An exhaust system component in the Temecula Valley, designed to reduce engine noise, is a vital element for vehicles operating in both rural and urban environments. These components contribute to regulatory compliance regarding noise pollution and improved vehicle performance.

The selection of an appropriate noise reduction device offers numerous advantages, including a more pleasant driving experience, decreased environmental impact, and potential enhancements to engine efficiency. Historically, the development of these systems has been driven by increasingly stringent environmental standards and consumer demand for quieter vehicles.

The subsequent sections will delve into the specific characteristics of noise reduction solutions available in the Temecula area, discussing factors such as material composition, design variations, and considerations for optimal installation and maintenance.

Essential Considerations for Noise Reduction Systems in Temecula

Selecting and maintaining effective noise reduction systems within the Temecula region requires careful attention to specific environmental and operational factors. The following guidelines provide critical insights for ensuring optimal performance and longevity.

Tip 1: Material Selection: Choose corrosion-resistant materials, such as stainless steel, to withstand the fluctuating temperatures and potential road salt exposure common in Temecula’s climate. Regular inspections for rust or degradation are crucial.

Tip 2: Compliance with Local Regulations: Ensure the selected system meets or exceeds all applicable noise ordinances enforced within Temecula and Riverside County. Consult with local authorities or certified technicians for up-to-date requirements.

Tip 3: Professional Installation: Engage qualified technicians experienced in installing noise reduction systems to guarantee proper fitment and prevent potential exhaust leaks. Improper installation can compromise performance and safety.

Tip 4: Regular Inspections: Conduct routine inspections for signs of damage, such as cracks, holes, or loose connections. Address any issues promptly to prevent further deterioration and maintain optimal noise reduction.

Tip 5: Maintenance Schedule: Adhere to a prescribed maintenance schedule, including periodic cleaning and replacement of worn components, as recommended by the manufacturer or a qualified technician. This proactive approach extends the lifespan of the system.

Tip 6: Consider Vehicle Usage: Factor in the typical driving conditions and usage patterns of the vehicle. Vehicles used for heavy towing or off-road activities may require more robust systems and more frequent maintenance.

By implementing these recommendations, vehicle owners can ensure the continued effectiveness and regulatory compliance of their noise reduction systems, contributing to a quieter and more environmentally responsible community.

The subsequent sections will explore common issues encountered with these systems and provide guidance on troubleshooting and resolving them efficiently.

1. Local Noise Ordinances and Noise Reduction Systems in Temecula

Temecula, and Riverside County in which it resides, maintains specific noise ordinances designed to regulate sound levels and maintain the quality of life for its residents. These ordinances directly impact the selection and application of noise reduction systems, including those used on vehicles. Failure to comply with these regulations can result in fines and legal repercussions. Therefore, anyone operating a vehicle with an internal combustion engine, particularly in residential areas or near sensitive receptors such as schools and hospitals, must ensure their vehicle’s noise reduction system adheres to the stipulated decibel limits. The effectiveness of such systems is directly tied to the vehicles compliance, and any modification or degradation that leads to excessive noise constitutes a violation. For instance, a truck used on a ranch in Temecula, while potentially operating in a more rural setting, must still meet noise level requirements when traveling on public roads or operating near property lines.

A concrete example illustrates the practical significance of understanding and adhering to local noise ordinances. Consider a situation where a ranch utilizes a modified vehicle with an altered exhaust system to traverse its property. While the vehicle may be primarily used on private land, any operation on public roadways necessitates adherence to noise regulations. If the noise levels exceed the permitted limit, the ranch owner could face penalties. Furthermore, even on private land, if the noise significantly impacts neighboring properties, complaints could lead to investigations and enforcement actions. Therefore, the appropriate selection, installation, and maintenance of these systems are not merely a matter of personal preference but a legal obligation.

In summary, compliance with local noise ordinances is a fundamental aspect of owning and operating vehicles. Proper selection and maintenance are essential to ensure vehicles meet the specified requirements, mitigating the risk of fines and contributing to a quieter community environment. The integration of effective noise reduction systems is not optional but legally mandated, highlighting the importance of understanding and adhering to applicable regulations.

2. Material Durability and Ranch Mufflers in Temecula

Material durability is a critical factor in the performance and longevity of noise reduction systems, particularly for vehicles operating in environments like those found in Temecula. The operational demands placed on a noise reduction system by ranch vehicles necessitate robust construction capable of withstanding harsh conditions. These conditions include exposure to rough terrain, temperature fluctuations, and corrosive elements such as road salts, agricultural chemicals, and moisture. The consequence of inadequate material durability is premature failure of the system, leading to increased noise pollution, reduced vehicle performance, and the need for frequent repairs or replacements. For example, a system constructed from low-grade steel will rapidly corrode in the presence of moisture and agricultural runoff, whereas a system made from stainless steel exhibits significantly greater resistance to these factors.

The practical significance of selecting durable materials becomes apparent when considering the downtime and associated costs incurred by a ranch operation due to noise reduction system failures. A malfunctioning noise reduction system can render a vehicle non-compliant with noise regulations, preventing its use on public roads. Furthermore, the cost of replacement parts and labor can quickly accumulate, impacting the ranch’s profitability. For example, a noise reduction system failure during harvest season could disrupt operations and lead to significant financial losses. Choosing corrosion-resistant materials, such as high-grade stainless steel or aluminized steel, can substantially extend the lifespan of the system, reducing downtime and minimizing repair expenses.

In conclusion, the selection of materials with high durability is not merely a matter of preference but a necessity for ranch vehicles operating in Temecula. The operational demands and environmental conditions necessitate components capable of withstanding corrosion, impacts, and extreme temperatures. Prioritizing material durability translates to reduced maintenance costs, minimized downtime, compliance with noise regulations, and ultimately, a more efficient and sustainable ranch operation. Overlooking this aspect can result in premature failures, increased expenses, and potential legal liabilities, underscoring the importance of informed decision-making in selecting these systems.

3. Professional Installation

The effective performance and longevity of noise reduction systems in the Temecula area, particularly for ranch vehicles, are significantly influenced by the quality of installation. Proper installation ensures the system functions as designed, meets regulatory requirements, and minimizes potential issues.

- Ensuring Optimal Fitment

Professional installation guarantees precise fitment of the system to the vehicle’s exhaust system. This prevents leaks, which compromise noise reduction efficiency and can lead to exhaust fumes entering the vehicle’s cabin. Incorrect fitment can also induce stress on the system, reducing its lifespan and potentially damaging other vehicle components. For a ranch vehicle constantly traversing uneven terrain, a secure, properly fitted system is crucial to prevent disconnections or damage.

- Adherence to Manufacturer Specifications

Certified technicians possess the knowledge and expertise to install the system according to the manufacturer’s specifications. This includes proper alignment, torque settings for fasteners, and placement of mounting hardware. Deviations from these specifications can void warranties and lead to premature system failure. For example, over-tightening clamps can damage the system’s pipes, while under-tightening can cause leaks.

- Compliance with Local Regulations

Professional installers are familiar with local noise ordinances and ensure the installed system complies with these regulations. This includes verifying the system’s noise reduction capabilities and ensuring it does not exceed permitted decibel levels. Non-compliance can result in fines and legal penalties, making professional installation a safeguard against such issues.

- Minimizing Potential Damage

Improper installation can damage the system or other vehicle components. Certified technicians have the tools and experience to install the system without causing damage, using techniques to avoid stress or strain on existing parts. For instance, using the wrong tools to remove old components can damage exhaust manifold studs, requiring costly repairs.

In summary, professional installation is a vital investment for vehicle owners in Temecula seeking to optimize the performance, longevity, and regulatory compliance of their noise reduction systems. By entrusting the installation process to qualified technicians, vehicle owners can mitigate the risks associated with improper installation, ensuring their systems function effectively and reliably, contributing to a quieter and more sustainable environment.

4. Inspection Frequency

Inspection frequency is a critical determinant of the operational effectiveness and lifespan of noise reduction systems, particularly for ranch vehicles operating in Temecula. The demanding conditions inherent in ranch work necessitate a proactive approach to maintenance and inspection, directly impacting the system’s ability to function as intended and comply with noise regulations.

- Corrosion Detection and Mitigation

Regular inspections allow for the early detection of corrosion, a prevalent issue due to exposure to moisture, road salts, and agricultural chemicals. Identifying corrosion at its onset enables timely mitigation measures, such as rust removal and protective coatings, preventing extensive damage. A ranch vehicle frequently exposed to fertilizers requires more frequent inspections than a vehicle primarily used for paved road transport.

- Damage Assessment from Terrain

Vehicles operating on uneven terrain are susceptible to physical damage to their noise reduction systems. Regular inspections reveal dents, cracks, or loose mountings resulting from impacts with rocks or other obstacles. Early detection allows for repairs or replacements before these damages compromise the system’s integrity and noise reduction capabilities. For instance, a muffler guard might be necessary based on inspection findings.

- Leak Identification and Repair

Exhaust leaks diminish the system’s ability to reduce noise effectively and can introduce hazardous fumes into the vehicle’s cabin. Regular inspections facilitate the identification of leaks, allowing for prompt repairs to restore the system’s functionality and ensure operator safety. Leaks are often indicated by unusual noises or visible soot deposits around joints and connections.

- Compliance Verification

Periodic inspections confirm the system’s continued compliance with local noise ordinances. Noise levels can gradually increase over time due to wear and tear or component degradation. Regular verification ensures the vehicle remains within legal limits, avoiding potential fines or operational restrictions. Sound level meters can be used during inspections to quantify noise output.

The facets highlight the integral role inspection frequency plays in maintaining optimal performance, ensuring regulatory compliance, and extending the operational life of the noise reduction system. Ranch vehicles in Temecula benefit significantly from a rigorous inspection schedule, mitigating the adverse effects of demanding working conditions and preserving the integrity of these critical components.

5. Performance Optimization

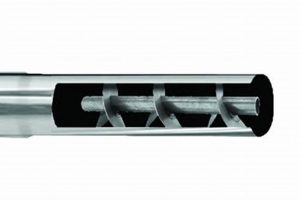

Performance optimization, in the context of ranch mufflers in Temecula, is the process of maximizing the efficiency and effectiveness of a vehicle’s exhaust system, specifically tailored to the demands of ranch operations. This involves selecting and maintaining components that improve engine output, fuel economy, and compliance with local noise regulations. A well-optimized system can enhance a ranch vehicle’s ability to handle heavy loads, navigate rough terrain, and operate for extended periods without compromising performance or environmental impact.

The selection of a muffler designed for performance optimization goes beyond simple noise reduction. Factors such as exhaust flow, backpressure, and material durability play crucial roles. A muffler that restricts exhaust flow can negatively impact engine horsepower and torque, hindering the vehicle’s ability to perform demanding tasks such as towing equipment or hauling supplies. Conversely, a system with excessive flow can compromise low-end torque, essential for navigating challenging terrain. The ideal system strikes a balance, optimizing exhaust flow for the specific engine and operational needs of the ranch vehicle. For instance, a ranch truck used for hauling hay may benefit from a muffler designed to improve low-end torque, while a vehicle used for transportation on paved roads might prioritize fuel efficiency and reduced noise levels.

Ultimately, performance optimization of a ranch muffler system in Temecula is about aligning the exhaust system’s characteristics with the specific operational requirements of the vehicle. This requires a comprehensive understanding of engine dynamics, exhaust flow principles, and local regulations. By carefully selecting and maintaining components that enhance engine performance, improve fuel economy, and ensure regulatory compliance, ranch owners can maximize the value and utility of their vehicles while minimizing their environmental impact. Ignoring this aspect can lead to reduced performance, increased fuel consumption, and potential legal liabilities, underscoring the importance of a strategic approach to performance optimization.

Frequently Asked Questions

This section addresses common inquiries regarding noise reduction systems for ranch vehicles operating in the Temecula region.

Question 1: What constitutes a “ranch muffler” in the context of Temecula?

A “ranch muffler” refers to a noise reduction system specifically designed for vehicles used in ranching operations. These systems are typically more robust and durable than standard mufflers, capable of withstanding the harsh conditions associated with ranch work. Considerations include material selection, construction techniques, and compliance with local noise regulations.

Question 2: How does the selection of a ranch muffler impact vehicle performance?

The choice of a muffler affects engine performance, fuel efficiency, and overall vehicle operation. A properly selected system optimizes exhaust flow, reducing backpressure and improving engine horsepower and torque. Conversely, an improperly selected system can restrict exhaust flow, leading to reduced performance and increased fuel consumption. Considerations are typically balanced between noise reduction requirements and performance goals.

Question 3: What are the key considerations when selecting a ranch muffler for a Temecula-based operation?

Crucial factors include material durability (resistance to corrosion and physical damage), compliance with local noise ordinances, exhaust flow characteristics, and ease of installation and maintenance. Ranching environments often expose vehicles to moisture, chemicals, and rough terrain, necessitating a robust and well-protected noise reduction system.

Question 4: How often should a ranch muffler system be inspected and maintained?

Inspection frequency depends on the vehicle’s usage and operating conditions. However, a general guideline is to inspect the system at least every three months for signs of corrosion, damage, or leaks. Regular maintenance, such as cleaning and replacing worn components, ensures optimal performance and compliance with noise regulations. Vehicles operating under severe conditions may require more frequent inspections.

Question 5: What are the potential consequences of operating a vehicle with a non-compliant or malfunctioning ranch muffler?

Operating a vehicle with a non-compliant or malfunctioning muffler can result in fines, legal penalties, and operational restrictions. Excessive noise pollution can also negatively impact the surrounding environment and community. Furthermore, a malfunctioning system can compromise vehicle performance and fuel efficiency.

Question 6: Can a ranch muffler system be modified to further enhance performance or reduce noise?

Modifications to noise reduction systems must be carefully considered, as they can impact compliance with local noise ordinances and void manufacturer warranties. While some modifications may enhance performance, others can compromise noise reduction capabilities. Consult with a qualified technician to determine the legality and feasibility of any proposed modifications.

This section provided answers to some frequently asked questions concerning ranch muffler systems within Temecula, CA. Each question was carefully examined to provide you with as much clarity as possible.

The subsequent section will explore practical guidance on selecting an appropriate vendor for these essential systems.

Ranch Muffler Considerations in Temecula

This exploration has outlined critical aspects concerning noise reduction systems for vehicles in Temecula, with a particular focus on those utilized in ranching operations. Key considerations include material durability, compliance with local noise ordinances, the significance of professional installation, the necessity of regular inspections, and strategies for optimizing system performance. Adherence to these principles directly influences operational efficiency, regulatory compliance, and the overall environmental impact.

The informed selection and diligent maintenance of a suitable noise reduction system represents a tangible investment in operational sustainability and community responsibility. Prioritizing these factors minimizes the potential for regulatory infractions, reduces equipment downtime, and contributes to a more harmonious coexistence with the surrounding environment. Continued vigilance and proactive engagement with evolving industry standards are essential to ensuring sustained compliance and optimal performance.