This specialized automotive component, prevalent in a specific Southeastern state, is designed to reduce noise emissions from a vehicle’s exhaust system. It is typically constructed from durable materials to withstand the corrosive effects of road salts and environmental conditions common to the region. For example, a vehicle operating near coastal areas might require more frequent inspections and potential replacement of this component due to accelerated corrosion.

The proper functioning of this component is vital for compliance with state and local noise ordinances, contributing to a quieter and more pleasant environment. Furthermore, maintaining this part in good condition can improve fuel efficiency and reduce harmful emissions. Historically, the design and materials used in these systems have evolved to meet increasingly stringent environmental regulations and consumer demands for quieter vehicles.

Therefore, the selection, maintenance, and repair of such a device become critical considerations for vehicle owners within this geographical area. The following sections will delve into the specifics of choosing the right system, identifying potential problems, and ensuring optimal performance and longevity.

Essential Maintenance Insights

The following recommendations address critical considerations for maintaining optimal exhaust system performance in a challenging environment. Adherence to these guidelines can extend lifespan and ensure compliance with local regulations.

Tip 1: Regular Inspections are Crucial: Schedule professional inspections at least annually. Early detection of corrosion or damage can prevent costly repairs and potential system failure.

Tip 2: Address Rust Promptly: Even minor surface rust should be addressed immediately. Application of rust inhibitors and protective coatings can significantly slow down the corrosion process.

Tip 3: Consider Material Composition: When replacing a system, investigate options offering enhanced corrosion resistance, such as stainless steel or aluminized steel. These materials provide superior longevity in harsh coastal environments.

Tip 4: Check for Exhaust Leaks: Conduct regular checks for exhaust leaks. These leaks not only diminish performance and fuel efficiency but also pose a potential safety hazard by allowing harmful gases to enter the vehicle’s cabin.

Tip 5: Minimize Short Trips: Frequent short trips do not allow the exhaust system to reach optimal operating temperatures, leading to moisture accumulation and accelerated corrosion. Whenever possible, incorporate longer drives to promote evaporation of accumulated moisture.

Tip 6: Choose Reputable Installers: Ensure that any replacement or repair work is performed by qualified technicians experienced with the challenges of exhaust systems in corrosive environments. Proper installation is critical for optimal performance and longevity.

Tip 7: Monitor Sound Levels: Pay attention to any changes in the exhaust note. Increased noise levels can indicate component failure or exhaust leaks requiring immediate attention.

Implementing these maintenance strategies is a proactive approach to minimizing the impact of environmental factors, resulting in extended lifespan, optimized performance, and reduced repair expenses.

Following these guidelines contributes to a reliable and compliant vehicle, leading to a safer and more enjoyable driving experience.

1. Corrosion Resistance

The performance and longevity of an exhaust system in the Southeastern region of the United States are inextricably linked to its capacity to withstand corrosion. The environmental conditions, characterized by high humidity, saltwater exposure (especially near coastal areas), and fluctuating temperatures, create an aggressive atmosphere that accelerates the degradation of metallic components.

- Material Selection

The choice of materials constitutes the first line of defense against corrosion. Stainless steel, aluminized steel, and specialized coatings are frequently employed to enhance resistance. Stainless steel alloys, in particular, offer superior protection against oxidation and chloride attack, making them a preferred option despite their higher cost. However, the specific grade and treatment of the steel are critical, as not all stainless steel provides equivalent levels of protection. The manufacturing process and welding techniques also influence the ultimate corrosion resistance.

- Road Salt Exposure

During the winter months, road salts are applied to mitigate icy conditions. These salts, primarily composed of sodium chloride and magnesium chloride, are highly corrosive and can rapidly degrade exhaust systems. The resulting salt spray, carried by road traffic, adheres to the undercarriage of vehicles, including the exhaust system. The repeated exposure to this salt spray accelerates the oxidation process, leading to rust formation and eventual component failure. Furthermore, the elevated temperatures of the exhaust system can exacerbate the corrosive effects of these salts.

- Environmental Humidity

The high relative humidity prevalent in the Southeastern climate contributes significantly to corrosion. Moisture, particularly in combination with pollutants and salts, creates an electrolytic environment that promotes the electrochemical corrosion process. The continuous condensation and evaporation cycles on the exhaust system’s surface can lead to the formation of localized corrosion cells, initiating pitting and accelerated metal loss. The presence of contaminants in the air, such as sulfur dioxide from industrial activities, can further enhance the corrosive potential of the humid environment.

- Protective Coatings

In addition to material selection, protective coatings play a critical role in extending the lifespan of exhaust systems. Ceramic coatings, zinc-rich primers, and polymeric sealants are frequently applied to create a barrier between the metallic components and the corrosive environment. These coatings prevent moisture, salts, and pollutants from directly contacting the metal surface, thus inhibiting the corrosion process. However, the effectiveness of these coatings depends on their proper application, adhesion, and resistance to abrasion and thermal degradation. Regular inspection and maintenance of these coatings are essential to ensure their continued protective function.

These facets of corrosion resistance highlight its fundamental importance to vehicle owners in this specific geographic area. Choosing an exhaust system with robust corrosion protection measures, coupled with diligent maintenance practices, represents a sound investment in the long-term reliability and performance of the vehicle.

2. Sound Regulation

Sound regulation pertaining to motor vehicles directly influences the design, performance characteristics, and legality of aftermarket exhaust systems, especially within states possessing specific noise ordinances. The efficacy of a system in mitigating exhaust noise is a critical factor in ensuring compliance and avoiding potential penalties.

- Decibel Limits and Legal Compliance

Many municipalities enforce specific decibel limits for vehicle exhaust noise. These limits are often measured at a specified distance from the vehicle under controlled conditions. Aftermarket exhaust systems, including those marketed for use in Florida, must meet these standards to be considered street legal. Non-compliance can result in fines, mandatory repairs, or vehicle impoundment.

- Muffler Design and Noise Reduction Technology

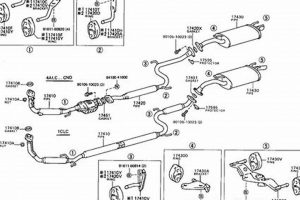

The internal design of a muffler is crucial in attenuating exhaust noise. Various technologies, such as baffles, resonators, and sound-absorbing materials, are employed to reduce the amplitude and frequency of sound waves generated by the engine. The selection and arrangement of these components directly impact the muffler’s ability to meet sound regulation standards without significantly hindering engine performance.

- Aftermarket Modifications and Tampering

Regulations often prohibit modifications to exhaust systems that increase noise levels beyond legal limits. This includes removing or altering components such as catalytic converters or resonators. Tampering with an exhaust system to achieve a louder sound can result in substantial fines and require the vehicle owner to restore the system to its original, compliant configuration.

- Enforcement and Vehicle Inspections

Enforcement of sound regulations typically involves law enforcement officers using sound level meters to measure exhaust noise. Periodic vehicle inspections may also include noise level checks to ensure compliance with state and local laws. These inspections serve as a deterrent against illegal modifications and help maintain acceptable noise levels within communities.

These interconnected aspects demonstrate that adherence to sound regulation is not merely a matter of legal compliance, but also a consideration of community well-being. Systems engineered to meet or exceed established standards ensure both vehicle legality and a reduction in noise pollution.

3. Material Durability

Material durability is a paramount concern regarding exhaust systems operating within the environmental conditions prevalent in Florida. Exposure to high humidity, saltwater spray, and elevated temperatures necessitates the use of robust materials engineered to resist corrosion and degradation. The longevity and reliability of a “Florida muffler” are directly proportional to the durability of its constituent materials.

- Stainless Steel Composition and Grades

The selection of stainless steel alloys is critical. While stainless steel generally offers superior corrosion resistance compared to conventional steel, variations exist among grades. Austenitic stainless steels, such as 304 and 316, are commonly employed due to their high chromium and nickel content, which provides enhanced protection against oxidation and chloride attack. Marine-grade 316 stainless steel exhibits even greater resistance to pitting corrosion, a common failure mode in coastal environments. The precise composition and heat treatment processes significantly influence the material’s overall durability.

- Aluminized Steel and Protective Coatings

Aluminized steel offers a cost-effective alternative, providing a layer of aluminum-silicon alloy bonded to the steel substrate. This aluminum layer forms a protective oxide film that inhibits corrosion. However, the integrity of this coating is essential; scratches or damage can compromise its effectiveness. Furthermore, the base steel beneath the aluminized layer remains susceptible to corrosion if the coating is breached. Additional protective coatings, such as ceramic-based formulations, can augment the corrosion resistance of aluminized steel.

- Weld Integrity and Corrosion Resistance

Welding processes significantly impact the durability of exhaust systems. Improper welding techniques can create stress concentrations and introduce defects that serve as initiation sites for corrosion. The use of appropriate filler metals and shielding gases is crucial to prevent oxidation and ensure the formation of strong, corrosion-resistant welds. Post-weld heat treatment can relieve residual stresses and further enhance weld integrity. The long-term performance of a “Florida muffler” depends heavily on the quality of its welds.

- Mounting Hardware and Isolation Techniques

The durability of mounting hardware and isolation components is also a critical consideration. Rubber isolators, used to dampen vibrations and reduce stress on the exhaust system, must be resistant to heat, ozone, and saltwater exposure. Corroded or degraded mounting hardware can lead to exhaust leaks and premature system failure. Stainless steel or coated hardware is preferred to minimize corrosion in these critical areas. Proper installation techniques are essential to prevent over-tightening or damage to mounting points.

The interplay of these material-related factors underscores the importance of selecting a “Florida muffler” constructed from durable materials and manufactured using robust techniques. A comprehensive understanding of these material properties and their influence on long-term performance is essential for vehicle owners seeking reliable and cost-effective exhaust solutions in challenging environments.

4. Professional Installation

The proper functioning and longevity of an exhaust system in Florida’s challenging environment are significantly influenced by the quality of its installation. Professional installation transcends merely attaching components; it encompasses a nuanced understanding of material compatibility, torque specifications, and environmental considerations specific to the region.

- Correct Component Selection and Compatibility

Professional installers possess the expertise to select the appropriate muffler and associated hardware compatible with the vehicle’s make, model, and intended use. This includes understanding the nuances of various steel alloys, coating types, and their resistance to corrosion prevalent in coastal areas. Incorrect component selection can lead to premature failure and void warranties.

- Proper Torque Specifications and Fastener Application

Adhering to precise torque specifications for all fasteners is crucial to prevent leaks and ensure secure attachment of the exhaust system. Over-tightening can damage components, while under-tightening can lead to vibrations, leaks, and eventual system failure. Professional installers utilize calibrated torque wrenches and apply anti-seize compounds to prevent corrosion and facilitate future removal.

- Exhaust System Alignment and Clearance

Proper alignment of the exhaust system is essential to prevent contact with the vehicle’s chassis or other components. Inadequate clearance can lead to vibrations, noise, and potential damage to the exhaust system or surrounding parts. Professional installers ensure correct positioning and secure mounting to minimize stress and maximize system lifespan.

- Welding Integrity and Corrosion Protection

For systems requiring welding, professional installers employ certified welders with experience in exhaust system fabrication. Proper welding techniques are essential to create strong, leak-free joints that resist corrosion. Following welding, the application of corrosion-resistant coatings to the weld area is crucial to prevent premature failure in Florida’s corrosive environment.

Therefore, while cost considerations may tempt some vehicle owners towards DIY installations, the expertise and precision offered by professional installers represent a significant investment in the long-term performance and reliability of a “Florida muffler”. The nuances of correct installation practices mitigate the risks of premature failure and ensure compliance with local regulations, contributing to a safer and more cost-effective ownership experience.

5. Exhaust Leaks

Exhaust leaks represent a significant concern for vehicle owners, particularly in regions with corrosive environments such as Florida. The integrity of the exhaust system, including the muffler, is continuously challenged by humidity, saltwater, and road salts, increasing the likelihood of leaks and associated complications. Understanding the causes and consequences of exhaust leaks is crucial for maintaining vehicle performance, ensuring compliance with emissions standards, and preserving the lifespan of the “Florida muffler”.

- Corrosion-Induced Failures

The prevalence of corrosive elements in Florida accelerates the degradation of exhaust system components, including the muffler. Road salts, humidity, and saltwater contribute to rust formation, weakening the metal and leading to pinhole leaks or structural failures. These leaks diminish the muffler’s ability to effectively dampen noise and can release harmful emissions into the atmosphere. Regular inspections are vital for detecting early signs of corrosion and preventing catastrophic failures.

- Weld Degradation and Joint Failures

The joints and welds within the exhaust system are particularly susceptible to leaks. The intense heat cycling and exposure to corrosive elements can weaken the welds, causing cracks and eventual separation. Additionally, poorly executed repairs or modifications can introduce stress points that accelerate weld degradation. Leaks at these points can significantly reduce the efficiency of the catalytic converter and trigger warning lights on the vehicle’s dashboard.

- Component Wear and Deterioration

Over time, the internal components of the muffler can wear down due to constant exposure to hot exhaust gases and vibrations. Baffles and resonators can become damaged or dislodged, creating pathways for exhaust gases to escape. This wear leads to increased noise levels, reduced fuel efficiency, and potential damage to other exhaust system components. Replacement of worn-out components is often necessary to restore the system’s integrity.

- Impact Damage and Physical Stress

Road debris, potholes, and accidents can cause physical damage to the exhaust system, leading to dents, cracks, and leaks. Impact damage can compromise the structural integrity of the muffler and other components, accelerating corrosion and leading to premature failure. Thorough inspections following any incident are crucial for identifying and addressing potential damage to the exhaust system.

These facets of exhaust leaks underscore their detrimental impact on the functionality and longevity of a “Florida muffler.” Early detection and prompt repair are essential for mitigating the adverse effects of leaks, ensuring optimal vehicle performance, and maintaining compliance with environmental regulations. Prioritizing regular maintenance and inspections is a proactive approach to preserving the integrity of the exhaust system in Florida’s challenging conditions.

6. Regular Inspection

Regular inspection is a critical component of exhaust system maintenance, particularly for vehicles operating in Florida’s corrosive coastal environment. These inspections serve as a proactive measure to identify and address potential issues before they escalate into costly repairs or system failures. For a “Florida muffler,” routine assessments extend its lifespan and maintain optimal performance.

- Early Detection of Corrosion

Inspections reveal the initial stages of corrosion, a pervasive threat in Florida due to humidity and saltwater exposure. Early detection allows for timely intervention with rust inhibitors or protective coatings, preventing the weakening of metallic components and extending the muffler’s operational life. Neglecting this can lead to complete structural failure, necessitating costly replacements.

- Identification of Exhaust Leaks

Exhaust leaks, often caused by corrosion or weld degradation, can diminish engine performance and increase emissions. Regular inspections pinpoint these leaks, enabling prompt repairs and preventing further damage to the catalytic converter or other exhaust system components. Detecting and addressing leaks also minimizes the risk of harmful gases entering the vehicle’s cabin.

- Assessment of Mounting Hardware and Isolators

Mounting hardware and rubber isolators are essential for securing the exhaust system and damping vibrations. Inspections assess their condition, identifying corrosion, wear, or damage that could compromise the system’s stability. Replacing degraded components prevents excessive stress on the muffler and ensures proper alignment, extending its lifespan.

- Verification of Sound Level Compliance

Florida has noise regulations that vehicles must adhere to. Routine inspections can help identify if the muffler is effectively reducing exhaust noise to compliant levels. Gradual deterioration or damage to the mufflers internal components can increase noise output. By identifying changes in sound levels, vehicle owners can address the issue promptly and avoid potential fines or penalties.

These facets illustrate that regular inspection transcends a mere visual assessment; it is a systematic evaluation of the “Florida muffler’s” structural integrity, performance, and regulatory compliance. Consistent inspections, performed by qualified technicians, are an essential investment in the long-term health and reliability of the vehicle’s exhaust system.

Frequently Asked Questions About Florida Mufflers

The following addresses common inquiries regarding these specialized automotive components, tailored to the unique environmental conditions of the region. These answers aim to provide clarity on aspects critical to performance, longevity, and regulatory compliance.

Question 1: What specific environmental factors contribute to the accelerated degradation of exhaust systems in Florida?

High humidity, saltwater exposure (particularly in coastal areas), and elevated temperatures significantly accelerate corrosion. Road salts used during occasional winter events further exacerbate this process, leading to premature failure of exhaust components.

Question 2: What materials offer the best corrosion resistance for a Florida muffler, and what are the trade-offs?

Stainless steel (grades 304 and 316) provides superior corrosion resistance, but incurs a higher initial cost. Aluminized steel offers a more economical alternative, but its protective coating can be compromised by scratches or damage, reducing its lifespan in harsh conditions.

Question 3: How frequently should a Florida muffler be inspected to ensure optimal performance and prevent costly repairs?

Professional inspections are recommended at least annually, or more frequently for vehicles operating primarily in coastal areas. Early detection of corrosion, leaks, or damage can prevent minor issues from escalating into major system failures.

Question 4: What are the potential consequences of neglecting exhaust leaks in Florida, beyond increased noise levels?

Unaddressed exhaust leaks can diminish fuel efficiency, reduce engine performance, damage catalytic converters, and potentially allow harmful gases to enter the vehicle’s cabin, posing a health hazard. Furthermore, leaks contribute to air pollution and violate emissions regulations.

Question 5: What role does professional installation play in maximizing the lifespan of a Florida muffler?

Professional installers possess the expertise to select compatible components, adhere to precise torque specifications, ensure proper alignment, and apply corrosion-resistant coatings. These factors contribute significantly to the system’s long-term performance and resistance to environmental degradation.

Question 6: How do local noise ordinances impact the selection and modification of exhaust systems in Florida?

Florida municipalities enforce specific decibel limits for vehicle exhaust noise. Modifications that increase noise levels beyond these limits are illegal and can result in fines, mandatory repairs, or vehicle impoundment. Aftermarket systems must meet these standards to be considered street legal.

Prioritizing durable materials, regular inspections, and professional installation are essential for maintaining optimal exhaust system performance and ensuring compliance with local regulations. Vehicle owners should be aware of the environmental challenges and proactive in mitigating their effects.

The following section will delve into specific maintenance strategies for prolonging the life of your system.

In Conclusion

The preceding discussion has detailed the multifaceted aspects of exhaust systems, specifically addressing the challenges posed by the Florida environment. Considerations of material durability, regulatory compliance, proper installation, and routine maintenance are paramount for vehicle owners seeking optimal performance and longevity. The persistent threat of corrosion, amplified by humidity, saltwater, and road salts, necessitates a proactive approach to system management.

Therefore, understanding these environmental factors and implementing appropriate preventative measures is essential for maximizing the lifespan and ensuring the reliable operation of the device. Prioritizing informed decision-making and diligent maintenance practices will contribute to reduced repair expenses, enhanced vehicle performance, and adherence to environmental regulations, ultimately benefiting both vehicle owners and the broader community.