Catalytic Converter Rebar Cage: Unlocking the Power of Efficiency

A catalytic converter rebar cage is a protective structure designed to prevent theft of catalytic converters from vehicles by making it more difficult to access and remove the converter. This cage is made of sturdy materials like steel and is securely attached to the vehicle’s exhaust system, providing a physical barrier against theft attempts.

Catalytic converter theft has become a common problem due to the valuable metals found within the converters, such as platinum, palladium, and rhodium. The rebar cage acts as a deterrent, discouraging thieves from targeting a vehicle and saving the owner from the hassle and expense of replacing a stolen converter.

By installing this protective device, vehicle owners can safeguard their valuable converters effectively and maintain the performance and emissions control of their vehicles.

Understanding The Role Of Catalytic Converters

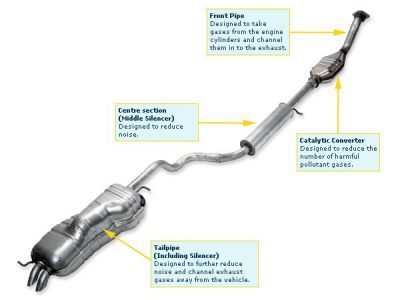

Understanding the role of catalytic converters is crucial when it comes to comprehending their importance in vehicle performance and environmental sustainability. These devices play a vital role in reducing harmful emissions by converting toxic gases produced during the combustion process into less harmful substances.

The primary purpose of catalytic converters is to enable the conversion of three harmful compounds – carbon monoxide, nitrogen oxides, and unburned hydrocarbons – into carbon dioxide, nitrogen, and water vapor respectively. By doing so, they contribute significantly to reducing air pollution and promoting cleaner air quality.

One of the key components of a catalytic converter is the rebar cage, which serves to support and protect the catalytic substrate. The cage is typically made of stainless steel and provides structural integrity to the converter.

In this blog post, we will explore the functionality of catalytic converter rebar cages and their contribution to the overall efficiency of the emission control system in vehicles.

Traditional Rebar Cages: Limitations And Challenges

Traditional rebar cages have long been used in the construction industry for reinforcing concrete structures. However, these conventional cages come with a number of limitations and challenges that can impact overall efficiency and performance.

One of the major drawbacks of traditional rebar cages is their limited flexibility. These cages are often pre-made off-site and may not accurately fit the specific dimensions of the project. As a result, the installation process becomes time-consuming and labor-intensive, leading to delays in construction timelines.

Moreover, maintenance becomes a significant challenge with traditional rebar cages. Due to their rigid structure, it is difficult to inspect and repair any damage caused by corrosion or wear and tear. This can lead to structural issues in the long run, compromising the integrity of the reinforced concrete.

Another disadvantage of conventional rebar cages is the inefficient use of material. These cages often require excessive amounts of rebar, resulting in unnecessary material costs and increased waste. Additionally, the weight and bulkiness of traditional cages can pose difficulties during transportation and storage.

To address these limitations, the development of innovative solutions such as catalytic converter rebar cages has gained momentum in recent years. These cages offer advantages such as improved flexibility, easy maintenance, and optimal use of materials to enhance construction efficiency and ensure long-term performance of reinforced concrete structures.

Introducing The Catalytic Converter Rebar Cage: Unlocking The Power Of Efficiency

Introducing the Catalytic Converter Rebar Cage: Unlocking the Power of Efficiency

Examining the Innovation Behind Catalytic Converter Rebar Cages

Efficiency and performance are essential factors when it comes to catalytic converters. That’s where the Catalytic Converter Rebar Cage shines. This innovative technology maximizes the potential of your vehicle’s catalytic converter, delivering enhanced efficiency and improved performance benefits.

The catalytic converter rebar cage works by efficiently directing exhaust flow, ensuring that the conversion process is optimized. By preventing gases from escaping too quickly, the rebar cage allows for more comprehensive chemical reactions, resulting in cleaner emissions and better fuel efficiency. Additionally, the rebar cage helps to minimize backpressure, reducing strain on the engine and improving overall performance.

With the Catalytic Converter Rebar Cage, drivers can experience the benefits of increased efficiency and performance without compromising on environmental responsibility. This breakthrough technology is revolutionizing the automotive industry, paving the way for a greener and more efficient future.

Enhanced Exhaust Gas Purification

Enhanced exhaust gas purification is a crucial factor in reducing harmful emissions. One effective solution to amplify the effectiveness of exhaust gas catalysis is the use of catalytic converter rebar cages. These rebar cages are specifically designed to improve the performance of catalytic converters by maximizing contact between the exhaust gas and the catalyst materials, thereby enhancing the conversion efficiency of harmful pollutants.

By strategically positioning the rebar cages within the catalytic converter, they ensure that a greater surface area of the catalyst substrate is exposed to the exhaust gas flow. This increased contact area promotes enhanced chemical reactions, allowing for more efficient conversion of carbon monoxide, nitrogen oxides, and hydrocarbons into less harmful substances.

Besides improving performance, catalytic converter rebar cages also provide structural support, enhancing the durability and longevity of the catalytic converter. The robust design and construction of these cages help to prevent catalyst substrate deterioration, reducing the risk of catalyst materials breaking loose and interfering with efficient exhaust gas purification.

Overall, the implementation of catalytic converter rebar cages plays a vital role in reducing harmful emissions, contributing to a cleaner and healthier environment.

Optimized Fuel Efficiency

When it comes to optimizing fuel efficiency, one effective solution is the use of catalytic converter rebar cages. These cages are designed to maximize fuel combustion efficiency and improve mileage, ultimately resulting in cost-effectiveness for vehicle owners.

The main purpose of a catalytic converter rebar cage is to enhance the oxidation and reduction reactions that occur during the exhaust gas treatment process. By promoting better mixing and distribution of air and fuel, these cages ensure that combustion happens more efficiently, reducing the amount of wasted fuel and emissions produced.

With improved fuel combustion efficiency, vehicles can achieve better mileage, allowing drivers to go further on a single tank of gas. This not only saves money on fuel costs but also reduces the environmental impact of excessive fuel consumption.

Overall, by incorporating catalytic converter rebar cages into vehicles, it is possible to enhance their fuel efficiency and achieve greater cost-effectiveness while minimizing emissions. This not only benefits individual drivers but also contributes to a more sustainable and environmentally friendly transportation system.

Extended Lifespan Of Catalytic Converters

Catalytic Converter Rebar Cage

The extended lifespan of catalytic converters is crucial for their efficient performance. Protecting catalytic converters from damage and wear is essential in order to maximize their overall lifespan. By taking certain preventive measures, it is possible to prolong the lifespan of catalytic converters effectively.

One way to protect catalytic converters is by installing a rebar cage. A rebar cage acts as a shield, preventing direct impacts on the converter. It helps to absorb the force during accidents or road debris hits, reducing the risk of physical damage.

In addition to using a rebar cage, regular maintenance is key to prolonging the lifespan of catalytic converters. This includes inspecting and replacing worn-out or damaged components, such as oxygen sensors, air filters, and spark plugs. Keeping the engine properly tuned and avoiding excessive idling or aggressive driving can also contribute to the overall health of the catalytic converter.

Compatibility With Existing Catalytic Converter Systems

Integrating catalytic converter rebar cages into vehicles requires compatibility with existing catalytic converter systems. This is crucial to ensure seamless installation and optimal performance. Compatibility should be considered for various vehicle makes and models to cater to a wide range of consumers.

When selecting a catalytic converter rebar cage, it is essential to determine the compatibility with the vehicle’s exhaust system, including the size and configuration. The rebar cage should fit perfectly without any modifications or alterations.

Moreover, compatibility with emissions regulations and standards is vital. The catalytic converter rebar cage should meet the required emission control standards and regulations for the specific vehicle make and model. It should effectively reduce harmful emissions and maintain compliance with environmental regulations.

Additionally, considering the durability and lifespan of the catalytic converter is important. The rebar cage should be made from high-quality materials that can withstand extreme temperatures and exposure to corrosive elements.

In conclusion, when integrating catalytic converter rebar cages into vehicles, compatibility with existing systems, including exhaust size and emissions regulations, must be carefully evaluated. By ensuring compatibility, vehicle owners can benefit from improved emissions control and a longer lifespan for their catalytic converter.

Credit: www.sec.gov

Installation And Maintenance Guidelines

In order to ensure proper installation and alignment of rebar cages for catalytic converters, there are a few key guidelines that should be followed. First and foremost, it is crucial to thoroughly understand the manufacturer’s instructions and specifications for the particular type of cage being used. This includes taking note of any required tools or equipment, as well as any specific installation techniques or restrictions.

When installing the rebar cage, it is important to carefully position and secure it in place, ensuring that it is properly aligned with the exhaust system components. This will help to optimize the flow of exhaust gases through the converter, maximizing its efficiency and performance.

Regular maintenance practices are also essential for keeping the catalytic converter and rebar cage working at their best. This includes visually inspecting the cage for any signs of damage or wear, and promptly addressing any issues that are identified. Additionally, it is important to periodically clean the cage and surrounding components to remove any built-up debris or contaminants that could affect its performance.

By following these installation and maintenance guidelines, you can help to ensure the proper functioning and longevity of your catalytic converter and rebar cage.

Emerging Advances In Catalytic Converter Rebar Cage Technology

Catalytic Converter Rebar Cage

Emerging Advances in Catalytic Converter Rebar Cage Technology

Exploring Ongoing Research and Development Efforts

Future Innovations in Catalytic Converter Rebar Cage Designs

The field of catalytic converter rebar cage technology is rapidly evolving, with ongoing research and development efforts focused on enhancing performance and efficiency. Innovations in this area aim to optimize the conversion of harmful emissions into less harmful substances, thereby reducing the environmental impact of vehicles.

One key area of focus is the development of advanced catalyst materials that offer improved conversion rates and durability. Researchers are also exploring the use of novel coating techniques to enhance the stability of catalytic converter rebar cages, ensuring their long-term functionality.

Furthermore, efforts are being made to design rebar cages that are more resistant to heat and vibration, allowing them to withstand the challenging operating conditions encountered within vehicle exhaust systems.

Future advancements in catalytic converter rebar cage designs may also involve incorporating sensor technologies that enable real-time monitoring and adjustment of catalyst performance, leading to increased efficiency and reduced emissions in vehicles.

Frequently Asked Questions Of Catalytic Converter Rebar Cage

Do Catalytic Converter Cages Work?

Yes, catalytic converter cages are effective in preventing thefts. They provide an extra layer of protection by encasing the converter, making it harder for thieves to access and remove. It is a reliable solution to deter theft and safeguard your vehicle’s catalytic converter.

Can You Weld Rebar To A Catalytic Converter?

No, you cannot weld rebar to a catalytic converter.

How Much Does It Cost To Put A Cage On Catalytic Converter?

The cost of installing a cage on your catalytic converter can vary depending on the make and model of your vehicle. However, on average, it can range from $100 to $300.

Which Is Better Catalytic Converter Cage Or Shield?

The better option, whether a catalytic converter cage or shield, depends on your specific needs and preferences. Both options provide protection for your catalytic converter, but the cage offers added security due to its physical barrier. Consider factors such as your vehicle’s location and level of risk to make an informed decision.

Conclusion

The catalytic converter rebar cage plays a crucial role in protecting and improving the performance of your vehicle’s exhaust system. By securely holding the catalytic converter in place, it prevents vibration, reduces emissions, and ensures optimal efficiency. It is important to invest in a high-quality rebar cage that meets industry standards and provides long-lasting durability.

So, prioritize the maintenance of this essential component to enjoy a smoother and more environmentally-friendly driving experience.