An exhaust system component used primarily in internal combustion engines, specifically motorcycles and automobiles, serves to reduce noise pollution and manage exhaust gases. This particular component, often associated with performance enhancement, typically features a distinctive design or construction aimed at optimizing engine output. These systems are frequently sought after by enthusiasts seeking to improve vehicle aesthetics and driving experience.

The significance of such a component lies in its potential to refine the sound profile of a vehicle, offering a deeper, more resonant tone. Moreover, modified exhaust systems can sometimes contribute to improved engine efficiency by reducing backpressure. Historically, such components have evolved from simple noise dampeners to sophisticated devices engineered for optimal airflow and performance characteristics. The demand for high-quality examples reflects a broader desire for personalized vehicle customization.

The following sections will explore various aspects of aftermarket exhaust systems, including their construction materials, performance characteristics, and regulatory considerations, as well as factors influencing the selection and installation of components designed to enhance vehicle performance and aesthetics.

Optimization Strategies for Exhaust Systems

This section provides essential considerations for achieving optimal performance and longevity from aftermarket exhaust components. Careful planning and execution are crucial for maximizing potential benefits.

Tip 1: Material Selection: Prioritize stainless steel or titanium construction for enhanced corrosion resistance and extended lifespan. Climatic conditions significantly influence material degradation, impacting long-term performance.

Tip 2: Diameter Considerations: Choose exhaust pipe diameters that complement engine displacement and intended performance goals. Oversized piping can reduce exhaust velocity, hindering low-end torque.

Tip 3: Proper Installation: Ensure precise alignment and secure mounting of all exhaust components. Improper installation can lead to leaks, vibrations, and premature failure.

Tip 4: Regular Inspection: Conduct routine inspections to identify potential issues such as rust, cracks, or loose connections. Early detection prevents minor problems from escalating into significant repairs.

Tip 5: Sound Level Compliance: Verify that the chosen exhaust system complies with local noise regulations. Non-compliance can result in fines and enforcement actions.

Tip 6: Heat Management: Implement heat shielding or wrapping to mitigate the transfer of heat to surrounding components and reduce under-hood temperatures. This enhances overall vehicle performance and reliability.

Tip 7: Professional Consultation: Seek advice from qualified technicians or exhaust system specialists prior to making any modifications. Expert guidance ensures informed decision-making and optimal results.

Adherence to these guidelines fosters optimal performance, extends the lifespan of exhaust components, and ensures compliance with applicable regulations. Proactive maintenance and careful attention to detail contribute to a superior ownership experience.

The subsequent section will address potential drawbacks and challenges associated with aftermarket exhaust modifications, promoting a balanced understanding of the subject matter.

1. Performance Enhancement

Aftermarket exhaust systems, including specialized components, are frequently implemented to augment engine performance characteristics. This enhancement is primarily achieved through a reduction in exhaust backpressure, facilitating more efficient evacuation of exhaust gases from the engine cylinders. Reduced backpressure enables the engine to operate with greater ease, potentially leading to an increase in horsepower and torque output. The degree of performance improvement varies depending on the specific design and construction of the component, the vehicle’s engine specifications, and any accompanying modifications.

The relationship between an aftermarket exhaust system and performance is not solely determined by reduced backpressure. The exhaust system’s design also influences the scavenging effect, which aids in drawing exhaust gases out of the cylinders during the valve overlap period. A well-designed system optimizes this scavenging effect, further improving engine efficiency. For example, performance-oriented systems often incorporate larger diameter piping and smoother bends to minimize flow restrictions and maximize exhaust gas velocity. However, it is crucial to note that excessively large piping can reduce exhaust gas velocity, potentially diminishing low-end torque.

In conclusion, the contribution to performance is multifaceted and depends on the system’s ability to balance backpressure reduction with optimized scavenging. Understanding this interplay is crucial for selecting an exhaust system that effectively enhances engine performance without compromising other aspects of vehicle operation. The subsequent discussion will examine the impact of these systems on acoustic properties, another key characteristic influencing user experience.

2. Acoustic Properties

The acoustic properties of aftermarket exhaust systems are a significant factor in their appeal and represent a key element in the overall driving experience. The sound produced by an exhaust system directly influences the perception of vehicle performance and quality.

- Exhaust Note Frequency

The frequency of the exhaust note, measured in Hertz (Hz), determines the pitch of the sound. Lower frequencies correspond to deeper, more resonant tones, while higher frequencies produce a raspier, more aggressive sound. The design of the muffler and the materials used directly influence the frequencies generated. Some performance-oriented systems are engineered to produce a distinct, low-frequency rumble at idle and a high-frequency roar at higher engine speeds.

- Exhaust Note Amplitude (Loudness)

Amplitude refers to the loudness of the exhaust note, typically measured in decibels (dB). Regulations often impose limits on permissible noise levels, necessitating careful consideration of the muffler’s design and construction. Some components incorporate adjustable valves or baffles to control the exhaust flow and modulate the sound level, allowing for customization of the acoustic profile. The perceived loudness can vary depending on the vehicle’s configuration and the environment in which it operates.

- Resonance and Drone

Resonance refers to the amplification of certain frequencies within the exhaust system, leading to a booming or droning sound, particularly at specific engine speeds. This phenomenon can be undesirable for some drivers, especially during prolonged highway driving. Manufacturers often employ techniques such as Helmholtz resonators or quarter-wave resonators to mitigate resonance and drone, ensuring a more comfortable and refined driving experience.

- Material Influence on Tone

The materials used in the construction of the exhaust system significantly impact the acoustic properties. Stainless steel, for example, tends to produce a brighter, more metallic sound, while titanium yields a higher-pitched, more aggressive tone. The thickness and gauge of the materials also influence the system’s ability to dampen vibrations and control the overall sound profile. Careful selection of materials is essential for achieving the desired acoustic characteristics.

In summary, the acoustic properties of aftermarket exhaust systems are complex and multifaceted, influenced by a variety of design parameters and material choices. Understanding these properties is essential for selecting a system that meets the driver’s preferences and complies with applicable noise regulations. The subsequent discussion will explore the impact of these systems on material durability, another crucial aspect influencing long-term performance and ownership satisfaction.

3. Material Durability

Material durability, a critical attribute of any exhaust system component, directly impacts the longevity and overall performance of specialized mufflers. Selecting materials that withstand extreme conditions is paramount for ensuring consistent operation and minimizing maintenance requirements.

- Corrosion Resistance

The exhaust system operates in an environment susceptible to corrosion due to exposure to moisture, road salts, and acidic exhaust gases. Materials such as stainless steel and titanium exhibit superior corrosion resistance compared to mild steel. The utilization of these materials in high-quality mufflers extends their lifespan and maintains structural integrity, preventing leaks and performance degradation. Premature corrosion can lead to costly repairs and reduced operational efficiency.

- Thermal Stress Management

Exhaust systems experience significant temperature fluctuations during vehicle operation. Repeated thermal cycling can induce stress on the material, leading to fatigue and eventual failure. High-grade alloys with high melting points and low coefficients of thermal expansion are preferred to mitigate the effects of thermal stress. This ensures that the muffler maintains its shape and structural integrity, even under extreme operating conditions. Inadequate thermal stress management results in cracking, warping, and diminished performance.

- Resistance to Mechanical Damage

The undercarriage of a vehicle is vulnerable to impacts from road debris and obstacles. A durable muffler must withstand these impacts without sustaining significant damage. Thicker gauge materials and reinforced construction enhance impact resistance, protecting the muffler from dents, punctures, and other forms of mechanical failure. Components constructed from brittle or thin materials are susceptible to damage, potentially compromising their performance and structural integrity.

- Weld Quality and Integrity

The quality of the welds used to join the various components of the muffler is crucial for its overall durability. Properly executed welds provide strong, leak-proof joints that resist cracking and separation under stress. High-quality welding techniques, such as TIG welding, ensure a consistent and durable bond between the components. Poorly executed welds are prone to failure, leading to exhaust leaks, vibrations, and reduced muffler lifespan.

In summation, the material composition and construction techniques employed in the manufacture of mufflers significantly affect their durability and long-term performance. Prioritizing materials with exceptional corrosion resistance, thermal stability, and mechanical strength ensures a reliable and long-lasting exhaust system. Neglecting these factors results in premature failure and increased maintenance costs. A comprehensive understanding of material durability is essential for selecting a high-quality muffler that meets the demands of its operating environment.

4. Flow Optimization

Flow optimization is a critical design parameter governing the performance and efficiency of exhaust systems. The ability of an exhaust system, including its muffler, to facilitate the unimpeded passage of exhaust gases directly influences engine output and overall vehicle performance. A well-optimized exhaust system minimizes backpressure, allowing the engine to expel spent gases more efficiently, resulting in enhanced power and fuel economy.

- Backpressure Reduction

Backpressure, the resistance encountered by exhaust gases as they exit the engine, is a primary concern in exhaust system design. A muffler designed for optimized flow minimizes this resistance, allowing the engine to breathe more freely. This reduction in backpressure can lead to increased horsepower and torque, particularly at higher engine speeds. A restrictive muffler, conversely, can impede exhaust flow, leading to power losses and reduced fuel efficiency. The internal design of a muffler, including the size and configuration of its chambers and baffles, directly affects its backpressure characteristics.

- Smooth Internal Geometry

Sharp bends and abrupt changes in diameter within a muffler create turbulence and restrict exhaust flow. Optimized mufflers incorporate smooth, gradual transitions and mandrel-bent tubing to minimize these disruptions. This smooth internal geometry reduces flow resistance and promotes more efficient gas evacuation. The design minimizes areas where exhaust gases can stagnate or collide, further reducing backpressure and improving overall system performance. This approach ensures that gases are expelled more quickly and completely from the system.

- Internal Volume and Resonance Tuning

The internal volume and configuration of a muffler’s chambers influence its resonance characteristics, which in turn can affect exhaust flow. A well-designed muffler is tuned to minimize undesirable resonance frequencies that could impede gas flow. These resonance effects can either assist or restrict exhaust flow, depending on their frequency and amplitude. By carefully tuning the internal volume and chamber dimensions, manufacturers can optimize the muffler’s resonance properties to promote more efficient gas evacuation across a wider range of engine speeds. The strategic placement of internal baffles and resonators can shape the system’s acoustic properties while simultaneously improving its flow characteristics.

- Surface Finish and Material Selection

The internal surface finish of a muffler influences the boundary layer friction encountered by exhaust gases. A smooth internal surface minimizes friction, facilitating more efficient flow. Polished or coated surfaces can further reduce friction, enhancing the system’s flow characteristics. Additionally, the choice of materials affects the thermal conductivity of the muffler, influencing gas temperature and density. Materials with high thermal conductivity can help to maintain exhaust gas temperature, reducing density and further improving flow. The combined effect of a smooth internal surface and optimized material selection contributes to a more efficient and free-flowing exhaust system.

The principles of flow optimization are fundamental to the design and performance of mufflers. A muffler engineered for optimal flow minimizes backpressure, promotes smooth gas evacuation, and contributes to enhanced engine performance. Therefore, selecting an exhaust system with flow optimization is a step to maximize the benefits of performance and longevity.

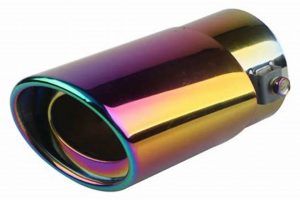

5. Aesthetic Appeal

The aesthetic appeal of aftermarket exhaust systems, specifically including components marketed under names such as “tiger muffler,” constitutes a significant factor influencing consumer purchasing decisions. The visual design and finish of these components contribute to the overall appearance of the vehicle, reflecting the owner’s individual preferences and style. This aesthetic dimension extends beyond mere functionality, representing a form of personalization and self-expression. The selection of a particular muffler often involves careful consideration of its visual integration with the vehicle’s existing design elements, seeking to enhance its perceived value and visual impact. For example, polished stainless steel mufflers are frequently chosen for their clean, modern appearance, while black ceramic-coated systems offer a more aggressive, performance-oriented aesthetic.

The practical significance of this aesthetic consideration lies in its direct impact on vehicle resale value and owner satisfaction. A well-integrated and visually appealing exhaust system can increase the vehicle’s perceived value in the aftermarket, attracting potential buyers who appreciate attention to detail and customization. Moreover, the owner’s personal satisfaction with the vehicle’s appearance is directly correlated with their overall ownership experience. A visually appealing exhaust system can enhance the sense of pride and enjoyment associated with vehicle ownership, contributing to a more positive and rewarding experience. Real-world examples include custom car builds where the exhaust system is a focal point, showcasing the vehicle’s performance capabilities and aesthetic refinement. The aesthetic features are carefully selected to work in synergy with the rest of the vehicles features. In some cases, exhaust tips are color-matched to the vehicle paint scheme, creating visual harmony.

In conclusion, aesthetic appeal is an integral component of the overall value proposition for aftermarket exhaust systems. Its impact extends beyond superficial considerations, influencing both vehicle resale value and owner satisfaction. Therefore, a comprehensive understanding of the visual design and integration aspects of these components is essential for manufacturers, retailers, and consumers alike. Recognizing the importance of aesthetics alongside functional performance ensures a more informed and satisfying purchasing decision.

Frequently Asked Questions About Aftermarket Exhaust Systems

The following section addresses common inquiries and misconceptions concerning aftermarket exhaust components. The information presented aims to provide clarity and promote informed decision-making.

Question 1: What is the primary benefit of installing a “tiger muffler” or similar aftermarket exhaust component?

The primary benefit often lies in the potential for improved engine performance through reduced exhaust backpressure. This may result in increased horsepower and torque. Other benefits include altered exhaust sound, and aesthetic modifications.

Question 2: Will installing such an exhaust void the vehicle’s warranty?

Installation of an aftermarket exhaust may, under certain circumstances, affect the vehicle’s warranty. This typically depends on whether the installed component is determined to be the direct cause of a subsequent mechanical failure. Consult with the vehicle manufacturer or a qualified legal professional for definitive guidance.

Question 3: Are there legal restrictions regarding the sound level of aftermarket exhaust systems?

Yes, many jurisdictions have regulations governing permissible exhaust noise levels. Non-compliance can result in fines or other penalties. It is incumbent upon the vehicle owner to ensure compliance with all applicable laws.

Question 4: What materials are commonly used in the construction of high-quality exhaust components?

Stainless steel and titanium are frequently employed due to their corrosion resistance and durability. Other materials, such as aluminized steel, may be used in less demanding applications.

Question 5: Does the diameter of the exhaust piping affect engine performance?

Yes, exhaust pipe diameter can significantly impact engine performance. Selecting the appropriate diameter is crucial for optimizing exhaust flow. Oversized piping can reduce exhaust velocity, negatively affecting low-end torque. Consult with a qualified technician for guidance on selecting the optimal diameter for the vehicle’s specifications.

Question 6: How frequently should an aftermarket exhaust system be inspected for potential problems?

Regular inspection is recommended to identify potential issues such as rust, leaks, or loose connections. The frequency of inspection should be determined based on the vehicle’s operating conditions and mileage. At a minimum, a visual inspection should be performed during routine maintenance intervals.

The information provided in this FAQ section is intended for general guidance purposes only and does not constitute professional advice. Consult with qualified experts for specific recommendations tailored to individual circumstances.

The following section will delve into the topic of selecting an appropriate component for a given application.

Conclusion

This exploration of aftermarket exhaust systems, including components marketed as “tiger muffler,” has illuminated several critical factors influencing performance, durability, and aesthetic appeal. The selection of such systems warrants careful consideration of materials, design characteristics, and regulatory compliance. Optimizing exhaust flow, mitigating backpressure, and ensuring structural integrity are paramount for maximizing both engine performance and system longevity. The acoustic properties and visual integration with the vehicle also play a significant role in consumer satisfaction.

Given the complexity and potential implications associated with aftermarket exhaust modifications, it is imperative to approach this area with diligence and informed decision-making. Further research and consultation with qualified professionals are strongly encouraged prior to undertaking any modifications. Responsible selection and installation practices are crucial for realizing the intended benefits while adhering to legal and safety standards. The continued advancement of exhaust system technology promises further refinements in performance and efficiency, underscoring the importance of staying abreast of industry developments. Therefore, we urge readers to approach this topic with both passion and pragmatism in mind.