The degradation of an exhaust system component, specifically its sound-dampening capabilities, results in increased noise emissions from a vehicle. This phenomenon, characterized by a reduction in the component’s ability to attenuate sound, can manifest through various mechanisms, such as corrosion, internal breakdown of sound-absorbing materials, or physical damage. As an example, the gradual rusting of a car’s exhaust silencer can progressively diminish its effectiveness in reducing engine noise.

This decline in functionality has significant ramifications. Increased noise pollution affects environmental quality and public health. Furthermore, regulatory compliance regarding vehicle noise standards may be compromised, potentially leading to legal penalties. Historically, advancements in exhaust system design focused on maximizing engine efficiency while minimizing noise output, making the maintenance of sound-dampening effectiveness a critical aspect of vehicle engineering and operation.

Understanding the causes and consequences of reduced exhaust noise control is essential for developing effective maintenance strategies and improving future system designs. The following sections will delve into the specific factors contributing to this decline, explore diagnostic methods for identifying the issue, and discuss potential remediation options.

Mitigating Exhaust System Degradation

The following recommendations address strategies to minimize the reduction in exhaust system sound attenuation, thereby prolonging component lifespan and ensuring continued compliance with noise regulations.

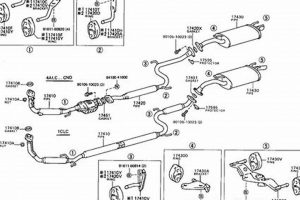

Tip 1: Regular Inspection for Corrosion: Conduct routine visual assessments of the exhaust system, paying particular attention to areas prone to moisture accumulation and salt exposure. Early detection of rust or corrosion allows for timely intervention, such as rust removal and protective coating application.

Tip 2: Implement Scheduled Maintenance: Adhere to manufacturer-recommended maintenance schedules, including exhaust system checks. Address minor issues promptly to prevent escalation into more significant problems requiring costly repairs or replacements.

Tip 3: Optimize Driving Habits: Aggressive driving, characterized by rapid acceleration and deceleration, places undue stress on the exhaust system, potentially accelerating component wear. Implement smoother driving techniques to minimize this stress.

Tip 4: Utilize High-Quality Replacement Parts: When replacement is necessary, opt for components manufactured to original equipment specifications or exceeding industry standards. Inferior parts may exhibit reduced durability and accelerated degradation.

Tip 5: Apply Protective Coatings: Consider applying heat-resistant and corrosion-resistant coatings to the exhaust system. These coatings provide an additional barrier against environmental factors that contribute to component deterioration.

Tip 6: Address Leaks Promptly: Exhaust leaks, regardless of their size, can compromise the system’s overall integrity and efficiency. Identifying and repairing leaks as soon as they are detected prevents further damage and potential safety hazards.

Tip 7: Ensure Proper Ventilation: During periods of vehicle inactivity, ensure adequate ventilation in the surrounding environment. Confined spaces with poor air circulation can exacerbate corrosion processes.

These strategies, when implemented consistently, will contribute to maintaining the performance and longevity of the exhaust system, reducing noise emissions and ensuring regulatory compliance.

The subsequent sections will explore advanced diagnostic techniques and emerging technologies aimed at further enhancing exhaust system durability and noise reduction capabilities.

1. Corrosion-Induced Weakening

Corrosion-induced weakening represents a primary mechanism through which the sound-dampening capacity of a muffler diminishes over time. The exhaust system, including the muffler, operates in an environment characterized by high temperatures, moisture, and corrosive combustion byproducts. Prolonged exposure to these elements initiates electrochemical reactions that degrade the metallic structure of the muffler, predominantly through oxidation and the formation of rust. This corrosion process weakens the metal, leading to perforations, thinning of the muffler walls, and compromised structural integrity. As the metal deteriorates, the ability of the muffler to contain and attenuate exhaust gases is significantly reduced.

The consequence of corrosion is a direct path for exhaust gases to escape without undergoing the intended sound-dampening process. The weakened and perforated structure loses its ability to effectively redirect and muffle sound waves, leading to an increase in noise emissions. For example, the accumulation of road salt during winter months accelerates corrosion on the undercarriage of vehicles, causing mufflers to rust through more rapidly. The resultant holes and cracks allow exhaust gases to bypass internal baffles and chambers, producing a louder and more aggressive exhaust note. The extent of the sound degradation is proportional to the degree of corrosion and the size and number of perforations.

Understanding the link between corrosion and muffler degradation is critical for predicting component lifespan and developing effective preventative maintenance strategies. Regular inspection for rust, application of protective coatings, and selection of corrosion-resistant materials during muffler construction are essential measures to mitigate the impact of corrosion-induced weakening. This, in turn, contributes to prolonged muffler effectiveness, reduced noise pollution, and adherence to vehicle noise regulations.

2. Material degradation impact

The degradation of materials within a muffler directly influences its sound attenuation capabilities. Mufflers employ various materials, including fiberglass packing, steel wool, and specifically designed chambers, to absorb and redirect sound waves generated by the engine. The efficacy of these materials in dampening sound diminishes as they deteriorate due to factors such as heat cycling, chemical exposure, and physical erosion. This degradation reduces the muffler’s ability to effectively absorb or cancel out engine noise, resulting in a noticeable increase in exhaust volume.

For instance, the fiberglass packing commonly used in mufflers can become compressed and brittle over time due to exposure to high exhaust temperatures. This compression reduces the packing’s density and its ability to absorb sound energy, leading to a louder exhaust note. Similarly, the internal baffles and chambers within a muffler can corrode or erode due to exposure to acidic combustion byproducts, altering their geometry and diminishing their effectiveness in redirecting sound waves. A practical example is the observation of exhaust systems on older vehicles where the deteriorated packing material results in a hollow or raspy exhaust sound, clearly indicating the muffler’s reduced sound-dampening performance.

Understanding the specific degradation mechanisms affecting muffler materials is crucial for designing more durable and effective exhaust systems. Material selection, internal structure design, and protective coatings can all play a role in minimizing material degradation and prolonging the lifespan of the muffler’s sound-attenuation capabilities. Addressing material degradation is essential for maintaining acceptable noise levels, complying with regulatory standards, and enhancing the overall driving experience.

3. Increased noise pollution

The correlation between a deteriorated muffler and elevated noise pollution levels represents a significant environmental and public health concern. As an exhaust system component loses its sound-dampening capabilities, the resultant increase in emitted noise directly contributes to the overall pollution burden in urban and suburban environments.

- Elevated Decibel Levels in Residential Areas

The degradation of a muffler leads to a direct increase in the decibel level of vehicle exhaust emissions. This heightened noise permeates residential areas, disrupting daily activities, sleep patterns, and overall quality of life for residents. Studies have shown that prolonged exposure to elevated noise levels can contribute to stress, anxiety, and other adverse health effects. The specific impact is particularly pronounced in densely populated areas where vehicle traffic is high.

- Compromised Environmental Soundscapes

A malfunctioning muffler alters the acoustic characteristics of the environment, disrupting natural soundscapes. The intrusive noise from vehicles with impaired mufflers masks natural sounds, such as birdsong or the rustling of leaves, diminishing the perceived tranquility and ecological value of green spaces within urban areas. The alteration of environmental soundscapes can negatively impact both human well-being and the behavior of wildlife.

- Reduced Speech Intelligibility and Communication

Increased noise pollution from vehicles with failing mufflers interferes with speech intelligibility, making it difficult to communicate effectively in outdoor environments. This poses a particular challenge in areas such as pedestrian walkways, outdoor cafes, and schoolyards, where clear communication is essential for safety and social interaction. The presence of excessive noise necessitates increased vocal effort, leading to vocal fatigue and communication strain.

- Negative Impact on Property Values

Areas with high levels of noise pollution, including that stemming from vehicles with impaired mufflers, often experience a decline in property values. Prospective homebuyers and renters are less likely to invest in properties located in noisy environments, leading to decreased demand and a corresponding reduction in property values. This negative impact disproportionately affects low-income communities often situated near major roadways with high traffic volumes.

These facets collectively illustrate the detrimental impact of a “dulls muffler” on increased noise pollution. The resultant environmental and social consequences underscore the importance of regular vehicle maintenance, strict enforcement of noise regulations, and the development of quieter transportation technologies. Addressing muffler degradation is, therefore, a crucial step in mitigating the adverse effects of noise pollution on communities and the environment.

4. Decreased engine performance

The functionality of the exhaust system, including the muffler, is intrinsically linked to overall engine performance. A compromised muffler, one experiencing degradation in its internal structure or exhibiting external damage, can impede the efficient expulsion of exhaust gases, subsequently affecting engine power output and fuel economy. The following points delineate the specific mechanisms through which a deteriorated muffler contributes to diminished engine performance.

- Increased Backpressure

A constricted or damaged muffler creates excessive backpressure within the exhaust system. This elevated pressure resists the free flow of exhaust gases from the engine cylinders, requiring the engine to expend additional energy during the exhaust stroke. The increased effort reduces the engine’s net power output, leading to a noticeable decrease in acceleration and overall performance. For example, a muffler clogged with rust or debris significantly impedes exhaust flow, resulting in a demonstrable reduction in horsepower and torque.

- Reduced Volumetric Efficiency

The presence of excessive backpressure interferes with the engine’s volumetric efficiency, the measure of how effectively an engine fills its cylinders with fresh air and fuel. When exhaust gases are not efficiently evacuated, they can remain in the combustion chamber, diluting the incoming air-fuel mixture. This dilution reduces the amount of oxygen available for combustion, leading to incomplete burning of fuel and a decrease in engine power. Consequently, the engine struggles to produce its rated power output, especially at higher engine speeds.

- Compromised Fuel Economy

The inefficiencies caused by a restricted muffler directly impact fuel economy. As the engine works harder to overcome increased backpressure and reduced volumetric efficiency, it consumes more fuel to maintain a given level of performance. This increased fuel consumption translates to lower miles per gallon (MPG) and higher operating costs. For example, a vehicle with a severely deteriorated muffler may experience a noticeable drop in fuel economy compared to its performance with a properly functioning exhaust system.

- Potential for Engine Overheating

In extreme cases, a severely restricted muffler can contribute to engine overheating. The inefficient expulsion of exhaust gases leads to a buildup of heat within the engine compartment. This excess heat can strain cooling system components, potentially leading to overheating and damage to critical engine parts. While less common, the overheating risk underscores the importance of maintaining a properly functioning exhaust system.

These interrelated factors highlight the critical role of a well-maintained muffler in ensuring optimal engine performance. Regular inspection of the exhaust system and prompt replacement of deteriorated components are essential steps in preventing performance degradation, maintaining fuel efficiency, and minimizing the risk of engine damage. The operational health of the muffler directly influences the engine’s ability to perform as designed, underscoring the importance of its upkeep.

5. Regulatory non-compliance risks

The deterioration of a muffler’s sound-dampening capabilities presents tangible risks of non-compliance with established noise pollution regulations. These regulations, enacted at local, state, and federal levels, set permissible decibel limits for vehicle exhaust emissions. A diminished muffler directly contributes to exceeding these limits, potentially resulting in legal and financial repercussions for vehicle owners and operators.

- Violation of Noise Ordinances

Municipalities frequently implement noise ordinances that specify maximum allowable decibel levels for vehicles operating within their jurisdictions. A vehicle equipped with a degraded muffler is substantially more likely to breach these limits, leading to the issuance of citations and fines. For instance, a vehicle exceeding the designated decibel threshold during a roadside noise inspection faces penalties that vary depending on the severity of the violation and local regulations. Consistent disregard for these ordinances can escalate to more severe legal consequences, including vehicle impoundment.

- Failure to Meet State Vehicle Inspection Standards

Many states mandate periodic vehicle inspections to ensure compliance with safety and emissions standards, including those pertaining to noise levels. During these inspections, a vehicle’s exhaust system is assessed to determine its functionality and compliance with regulatory requirements. A deteriorated muffler that fails to meet the specified noise standards results in the vehicle’s rejection, preventing its legal operation on public roadways until the issue is rectified and the vehicle passes a subsequent inspection. The inability to pass inspection can impede vehicle registration renewal and resale.

- Breach of Federal Noise Emission Standards

Federal regulations establish noise emission standards for new motor vehicles, requiring manufacturers to equip vehicles with exhaust systems that meet specified noise limits throughout their operational lifespan. While these standards primarily apply to vehicle manufacturers, modifications or neglect that compromise the exhaust system’s performance, resulting in noise levels exceeding federal thresholds, can expose vehicle owners to potential liability. Although direct enforcement against individual owners is less common, persistent violations can attract scrutiny from federal agencies.

- Commercial Vehicle Operating Restrictions

Commercial vehicles, such as trucks and buses, are often subject to stricter noise regulations than privately owned passenger vehicles. These regulations are enforced to minimize noise pollution in residential areas and during nighttime operations. A commercial vehicle operating with a degraded muffler risks violation of these regulations, leading to fines, operational restrictions (e.g., limitations on operating hours or routes), and potential suspension of operating permits. Non-compliance can significantly impact the profitability and operational efficiency of commercial transportation companies.

The interplay between a compromised muffler and the risks of regulatory non-compliance is a clear and present concern. Failing to maintain a properly functioning exhaust system exposes vehicle owners and operators to a range of legal and financial penalties, underscoring the importance of regular maintenance and prompt repair or replacement of deteriorated mufflers. Compliance with noise regulations is not only a legal obligation but also a crucial aspect of responsible vehicle operation and environmental stewardship.

6. Component lifespan reduction

The degradation of a muffler’s effectiveness, commonly referred to as “dulls muffler,” is directly correlated with a reduced lifespan of the component itself. This reduction stems from a cascade of factors initiated by the weakening of the muffler’s structural integrity and internal materials. The following explores the mechanisms through which “dulls muffler” accelerates the decline in component lifespan.

- Accelerated Corrosion Due to Inefficient Exhaust Flow

A muffler experiencing internal breakdown or physical damage often exhibits altered exhaust flow patterns. These altered patterns can lead to localized hotspots and increased turbulence within the muffler. The elevated temperatures and turbulent flow exacerbate corrosion processes, particularly in areas already weakened by rust or material fatigue. For example, a damaged internal baffle may create a zone of concentrated heat, accelerating corrosion in that specific area and leading to premature failure of the muffler casing. This accelerated corrosion shortens the muffler’s overall lifespan.

- Increased Stress on Remaining Structural Elements

As portions of the muffler degrade, the remaining structural elements bear an increased load. For instance, if the outer casing of the muffler develops significant perforations, the internal baffles and supports become more vulnerable to vibration and mechanical stress. The increased stress accelerates fatigue and cracking of these remaining components, leading to a more rapid overall deterioration of the muffler assembly. The effect is analogous to removing supports from a structure; the remaining supports experience heightened strain and are more likely to fail prematurely.

- Chemical Attack from Uncontrolled Combustion Byproducts

A properly functioning muffler facilitates efficient combustion and manages the flow of exhaust gases, including corrosive byproducts. However, when a muffler becomes “dulls,” it may not effectively neutralize or contain these corrosive elements. This leads to increased exposure of the muffler’s internal components to harsh chemicals, accelerating material degradation. For example, sulfur compounds present in exhaust gases can react with metallic components, forming corrosive sulfates that weaken the metal and shorten the lifespan of the muffler. The uncontrolled chemical attack significantly reduces the durability of the component.

- Reduced Resistance to Environmental Factors

The structural weakening associated with “dulls muffler” reduces the component’s resistance to external environmental factors. A compromised muffler is more susceptible to damage from impacts, road debris, and extreme temperature fluctuations. For example, a rusted-through muffler casing is easily punctured by road debris, leading to immediate failure. Similarly, a muffler with weakened internal supports is more vulnerable to damage from vibration caused by rough road conditions. The diminished resistance to environmental stressors hastens the component’s demise.

These interconnected factors illustrate that “dulls muffler” is not merely a cosmetic issue; it represents a fundamental degradation of the component that significantly reduces its lifespan. Addressing the underlying causes of muffler deterioration, such as corrosion and material fatigue, is essential for extending the component’s operational life, maintaining vehicle performance, and minimizing environmental impact. Timely maintenance and component replacement are crucial strategies in mitigating the accelerated lifespan reduction associated with a “dulls muffler.”

Frequently Asked Questions

The following questions and answers address common inquiries regarding the decline in exhaust system performance, specifically concerning the reduction in its sound-dampening capabilities.

Question 1: What constitutes the primary indicator of a degrading muffler?

The most readily apparent sign is a noticeable increase in the vehicle’s exhaust noise. This manifests as a louder, raspier, or more pronounced exhaust note compared to its original sound profile.

Question 2: What are the most prevalent causes contributing to the deterioration of a muffler?

Corrosion, stemming from exposure to moisture, road salt, and acidic combustion byproducts, represents a primary factor. Additionally, degradation of internal sound-absorbing materials, such as fiberglass packing, contributes significantly.

Question 3: How does a compromised muffler impact vehicle fuel efficiency?

A restricted or damaged muffler can increase backpressure within the exhaust system. This elevated backpressure forces the engine to work harder to expel exhaust gases, leading to increased fuel consumption and reduced fuel economy.

Question 4: What potential legal ramifications arise from operating a vehicle with an excessively noisy exhaust system?

Exceeding established noise limits can result in citations, fines, and failure to pass vehicle inspections. Repeated violations may lead to more severe penalties, including vehicle impoundment, depending on local regulations.

Question 5: Can a degraded muffler adversely affect overall engine performance?

Yes. Excessive backpressure caused by a failing muffler impedes the efficient expulsion of exhaust gases, reducing engine power output, acceleration, and overall performance.

Question 6: What preventative measures can be implemented to prolong the lifespan of a muffler?

Regular inspection for corrosion, application of protective coatings, avoidance of aggressive driving habits, and utilization of high-quality replacement parts contribute to extending muffler lifespan and maintaining its performance.

In summary, recognizing the symptoms and causes of a deteriorating muffler is crucial for maintaining vehicle performance, ensuring regulatory compliance, and mitigating environmental impact.

The subsequent section will explore advanced diagnostic techniques and technological advancements aimed at enhancing exhaust system durability.

Conclusion

The preceding analysis has detailed the ramifications of a “dulls muffler,” encompassing diminished sound attenuation, potential regulatory breaches, reduced engine performance, and shortened component lifespan. The progressive degradation of this essential exhaust system component presents a multifaceted challenge that demands attention from vehicle owners, maintenance professionals, and regulatory bodies alike. The compounding effects of corrosion, material fatigue, and altered exhaust dynamics underscore the critical need for proactive maintenance strategies.

The long-term implications of neglecting exhaust system health extend beyond individual vehicle performance, impacting noise pollution levels and environmental quality. Therefore, a concerted effort towards promoting responsible vehicle maintenance and fostering technological innovation in exhaust system design is paramount. The ongoing pursuit of durable materials, advanced noise reduction techniques, and robust corrosion prevention methods will contribute to mitigating the adverse effects associated with a “dulls muffler” and ensure a more sustainable and quieter transportation landscape.