material should be selected to not produce corrosion.

- System Integration and Backpressure Management

The component must be integrated into the overall exhaust system in a way that minimizes backpressure and optimizes exhaust flow. This includes considering the diameter and configuration of the upstream and downstream exhaust components, as well as the overall length and layout of the system. Excessive backpressure can reduce engine performance, increase fuel consumption, and potentially damage engine components. Effective backpressure management is crucial for achieving optimal engine performance and longevity.

Optimizing exhaust flow through a high-quality exhaust system component involves careful consideration of pipe diameter, baffle design, surface smoothness, and overall system integration. Balancing these factors is critical for achieving the desired performance characteristics, whether it be increased power output, improved fuel economy, or reduced emissions. The ability of the component to effectively manage exhaust flow is a key determinant of its overall quality and effectiveness.

4. Engine Efficiency

Engine efficiency, defined as the ratio of useful work output to energy input, is significantly influenced by the performance characteristics of the exhaust system. A key component within this system directly impacts the engine’s ability to effectively expel combustion gases, consequently affecting fuel consumption, power generation, and overall engine health.

- Backpressure Optimization

An exhaust system component design impacts the level of backpressure exerted on the engine. Excessive backpressure hinders the efficient expulsion of exhaust gases, forcing the engine to work harder and consume more fuel. Conversely, insufficient backpressure can reduce cylinder scavenging, negatively affecting torque and power output at lower engine speeds. The component must strike a balance to optimize backpressure for the specific engine configuration, maximizing efficiency across the operating range.

- Scavenging Enhancement

The design of a component within a properly tuned exhaust system can promote efficient cylinder scavenging. Scavenging refers to the process of removing residual exhaust gases from the cylinder during the overlap period between the exhaust and intake valves opening. Improved scavenging allows for a more complete filling of the cylinder with fresh air and fuel, resulting in a more powerful and efficient combustion event. The component’s geometry and internal baffling can be designed to generate negative pressure waves that assist in scavenging, improving overall engine efficiency.

- Thermal Management

The exhaust system component influences the thermal management of the engine by affecting the rate at which heat is dissipated. An inefficient component can trap heat, leading to increased engine temperatures and reduced volumetric efficiency. Conversely, a component that promotes rapid heat dissipation can help maintain optimal engine temperatures, improving combustion efficiency and reducing the risk of overheating. The material selection and design of the component play a critical role in thermal management.

- Catalytic Converter Integration

The component’s design and location relative to the catalytic converter impact the converter’s efficiency. A properly positioned unit can ensure that exhaust gases reach the converter at the optimal temperature for efficient pollutant conversion. Conversely, a poorly designed system can result in suboptimal converter temperatures, reducing its effectiveness and increasing emissions. Seamless integration with the catalytic converter is essential for maximizing both engine efficiency and emissions control.

In summary, the optimization of exhaust flow, scavenging, thermal management, and catalytic converter integration through a properly designed system element directly contributes to enhanced engine efficiency. A well-engineered component minimizes backpressure, promotes efficient cylinder scavenging, manages engine temperatures, and supports optimal catalytic converter function, resulting in improved fuel economy, increased power output, and reduced emissions.

5. Emission Control

Emission control constitutes a critical aspect of modern vehicle design, with the exhaust system playing a pivotal role in mitigating harmful pollutants released into the atmosphere. Within this system, the proper functioning of its component is crucial for ensuring effective emission reduction, impacting both environmental compliance and public health.

- Catalytic Converter Compatibility

Compatibility with catalytic converters is a primary consideration. The location and design can influence the temperature and flow of exhaust gases reaching the converter, directly affecting its efficiency in converting pollutants like hydrocarbons, carbon monoxide, and nitrogen oxides into less harmful substances. For example, a system not correctly integrated may lead to suboptimal catalytic converter temperatures, reducing its effectiveness and increasing emissions output. This leads to regulatory penalties and environmental damage.

- Backpressure Regulation and Engine Efficiency

Regulation of backpressure is another critical factor. Excessive backpressure hinders the engine’s ability to expel exhaust gases, leading to reduced fuel efficiency and increased emissions. A well-designed component minimizes backpressure while still allowing for effective noise reduction and proper functioning of the catalytic converter. An example of this would be a system with unrestricted airflow, potentially improving engine performance but at the expense of increased pollutant output.

- Leak Prevention and System Integrity

Prevention of leaks is paramount for effective emission control. Exhaust leaks allow uncombusted hydrocarbons and other pollutants to escape into the atmosphere, bypassing the catalytic converter. A properly sealed system, with durable joints and corrosion-resistant materials, ensures that all exhaust gases are processed by the converter before being released. For instance, a system constructed with low-quality materials may corrode and develop leaks, leading to a significant increase in emissions and the potential for health hazards.

- Sound Attenuation and Regulatory Compliance

Sound attenuation is also linked to regulatory compliance. Although the primary function is to reduce noise, the design and construction influence the system’s ability to meet emission standards. A system modified solely for performance, without regard to emission controls, may exceed legal noise limits while also failing to adequately reduce pollutants. Therefore, balancing performance and compliance is crucial.

In conclusion, the selection and maintenance of an exhaust system element are integral to effective emission control. By ensuring catalytic converter compatibility, regulating backpressure, preventing leaks, and maintaining sound attenuation within regulatory limits, this element contributes significantly to reducing harmful emissions and promoting environmental stewardship. This proactive approach ensures vehicles operate efficiently, while adhering to stringent environmental standards.

6. Heat Resistance

Heat resistance is a paramount consideration in the design and material selection of the exhaust system component. The component operates in an environment characterized by extremely high temperatures generated by the engine’s combustion process. Its ability to withstand these temperatures without degradation or failure directly affects its longevity, performance, and safety. Proper heat resistance ensures structural integrity and prevents premature wear, contributing to the vehicle’s overall reliability.

- Material Selection for High-Temperature Environments

The choice of materials is crucial for heat resistance. Stainless steel, aluminized steel, and specialized alloys are commonly employed due to their ability to maintain strength and resist oxidation at elevated temperatures. For instance, stainless steel exhibits superior corrosion resistance and maintains structural integrity at temperatures exceeding 800C. The use of appropriate materials prevents warping, cracking, and melting, ensuring the component retains its intended shape and functionality throughout its operational lifespan. Improper material choices, on the other hand, would lead to premature failure and potential safety hazards due to exhaust leaks or structural collapse.

- Thermal Expansion and Contraction Management

Materials expand and contract with changes in temperature. The component’s design must accommodate these thermal expansions and contractions to prevent stress concentrations and potential cracking. Expansion joints, flexible couplings, and strategic mounting points are incorporated to allow for controlled movement. For example, a poorly designed system lacking expansion joints may experience excessive stress on welds and mounting brackets, leading to premature failure. Effective thermal expansion management ensures the component can withstand repeated temperature cycles without compromising its structural integrity.

- Heat Dissipation and Insulation

The component can be designed to facilitate heat dissipation or to provide insulation, depending on the specific application. Heat shields, ceramic coatings, and air gaps can be used to reduce heat transfer to surrounding components, protecting sensitive parts from excessive temperatures. For instance, heat shields are often placed between the component and the vehicle’s undercarriage to prevent damage to fuel lines or wiring. Conversely, maximizing heat dissipation can improve exhaust gas flow and reduce backpressure. Balancing heat dissipation and insulation is essential for optimizing both performance and safety.

- Impact of Exhaust Gas Temperature (EGT) on Durability

Exhaust Gas Temperature (EGT) directly affects the long-term durability of the component. Higher EGTs accelerate the degradation of materials, increasing the risk of corrosion, oxidation, and structural failure. Factors such as engine tuning, fuel type, and driving conditions can influence EGTs. A component operating under consistently high EGT conditions requires more robust materials and design features to ensure longevity. Monitoring EGTs and adjusting operating parameters can help prolong the component’s lifespan and maintain optimal performance.

These considerations underscore the critical role of heat resistance in ensuring the reliable and safe operation of the exhaust system element. The careful selection of materials, the management of thermal expansion, and the optimization of heat dissipation are essential for maximizing the component’s lifespan and maintaining its performance under extreme thermal conditions. A system with inadequate heat resistance is prone to premature failure, compromising both vehicle performance and safety.

7. System Integration

The operational effectiveness of an exhaust system element is inextricably linked to its integration within the broader vehicle architecture. Proper system integration ensures that the component functions harmoniously with other vehicle systems, maximizing performance, minimizing adverse effects, and meeting regulatory requirements. The following facets explore the critical considerations for successful integration.

- Engine Management System Compatibility

The exhaust system’s characteristics directly impact the engine management system (EMS). Backpressure levels and exhaust gas composition influence the EMS’s ability to optimize fuel delivery, ignition timing, and other critical parameters. An exhaust component that deviates significantly from the original equipment manufacturer’s (OEM) specifications can disrupt the EMS’s calibration, leading to reduced performance, increased emissions, or even engine damage. For example, a performance-oriented exhaust system that dramatically reduces backpressure may require recalibration of the EMS to prevent lean fuel conditions and potential engine knocking. Proper integration requires careful consideration of the exhaust system’s impact on the EMS and may necessitate adjustments to the EMS programming.

- Chassis and Body Clearance

Physical compatibility with the vehicle’s chassis and body is a fundamental aspect of system integration. The exhaust component must be designed to provide adequate clearance from other components, such as fuel lines, brake lines, suspension components, and the vehicle’s body panels. Insufficient clearance can lead to contact, vibration, and potential damage to both the exhaust system and surrounding components. For example, an exhaust system that rubs against the undercarriage can generate excessive noise, transmit vibrations into the cabin, and even create a fire hazard if it contacts flammable materials. Proper integration involves careful measurement and design to ensure adequate clearance throughout the vehicle’s operating range.

- Emissions Control System Synergy

The exhaust component must work in concert with the vehicle’s emissions control system, including catalytic converters, oxygen sensors, and other emission-related devices. The component’s design can influence the temperature and flow characteristics of exhaust gases reaching the catalytic converter, impacting its efficiency in reducing harmful pollutants. For example, an exhaust system that significantly alters exhaust gas temperature may reduce the catalytic converter’s effectiveness, leading to increased emissions and potential failure to meet regulatory standards. Proper integration requires careful consideration of the exhaust system’s impact on the emissions control system and may necessitate modifications to other emission-related components to maintain compliance.

- Noise, Vibration, and Harshness (NVH) Mitigation

The exhaust system contributes significantly to the vehicle’s overall NVH characteristics. An improperly integrated component can generate excessive noise, vibration, and harshness, detracting from the driving experience. The design should incorporate features to minimize these undesirable effects, such as resonators, mufflers, and vibration dampers. For example, an exhaust system lacking adequate sound attenuation may produce excessive drone at certain engine speeds, creating an unpleasant driving experience. Proper integration involves careful tuning of the exhaust system to minimize NVH while maintaining performance and emissions compliance.

Effective integration is not simply about bolting components together. It requires a holistic understanding of the vehicle’s various systems and how they interact. A well-integrated exhaust system element optimizes performance, minimizes adverse effects, and ensures that the vehicle operates smoothly, efficiently, and within regulatory limits. Neglecting system integration can lead to a host of problems, including reduced performance, increased emissions, component damage, and an unsatisfactory driving experience.

Frequently Asked Questions about King Muffler Systems

The following addresses common inquiries regarding the function, maintenance, and selection of high-performance exhaust system elements.

Question 1: What distinguishes a “king muffler” from standard automotive mufflers?

The designation denotes a superior level of engineering and materials science, typically resulting in enhanced durability, optimized exhaust flow, and improved sound attenuation compared to conventional mufflers. They are designed for longevity and performance.

Question 2: How does altering the muffler impact a vehicle’s emissions?

Modifying the muffler can indirectly influence emissions. While the muffler itself does not directly control emissions, changes to exhaust flow and backpressure can affect the catalytic converter’s efficiency. Modifications should comply with emissions regulations.

Question 3: What are common indicators suggesting that a muffler requires replacement?

Notable indicators include excessive exhaust noise, visible rust or corrosion, physical damage such as dents or holes, and a noticeable decrease in fuel efficiency. A professional inspection is recommended for accurate diagnosis.

Question 4: Is professional installation required for king muffler systems, or can installation be performed independently?

Professional installation is generally recommended, particularly for complex systems. Proper installation ensures correct fitment, optimal performance, and prevents potential damage to the exhaust system or surrounding vehicle components. Incorrect installation can void warranties.

Question 5: What maintenance procedures are necessary to extend the lifespan of a king muffler?

Regular inspections for corrosion, prompt repair of any exhaust leaks, and avoidance of harsh driving conditions can contribute to an extended muffler lifespan. Periodic cleaning of the exhaust system may also be beneficial.

Question 6: Can a “king muffler” improve a vehicle’s horsepower or fuel economy?

A high-performance system, by optimizing exhaust flow and reducing backpressure, can potentially contribute to a modest increase in horsepower and/or fuel economy. However, the extent of any improvement depends on various factors, including the vehicle’s engine and overall exhaust system design.

In essence, choosing a high-quality muffler system involves considerations of durability, performance, compliance, and proper installation. Maintenance and prompt attention to potential issues are crucial for maximizing its lifespan.

The next section will explore specific case studies demonstrating the performance benefits of optimized exhaust systems.

Conclusion

This exploration has detailed the significance of the component, from material durability and noise reduction to engine efficiency and emission control. The selection impacts vehicle performance, regulatory adherence, and long-term operational costs. Careful consideration of design characteristics and integration within the broader vehicle system is paramount.

The implementation of a quality system represents a tangible investment in the longevity and performance of a vehicle. Its impact extends beyond mere noise reduction, influencing engine efficiency, emissions compliance, and overall driving experience. Further research and technological advancements will undoubtedly continue to refine the design and performance capabilities of exhaust components, reinforcing their critical role in automotive engineering.