A vehicular component designed to reduce the acoustic intensity of engine exhaust is the central focus. This device mitigates noise pollution generated by internal combustion engines, contributing to a more peaceful environment. As an example, consider an aging vehicle exhibiting excessive engine noise; replacing the problematic element with a new unit significantly reduces the decibel level, making the vehicle compliant with noise regulations.

The importance of this component lies in its contribution to public health and environmental protection. Excessive vehicle noise can lead to stress, hearing impairment, and disruption of daily life. Furthermore, historical developments in automotive engineering demonstrate a consistent focus on mitigating these auditory effects, evolving from simple baffle systems to sophisticated resonance chambers that cancel out specific frequencies. The ongoing refinement of these systems continues to address the increasingly stringent demands for quieter transportation.

Understanding the function and maintenance of these essential components is crucial for vehicle owners and automotive professionals. The following sections will delve into specific aspects, including material composition, common failure modes, and best practices for ensuring optimal performance and longevity.

Maintenance and Longevity Strategies

The following guidelines offer advice for maximizing the operational lifespan and effectiveness of exhaust noise reduction components. Adherence to these recommendations contributes to reduced vehicle noise and prolonged system integrity.

Tip 1: Conduct Regular Visual Inspections: Periodically examine the component for signs of corrosion, physical damage, or leaks. Early detection of these issues prevents escalated damage and potential system failure. For example, rust accumulation on welded joints warrants immediate attention and potential repair.

Tip 2: Address Exhaust Leaks Promptly: Exhaust leaks compromise the system’s noise reduction capabilities and can lead to reduced fuel efficiency. Repairing or replacing damaged sections ensures optimal performance. An audible hissing sound originating from the exhaust system signifies a probable leak that demands immediate rectification.

Tip 3: Avoid Short Trip Driving: Short trips do not allow the exhaust system to reach optimal operating temperature, resulting in moisture accumulation and accelerated corrosion. When possible, incorporate longer drives into the routine to promote evaporation of accumulated moisture.

Tip 4: Ensure Proper Engine Function: Engine malfunctions, such as misfires or excessive fuel consumption, can deposit unburned hydrocarbons into the exhaust system, potentially damaging the catalytic converter and reducing the effectiveness of sound suppression measures. Regular engine maintenance is paramount.

Tip 5: Select High-Quality Replacement Parts: When replacement is necessary, opt for components constructed from durable materials with corrosion-resistant coatings. Inferior parts may exhibit premature failure, necessitating more frequent and costly repairs.

Tip 6: Professional Installation is Recommended: Proper installation ensures a secure and leak-free connection. Incorrect installation can lead to exhaust leaks, vibration, and premature wear. Consult with a qualified mechanic for optimal results.

Tip 7: Be Mindful of Road Hazards: Avoid driving over large debris or objects that could impact and damage the exhaust system. Road hazards can cause dents, punctures, or complete separation of components, necessitating immediate repair or replacement.

Implementing these maintenance and preventative measures significantly extends the service life and enhances the effectiveness of exhaust noise reduction systems. These practices contribute to a quieter, more environmentally responsible vehicle operation.

The subsequent sections will address frequently asked questions and provide further insights into related automotive technologies.

1. Noise Reduction

Effective noise reduction is a primary function of exhaust systems, including those manufactured under the brand designation. The following discussion clarifies key facets of noise mitigation within the context of these components.

- Acoustic Absorption Materials

The utilization of specialized materials designed to absorb sound waves is integral to noise reduction. Fiberglass packing, steel wool, or ceramic composites line the interior chambers. These substances convert acoustic energy into thermal energy through friction, diminishing the amplitude of sound waves as they propagate through the system. For instance, a design incorporating a greater volume of absorption material generally results in a lower overall noise output.

- Resonance Chamber Design

Resonance chambers are carefully calibrated to cancel out specific frequencies generated by the engine’s combustion process. These chambers operate on the principle of destructive interference, where sound waves of equal amplitude but opposite phase combine to nullify each other. Engineering these chambers requires precise calculations based on engine characteristics and desired noise reduction targets. An effectively designed chamber significantly reduces the prevalence of specific, bothersome frequencies.

- Baffle Systems

Baffles are strategically placed partitions within the exhaust system that force exhaust gases to follow a tortuous path. This redirection of flow disrupts the sound waves and reduces their energy. The number, shape, and arrangement of baffles significantly impact the overall noise reduction capabilities. Designs employing a greater number of baffles generally produce a quieter exhaust note, albeit possibly at the expense of increased backpressure.

- Helmholtz Resonators

Helmholtz resonators are tuned cavities that absorb sound at a specific frequency. These resonators function similarly to blowing across the top of a bottle; the air within the cavity oscillates at a particular frequency, dissipating acoustic energy. Integrating Helmholtz resonators into an exhaust system allows for targeted noise reduction, addressing specific frequencies that may be particularly prominent or undesirable. This selective dampening improves overall sound quality and minimizes perceived noise levels.

The effectiveness of any exhaust noise reduction system hinges on the synergistic application of these diverse techniques. Careful consideration of materials, chamber design, baffle configuration, and resonance principles is essential for achieving optimal noise suppression while maintaining acceptable exhaust flow characteristics. Understanding the nuances of these elements ensures that systems are capable of meeting regulatory standards and contributing to a quieter environment.

2. Material Durability

Material durability constitutes a critical factor in the performance and longevity of exhaust components. The operational environment presents a multitude of challenges, including extreme temperatures, exposure to corrosive agents, and mechanical stress. Consequently, the selection of appropriate materials directly influences the lifespan and effectiveness of the exhaust system.

- Corrosion Resistance

Exhaust systems are subjected to highly corrosive environments resulting from combustion byproducts, road salts, and atmospheric moisture. Materials lacking inherent corrosion resistance exhibit premature degradation, leading to exhaust leaks, structural failure, and diminished noise reduction capabilities. Stainless steel, aluminized steel, and specialized coatings offer enhanced protection against corrosion, extending the component’s operational life and ensuring sustained performance.

- Thermal Stability

Exhaust gases can reach temperatures exceeding 500 degrees Celsius. The chosen materials must maintain their structural integrity and mechanical properties at these elevated temperatures. Materials exhibiting poor thermal stability can experience warping, cracking, and ultimately, failure. Alloys with high melting points and low coefficients of thermal expansion are preferred to minimize thermal stress and ensure long-term reliability.

- Mechanical Strength

Exhaust systems are subjected to vibrational stresses and impacts from road debris. The material must possess adequate mechanical strength to withstand these forces without cracking or fracturing. High-strength steel and reinforced composites offer superior resistance to mechanical damage, ensuring the component’s structural integrity throughout its service life. Wall thickness and weld quality also contribute significantly to overall mechanical durability.

- Weld Integrity

Welding is a critical process in the fabrication of exhaust systems. The welds must exhibit comparable or superior durability to the base materials. Improper welding techniques or the use of incompatible filler metals can create weak points prone to failure. Certified welding procedures and rigorous quality control measures are essential to ensure robust and long-lasting welds, preventing premature leaks and structural degradation.

The interplay of these material characteristics determines the overall durability of an exhaust system. A component utilizing corrosion-resistant materials but lacking adequate thermal stability or weld integrity may still exhibit premature failure. Optimizing the selection and processing of materials is crucial for achieving long-term reliability, sustained performance, and compliance with noise regulations.

3. Exhaust Flow

Exhaust flow represents a critical performance parameter directly influencing the operational efficiency and acoustic properties of an automotive exhaust system, including components marketed under specific brands. Restrictions to exhaust flow increase backpressure on the engine, potentially reducing horsepower and fuel economy. Conversely, unrestricted flow can amplify exhaust noise, exceeding regulatory limits and diminishing driving comfort. The design and internal structure of an exhaust system, particularly the element designed to reduce sound, significantly impacts exhaust flow characteristics.

The internal configuration, including baffle design, chamber dimensions, and the type of sound-absorbing materials employed, directly affects the pathway and velocity of exhaust gases. For instance, a system with tightly packed baffles provides substantial sound attenuation but can impede exhaust flow, leading to increased backpressure. The optimal design balances sound reduction with minimizing flow restriction to achieve both a quiet and efficient vehicle operation. Aftermarket performance exhaust systems sometimes prioritize exhaust flow at the expense of noise reduction, necessitating careful consideration of the trade-offs between power and sound levels.

Understanding the relationship between exhaust flow and the component designated for noise reduction is essential for selecting and maintaining a vehicle’s exhaust system. Restrictions can manifest as reduced engine performance and increased fuel consumption, while excessive flow can result in unacceptable noise levels. Manufacturers carefully engineer their designs to achieve an optimal balance, but modifications or replacements should be chosen with careful consideration of the vehicle’s intended use and regulatory compliance. This understanding contributes to informed decision-making regarding system modifications and maintenance, ensuring both performance and environmental responsibility.

4. Corrosion Resistance

Corrosion resistance is a critical determinant of the service life and performance of exhaust systems, including those designated as a particular brand or model. The exhaust environment subjects the components to extreme conditions, including high temperatures, moisture, and corrosive byproducts of combustion. The ability of the muffler to withstand these conditions directly impacts its longevity, noise reduction capabilities, and overall cost-effectiveness.

- Material Selection and Coatings

The choice of materials and protective coatings significantly influences corrosion resistance. Stainless steel and aluminized steel are commonly employed due to their inherent resistance to oxidation. However, even these materials benefit from additional coatings, such as ceramic-based formulations, to enhance protection against specific corrosive agents. The application of these coatings extends the service life of the exhaust system, reducing the frequency of replacements and associated costs. Failure to utilize corrosion-resistant materials leads to premature rusting and degradation, ultimately compromising the muffler’s structural integrity.

- Weld Integrity and Corrosion

Welded joints are particularly susceptible to corrosion due to alterations in the metal’s microstructure during the welding process. Proper welding techniques and the use of compatible filler metals are essential to minimize corrosion at these points. Post-weld treatments, such as passivation, can further enhance corrosion resistance by removing surface contaminants and promoting the formation of a protective oxide layer. Poorly executed welds represent a common point of failure in exhaust systems, leading to leaks and accelerated corrosion.

- Environmental Factors and Corrosion Rates

Geographic location and driving conditions significantly impact corrosion rates. Vehicles operating in regions with high concentrations of road salt or in humid climates experience accelerated corrosion. Frequent short trips, which do not allow the exhaust system to reach operating temperature, also contribute to moisture accumulation and corrosion. Understanding these environmental factors allows for the selection of appropriate materials and coatings tailored to specific operating conditions, maximizing corrosion resistance and extending the system’s lifespan.

- Maintenance and Corrosion Prevention

Regular inspection and maintenance can mitigate the effects of corrosion. Washing the vehicle, particularly the undercarriage, removes road salt and other corrosive agents. The application of rust inhibitors and protective coatings provides an additional barrier against corrosion. Addressing minor surface rust promptly prevents it from spreading and compromising the structural integrity of the exhaust system. Proactive maintenance significantly extends the lifespan of the muffler and minimizes the risk of costly repairs.

In summary, corrosion resistance is paramount to the long-term performance and reliability of exhaust systems, including models designated by name. Material selection, welding techniques, environmental factors, and maintenance practices all contribute to the system’s ability to withstand corrosive environments. Investing in corrosion-resistant materials and implementing preventative maintenance measures ensures optimal performance, reduces replacement frequency, and contributes to environmental responsibility by minimizing the disposal of prematurely failed components.

5. Component Integration

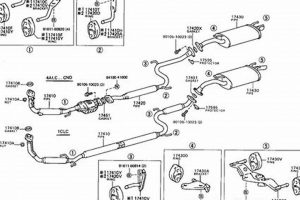

Effective component integration is crucial for the optimal function and longevity of any exhaust system, and specifically impacts the performance and reliability of a “Wilson Muffler” when incorporated within a larger vehicular setup. This refers to the seamless interaction and compatibility of the muffler with other exhaust components, engine management systems, and the vehicle’s overall design.

- Exhaust Manifold Compatibility

The exhaust manifold directs exhaust gases from the engine cylinders into the exhaust system. The design of the manifold, including its outlet diameter and flow characteristics, must be compatible with the inlet design of the “Wilson Muffler”. Mismatched interfaces can create backpressure, reduce engine efficiency, and potentially damage the muffler. A properly matched system ensures smooth gas flow, maximizing performance and minimizing stress on the muffler components.

- Piping Diameter and Material Consistency

The diameter of the exhaust piping leading to and from the “Wilson Muffler” should maintain consistent flow characteristics to prevent turbulence and backpressure. Abrupt changes in diameter can disrupt gas flow and negatively impact engine performance. Furthermore, utilizing similar materials for the piping and the muffler minimizes galvanic corrosion and extends the overall system lifespan. Consistent material properties ensure uniform expansion and contraction under thermal stress, preventing leaks and structural damage.

- Mounting and Support Systems

Adequate mounting and support systems are essential for securing the “Wilson Muffler” to the vehicle’s chassis. Proper mounting prevents excessive vibration and stress on the muffler body and its connecting pipes. Insufficient support can lead to premature failure due to fatigue and physical damage from road debris. Vibration dampening mounts are particularly important for minimizing noise transmission and extending the lifespan of the entire exhaust system.

- Catalytic Converter Integration

The catalytic converter, positioned upstream of the “Wilson Muffler” in most modern vehicles, plays a critical role in emissions control. The backpressure created by the catalytic converter influences the muffler’s performance and sound characteristics. The “Wilson Muffler” must be designed to operate effectively in conjunction with the catalytic converter, ensuring optimal emissions reduction and noise suppression. An improperly integrated system can lead to reduced engine performance and potential damage to both the catalytic converter and the muffler.

The successful integration of a “Wilson Muffler” within a vehicle’s exhaust system depends on careful consideration of these interconnected factors. A holistic approach, encompassing manifold compatibility, piping consistency, robust mounting, and catalytic converter integration, ensures optimal performance, longevity, and compliance with noise and emissions regulations. Ignoring these integration aspects can lead to reduced efficiency, increased noise levels, and premature component failure.

6. Regulatory Compliance

Regulatory compliance exerts a significant influence on the design, manufacturing, and distribution of vehicular exhaust systems, directly affecting components marketed under the “Wilson Muffler” designation. Adherence to established noise emission standards and safety regulations is paramount for manufacturers seeking to legally sell and distribute their products within specific jurisdictions. This compliance necessitates rigorous testing, documentation, and adherence to prescribed manufacturing practices.

- Noise Emission Standards

Governmental bodies at local, national, and international levels impose stringent noise emission standards for motor vehicles. These standards, typically measured in decibels, dictate the maximum permissible noise levels generated by a vehicle’s exhaust system. “Wilson Mufflers” must be engineered to attenuate exhaust noise within these legal limits. Failure to comply with these standards can result in fines, product recalls, and restrictions on sales within specific markets. For instance, California’s stringent noise regulations require aftermarket exhaust systems, including “Wilson Mufflers”, to undergo testing and certification to demonstrate compliance before being legally sold and installed on vehicles within the state. These regulatory requirements impact the design and materials used in the construction of these noise reduction devices.

- Safety Standards and Material Requirements

In addition to noise emissions, regulatory bodies establish safety standards governing the construction and materials used in exhaust systems. These standards address issues such as flammability, corrosion resistance, and structural integrity. “Wilson Mufflers” must be constructed from materials that can withstand the high temperatures and corrosive environments associated with exhaust gases, ensuring safe and reliable operation. Compliance with these standards often involves adherence to specific material specifications, welding procedures, and quality control protocols. For example, regulations may mandate the use of specific grades of stainless steel or aluminized steel to ensure adequate corrosion resistance and prevent premature failure of the muffler.

- Emissions Control System Compatibility

Modern exhaust systems incorporate components designed to reduce harmful emissions, such as catalytic converters and oxygen sensors. “Wilson Mufflers” must be designed to be compatible with these emissions control systems and should not impede their proper functioning. Regulations often prohibit modifications to exhaust systems that compromise emissions performance or violate tampering laws. The design of a “Wilson Muffler” must account for the backpressure created by the catalytic converter and ensure that it does not negatively impact engine performance or emissions output. Compliance with these regulations requires careful engineering and testing to ensure compatibility and optimal emissions control.

- Certification and Labeling Requirements

To demonstrate compliance with applicable regulations, manufacturers of “Wilson Mufflers” are often required to undergo certification processes and affix labels indicating compliance. These labels provide assurance to consumers and regulatory authorities that the product meets the required standards. Certification may involve independent testing by accredited laboratories to verify noise emissions, material properties, and emissions control system compatibility. Labeling requirements vary by jurisdiction but typically include information such as the manufacturer’s name, product identification number, and compliance statements. Failure to properly certify and label products can result in penalties and legal action.

The stringent regulatory landscape surrounding vehicular exhaust systems necessitates a proactive approach to compliance for manufacturers of “Wilson Mufflers”. Adherence to noise emission standards, safety regulations, emissions control system compatibility requirements, and certification protocols is essential for ensuring legal market access, consumer safety, and environmental protection. The ongoing evolution of these regulations requires manufacturers to remain vigilant and adapt their designs and manufacturing processes to maintain compliance and uphold their reputation for quality and responsible manufacturing practices. Non-compliance carries significant consequences, potentially jeopardizing the company’s operations and brand image.

Frequently Asked Questions Regarding Exhaust Noise Reduction Components

The following section addresses common inquiries concerning exhaust systems designed to reduce noise, including those components associated with the designated brand. This information aims to clarify prevalent misconceptions and provide a factual understanding of related aspects.

Question 1: What is the typical lifespan of a vehicular sound dampening device?

The operational lifespan varies based on material composition, driving conditions, and maintenance practices. Units constructed from stainless steel, subjected to moderate driving conditions, and regularly inspected for corrosion can last upwards of 7-10 years. However, components exposed to harsh environments or lacking proper maintenance may require replacement within 3-5 years.

Question 2: Does altering the stock configuration of an exhaust system void the vehicle warranty?

Modifying the original exhaust system, including the installation of aftermarket components, may affect the vehicle’s warranty. While certain alterations are permissible, modifications that demonstrably cause damage to the engine or other vehicle systems can void warranty coverage. Consult the vehicle manufacturer’s warranty documentation for specific details regarding permissible modifications.

Question 3: How does the size of an exhaust noise reduction system affect its performance?

The size of the component directly influences its capacity for sound attenuation and its impact on exhaust flow. Larger systems generally offer superior noise reduction due to increased internal volume and surface area for sound absorption. However, excessively large systems can also increase backpressure and negatively affect engine performance. Optimal sizing depends on the vehicle’s engine characteristics and desired performance profile.

Question 4: Can a damaged sound-dampening component affect fuel efficiency?

A compromised element within the exhaust system, particularly one with internal damage or external leaks, can reduce fuel efficiency. Exhaust leaks disrupt the oxygen sensor readings, causing the engine control unit to adjust the air-fuel mixture incorrectly. This inefficiency translates to increased fuel consumption and reduced engine performance. Prompt repair or replacement is recommended to restore optimal fuel economy.

Question 5: Are there specific signs indicating the need for replacement?

Several indicators signal the need for replacement, including excessive exhaust noise, visible corrosion or physical damage, and reduced engine performance. An audible rattling or hissing sound originating from the exhaust system, along with a noticeable decrease in acceleration, suggests a potential problem requiring immediate attention. A thorough inspection by a qualified mechanic confirms the need for replacement.

Question 6: What are the environmental implications of using non-compliant noise reduction devices?

Operating vehicles with non-compliant systems contributes to increased noise pollution, negatively impacting public health and environmental quality. Excessive vehicle noise can lead to stress, sleep disturbances, and hearing impairment. Furthermore, the use of poorly designed systems can reduce fuel efficiency and increase harmful emissions, exacerbating environmental problems. Adherence to noise regulations and the use of properly functioning components are essential for responsible vehicle operation.

Understanding these frequently asked questions provides valuable insights into the maintenance, performance, and regulatory considerations associated with vehicular sound dampening devices.

The subsequent section delves into advanced technologies and future trends in automotive noise reduction.

Conclusion

This exploration has presented a comprehensive overview of vehicular exhaust noise reduction systems, exemplified by components such as the “Wilson Muffler”. Key areas addressed include the fundamental principles of noise reduction, the critical role of material durability, the impact of exhaust flow characteristics, and the imperative of regulatory compliance. Additionally, the significance of component integration and the practical aspects of maintenance have been discussed, alongside responses to frequently asked questions. This detailed examination underscores the multifaceted nature of these systems and their importance in both vehicle performance and environmental responsibility.

Continued vigilance in maintaining and upgrading exhaust noise reduction technologies remains essential. The pursuit of quieter and more efficient vehicles necessitates ongoing innovation in materials science, acoustic engineering, and manufacturing processes. Further research and development in this area hold the key to mitigating noise pollution and fostering a more sustainable transportation future. Therefore, a commitment to understanding and adhering to best practices in exhaust system management is crucial for both vehicle owners and the automotive industry as a whole.