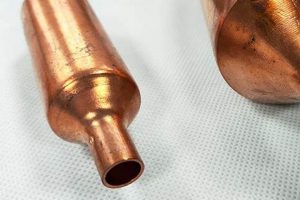

An exhaust component featuring a specific entry diameter of six inches is designed to manage engine noise. Typically installed as part of a vehicle’s exhaust system, this component reduces the sound pressure generated by the engine’s combustion process. For example, a heavy-duty truck might employ such a device to comply with noise regulations and improve driver comfort.

Employing a component with this inlet dimension offers several advantages. It can optimize exhaust flow in certain engine configurations, potentially leading to improved engine efficiency. Furthermore, effective noise reduction contributes to a more pleasant operating environment and aids in meeting environmental standards. Historically, the development of these components has mirrored advancements in engine technology and growing awareness of noise pollution.

The following sections will delve into the design considerations, material selection, and applications associated with this type of exhaust system component, offering a more in-depth understanding of its functionality and performance characteristics.

Essential Considerations for Implementing a Six-Inch Inlet Diameter Muffler

This section presents crucial guidelines for the selection and integration of an exhaust component characterized by a six-inch inlet dimension. Adherence to these points ensures optimal performance and longevity.

Tip 1: Verify Exhaust System Compatibility: Ensure the existing exhaust piping and engine parameters are suitable for an inlet diameter of six inches. Mismatched dimensions can impede exhaust flow and negate noise reduction benefits.

Tip 2: Material Selection Based on Application: Employ appropriate materials based on operating temperature, environmental exposure, and desired lifespan. Stainless steel offers superior corrosion resistance in demanding environments, while aluminized steel represents a cost-effective alternative for less severe conditions.

Tip 3: Proper Installation Techniques: Use correct welding or clamping procedures to ensure a secure and leak-free connection. Improper installation can lead to exhaust leaks, reduced performance, and potential safety hazards.

Tip 4: Consider Flow Dynamics: Optimize the internal design to minimize backpressure. Excessive backpressure can reduce engine power output and increase fuel consumption.

Tip 5: Adherence to Noise Regulations: Select a model that complies with all applicable noise emission standards. Failure to meet these standards can result in penalties and operational restrictions.

Tip 6: Regular Inspection and Maintenance: Periodically examine the component for signs of corrosion, damage, or leaks. Promptly address any issues to prevent further deterioration and ensure continued functionality.

Effective integration of this specific exhaust component requires careful planning, appropriate material selection, and meticulous installation. Following these guidelines will ensure optimal performance and adherence to regulatory requirements.

The subsequent section will present a detailed analysis of the performance characteristics and efficiency considerations relevant to this component.

1. Inlet Diameter

The “inlet diameter” is a critical parameter when evaluating the performance characteristics of an exhaust system component, particularly in the context of a six-inch inlet muffler. The dimension directly influences exhaust flow, noise attenuation, and overall engine efficiency. Selecting the appropriate inlet diameter is crucial for optimizing system performance.

- Exhaust Flow Rate

The inlet diameter directly determines the volume of exhaust gases that can enter the muffler per unit of time. A six-inch inlet facilitates a high flow rate, suitable for engines with large displacement or those operating at high RPM. Restricting the inlet diameter can create backpressure, negatively impacting engine performance. The selection process must align the inlet diameter with the engine’s exhaust volume requirements.

- Noise Reduction Efficiency

While the internal design of the muffler primarily dictates noise reduction, the inlet diameter plays a role in the frequencies that are effectively attenuated. A larger inlet may allow lower frequency sounds to propagate more readily, requiring specific internal baffle configurations for effective suppression. Optimizing the inlet diameter in conjunction with internal muffler design achieves desired noise reduction across the entire engine operating range.

- Engine Backpressure

The inlet diameter contributes to the overall backpressure within the exhaust system. A smaller diameter creates greater resistance to exhaust flow, leading to increased backpressure. Excessive backpressure reduces engine power output, increases fuel consumption, and potentially elevates engine operating temperatures. The six-inch inlet dimension aims to minimize backpressure, particularly in applications where high exhaust flow is essential.

- Component Compatibility

The inlet diameter must be compatible with the exhaust manifold outlet and the subsequent piping. A six-inch inlet requires corresponding exhaust system components to ensure a smooth transition and prevent flow restrictions. Incompatible diameters necessitate adapters, which can introduce turbulence and reduce system efficiency. Proper integration of the six-inch inlet muffler requires careful consideration of the entire exhaust system layout.

In summary, the inlet diameter of a muffler, specifically in the context of a six-inch configuration, is a key determinant of exhaust flow, noise reduction, backpressure, and system compatibility. Optimizing this parameter is crucial for achieving desired engine performance and meeting noise regulations.

2. Noise Reduction

The primary function of a muffler, particularly one with a six-inch inlet, is the attenuation of engine exhaust noise. The inlet diameter, while facilitating exhaust flow, indirectly affects the overall noise reduction capabilities. Muffler designs incorporate internal baffles, chambers, and sound-absorbing materials to mitigate the sound waves generated by the combustion process. These internal structures are engineered to reduce the amplitude and alter the frequency of the sound waves, thereby decreasing perceived noise levels. For instance, a heavy-duty truck equipped with a six-inch inlet muffler relies on this noise reduction to comply with stringent environmental regulations and ensure driver comfort during long hauls. The effectiveness of noise reduction is directly linked to the muffler’s internal design, the properties of the sound-absorbing materials, and the overall volume of the muffler body.

Practical applications demonstrate the direct correlation between muffler design and noise reduction efficiency. In the automotive industry, various muffler types, such as baffled, chambered, and absorption mufflers, are employed depending on the desired noise characteristics. Baffled mufflers utilize a series of plates or deflectors to redirect and cancel out sound waves. Chambered mufflers employ resonating chambers to target specific frequencies. Absorption mufflers incorporate sound-absorbing materials, such as fiberglass or steel wool, to dissipate sound energy. The selection of a specific muffler type depends on the target noise reduction levels and the acceptable backpressure limits. A six-inch inlet muffler, when coupled with an effective internal design, significantly contributes to reducing noise pollution and enhancing the acoustic environment.

Understanding the interplay between the six-inch inlet dimension and the internal noise reduction mechanisms is crucial for optimizing exhaust system performance. Challenges in achieving desired noise reduction levels often involve balancing exhaust flow with acoustic attenuation. Excessive backpressure, a potential consequence of aggressive noise reduction designs, can negatively impact engine efficiency. Therefore, careful engineering and material selection are paramount to achieve both effective noise reduction and minimal performance penalties. The practical significance lies in the ability to engineer quieter, more efficient vehicles that meet regulatory requirements and enhance the overall driving experience.

3. Exhaust Flow and the Six-Inch Inlet Muffler

Exhaust flow, the movement of combustion byproducts from an engine’s cylinders through the exhaust system, is directly influenced by the dimensions of the system’s components. The six-inch inlet muffler serves as a critical point of interface for this flow, dictating its volume and velocity entering the noise reduction apparatus. A properly sized inlet minimizes restrictions, allowing for efficient evacuation of exhaust gases. Conversely, an undersized inlet creates backpressure, impeding engine performance. For example, a high-performance engine paired with an insufficient muffler inlet experiences reduced power output due to the accumulation of exhaust gases within the cylinders, hindering the next combustion cycle. The six-inch diameter represents a specific design choice, balancing flow capacity with the physical constraints of the vehicle and the requirements of the noise attenuation mechanisms within the muffler.

The design of the muffler’s internal components interacts with the incoming exhaust flow to achieve noise reduction. Baffles, resonators, and absorption materials are strategically placed to disrupt sound waves. However, these components also introduce resistance to the flow. The six-inch inlet provides a sufficient initial area to mitigate the overall impact of these internal restrictions. Consider a commercial truck requiring effective noise suppression without sacrificing engine efficiency. A six-inch inlet muffler, coupled with carefully engineered internal baffling, can achieve both objectives. The inlet diameter, in conjunction with the internal design, is calibrated to maintain optimal exhaust velocity and minimize backpressure, ensuring efficient engine operation while adhering to noise regulations.

In summary, the six-inch inlet muffler plays a crucial role in managing exhaust flow within an engine’s exhaust system. The diameter influences engine performance, noise reduction, and fuel efficiency. The successful implementation depends on selecting an appropriate design which matches the engine characteristics. Although a six inch inlet muffler is a considerable size, improper design can cause greater harm than good when used for the wrong type of vehicle or wrong engine.

4. Back Pressure

Back pressure, the resistance to exhaust flow within an engine’s exhaust system, is a critical parameter influencing engine performance and efficiency. The six-inch inlet muffler, as a component within this system, directly impacts back pressure levels. Understanding this relationship is essential for optimizing engine operation.

- Inlet Diameter and Resistance

The diameter of the muffler inlet inherently affects exhaust flow resistance. A six-inch inlet provides a relatively large cross-sectional area, minimizing flow restriction compared to smaller inlets. However, the internal design of the muffler, including baffles and chambers, also contributes to overall back pressure. An improperly designed muffler with a six-inch inlet can still generate excessive back pressure if internal components are restrictive.

- Engine Performance Implications

Elevated back pressure negatively impacts engine performance. It hinders the expulsion of exhaust gases from the cylinders, reducing volumetric efficiency and power output. Increased back pressure also elevates exhaust gas temperatures, potentially leading to premature component failure and decreased fuel economy. Selecting a six-inch inlet muffler with a low-restriction design is crucial for maintaining optimal engine performance.

- Muffler Design and Back Pressure Mitigation

Muffler designs aim to balance noise reduction with minimal back pressure. Straight-through mufflers, characterized by a perforated core surrounded by sound-absorbing material, offer low flow resistance but may provide less effective noise attenuation compared to chambered designs. Chambered mufflers, utilizing internal partitions to redirect sound waves, often exhibit higher back pressure. A well-designed six-inch inlet muffler optimizes internal geometry to minimize flow restrictions while achieving desired noise reduction levels.

- Application-Specific Considerations

The acceptable level of back pressure varies depending on the engine type and application. High-performance engines typically require exhaust systems with minimal back pressure to maximize power output. Conversely, some applications prioritize noise reduction over absolute performance, allowing for slightly higher back pressure levels. Selecting a six-inch inlet muffler tailored to the specific engine and application is essential for achieving optimal results. For example, a diesel engine may tolerate a higher back pressure than a gasoline engine due to its combustion characteristics.

The relationship between back pressure and the six-inch inlet muffler is complex, involving considerations of inlet diameter, internal muffler design, and engine application. Proper selection and design are crucial for balancing noise reduction with optimal engine performance. Ignoring back pressure implications can lead to reduced power output, increased fuel consumption, and potential engine damage.

5. Material Durability

Material durability is a paramount consideration in the design and selection of a six-inch inlet muffler. The exhaust system environment subjects the muffler to extreme conditions, including high temperatures, corrosive gases, and mechanical stresses. Therefore, the choice of materials directly impacts the component’s lifespan and performance reliability.

- Corrosion Resistance

Exhaust gases contain corrosive compounds, such as sulfur dioxide and water vapor, which can degrade metallic components. Materials with inherent corrosion resistance, such as stainless steel (typically 304 or 409 grades) and aluminized steel, are commonly employed. Stainless steel provides superior corrosion protection but is more expensive. Aluminized steel offers a cost-effective compromise, providing a protective aluminum coating that delays corrosion. For instance, a six-inch inlet muffler installed on a commercial vehicle operating in a region with harsh winter conditions, where road salts are prevalent, necessitates a material with exceptional corrosion resistance to prevent premature failure.

- Thermal Fatigue Resistance

The muffler experiences significant temperature fluctuations during engine operation. Repeated heating and cooling cycles induce thermal stress, potentially leading to cracking and fatigue failure. Materials with high thermal fatigue resistance, characterized by low thermal expansion coefficients and high yield strengths, are preferred. Stainless steel exhibits superior thermal fatigue resistance compared to carbon steel. The six-inch inlet muffler on a turbocharged engine, subject to rapid and extreme temperature changes, demands a material capable of withstanding thermal stress without compromising structural integrity.

- Mechanical Strength

The muffler is subjected to mechanical stresses from vehicle vibrations, exhaust gas pressure, and external impacts. The chosen material must possess adequate tensile strength and yield strength to withstand these stresses without deformation or fracture. Thicker gauge materials enhance mechanical strength but also increase weight and cost. Consider an off-road vehicle, where the six-inch inlet muffler is vulnerable to impacts from rocks and debris. In this scenario, a robust material with sufficient thickness is essential to prevent damage and maintain functionality.

- Weldability and Manufacturability

The ease with which a material can be welded and formed into the desired shape affects manufacturing costs and the integrity of the final product. Stainless steel and aluminized steel are readily weldable using various techniques, such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding. Proper welding procedures are crucial to ensure strong and leak-free joints. A six-inch inlet muffler with complex internal baffling requires a material that can be easily formed and welded to create the intricate structures necessary for noise reduction. Poor weldability can lead to structural weaknesses and premature failure.

In conclusion, material durability is a critical factor in determining the performance and longevity of a six-inch inlet muffler. The selection of appropriate materials, such as stainless steel or aluminized steel, based on the specific application requirements, ensures resistance to corrosion, thermal fatigue, and mechanical stresses. Proper welding and manufacturing techniques are equally important in maintaining the structural integrity of the component. Therefore, a holistic approach to material selection and manufacturing is crucial for achieving a durable and reliable exhaust system component.

6. Engine Compatibility

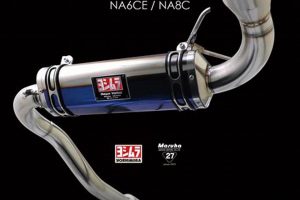

Engine compatibility is a crucial determinant in the effective utilization of a six-inch inlet muffler. The performance benefits derived from such a component namely optimized exhaust flow and noise reduction are contingent upon its suitability for the engine’s specific characteristics. An improperly matched muffler can negate these advantages, resulting in reduced engine efficiency, increased backpressure, and inadequate noise suppression. The volume of exhaust gases generated by the engine, its operating RPM range, and its power output are primary factors influencing this compatibility. For instance, a large displacement diesel engine in a heavy-duty truck necessitates a muffler capable of handling a substantial exhaust volume. A six-inch inlet muffler, appropriately designed, often meets this demand. Conversely, a smaller engine may not require such a large inlet, and its integration could even prove detrimental.

Practical applications illustrate the importance of ensuring engine compatibility. Installing a six-inch inlet muffler on a small displacement engine designed for fuel efficiency, for example, could lead to a decrease in exhaust velocity. This reduction in velocity can hinder the scavenging of exhaust gases from the combustion chamber, ultimately diminishing engine performance and fuel economy. Similarly, a high-performance engine may necessitate a more specialized muffler design, even with a six-inch inlet, to minimize backpressure and maximize exhaust flow. The internal baffling and flow characteristics must be meticulously engineered to match the engine’s output parameters. Failure to account for these factors can result in a mismatch between the muffler’s capabilities and the engine’s requirements, leading to suboptimal performance.

In summary, engine compatibility is a fundamental consideration in the implementation of a six-inch inlet muffler. A mismatch between the muffler’s design and the engine’s characteristics can negate the potential benefits of reduced noise and optimized exhaust flow. Careful consideration of engine size, RPM range, and power output is essential for selecting a muffler that aligns with the engine’s specific requirements. Challenges in achieving optimal compatibility often stem from variations in engine design and operating conditions. The practical significance of this understanding lies in the ability to engineer exhaust systems that maximize engine efficiency, minimize noise pollution, and ensure long-term reliability.

7. Regulatory Compliance

Regulatory compliance exerts a substantial influence on the design and application of exhaust components, including those featuring a six-inch inlet. Noise emission standards, mandated by governmental bodies and environmental agencies, dictate permissible sound levels generated by vehicles and machinery. A six-inch inlet muffler, therefore, must be engineered to attenuate exhaust noise sufficiently to meet these regulations. Non-compliance can result in substantial penalties, operational restrictions, and reputational damage. Consequently, manufacturers prioritize noise reduction as a primary design objective, integrating specific internal features and sound-absorbing materials to ensure conformity. For example, commercial trucks operating in urban environments are often subject to stringent noise ordinances, requiring the utilization of mufflers certified to meet specific decibel limits. The six-inch inlet dimension, while contributing to exhaust flow, must not compromise the muffler’s ability to meet these mandatory acoustic performance standards.

The implementation of regulatory mandates extends beyond noise emissions to include exhaust gas composition. While the six-inch inlet dimension primarily addresses exhaust flow and noise reduction, it indirectly affects the efficiency of catalytic converters and other emission control devices downstream in the exhaust system. Restrictions in exhaust flow, caused by an improperly designed muffler, can impede the performance of these catalytic devices, potentially leading to increased pollutant emissions. Regulatory compliance, therefore, necessitates a holistic approach to exhaust system design, ensuring that the muffler, including its inlet dimensions, does not compromise the effectiveness of other emission control components. Automotive manufacturers often conduct extensive testing and simulations to verify that their exhaust systems, including the six-inch inlet muffler, meet both noise and emission regulations under various operating conditions.

In summary, regulatory compliance is a driving force in the design and application of six-inch inlet mufflers. Noise emission standards necessitate effective acoustic attenuation, while broader environmental regulations require a comprehensive approach to exhaust system design. The six-inch inlet dimension, while influencing exhaust flow, must not compromise the muffler’s ability to meet these mandatory performance criteria. This interdependence highlights the practical significance of aligning muffler design with regulatory requirements, ensuring that vehicles and machinery operate within acceptable environmental and legal boundaries.

Frequently Asked Questions

This section addresses common inquiries regarding exhaust components featuring a six-inch inlet diameter, providing clarity on their function, applications, and performance characteristics.

Question 1: What are the primary applications for a six-inch inlet muffler?

Components with this inlet dimension are typically employed in heavy-duty vehicles, industrial equipment, and other applications requiring substantial exhaust flow capacity. Examples include diesel trucks, construction machinery, and stationary generators.

Question 2: How does the inlet diameter affect exhaust flow and engine performance?

The inlet diameter directly influences the volume of exhaust gases that can pass through the muffler. A six-inch inlet is designed to minimize flow restriction and backpressure, thereby optimizing engine performance. Undersized inlets can impede exhaust flow, reducing power output and fuel efficiency.

Question 3: What materials are commonly used in the construction of these mufflers?

Common materials include aluminized steel, which offers a balance of cost and corrosion resistance, and stainless steel, which provides superior durability in demanding environments. The selection of material depends on the application and operating conditions.

Question 4: Do six-inch inlet mufflers require specialized installation procedures?

While the installation process is similar to that of other mufflers, it is crucial to ensure proper alignment and sealing to prevent exhaust leaks. Welding or clamping techniques must be appropriate for the materials involved, and adherence to manufacturer’s recommendations is essential.

Question 5: How can the performance of a six-inch inlet muffler be evaluated?

Performance can be assessed by measuring exhaust backpressure, noise levels, and engine performance metrics. A properly functioning muffler will minimize backpressure while effectively attenuating exhaust noise to meet regulatory standards.

Question 6: Are there specific regulatory requirements governing the use of these mufflers?

Yes, noise emission standards are prevalent in many jurisdictions, dictating permissible sound levels for vehicles and equipment. The selected muffler must comply with these regulations, and documentation verifying compliance may be required.

Understanding the functionality and characteristics of components with a six-inch inlet dimension is crucial for effective implementation and maintenance in various applications.

The subsequent section will provide a glossary of related terms, clarifying technical terminology associated with exhaust systems and muffler technology.

Conclusion

This exploration has outlined the function, benefits, and considerations surrounding the selection and implementation of a 6 inch inlet muffler. Its role in managing exhaust flow, reducing noise, and ensuring engine compatibility has been detailed. The importance of material selection, design optimization for backpressure, and adherence to regulatory standards has been emphasized, solidifying the component’s significance in various industrial and automotive contexts.

As engine technology advances and environmental regulations become more stringent, the demand for efficient and reliable exhaust solutions will only increase. A comprehensive understanding of exhaust system components, particularly the 6 inch inlet muffler, is crucial for engineers, technicians, and decision-makers in related fields. Continued research and development will undoubtedly lead to further advancements in muffler technology, optimizing performance and minimizing environmental impact.