These components are integral parts of a vehicle’s exhaust system, designed to reduce noise generated by the engine. One component primarily attenuates sound waves through internal baffling and chambers, while the other fine-tunes exhaust flow and further diminishes specific frequencies. For example, a performance vehicle might utilize aftermarket versions to achieve a desired exhaust note.

The effective reduction of engine noise contributes significantly to driver and passenger comfort, as well as compliance with noise pollution regulations. Historically, rudimentary designs were implemented to address the disruptive nature of early engine technology. Modern iterations are engineered for optimal performance, balancing sound reduction with minimal backpressure to maintain engine efficiency.

Understanding the function and maintenance of these components is essential for vehicle owners and automotive technicians alike. Subsequent discussions will delve into specific types, common issues, and diagnostic procedures related to these essential exhaust system elements.

Essential Considerations for Exhaust System Components

Maintaining optimal functionality of key exhaust system elements is crucial for vehicle performance and regulatory compliance. The following points offer guidance on proper care and evaluation.

Tip 1: Regular Inspection is Paramount: Conduct periodic visual inspections for signs of corrosion, physical damage, or leaks. Early detection can prevent more extensive and costly repairs.

Tip 2: Listen for Unusual Noises: Changes in exhaust sound, such as rattling or excessive loudness, often indicate internal damage or degradation of these components.

Tip 3: Address Rust Promptly: Surface rust can be treated with rust inhibitors to prevent further deterioration. Significant rust necessitates component replacement.

Tip 4: Ensure Proper Mounting: Verify that all mounting hardware is secure and that rubber insulators are in good condition. Loose or damaged mounts can cause vibrations and premature wear.

Tip 5: Consider Material Upgrades: When replacing these parts, consider using stainless steel or other corrosion-resistant materials for increased longevity, particularly in regions with harsh weather conditions.

Tip 6: Seek Professional Diagnosis: If experiencing persistent exhaust-related issues, consult a qualified automotive technician for a comprehensive diagnosis and repair.

Adherence to these recommendations can significantly extend the lifespan and improve the performance of exhaust systems, ensuring both vehicle efficiency and compliance with noise emission standards.

These maintenance practices are foundational for a well-functioning exhaust system. The following sections will explore advanced diagnostics and repair procedures.

1. Noise Reduction Effectiveness

Noise reduction effectiveness in automotive exhaust systems is intrinsically linked to the design and functionality of components, particularly the muffler and resonator. The primary function of these parts is to attenuate engine exhaust noise, thereby ensuring compliance with regulatory standards and enhancing vehicle occupant comfort.

- Internal Baffling and Chamber Design

The internal structure, composed of baffles and chambers, is crucial for sound wave attenuation. These components are engineered to reflect and redirect sound waves, causing them to interfere constructively and destructively, thus reducing overall noise output. For instance, a complex chamber design can effectively diminish specific frequency ranges, leading to a quieter exhaust note.

- Material Properties and Acoustic Absorption

The materials used in construction play a significant role in acoustic absorption. Some components utilize fiberglass packing or other sound-deadening materials to absorb sound waves as they pass through the system. Material density and composition directly impact the component’s ability to reduce noise levels, with denser materials generally offering greater attenuation.

- Resonator Frequency Tuning

Resonators are specifically tuned to cancel out certain frequencies that contribute to unpleasant or excessive exhaust noise. By creating a standing wave that is 180 degrees out of phase with the targeted frequency, the resonator effectively neutralizes the sound. This precise tuning is essential for achieving a desired exhaust tone without compromising noise reduction.

- Exhaust Flow Dynamics and Backpressure

Effective noise reduction must be balanced with the need to maintain optimal exhaust flow and minimize backpressure. Excessive backpressure can reduce engine performance and fuel efficiency. Therefore, components are designed to attenuate sound while allowing exhaust gases to flow freely. The balance between noise reduction and performance is a critical consideration in component design.

The integration of these design elements determines the overall noise reduction effectiveness of the exhaust system. Modern systems are often engineered using computational fluid dynamics and acoustic modeling to optimize performance and ensure that vehicles meet stringent noise emission requirements. The interplay between design, materials, and tuning defines the functionality of a muffler and resonator, ultimately affecting the acoustic signature and performance characteristics of the vehicle.

2. Exhaust Flow Optimization

Exhaust flow optimization, within the context of muffler and resonator design, is the engineering process aimed at minimizing backpressure and turbulence in the exhaust system while effectively attenuating noise. It’s a critical consideration, as restrictions in exhaust flow can negatively impact engine performance, fuel efficiency, and overall vehicle responsiveness.

- Component Geometry and Internal Design

The shape and internal structure of mufflers and resonators significantly affect exhaust flow. Straight-through designs or those with gradually changing diameters minimize flow restrictions. For instance, a chambered muffler with smooth, rounded transitions will typically offer better flow characteristics compared to one with sharp angles or abrupt constrictions. The geometry is meticulously designed to balance sound attenuation with flow efficiency.

- Pipe Diameter and Material Selection

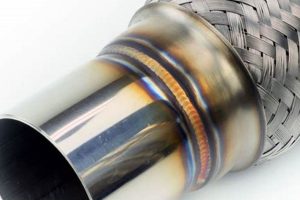

The diameter of the exhaust piping, as well as the materials used, directly impacts flow capacity and frictional losses. Larger diameter pipes allow for increased flow volume, but must be appropriately sized to maintain exhaust gas velocity. Smooth-walled materials, such as stainless steel, reduce friction and improve overall flow efficiency compared to rougher materials like aluminized steel. The choice of diameter must harmonize with the engine’s displacement and intended performance characteristics.

- Resonator Placement and Tuning

Resonators, while primarily intended for sound cancellation, also influence exhaust flow dynamics. Strategic placement of resonators can reduce turbulence and promote smoother flow, particularly in areas where exhaust gases converge or change direction. Tuning the resonator’s internal volume and length to specific frequencies further optimizes flow characteristics by minimizing backpressure at critical engine speeds. This strategic placement optimizes both sound and flow.

- Minimizing Backpressure and Turbulence

The overarching goal of exhaust flow optimization is to minimize backpressure, the resistance to exhaust gas flow, and turbulence, which disrupts smooth flow patterns. Excessive backpressure reduces engine horsepower and torque, particularly at higher RPMs. Minimizing turbulence promotes more efficient scavenging of exhaust gases from the cylinders, leading to improved engine performance and fuel economy. Optimized components result in more responsive acceleration and better overall driving experience.

The synergistic relationship between muffler and resonator design and exhaust flow optimization underscores the importance of a comprehensive approach. By carefully considering component geometry, material selection, resonator placement, and the overarching need to minimize backpressure and turbulence, manufacturers can develop exhaust systems that enhance both vehicle performance and driver satisfaction. The advancements in exhaust technology continue to push these boundaries.

3. Material Corrosion Resistance

Material corrosion resistance is a critical attribute for components of an exhaust system, particularly mufflers and resonators, due to their constant exposure to corrosive byproducts of combustion and environmental elements. Premature failure of these components due to corrosion can lead to increased noise levels, reduced engine performance, and costly repairs. The selection of materials with inherent resistance to corrosion is, therefore, paramount for ensuring the longevity and reliability of exhaust systems.

- Exposure to Condensates and Acids

During engine operation, exhaust gases contain water vapor, carbon dioxide, and sulfur dioxide, which can condense within the exhaust system as it cools. These condensates form corrosive acids, such as carbonic and sulfuric acid, which attack the internal surfaces of mufflers and resonators. Materials with poor corrosion resistance, like mild steel, are particularly susceptible to this type of corrosion. The selection of corrosion-resistant alloys minimizes the destructive effect of these condensates.

- Road Salt and Environmental Factors

Vehicles operating in regions with cold climates are frequently exposed to road salt, which accelerates corrosion of exhaust system components. Salt spray can penetrate seams and joints, leading to rapid deterioration of unprotected materials. Additionally, exposure to moisture, humidity, and other environmental pollutants further exacerbates corrosion processes. The employment of materials like stainless steel, which forms a protective oxide layer, effectively combats these external corrosive agents.

- Elevated Temperatures and Oxidation

Exhaust systems operate at elevated temperatures, which can accelerate oxidation processes. At high temperatures, metals can react with oxygen in the air, forming oxide scales that weaken the material and eventually lead to failure. Some alloys, like those containing chromium and nickel, exhibit excellent resistance to oxidation at high temperatures, making them suitable for use in mufflers and resonators. This characteristic is crucial for maintaining structural integrity over the operational lifespan of the vehicle.

- Galvanic Corrosion Considerations

Galvanic corrosion can occur when dissimilar metals are in contact in the presence of an electrolyte. For example, if a steel muffler is connected to an aluminum exhaust pipe, galvanic corrosion can occur at the junction, leading to accelerated corrosion of the less noble metal. To mitigate this, materials with similar electrochemical potentials should be used, or appropriate isolation techniques, such as the use of insulating bushings, should be employed. This prevents the formation of a galvanic cell and minimizes the risk of corrosion.

The integration of materials with high corrosion resistance is a fundamental requirement for ensuring the durability and longevity of mufflers and resonators. By carefully considering the corrosive environments to which these components are exposed and selecting appropriate materials, manufacturers can significantly extend the lifespan of exhaust systems, reducing maintenance costs and ensuring optimal vehicle performance. These considerations are central to the design and engineering of robust and reliable exhaust components.

4. Mounting hardware integrity

The integrity of mounting hardware is intrinsically linked to the performance and longevity of mufflers and resonators within a vehicle’s exhaust system. Mounting hardware, including brackets, hangers, and rubber isolators, secures these components to the vehicle’s chassis. A compromised mounting system can induce stress fractures in the exhaust piping and directly affect the operational efficiency and lifespan of the noise reduction components. The degradation of rubber isolators, for example, allows increased vibration to transmit to the vehicle’s frame, leading to discomfort for occupants and potential damage to surrounding components. A real-world scenario involves a vehicle frequently driven on rough roads; the increased vibrations, coupled with degraded rubber isolators, can cause stress fractures in the muffler’s welds, leading to premature failure and necessitating replacement. The mounting hardware is a protective factor in the effectiveness of mufflers and resonators.

Furthermore, improperly installed or corroded mounting hardware can lead to exhaust leaks, reducing engine efficiency and potentially introducing harmful exhaust gases into the vehicle cabin. Consider a case where rusted mounting bolts fail, allowing the muffler to shift and create a gap at the exhaust manifold connection. This leak not only diminishes the effectiveness of the catalytic converter but also poses a health risk to vehicle occupants. Regular inspection and timely replacement of worn or damaged mounting hardware are therefore essential preventative maintenance measures. Also, the maintenance of mounting hardware contributes to the system’s overall efficacy.

In summary, the integrity of mounting hardware is not merely an ancillary concern but a fundamental aspect of muffler and resonator functionality. Proper maintenance and timely replacement of compromised mounting components ensure that the exhaust system operates efficiently, safely, and within regulatory noise emission standards. Neglecting mounting hardware can lead to cascading failures, increased repair costs, and potential safety hazards. To prevent failures make sure to check on your car or to have it checked by an Automotive Technician regularly.

5. System backpressure impact

The degree to which exhaust gases are impeded from exiting an engine, commonly referred to as system backpressure, directly influences the performance and operational efficiency of a vehicle. Mufflers and resonators, as integral components of the exhaust pathway, play a crucial role in determining the level of backpressure exerted on the engine.

- Muffler Design and Restriction

The internal design of mufflers, particularly the configuration of baffles and chambers, inherently creates some level of backpressure. Highly restrictive muffler designs, characterized by complex internal pathways, significantly increase backpressure. This can impede exhaust gas flow, leading to reduced engine power and fuel economy. Conversely, performance-oriented mufflers are engineered with less restrictive designs to minimize backpressure, optimizing engine output. A practical example is the comparison between a stock muffler on a passenger vehicle and an aftermarket performance muffler, where the latter typically demonstrates reduced backpressure.

- Resonator Volume and Placement

Resonators, designed to attenuate specific exhaust frequencies, can also contribute to backpressure depending on their size and location within the exhaust system. A resonator with a small internal volume or strategically positioned in a narrow section of the exhaust stream can create a bottleneck, increasing backpressure. Conversely, a properly sized and positioned resonator can minimize flow disruption while effectively dampening unwanted sound frequencies. For instance, a poorly placed resonator in a high-performance vehicle can negate the benefits of a less restrictive muffler by creating excessive backpressure.

- Pipe Diameter and Flow Dynamics

The diameter of the exhaust piping, including the sections connected to the muffler and resonator, directly impacts the overall system backpressure. Undersized piping restricts exhaust flow, increasing backpressure and hindering engine performance. Conversely, oversized piping can reduce exhaust gas velocity, leading to poor scavenging and decreased low-end torque. The optimal pipe diameter is carefully calculated to balance flow capacity with exhaust gas velocity, minimizing backpressure while maintaining efficient exhaust scavenging. The selection of proper diameter is essential for optimizing engine performance across the RPM range.

- Catalytic Converter Integration

Although not a primary focus here, it’s vital to acknowledge that catalytic converters, often situated upstream of mufflers and resonators, also contribute to overall system backpressure. A clogged or inefficient catalytic converter can significantly increase backpressure, negatively impacting engine performance. The integration of high-flow catalytic converters with optimized mufflers and resonators is a common strategy to minimize backpressure and maximize engine output. Maintaining a balance in the exhaust system is essential to avoiding any one part in the system from becoming a bottleneck.

In conclusion, system backpressure is a critical parameter influenced by the design and integration of mufflers and resonators. Minimizing backpressure is essential for optimizing engine performance, fuel efficiency, and overall vehicle responsiveness. The selection of appropriate components and careful consideration of exhaust system design are crucial for achieving the desired balance between sound attenuation and engine performance, demonstrating the intricate relationship between these elements.

Frequently Asked Questions

The following section addresses common inquiries regarding the function, maintenance, and replacement of exhaust system components.

Question 1: What is the primary function of a muffler?

The primary function is to attenuate noise generated by the engine’s exhaust gases. It achieves this through internal chambers and baffles designed to reduce sound wave amplitude.

Question 2: How does a resonator differ from a muffler?

A resonator is typically tuned to cancel specific frequencies within the exhaust sound spectrum. While mufflers offer broader noise reduction, resonators target particular tones to refine the overall exhaust note.

Question 3: What are common signs of a failing muffler or resonator?

Increased exhaust noise, rattling sounds emanating from beneath the vehicle, and visible corrosion or physical damage are indicative of potential issues.

Question 4: Does replacing these components affect engine performance?

Replacement with aftermarket components can influence performance. High-flow designs may reduce backpressure, potentially increasing horsepower, while restrictive designs can diminish performance.

Question 5: How often should these parts be inspected?

Visual inspection is advisable during routine vehicle maintenance, typically every 12 months or 12,000 miles, or as recommended by the vehicle manufacturer.

Question 6: Can a damaged component impact fuel efficiency?

A severely corroded or damaged component that creates exhaust leaks can negatively affect engine performance and, consequently, fuel efficiency.

Proper maintenance and timely replacement of these components are essential for optimal vehicle operation and regulatory compliance.

The subsequent section will delve into specific diagnostic procedures for identifying exhaust system problems.

Concluding Remarks on Exhaust System Components

This exploration has elucidated the vital role of components within a vehicle’s exhaust system, emphasizing their contributions to noise reduction, emissions control, and overall engine performance. The interplay between design, materials, and maintenance directly impacts both regulatory compliance and the driving experience. A thorough understanding of their function and potential failure modes is essential for vehicle owners and technicians alike.

Continued advancements in materials science and engineering promise further refinements in performance and longevity of these essential components. Prioritizing proactive inspection and adherence to recommended maintenance schedules will ensure optimal functionality, minimize environmental impact, and preserve the operational integrity of automotive exhaust systems. Neglecting these aspects can lead to significant consequences, both environmentally and economically.

![Why Choose Muffler Brothers: [Your City]'s Exhaust Pros Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions Why Choose Muffler Brothers: [Your City]'s Exhaust Pros | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://dnamufflers.com/wp-content/uploads/2025/06/th-880-300x200.jpg)

![King Muffler: Best Performance Exhaust [Updated] Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions King Muffler: Best Performance Exhaust [Updated] | Safem Fabrication - Precision Engineering & Custom Manufacturing Solutions](https://dnamufflers.com/wp-content/uploads/2025/06/th-764-300x200.jpg)