This automotive component is a type of exhaust system part designed to reduce noise levels emanating from a vehicle’s engine. It is characterized by its larger casing, engineered to create a quieter sound profile compared to performance-oriented alternatives. As an example, it’s often chosen for vehicles where minimizing exhaust noise is prioritized over maximizing horsepower gains.

The significance of this particular component lies in its ability to provide a balance between performance and sound reduction. Its benefits include a less aggressive exhaust note, making it suitable for daily driving and residential areas where noise ordinances are enforced. Historically, the development of such components reflects a growing demand for vehicles that offer both power and refinement.

Understanding its design, application, and impact on vehicle performance is essential for informed decision-making when modifying or maintaining an exhaust system. The following sections will delve deeper into these aspects, exploring its construction, installation considerations, and potential effects on fuel efficiency and engine output.

Installation and Maintenance Tips

Proper installation and maintenance are crucial to ensure optimal performance and longevity of this automotive component. Adherence to these guidelines will help prevent premature wear and maximize its intended sound-dampening capabilities.

Tip 1: Verify Compatibility: Before installation, confirm that the component is compatible with the vehicle’s make, model, and year. Consult the manufacturer’s specifications or a qualified mechanic to avoid potential fitment issues.

Tip 2: Professional Installation Recommended: While DIY installation is possible, engaging a certified mechanic ensures proper welding, alignment, and secure mounting, reducing the risk of leaks or damage.

Tip 3: Use Appropriate Hardware: Employ high-quality clamps, hangers, and gaskets during installation. Inferior hardware can lead to premature failure and exhaust leaks, negating the component’s noise reduction benefits.

Tip 4: Inspect Welds Regularly: Periodically examine weld points for cracks or corrosion. Promptly address any issues to prevent exhaust leaks and maintain structural integrity.

Tip 5: Monitor for Rust and Corrosion: Apply a rust preventative coating, particularly in regions with harsh weather conditions, to prolong the component’s lifespan and preserve its appearance.

Tip 6: Check for Obstructions: Ensure that the exhaust system, including the component, is free from obstructions such as road debris or undercarriage damage. Obstructions can restrict exhaust flow and negatively impact performance.

Tip 7: Listen for Unusual Noises: Pay attention to any abnormal sounds emanating from the exhaust system. Rattling, hissing, or excessive noise could indicate a leak or internal damage requiring immediate attention.

By following these guidelines, owners can maximize the effectiveness of this component, ensuring a quieter and more enjoyable driving experience while maintaining vehicle performance.

The concluding section will summarize the key benefits and applications of this noise-reduction solution, solidifying its role in the automotive landscape.

1. Sound Dampening

Sound dampening is a primary function achieved by the 70 Series, influencing its design, application, and market positioning. It fundamentally shapes the driving experience and the muffler’s suitability for various vehicle types and usage scenarios.

- Chambered Design and Noise Cancellation

The internal chambered design within the 70 Series muffler acts as a sound wave disruptor. As exhaust gases pass through, the chambers reflect and cancel out specific frequencies, reducing overall noise levels. This contrasts with straight-through muffler designs, which prioritize exhaust flow over noise reduction. In residential areas, vehicles equipped with this chambered muffler are less likely to violate noise ordinances.

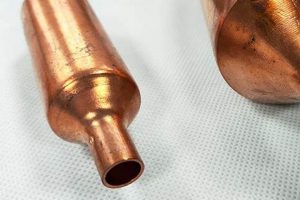

- Muffler Casing Size and Sound Absorption

The physical dimensions of the muffler casing directly correlate with its sound-dampening capabilities. A larger casing allows for increased internal volume, providing more space for sound wave attenuation. The 70 Series, typically larger than performance-oriented mufflers, utilizes this principle. However, the increased size may present installation challenges in vehicles with limited undercarriage space.

- Material Composition and Sound Insulation

The materials used in muffler construction affect sound insulation. While stainless steel is common for its durability and corrosion resistance, some mufflers incorporate additional insulating layers to further dampen sound. The 70 Series, generally constructed from steel, relies primarily on its chambered design and casing size for noise reduction, potentially lacking the enhanced insulation found in specialized sound-dampening mufflers.

- Frequency-Specific Noise Reduction

Different muffler designs target specific frequency ranges for noise reduction. The 70 Series is typically tuned to reduce mid-range frequencies, minimizing the droning sound often associated with aftermarket exhaust systems. This contrasts with mufflers designed for high-frequency noise reduction, which are more common in applications requiring minimal exhaust backpressure. This frequency-specific tuning contributes to a more refined and less aggressive exhaust note.

The interplay of these factorschambered design, casing size, material composition, and frequency-specific tuningdefines the sound-dampening characteristics of the 70 Series muffler. Its effectiveness in reducing exhaust noise makes it a suitable choice for drivers prioritizing a quieter driving experience without sacrificing engine performance entirely.

2. Large casing

The characteristic large casing associated with this muffler design is a defining feature that directly influences its performance and application. It is not merely an aesthetic element, but a functional component contributing to the sound-dampening properties for which the muffler is known.

- Increased Internal Volume for Sound Attenuation

The expansive internal volume afforded by the large casing provides greater space for sound waves to dissipate and cancel each other out. This is achieved through a complex arrangement of internal chambers and baffles that redirect and dampen exhaust pulses. This design approach contrasts with smaller, more compact mufflers that prioritize exhaust flow over sound reduction. The larger volume translates directly into enhanced noise reduction capabilities.

- Enhanced Resonance Chamber Effect

The increased size facilitates the creation of larger resonance chambers within the muffler. These chambers are specifically tuned to attenuate certain frequencies, effectively reducing the droning sound that can be prevalent in performance exhaust systems. The large casing allows for more precise tuning of these resonance chambers, resulting in a more refined and less intrusive exhaust note. This makes it suitable for vehicles where minimizing noise pollution is a priority.

- Potential for Reduced Exhaust Velocity

While beneficial for sound reduction, the large casing and internal baffling can potentially reduce exhaust gas velocity. This can, in turn, affect engine performance, particularly at higher RPMs. The design trade-off is between minimizing noise and maximizing power output. The internal architecture is carefully engineered to strike a balance between these two competing factors, although the primary emphasis remains on sound attenuation.

- Physical Size and Installation Considerations

The significant dimensions of the casing impact installation requirements. The larger size necessitates adequate undercarriage space, potentially limiting its compatibility with certain vehicle models. Additionally, the increased weight may require sturdier mounting hardware to ensure secure and stable installation. These practical considerations must be addressed when selecting this muffler for a specific application.

In summary, the large casing is an integral element that directly influences the sound-dampening capabilities and installation considerations of the muffler. Its design reflects a deliberate compromise between noise reduction and performance, making it a suitable choice for applications where a quiet exhaust note is paramount. Understanding the implications of the casing’s size is crucial for making an informed decision about its suitability for a particular vehicle.

3. Vehicle compatibility

Vehicle compatibility is a paramount consideration when selecting any aftermarket automotive component, including the featured muffler. Ensuring proper fitment and functionality is crucial for optimal performance and avoiding potential damage to the vehicle or the component itself. Mismatched components can lead to reduced efficiency, increased noise, or even mechanical failure.

- Exhaust System Diameter and Configuration

The diameter of the vehicle’s existing exhaust system must match the inlet and outlet diameters of the muffler. Discrepancies require adapters, which can introduce flow restrictions and compromise performance. Similarly, the configuration of the exhaust system, including pipe routing and hanger locations, must be compatible with the physical dimensions and mounting points of the selected muffler. For example, a vehicle with a dual exhaust system requires a muffler designed for such configurations, while a single exhaust system mandates a different design.

- Undercarriage Space and Clearance

The physical size of the 70 Series muffler, particularly its large casing, necessitates adequate undercarriage space. Insufficient clearance can lead to the muffler contacting the vehicle’s frame or suspension components, resulting in unwanted noise, vibration, and potential damage. Prior to purchase, careful measurements of the available space are essential. Vehicles with lowered suspensions or limited ground clearance may not be suitable candidates for this particular muffler design.

- Engine Displacement and Exhaust Flow Requirements

Engine displacement and horsepower output dictate the exhaust flow requirements. Selecting a muffler that is either too restrictive or too free-flowing can negatively impact engine performance. A restrictive muffler can increase backpressure, reducing horsepower and fuel efficiency. Conversely, a muffler that is too free-flowing may not provide adequate sound dampening. Matching the muffler’s flow characteristics to the engine’s needs is critical for optimal performance and sound quality. Smaller displacement engines may not require the flow capacity of a muffler designed for larger, more powerful engines.

- Year, Make, and Model-Specific Variations

Even within the same vehicle make and model, variations in exhaust system design can occur across different model years. These variations can include changes in pipe diameter, hanger locations, and catalytic converter placement. Consulting the manufacturer’s specifications or utilizing online compatibility tools is crucial to ensure that the selected muffler is specifically designed for the vehicle’s year, make, and model. Failure to account for these variations can result in fitment issues and necessitate costly modifications.

In conclusion, vehicle compatibility is not simply a matter of physical fitment. It encompasses a range of factors, including exhaust system diameter, undercarriage space, engine displacement, and model-year variations. Careful consideration of these factors is essential to ensure optimal performance, sound quality, and longevity of the featured muffler. Disregarding these considerations can lead to reduced efficiency, increased noise, or even mechanical failure, highlighting the importance of thorough research and verification prior to purchase.

4. Installation complexity

The installation complexity associated with the 70 Series muffler stems primarily from its size and intended application. This complexity directly impacts the cost and time required for installation, as well as the skill level necessary to ensure proper fitment and functionality. Factors contributing to this complexity include the need for precise welding, accurate pipe alignment, and secure mounting to prevent leaks and vibrations. For instance, retrofitting this muffler onto a vehicle with a significantly different exhaust system configuration may necessitate extensive modifications, increasing both the labor and material costs. Moreover, the larger dimensions of the muffler can create challenges in tight undercarriage spaces, demanding careful planning and execution during the installation process.

Furthermore, the selection of appropriate hardware, such as hangers, clamps, and gaskets, adds another layer to the installation complexity. Using inferior hardware can lead to premature failure, exhaust leaks, and compromised sound dampening, negating the benefits of the muffler. Proper welding techniques are also crucial to ensure a robust and leak-free connection between the muffler and the existing exhaust system. The need for specialized tools, such as a pipe cutter, welder, and exhaust bender, further contributes to the complexity, potentially requiring professional assistance. Consider a scenario where a novice attempts to install the muffler without proper tools or knowledge. This could lead to misalignment, leaks, and ultimately, a substandard installation that fails to meet the intended performance standards.

In summary, the installation complexity of the 70 Series muffler is a significant factor that must be carefully considered before purchase and installation. While DIY installation may be feasible for experienced individuals with the appropriate tools and skills, professional installation is often recommended to ensure proper fitment, optimal performance, and long-term reliability. Understanding the challenges associated with installation complexity allows for informed decision-making, preventing potential problems and maximizing the benefits of this noise-reduction solution.

5. Performance impact

The installation of an aftermarket muffler, specifically the model in question, inevitably influences a vehicle’s performance characteristics. Understanding the nature and extent of this impact is critical for informed decision-making regarding exhaust system modifications.

- Backpressure Modulation and Horsepower Output

The design of this muffler, characterized by its large casing and internal baffling, introduces a degree of backpressure into the exhaust system. Excessive backpressure can impede the expulsion of exhaust gases, reducing horsepower, particularly at higher RPMs. However, a complete absence of backpressure is also detrimental, potentially leading to a loss of low-end torque. The performance impact, therefore, hinges on striking a balance. The specific design aims to minimize the negative effects of backpressure while still providing adequate sound dampening. Actual horsepower gains or losses are contingent upon the engine’s characteristics and the rest of the exhaust system configuration. For instance, an engine already optimized for low backpressure may experience a slight reduction in horsepower, whereas an engine with a highly restrictive stock exhaust may see a modest improvement.

- Exhaust Gas Velocity and Torque Delivery

The internal chambers and baffles within the muffler inevitably affect the velocity of exhaust gases. Reduced velocity can impact torque delivery, particularly at lower RPMs. A properly designed system seeks to maintain adequate exhaust velocity to facilitate scavenging, which is the efficient removal of exhaust gases from the cylinders. The design attempts to minimize velocity reduction, but a performance trade-off exists. For example, a smaller, more restrictive muffler might increase exhaust velocity but compromise sound quality. Conversely, a straight-through muffler might maximize exhaust velocity but offer minimal sound attenuation. The internal design seeks a compromise, prioritizing sound dampening while minimizing the negative effects on exhaust gas velocity and low-end torque.

- Fuel Efficiency Considerations

Changes to the exhaust system can indirectly affect fuel efficiency. An overly restrictive exhaust can increase engine load, leading to decreased fuel economy. Conversely, an optimized exhaust system that reduces backpressure and improves scavenging can potentially enhance fuel efficiency. The impact on fuel economy is generally subtle and dependent on driving habits. Aggressive driving will negate any potential fuel efficiency gains, while conservative driving may reveal a marginal improvement. The relatively modest impact on performance suggests that the fuel efficiency implications are also likely to be minimal.

- Catalytic Converter Efficiency and Emissions Compliance

Modifications to the exhaust system can, in certain instances, affect the efficiency of the catalytic converter. Altering exhaust gas temperature or flow characteristics can potentially compromise the converter’s ability to reduce emissions. It is imperative to ensure that any aftermarket exhaust component, including the one in question, is compliant with local emissions regulations. Failure to maintain emissions compliance can result in fines and failure to pass inspection. Furthermore, tampering with the catalytic converter itself is illegal in many jurisdictions. The modification should not interfere with the catalytic converter’s functionality or placement.

In conclusion, the performance impact of installing the 70 Series muffler is multifaceted and dependent on a range of factors, including engine characteristics, driving habits, and the overall exhaust system configuration. While the design prioritizes sound dampening, the performance trade-offs are generally modest. Careful consideration of these factors is essential for achieving the desired balance between sound quality and performance.

6. Durability assessment

Durability assessment is a critical factor in evaluating the long-term value and performance of the “flowmaster 70 series muffler.” The ability of this component to withstand environmental stressors and operational demands directly affects its lifespan and overall cost-effectiveness. A comprehensive durability assessment considers multiple facets, from material composition to manufacturing processes, to predict and mitigate potential failure points.

- Material Corrosion Resistance

The primary material, typically aluminized steel or stainless steel, dictates the muffler’s resistance to corrosion. Exposure to road salts, moisture, and exhaust byproducts can accelerate corrosion, leading to structural weakening and eventual failure. Stainless steel offers superior corrosion resistance compared to aluminized steel, thereby extending the muffler’s lifespan, particularly in regions with harsh winter conditions. The presence of surface rust or pitting indicates compromised corrosion resistance and potential for premature failure. For example, a muffler exposed to road salt for several winters without proper maintenance is likely to exhibit significant corrosion compared to one used in a dry climate.

- Weld Integrity and Fatigue Resistance

The quality of the welds connecting the various components of the muffler is crucial for structural integrity. Poorly executed welds can create stress concentration points, leading to fatigue cracking under the constant vibrations and temperature fluctuations experienced during vehicle operation. Visual inspection for cracks, porosity, or incomplete fusion is essential in assessing weld integrity. A well-executed weld should exhibit a smooth, consistent bead with full penetration. Example: A muffler with visibly cracked welds near the inlet or outlet pipe is at high risk of exhaust leaks and eventual structural failure.

- Internal Baffle Design and Structural Stability

The internal baffle design, responsible for sound dampening, must also withstand the constant pressure waves and thermal stresses generated by exhaust gases. Inadequate baffle design or weak construction can lead to baffle failure, resulting in increased noise levels and reduced muffler efficiency. The structural stability of the baffles is assessed through methods such as vibration testing and finite element analysis, simulating real-world operating conditions. A muffled rattling sound emanating from the muffler could indicate a broken or detached internal baffle, signifying a structural weakness.

- External Casing Thickness and Impact Resistance

The thickness of the external casing provides protection against physical damage from road debris, impacts, and accidental grounding. Thicker casings offer greater resistance to dents and punctures, preserving the muffler’s structural integrity and preventing exhaust leaks. Regular inspection for dents, scrapes, or punctures is essential, particularly on vehicles frequently driven on rough roads. A severely dented muffler may experience restricted exhaust flow and compromised sound dampening, necessitating replacement.

In conclusion, a comprehensive durability assessment of the “flowmaster 70 series muffler” requires careful consideration of material corrosion resistance, weld integrity, internal baffle design, and external casing thickness. These factors collectively determine the muffler’s ability to withstand the rigors of daily use and environmental exposure, directly impacting its lifespan and overall value proposition. Ignoring durability assessment can lead to premature failure and increased maintenance costs, underscoring its importance in selecting an exhaust system component.

Frequently Asked Questions

This section addresses common inquiries regarding the functionality, application, and suitability of this particular automotive component. The information presented aims to provide clarity and promote informed decision-making.

Question 1: Is the Flowmaster 70 Series muffler suitable for high-performance applications?

The 70 Series muffler prioritizes sound dampening over maximizing exhaust flow. While it can be used on performance vehicles, alternatives designed for minimal backpressure may yield greater horsepower gains. Its primary benefit lies in noise reduction, making it suitable for applications where a quieter exhaust note is desired.

Question 2: Does the Flowmaster 70 Series muffler require specialized installation tools?

Installation may require welding equipment, pipe cutters, and specialized exhaust hangers, depending on the vehicle and existing exhaust system configuration. While some installations can be performed with basic tools, professional installation is often recommended to ensure proper fitment and prevent leaks.

Question 3: What is the expected lifespan of the Flowmaster 70 Series muffler?

The lifespan depends on factors such as material (aluminized steel vs. stainless steel), climate, and driving conditions. Stainless steel variants generally offer superior corrosion resistance and longer lifespan. Regular inspection and maintenance can help prolong the muffler’s operational life.

Question 4: Will the Flowmaster 70 Series muffler void the vehicle’s warranty?

Installation of an aftermarket muffler may affect the vehicle’s warranty, particularly if the modification directly causes a failure. It is advisable to consult the vehicle manufacturer or warranty provider to determine the specific impact of exhaust system modifications.

Question 5: How does the Flowmaster 70 Series muffler compare to other Flowmaster series in terms of sound?

The 70 Series is among the quietest offerings from Flowmaster, designed for minimal exhaust noise. Other series, such as the Super 10 or 40 Series, produce a more aggressive and louder exhaust note.

Question 6: Can the Flowmaster 70 Series muffler be used on any vehicle?

Compatibility depends on factors such as exhaust system diameter, undercarriage space, and engine specifications. It is crucial to verify compatibility before purchase to ensure proper fitment and avoid potential installation issues.

This FAQ section provides a concise overview of common questions regarding the Flowmaster 70 Series muffler. Additional research and professional consultation are encouraged for specific applications.

The following section delves into real-world applications and case studies, further illustrating the component’s capabilities and limitations.

Conclusion

The preceding analysis has explored various facets of the “flowmaster 70 series muffler,” encompassing its design principles, installation considerations, performance implications, durability characteristics, and common inquiries. Its significance lies in providing a balance between sound reduction and performance, catering to applications where a quieter exhaust note is prioritized. However, potential performance trade-offs and compatibility limitations warrant careful consideration.

The decision to incorporate the “flowmaster 70 series muffler” into a vehicle’s exhaust system should be based on a comprehensive understanding of its attributes and a thorough assessment of individual needs and objectives. Further research and professional consultation are recommended to ensure optimal outcomes. The future of exhaust system technology may bring forth innovations that further refine the balance between performance, sound, and environmental impact, but the fundamental principles of noise reduction and exhaust flow will remain central to design considerations.