Best Mike's Muffler & Custom Exhaust Near You: Experts!

8 January 2026

0 comment

Maximize Your Ride: DC Sports Exhaust Muffler Power!

7 January 2026

0 comment

Exhaust vs. Muffler: Key Differences Explained + Tips

7 January 2026

0 comment

Walker Exhaust: SoundFX Muffler Upgrade | Deep Tone

5 January 2026

0 comment

7 March 2026

0 comment

The components responsible for vehicle deceleration and exhaust noise reduction are critical systems for safe and compliant...

7 October 2025

0 comment

A specific automotive service location situated in a particular geographic area is the focal point. This entity...

Monro Muffler Carthage NY: Expert Car Care Nearby

6 October 2025

0 comment

Saranac Lake's Monro Muffler: Expert Exhaust & More!

4 October 2025

0 comment

Best TP Brake & Muffler Repair Near Rome NY: Experts!

4 October 2025

0 comment

22 October 2025

0 comment

A cylindrical component, typically constructed from steel or aluminum, with a three-inch diameter, designed for integration into...

Kingsport's Jeff's Pipe & Muffler: Expert Exhaust

21 October 2025

0 comment

DIY Muffler Pipe Repair Tips: Extend Your Pipe Life!

21 October 2025

0 comment

Why Exhaust Pipe & Muffler Disconnected? Causes & Fixes

20 October 2025

0 comment

Help! Ear Ache & Muffled Hearing: Causes & Relief

22 October 2025

0 comment

Otalgia, often accompanied by a diminished capacity to perceive auditory stimuli clearly, can stem from various etiologies....

Quiet Ride: Honda Accord Muffler Excellence

8 March 2026

0 comment

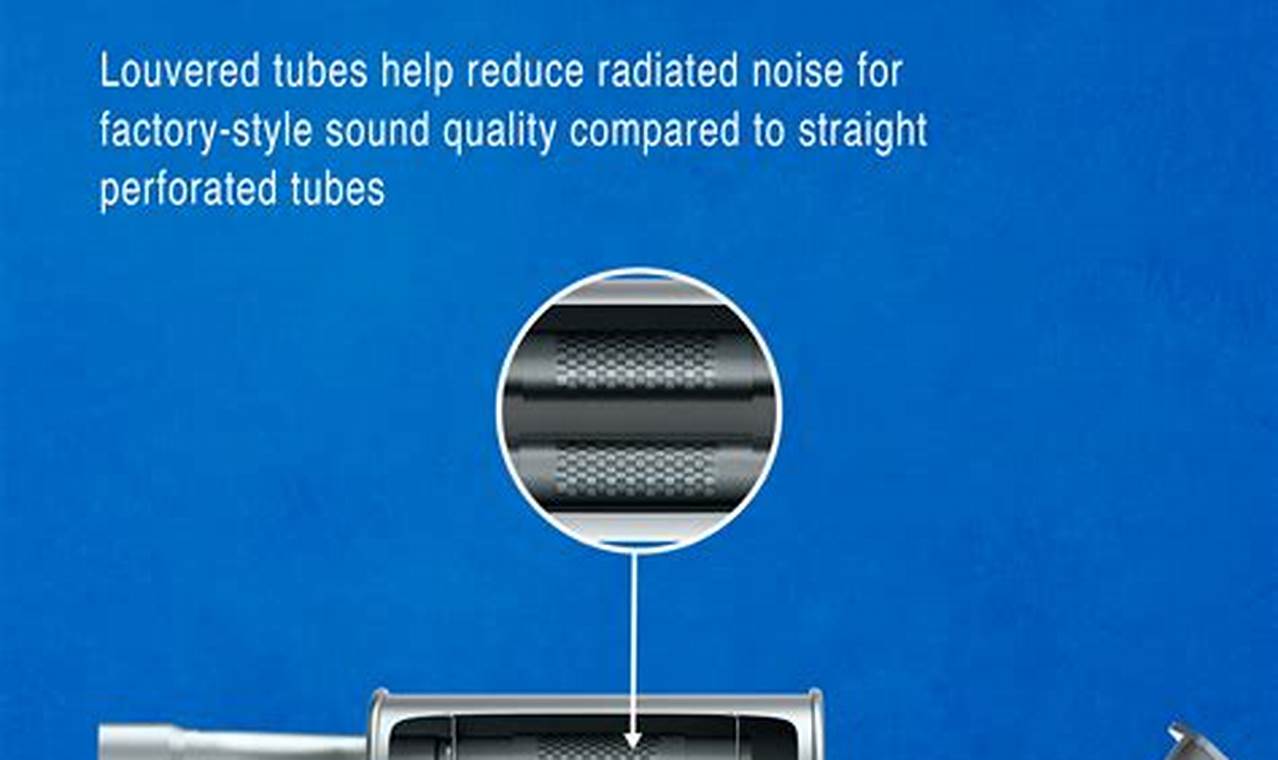

An exhaust system component designed to reduce engine noise on a specific vehicle model. This part diminishes...

Fixing Muffled Mic Sound: Causes & Solutions

8 March 2026

0 comment

Quick Fix: How to Fix Muffled Earphones + Tips

4 March 2026

0 comment

Do Muffler Tips Change Sound? + Awesome Sound!

3 March 2026

0 comment

![Rainbow Muffler Willoughby Hills OH: [Expert Repair] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Rainbow Muffler Willoughby Hills OH: [Expert Repair] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/03/th-136-300x200.jpg)