This component, specific to a particular model year and vehicle, is a critical part of the exhaust system. Its primary function is to reduce the noise produced by the engine’s combustion process as exhaust gases are expelled. Without it, the sound levels emanating from the vehicle would be significantly higher, potentially violating noise regulations and creating an unpleasant driving experience.

The proper functioning of this component contributes to a more comfortable and legally compliant operation of the vehicle. Historically, advancements in its design have focused on balancing noise reduction with minimal backpressure, which can negatively impact engine performance and fuel efficiency. The materials and construction techniques used are often tailored to withstand the harsh conditions of the exhaust system, including high temperatures and corrosive gases.

The subsequent sections will delve into the selection criteria, potential issues, and maintenance considerations associated with this essential element of the vehicle’s exhaust system. These sections will provide detailed information to ensure its optimal performance and longevity.

Guidance on Maintenance and Selection

The following guidelines address key aspects of maintaining and, if necessary, replacing this exhaust component. Adhering to these recommendations can optimize vehicle performance and extend its lifespan.

Tip 1: Regular Inspection: Periodically examine the exterior for signs of rust, corrosion, or physical damage. Early detection can prevent further deterioration and potential exhaust leaks.

Tip 2: Listen for Unusual Noises: Changes in exhaust sound, such as rattling or excessive loudness, may indicate internal damage or a compromised structure. Address these issues promptly.

Tip 3: Consider Material Quality: When replacing this component, opt for materials that offer superior corrosion resistance, such as stainless steel. This enhances durability and longevity, particularly in regions with harsh weather conditions.

Tip 4: Verify Compatibility: Ensure any replacement component is specifically designed and validated for the intended vehicle model year and engine configuration. Incompatible parts can lead to performance issues or premature failure.

Tip 5: Professional Installation: Unless possessing the requisite expertise and tools, entrust the installation to a qualified technician. Improper installation can result in leaks, damage to other exhaust components, or safety hazards.

Tip 6: Check Exhaust Hangers: Inspect the rubber hangers that support the exhaust system. Deteriorated or broken hangers can cause excessive movement, leading to stress and potential failure of the exhaust component.

Tip 7: Address Issues Promptly: Ignoring minor problems can lead to more significant and costly repairs. Addressing issues early helps maintain optimal vehicle performance and prevents further damage.

Implementing these maintenance and selection strategies can contribute significantly to the reliable operation and longevity of the exhaust system, ensuring a more enjoyable and efficient driving experience.

The concluding section will summarize the critical aspects discussed and offer final recommendations.

1. Noise Reduction

The primary function of the subject exhaust component within the 2017 Silverado is noise reduction. The internal design, consisting of chambers and baffles, manipulates sound waves generated by the engine’s combustion process. This manipulation involves reflection and interference, effectively canceling out certain frequencies and diminishing the overall sound pressure level emitted from the exhaust system. The effectiveness of this noise reduction directly impacts the vehicle’s compliance with local noise ordinances, as well as the comfort of the driver and passengers. A faulty or removed unit will result in significantly increased exhaust noise.

Instances of aftermarket modifications replacing the original equipment with so-called “performance” units often demonstrate the trade-off between increased horsepower and noise reduction. While some aftermarket components may offer marginal performance gains, they frequently do so at the expense of increased sound levels, potentially violating noise regulations and causing discomfort. Conversely, the selection of a replacement component engineered for enhanced noise reduction might improve driving experience, but it could potentially restrict exhaust flow and negatively affect engine output.

In summary, the effectiveness of the exhaust components noise reduction capabilities is a crucial factor in maintaining legal compliance, driver comfort, and the overall driving experience of the 2017 Silverado. Compromising this function, whether through damage or modification, can have significant consequences ranging from legal penalties to a less enjoyable vehicle operation.

2. Exhaust Flow

The flow of exhaust gases through the 2017 Silverado’s exhaust system is inextricably linked to the performance and design of the exhaust component. The component’s internal structure presents a carefully calculated path for these gases. This design balances noise reduction with the need to minimize backpressure on the engine. Excessive backpressure hinders the expulsion of exhaust gases, reducing engine efficiency and potentially leading to decreased horsepower and fuel economy. The relationship is a cause-and-effect: a poorly designed or clogged component restricts exhaust flow, which in turn negatively impacts engine performance. For example, a corroded internal baffle obstructing the flow path can noticeably reduce the Silverado’s acceleration capabilities.

Conversely, a component designed to maximize exhaust flow, often found in aftermarket performance applications, may reduce backpressure, but at the cost of increased noise levels. These designs often employ straight-through designs or larger diameter pipes to facilitate quicker evacuation of exhaust gases. The selection of the component, therefore, represents a compromise between performance and noise. The practical significance lies in understanding these trade-offs. A vehicle owner seeking to maintain factory performance and noise levels should opt for a replacement component that replicates the original design’s flow characteristics. A driver prioritizing performance may consider an aftermarket option, provided they are aware of the potential increase in noise.

In summary, the effectiveness of the exhaust component in managing exhaust flow directly influences the 2017 Silverado’s engine performance and noise output. Maintaining an optimal balance between these factors requires a thorough understanding of the components internal design and its impact on the engine’s ability to efficiently expel exhaust gases. Choosing the appropriate component, whether for maintenance or modification, demands careful consideration of the desired performance characteristics and the potential trade-offs involved.

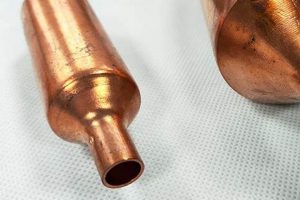

3. Material Durability

The longevity and functional effectiveness of the 2017 Silverado’s exhaust component are directly dependent on the material used in its construction. The exhaust system operates in a harsh environment, exposed to high temperatures, corrosive exhaust gases, road debris, and environmental elements like salt and moisture. Therefore, the material selection plays a critical role in resisting degradation and ensuring the component’s structural integrity over its intended lifespan. For instance, a component constructed from low-grade steel is susceptible to rapid corrosion, leading to exhaust leaks, increased noise levels, and potential damage to other components. The result is a premature replacement, incurring additional costs and inconvenience. The material’s ability to withstand these conditions directly impacts the component’s ability to perform its intended function of noise reduction and efficient exhaust flow.

Manufacturers often employ aluminized steel or stainless steel to enhance durability. Aluminized steel provides a layer of aluminum protection against corrosion, extending the component’s lifespan compared to untreated steel. Stainless steel offers superior corrosion resistance, particularly in regions with high salt exposure. The cost of materials directly correlates with its durability; stainless steel, while more expensive, offers a significantly longer service life. For example, a 2017 Silverado operated in a northern state with frequent road salting will benefit considerably from a stainless steel replacement, as it will resist the corrosive effects of salt far better than an aluminized steel option. The choice of material represents a long-term investment decision, balancing upfront cost with the potential for reduced maintenance and replacement expenses over the vehicle’s lifespan.

In conclusion, material durability is a paramount consideration in the selection and maintenance of the 2017 Silverado’s exhaust component. The choice of material directly influences the component’s resistance to corrosion, heat, and physical damage, thereby affecting its lifespan and performance. Selecting a component constructed from durable materials, such as aluminized or stainless steel, represents a strategic investment that minimizes the risk of premature failure and ensures the continued functionality of the exhaust system. Understanding the material’s properties and its impact on the components durability is essential for informed decision-making when replacing or upgrading this critical element.

4. Vehicle Compatibility

The proper functioning of the exhaust system in a 2017 Silverado, and by extension, the installed component, hinges on strict vehicle compatibility. This compatibility extends beyond mere physical fitment; it encompasses engineering parameters such as exhaust gas volume, backpressure requirements, and mounting point specifications. Using a component not specifically designed for the 2017 Silverado can result in diminished engine performance, increased noise levels, and potential damage to other exhaust components. A practical example is attempting to install a component designed for a different engine size or cab configuration. The mismatch can lead to improper exhaust flow, reduced fuel efficiency, and the potential for exhaust leaks at the connection points. The correct fitment prevents structural stress and ensures alignment with the vehicle’s hanger system.

Furthermore, considerations of vehicle compatibility also encompass emissions standards. A component intended for a different vehicle might not meet the 2017 Silverado’s specific emission control requirements, potentially causing the vehicle to fail inspection and violating environmental regulations. The engineering specifications of the original equipment component are designed to optimize performance while adhering to these regulations. For instance, an aftermarket part designed for increased horsepower may circumvent certain emission controls, leading to increased pollutant output. A replacement certified for the 2017 Silverado ensures that the vehicle continues to meet the required emission standards, thereby avoiding potential legal ramifications and environmental concerns.

In summary, strict adherence to vehicle compatibility is essential for the proper functioning, longevity, and legal compliance of the component. Improper fitment can lead to performance degradation, increased noise, potential damage, and violation of emissions regulations. When replacing or upgrading, ensuring the component is specifically designed and certified for the 2017 Silverado is paramount. Neglecting vehicle compatibility can result in significant costs and operational issues, ultimately undermining the vehicle’s performance and reliability.

5. Emission Compliance

Emission compliance, a critical aspect of automotive engineering, directly influences the design and functionality of the exhaust component in a 2017 Silverado. Regulatory standards mandate specific limits on pollutants released into the atmosphere, dictating the criteria this component must meet to ensure the vehicle’s adherence to these environmental requirements.

- Catalytic Converter Integration

The component’s physical location often incorporates the catalytic converter, a device that reduces harmful emissions by converting pollutants like hydrocarbons, carbon monoxide, and nitrogen oxides into less harmful substances. A damaged or inefficient component could compromise the catalytic converter’s performance, leading to increased emissions and potential failure to meet regulatory standards.

- Backpressure Management

The design influences backpressure within the exhaust system. Excessive backpressure can reduce engine efficiency and increase fuel consumption, indirectly affecting emissions. Conversely, insufficient backpressure can impair the catalytic converter’s ability to function optimally. The component must strike a balance to ensure effective emissions control without negatively impacting engine performance.

- Sound Level Regulations

While primarily designed for noise reduction, the component’s noise-dampening capabilities also contribute to overall emission compliance. Noise pollution is considered an environmental concern, and regulatory bodies often set limits on vehicle noise levels. A component that fails to adequately suppress exhaust noise can result in non-compliance, leading to fines or restrictions.

- Material Composition Restrictions

Regulations may restrict the use of certain materials in the exhaust system to prevent the release of harmful substances during operation or disposal. The component’s construction must adhere to these material restrictions, ensuring that it does not contribute to environmental pollution through its composition or degradation.

The multifaceted relationship between emission compliance and the design, material, and functionality of the 2017 Silverado’s exhaust component underscores the importance of selecting a replacement that meets or exceeds original equipment specifications. Failure to do so can result in legal penalties, environmental damage, and compromised vehicle performance.

6. Replacement Options

The availability of suitable replacements for the 2017 Silverado exhaust component constitutes a critical aspect of vehicle maintenance and repair. A range of alternatives exists, each characterized by distinct performance characteristics, material composition, and cost implications. Understanding these options enables informed decision-making when addressing component failure or seeking performance enhancements.

- OEM (Original Equipment Manufacturer)

OEM replacements represent components produced by or for the vehicle manufacturer. These are designed to replicate the original component’s specifications, ensuring compatibility and maintaining factory performance characteristics. Selecting an OEM replacement provides assurance of proper fitment and adherence to emission standards, though it typically represents the highest cost option. An example is purchasing a replacement part directly from a GM dealership or an authorized parts supplier.

- Aftermarket Replacements (Direct Fit)

Direct-fit aftermarket components are engineered to match the dimensions and specifications of the original component, facilitating straightforward installation. These options offer a cost-effective alternative to OEM parts, with varying levels of quality and performance. A common example involves a brand offering a component advertised as a “direct replacement” for the 2017 Silverado, requiring no modifications for installation. The reliability and longevity can be lower than an OEM.

- Performance Aftermarket (Modified Flow)

These components are designed to alter the exhaust flow characteristics, often aiming to increase engine horsepower and torque. Performance options frequently employ larger diameter pipes and less restrictive internal designs, which can lead to increased noise levels. Before opting for such a replacement, it’s necessary to ensure it doesn’t violate local noise regulations. Common examples include cat-back exhaust systems designed to improve exhaust flow.

- Universal Muffler (Requires Modification)

Universal components are not specifically designed for the 2017 Silverado and require modification for proper fitment. These options offer the lowest upfront cost but demand specialized skills and equipment for installation. Improper installation can lead to exhaust leaks, reduced performance, and potential damage. Using a universal part demands precise cutting and welding to integrate into the existing exhaust system.

The selection of a replacement option for the 2017 Silverado exhaust component depends on individual priorities, balancing cost, performance requirements, and the level of expertise available for installation. While OEM replacements offer guaranteed compatibility and performance, aftermarket options can provide cost savings or performance enhancements, but at the potential expense of increased noise or reduced lifespan. Consideration of these factors is vital to ensure optimal performance and compliance with regulatory standards.

Frequently Asked Questions

The following section addresses common inquiries and misconceptions regarding the exhaust component specific to the 2017 Silverado. The information presented is intended to provide clarity and inform decision-making related to maintenance, repair, and replacement.

Question 1: What is the expected lifespan?

The lifespan is contingent upon several factors, including environmental conditions, driving habits, and the material from which it is constructed. Components subjected to harsh winters with road salt exposure may experience accelerated corrosion, reducing their lifespan. Generally, an OEM component can last between 5-7 years under normal conditions. Aftermarket alternatives may have a shorter lifespan depending on the quality of materials used.

Question 2: How can one identify a failing component?

Indications of a failing unit include a noticeable increase in exhaust noise, the presence of rust or physical damage, and decreased engine performance. A rattling sound emanating from the exhaust system may also indicate internal damage. A visual inspection for corrosion and leaks is recommended.

Question 3: Does replacing with an aftermarket component void the vehicle’s warranty?

The installation of an aftermarket component generally does not automatically void the entire vehicle warranty. However, if the aftermarket part causes damage to other components covered by the warranty, the warranty coverage for those specific parts may be voided. It is advisable to consult with a qualified mechanic or the vehicle manufacturer regarding warranty implications prior to installation.

Question 4: Can a larger component improve engine performance?

Installing a larger component without proper engine tuning or modifications may not necessarily improve engine performance. While a less restrictive exhaust system can potentially increase horsepower, simply increasing the size without addressing other factors like fuel delivery and air intake can result in negligible or even negative performance impacts. Careful consideration of the entire exhaust system and engine parameters is essential.

Question 5: Are all replacement components compliant with emission regulations?

Not all replacement parts are compliant with emission regulations. It is critical to verify that any replacement component is certified to meet the emission standards applicable to the 2017 Silverado. Using a non-compliant part can result in fines and the inability to pass state inspections. Reviewing the manufacturer’s specifications and certifications is highly recommended.

Question 6: Is professional installation required for a replacement?

While it is possible to install a replacement component without professional assistance, proper installation requires specialized tools and knowledge of exhaust system mechanics. Incorrect installation can lead to exhaust leaks, damage to other components, and potential safety hazards. Professional installation is generally recommended to ensure proper fitment and avoid potential complications.

This FAQ section provided insights into the lifespan, detection of failure, warranty implications, and regulatory compliance related to the 2017 Silverado’s exhaust component. Choosing the proper replacement will ensure seamless vehicle efficiency.

The subsequent section will delve into advanced maintenance and troubleshooting practices for the 2017 Silverado exhaust system.

2017 Silverado Muffler

This exploration has addressed the multifaceted role of the 2017 Silverado muffler, encompassing its function in noise reduction, exhaust flow management, material durability considerations, vehicle compatibility requirements, emission compliance, and replacement options. The analysis has highlighted the interdependence of these factors and their collective impact on vehicle performance, regulatory adherence, and operational longevity. Selecting the correct, well-maintained component is crucial.

Recognizing the importance of this often-overlooked element of the exhaust system enables informed decision-making regarding maintenance, repair, and modification. Further research into evolving exhaust technologies and regulatory standards is encouraged to ensure continued optimal vehicle performance and environmental responsibility. Prioritizing proper maintenance and timely replacement contributes significantly to the 2017 Silverado’s overall reliability and value retention.