What is a Catalytic Converter Made of: Unveiling the Hidden Power Words.

A catalytic converter is primarily made of platinum, palladium, and rhodium metals. A catalytic converter is an essential component of modern automobiles, responsible for reducing harmful emissions released into the environment.

Made primarily of platinum, palladium, and rhodium metals, this device plays a crucial role in converting toxic gases produced by the engine, such as carbon monoxide, nitrogen oxide, and hydrocarbons, into less harmful substances. By utilizing these precious metals as catalysts, the catalytic converter facilitates a chemical reaction that transforms these pollutants into carbon dioxide, water vapor, and nitrogen gas.

This process effectively helps to mitigate the adverse impact of vehicle emissions on air quality and human health. Understanding the composition and function of a catalytic converter provides valuable insight into the role it plays in reducing harmful pollutants and preserving the environment.

The Basics Of Catalytic Converters

A catalytic converter is an essential component of a vehicle’s exhaust system. It is made up of a ceramic or metallic honeycomb structure coated with various catalysts, including platinum, palladium, and rhodium. The purpose of a catalytic converter is to reduce harmful emissions from the engine.

When exhaust gases pass through the catalytic converter, the catalysts facilitate chemical reactions that convert toxic pollutants, such as carbon monoxide, nitrogen oxides, and hydrocarbons, into less harmful substances like carbon dioxide, nitrogen, and water vapor.

Catalytic converters play a vital role in reducing air pollution and ensuring compliance with emission standards. They help to decrease the release of harmful pollutants that contribute to smog and respiratory problems. Additionally, they contribute to the overall fuel efficiency of a vehicle, allowing it to perform better while reducing environmentally damaging emissions.

In conclusion, catalytic converters are crucial for minimizing the negative impact of vehicle emissions on the environment and human health. Understanding their composition and function is key to appreciating their significance in modern automotive technology.

Unveiling The Components: What Catalytic Converters Are Made Of

Unveiling the Components: What Catalytic Converters are Made of

Introduction to the materials used in catalytic converters

Catalytic converters are intricate devices that are an essential component of modern vehicles’ exhaust systems. These converters play a crucial role in reducing harmful emissions, helping to keep the environment clean. Understanding what catalytic converters are made of can give us insights into their functionality and importance.

The primary components of a catalytic converter include:

| 1. Catalyst Support Material: | Typically made of ceramic or metal, this material provides a stable structure for the catalyst. |

| 2. Catalyst: | Usually composed of precious metals like platinum, palladium, and rhodium, the catalyst facilitates chemical reactions that convert harmful pollutants into less harmful substances. |

| 3. Heat Shield: | Located near the catalyst, this heat shield prevents excessive heat loss and helps maintain optimum operating temperature. |

| 4. Oxygen Sensors: | Oxygen sensors monitor the oxygen levels in the exhaust gases and provide valuable feedback to the vehicle’s engine control unit. |

| 5. Shell: | Constructed from stainless steel or another durable metal, the shell encases and protects the inner components of the catalytic converter. |

Each component in a catalytic converter serves a specific purpose and works together to ensure effective emission control. With the understanding of these critical elements, we can appreciate the crucial role catalytic converters play in reducing air pollution.

The Hidden Power Words: Key Catalysts In Action

When it comes to catalytic converters, there are hidden power words that play a crucial role in reducing emissions. These power words are actually platinum group metals (PGMs) such as rhodium, palladium, and platinum. They act as catalysts, provoking chemical reactions that convert harmful exhaust gases into less harmful substances.

Uncovering the power words behind catalytic converters is an essential step in understanding how they work. One of the most noteworthy PGMs is platinum, which is responsible for converting carbon monoxide and nitrogen oxide into carbon dioxide and nitrogen gas.

Rhodium is another key catalyst that helps reduce nitrogen oxide emissions. Palladium, on the other hand, focuses on converting harmful hydrocarbons and carbon monoxide into harmless carbon dioxide and water vapor.

Together, these power words, the PGMs, work in harmony to create a chemical reaction that significantly reduces harmful emissions from vehicles.

Innovations In Catalytic Converter Technology

What is a Catalytic Converter Made of

Innovations in Catalytic Converter Technology

Advancements in catalytic converter design and development

- Exploring alternative catalyst materials for enhanced performance

- The future of catalytic converter technology: trends and possibilities

Catalytic converters have come a long way in terms of design and development. Manufacturers are continuously exploring alternative catalyst materials to enhance the performance of these crucial emission control devices. By utilizing innovative technologies, catalytic converters have become more efficient at converting harmful pollutants into less harmful substances. These advancements have led to improved fuel efficiency and reduced exhaust emissions, contributing to a cleaner and greener environment. Additionally, ongoing research and development in catalytic converter technology are focused on addressing challenges such as durability, cost, and compliance with increasingly stringent emissions standards. To keep up with ever-evolving regulations and consumer demands, the future of catalytic converter technology will likely witness further improvements and breakthroughs. As a result, we can expect to see trends like the use of new materials, advanced manufacturing techniques, and the integration of intelligent systems in catalytic converters.

Environmental Impact Of Catalytic Converters

A catalytic converter is primarily composed of three main components: the catalyst, the shell, and the exhaust pipe. The catalyst, typically made of platinum, palladium, and rhodium, serves as the active substance responsible for facilitating the chemical reactions that convert harmful exhaust emissions into less harmful substances. The shell, made of stainless steel, provides durability and protection for the catalyst. The exhaust pipe connects the catalytic converter to the vehicle’s exhaust system, allowing the exhaust gases to flow through the converter.

Catalytic converters play a crucial role in reducing air pollution by converting harmful pollutants, such as carbon monoxide, nitrogen oxide, and unburned hydrocarbons, into less harmful substances like carbon dioxide, nitrogen, and water vapor. These conversions take place through various chemical reactions, including oxidation, reduction, and the conversion of nitrogen oxides.

Despite their effectiveness in reducing emissions, catalytic converters face certain environmental challenges. For example, the catalyst materials used in converters are finite natural resources and their extraction can lead to environmental degradation. Additionally, the performance of catalytic converters can be affected by factors such as temperature, contaminants, and engine conditions, which may decrease their overall efficiency. To address these challenges, ongoing research is focused on developing more sustainable catalyst materials and improving the overall design and performance of catalytic converters.

| Advantages | Disadvantages |

|---|---|

| Significantly reduces harmful emissions | Finite natural resources |

| Plays a crucial role in reducing air pollution | Performance affected by various factors |

| Enables conversion of harmful pollutants into less harmful substances |

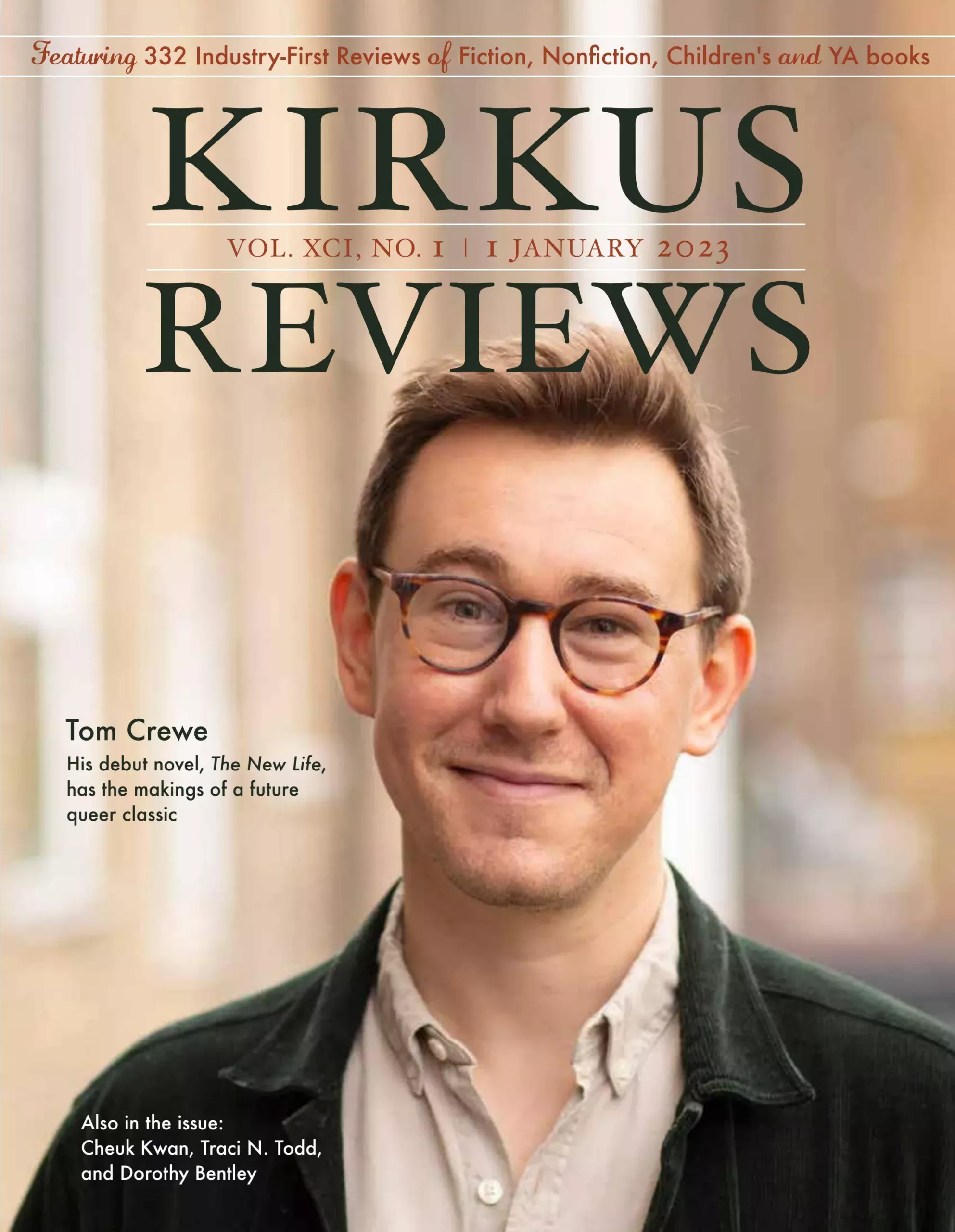

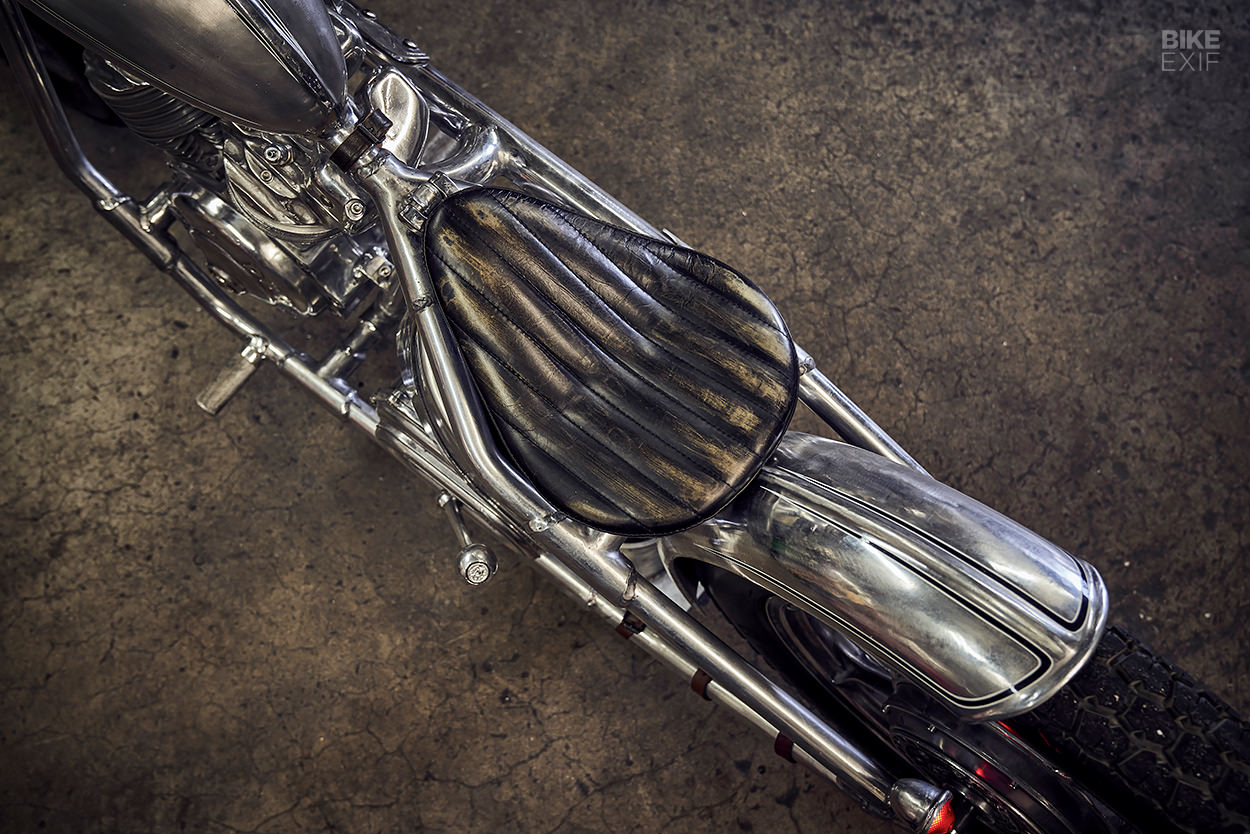

Credit: www.bikeexif.com

Maintenance And Troubleshooting Of Catalytic Converters

Catalytic converters play a crucial role in reducing harmful emissions from vehicles. When properly maintained, they can last for many years. To preserve the lifespan of your catalytic converter, follow these tips:

- Ensure your engine is running efficiently. A poorly tuned engine can lead to increased fuel consumption and damage the converter over time.

- Regularly inspect and repair any exhaust leaks. Leaks can introduce outside air into the exhaust system, affecting the converter’s performance.

- Use the recommended fuel and engine oil for your vehicle. Certain additives and contaminants in low-quality fuel and oil can negatively impact the converter.

- Avoid sudden temperature changes. Let the engine warm up gradually and avoid rapid acceleration, as extreme temperature fluctuations can stress the converter.

| Issue | Troubleshooting Technique |

|---|---|

| Reduced engine performance | Check for clogged or damaged converter. Replace if necessary. |

| Increasing emissions | Inspect the converter for damage, leaks, or contamination. |

| Rattling noise | Inspect for loose heat shields or damaged internal components. |

Knowing when to replace your catalytic converter is essential to maintain your vehicle’s performance. Look out for signs such as reduced engine power, increased emissions, and a rotten egg smell. If you experience these symptoms, it is recommended to consult a professional mechanic to assess the condition of your converter and determine if a replacement is necessary.

The Catalytic Converter Market: Trends And Regulations

The global market for catalytic converters has been witnessing significant growth in recent years. This can be attributed to the increasing stringency of emission regulations imposed by governments across the globe. Catalytic converters are widely used in automotive vehicles to reduce harmful emissions such as carbon monoxide, nitrogen oxides, and hydrocarbons. They play a crucial role in minimizing air pollution and improving overall air quality.

In terms of market dynamics, the demand for catalytic converters is expected to rise due to the growing sales of vehicles worldwide. Additionally, advancements in technology have led to the development of more efficient and durable catalytic converter systems, which further fuels the market growth.

Key industry players in the catalytic converter market include top automotive manufacturers and suppliers such as Johnson Matthey, BASF SE, Tenneco Inc., and Faurecia. These companies are continuously investing in research and development activities to enhance their product offerings and stay competitive in the market.

Regulatory Standards And Compliance Requirements For Catalytic Converters

Regulatory bodies around the world have implemented strict standards and emissions regulations for vehicles, which often include specific requirements for catalytic converters. These standards ensure that vehicles meet the necessary emission limits and contribute to a cleaner environment.

For instance, in the United States, the Environmental Protection Agency (EPA) has set emissions standards and compliance requirements for catalytic converters under the Clean Air Act. Similarly, the European Union has established the Euro standards, which determine the permissible emission levels for vehicles sold in European countries.

Manufacturers and suppliers of catalytic converters need to adhere to these regulatory standards and guidelines to ensure their products meet the necessary emission reduction targets. Compliance with these regulations is important not only for legal reasons but also to maintain a positive brand image and meet customer expectations.

Frequently Asked Questions On What Is A Catalytic Converter Made Of

What Is In A Catalytic Converter That Is So Valuable?

A catalytic converter contains precious metals that help reduce emissions from a vehicle’s exhaust. These metals, including platinum, palladium, and rhodium, are valuable as they serve as catalysts, promoting chemical reactions that convert harmful pollutants into less harmful substances.

How Much Is The Metal In A Catalytic Converter Worth?

Metal in a catalytic converter can be worth between $50 and $250, depending on the type and quantity.

How Much Is The Platinum In A Catalytic Converter Worth?

Platinum in a catalytic converter is valuable, worth around $500 to $2,500, depending on its size and condition.

Can A Car Run Without A Catalytic Converter?

Yes, a car can run without a catalytic converter. However, it is against the law in many places, as the catalytic converter reduces harmful emissions.

Conclusion

Catalytic converters play a critical role in reducing harmful emissions from vehicles. By converting toxic gases into less harmful ones, they contribute to a cleaner environment. Understanding what a catalytic converter is made of gives us insight into its efficiency and durability.

With components like platinum, palladium, and rhodium, these devices are designed to withstand high temperatures and chemical reactions. Maintaining and replacing catalytic converters as needed ensures their effectiveness and helps keep our air clean.