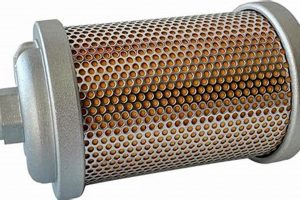

A component designed to significantly reduce exhaust noise in internal combustion engines, particularly those generating high levels of sound pressure. This device often employs advanced sound dampening materials and complex internal geometries to achieve optimal noise reduction. For instance, large diesel engines in commercial vehicles or power generators frequently utilize this type of exhaust system component.

Effective noise abatement is crucial for regulatory compliance, environmental protection, and operational efficiency. Minimizing sound pollution improves working conditions, reduces community disturbance, and can contribute to enhanced engine performance by optimizing exhaust flow. Historically, advancements in materials science and acoustic engineering have driven the development of more effective sound suppression solutions.

The following sections will delve into the specific design considerations, performance characteristics, and application scenarios relevant to these advanced sound suppression devices, as well as explore the latest innovations in this field.

Essential Considerations for Enhanced Exhaust Noise Reduction

Optimizing the effectiveness of large-scale exhaust silencing systems requires careful attention to several key factors. These considerations ensure not only optimal noise reduction but also long-term reliability and compliance with relevant standards.

Tip 1: Material Selection is Paramount: The materials used in construction must withstand high temperatures, corrosive exhaust gases, and vibration. Stainless steel and specialized alloys are frequently employed for their durability and resistance to degradation.

Tip 2: Internal Baffle Design is Critical: The arrangement and geometry of internal baffles play a crucial role in sound wave attenuation. Complex chamber designs that promote destructive interference are often preferred for maximizing noise reduction across a broad frequency range.

Tip 3: Proper Sizing is Essential for Performance: Selecting the appropriate size of the silencing device is vital to avoid backpressure issues that can negatively impact engine performance. Computational Fluid Dynamics (CFD) simulations can aid in determining optimal dimensions.

Tip 4: Insulation Enhances Noise Dampening: Incorporating high-density insulation materials around the external casing helps to absorb and dissipate residual sound energy, further reducing noise levels emitted into the surrounding environment.

Tip 5: Regular Inspections Prolong Lifespan: Periodic inspections should be conducted to identify and address any signs of wear, corrosion, or damage. Prompt repairs can prevent minor issues from escalating into more significant problems, extending the service life of the unit.

Tip 6: Consider Acoustic Enclosures for Enhanced Noise Reduction: In particularly sensitive environments, integrating the silencer within an acoustic enclosure can provide an additional layer of noise attenuation, further minimizing environmental impact.

By prioritizing these factors, operators can ensure optimal performance, longevity, and compliance with noise regulations. Implementing these best practices contributes to a quieter, more sustainable operating environment.

The following sections will delve further into specific applications and case studies that illustrate the effective implementation of these principles.

1. Capacity

In the context of advanced exhaust silencing systems, “capacity” refers to the volume of exhaust gas a device is designed to handle effectively. This parameter is paramount as it directly impacts the system’s ability to reduce noise levels without creating excessive backpressure. A system with insufficient capacity for a given engine will be ineffective at silencing and may also impede engine performance. For instance, a “mega muffler” designed for a large industrial generator must have a sufficient internal volume and flow path area to accommodate the high exhaust gas volume produced by the engine; otherwise, the sound attenuation will be compromised, and the engine’s efficiency may decrease.

Proper capacity ensures that the exhaust gases have adequate residence time within the silencing chamber, allowing for effective sound wave attenuation through absorption and destructive interference. Oversizing, while avoiding backpressure issues, can lead to increased cost and physical space requirements. Therefore, precise calculation and design are critical. Examples of real-world applications include large marine engines requiring silencing systems capable of handling enormous exhaust volumes while meeting stringent environmental noise regulations. Selecting the correct capacity involves detailed analysis of engine specifications, operating conditions, and noise reduction targets.

In summary, capacity is a fundamental design consideration for advanced exhaust noise reduction systems. It directly affects performance, engine efficiency, and compliance with noise standards. Understanding capacity is vital for selecting and implementing suitable silencing solutions for various high-volume exhaust applications. Incorrect calculations result in poor performance and potential engine damage. Optimizing exhaust silencing performance relies on balancing exhaust flow management and sound dampening.

2. Durability

Durability is a critical performance parameter for large-scale exhaust silencing systems. These systems often operate in harsh environments, exposed to high temperatures, corrosive gases, and mechanical vibration. Consequently, the longevity and reliability of the silencing device are paramount for ensuring continuous operation and minimizing maintenance costs.

- Material Resistance to Corrosion

The exhaust gases produced by internal combustion engines contain corrosive substances such as sulfur oxides and nitrogen oxides. The materials used in the silencer’s construction must resist degradation from these compounds to prevent premature failure. For example, stainless steel alloys with high chromium and nickel content are commonly employed to provide superior corrosion resistance in harsh exhaust environments. Failure to adequately address corrosion can lead to leaks, reduced noise attenuation, and eventual structural failure.

- Thermal Stress Management

Exhaust gases can reach temperatures of several hundred degrees Celsius, creating significant thermal stresses on the silencer’s components. The design must accommodate these stresses through appropriate material selection and structural design to prevent cracking or deformation. For instance, expansion joints are often incorporated into the silencer’s construction to allow for thermal expansion and contraction, reducing stress concentrations. Inadequate thermal stress management can result in material fatigue and eventual failure.

- Resistance to Vibration Fatigue

Engines generate significant vibration, which can induce fatigue in the silencer’s components. The design must account for these vibrations to prevent fatigue cracking and structural failure. For example, reinforcing ribs and brackets are often used to stiffen the silencer’s structure and reduce vibration amplitudes. Additionally, vibration isolation mounts can be employed to minimize the transmission of vibration from the engine to the silencer. Neglecting vibration fatigue can shorten the silencer’s lifespan and increase maintenance requirements.

- Resistance to Erosion

Particulate matter present in the exhaust gas stream can erode the internal surfaces of the silencing device over time. Abrasive particles impact the components causing gradual erosion and wear, reducing their efficiency and durability. Robust internal lining, abrasion resistant coating or selection of specialized alloy materials can mitigate this issue. Lack of erosion management can result in a shorter operational lifespan, leading to poor noise attenuation and structural compromise.

The overall durability of the exhaust silencing system depends on the careful consideration of these factors. Selecting appropriate materials, designing for thermal stress and vibration, and protecting against corrosion and erosion are essential for ensuring a long and reliable service life. Ignoring any of these aspects can lead to premature failure and increased operational costs. Therefore, engineers will choose quality durable parts to maximize the effectiveness.

3. Attenuation

Attenuation, in the context of high-capacity exhaust silencing systems, refers to the reduction in sound pressure level as exhaust gases pass through the device. Effective attenuation is the primary function of these systems, dictating their design, materials, and overall performance. The degree of attenuation required depends on regulatory noise limits, environmental factors, and the specific characteristics of the engine generating the exhaust.

- Reactive Attenuation

Reactive attenuation relies on the principle of wave interference to cancel out sound waves. It involves creating chambers and passages within the silencer that reflect sound waves back upon themselves, causing destructive interference and reducing the overall sound level. An example would be expansion chambers strategically placed within the system to reflect and cancel specific frequencies generated by the engine. This technique is particularly effective for low-frequency noise reduction, common in large engines.

- Absorptive Attenuation

Absorptive attenuation employs sound-absorbing materials to convert sound energy into heat. These materials, typically porous substances like fiberglass or mineral wool, are strategically placed within the silencer to line the exhaust gas flow path. As sound waves pass through the material, friction between the waves and the material fibers dissipates energy. High-capacity systems often combine absorptive materials with reactive elements to achieve a broad spectrum of noise reduction.

- Frequency-Specific Attenuation

Engines produce noise across a range of frequencies, but certain frequencies may be more prominent or problematic. Advanced silencing systems are often designed to target specific frequencies through tuned resonators or Helmholtz chambers. These components are designed to resonate at the target frequency, effectively canceling it out. Frequency-specific attenuation is critical in applications where regulatory limits are stringent or where certain tonal noises are particularly disruptive.

- Backpressure Impact on Attenuation

While attenuation is the primary goal, it must be achieved without creating excessive backpressure. Backpressure restricts exhaust flow, negatively affecting engine performance, fuel efficiency, and potentially increasing emissions. Silencer design must carefully balance attenuation performance with flow dynamics to minimize backpressure. Computational fluid dynamics (CFD) simulations are often used to optimize internal geometries and ensure adequate flow capacity.

The effectiveness of a large-scale exhaust silencing system hinges on the strategic application of these attenuation techniques. Achieving optimal performance requires a comprehensive understanding of engine noise characteristics, regulatory requirements, and the trade-offs between attenuation, backpressure, and system size. Systems for large engines typically integrate all four strategies to ensure optimal performance and environmental compliance.

4. Flow Dynamics

Flow dynamics is a critical consideration in the design and performance of high-capacity exhaust silencing systems. The movement of exhaust gases through the device directly impacts its effectiveness, backpressure, and overall influence on engine operation. Optimizing flow dynamics ensures efficient noise reduction without compromising engine performance.

- Pressure Drop Management

The passage of exhaust gases through any silencing system inevitably creates a pressure drop. Excessive pressure drop, or backpressure, can impede engine performance, reduce fuel efficiency, and increase emissions. Silencer design must minimize pressure drop while achieving the desired level of noise attenuation. Internal geometries, baffle designs, and material selection all contribute to pressure drop. For instance, sharp bends and constrictions in the exhaust flow path increase turbulence and pressure loss. Optimizing these elements through computational fluid dynamics (CFD) simulations is crucial for balancing noise reduction and engine performance.

- Turbulence and Laminar Flow

The nature of the exhaust gas flowwhether turbulent or laminarinfluences both noise generation and pressure drop. Turbulent flow tends to generate more noise, requiring greater attenuation efforts. However, it also promotes mixing and heat transfer within the silencer, which can be beneficial. Laminar flow, on the other hand, reduces noise generation but can lead to stagnation and increased backpressure in poorly designed systems. The ideal design aims for a balance between turbulence and laminar flow, promoting efficient noise reduction without excessive pressure loss. Baffle placement and diffuser design contribute to managing turbulence levels.

- Velocity Distribution

The distribution of exhaust gas velocity within the silencer affects its performance and durability. Uneven velocity distribution can lead to localized hot spots, increased erosion, and uneven noise attenuation. A well-designed system ensures uniform velocity distribution across the silencer’s cross-section, minimizing these issues. Diffusers and flow straighteners are often employed to achieve uniform velocity distribution. For example, a diffuser placed upstream of the silencer’s main chamber can slow down and evenly distribute the exhaust gas flow, improving noise reduction and extending the system’s lifespan.

- Resonance and Acoustic Impedance

The flow dynamics within a silencer also influence its acoustic impedance, which is a measure of its resistance to sound wave propagation. Matching the silencer’s acoustic impedance to that of the exhaust system is critical for efficient noise reduction. Mismatched impedance can lead to sound wave reflections and reduced attenuation. Resonance effects, where the silencer’s internal cavities amplify certain frequencies, can also impact noise reduction performance. Careful design of the silencer’s internal geometry is essential for managing acoustic impedance and minimizing resonance effects.

These aspects of flow dynamics are integral to the overall performance and effectiveness of “mega muffler”. By carefully managing pressure drop, turbulence, velocity distribution, and acoustic impedance, engineers can design silencing systems that deliver optimal noise reduction without compromising engine performance or durability. The successful implementation of “mega muffler” depends on a comprehensive understanding and skillful application of these principles.

5. Material Science

Material science plays a pivotal role in the design and functionality of high-capacity exhaust silencing systems. The extreme operating conditions, characterized by high temperatures, corrosive environments, and mechanical stress, necessitate careful selection of materials with specific properties. The effectiveness and longevity of the silencing device are directly contingent upon the materials employed. For example, stainless steel alloys are frequently utilized due to their inherent resistance to corrosion and ability to withstand elevated temperatures. However, specific grades of stainless steel, such as 316L, may be preferred over others based on their enhanced resistance to chloride-induced pitting, a common degradation mechanism in marine environments where exhaust systems are exposed to saltwater. Consequently, a thorough understanding of material properties and their interaction with the operating environment is essential for ensuring the reliable performance of the silencing system.

Furthermore, material science informs the development of advanced sound-absorbing materials used within the silencing system. Traditional materials like fiberglass and mineral wool are effective at attenuating sound waves, but they may degrade over time due to exposure to moisture and vibration. Therefore, research is focused on developing more durable and environmentally friendly alternatives, such as porous ceramics and composite materials. These materials offer improved resistance to degradation, enhanced sound absorption characteristics, and the potential for reduced weight. The application of these advanced materials requires a detailed understanding of their acoustic properties, thermal stability, and mechanical strength. For instance, the pore size and density of a porous ceramic material directly influence its sound absorption coefficient, while its thermal conductivity affects its ability to dissipate heat generated by the exhaust gases.

In conclusion, material science is an indispensable component in the design and construction of “mega muffler”. The selection and application of appropriate materials are critical for ensuring the silencing system’s durability, performance, and environmental compatibility. Challenges remain in developing cost-effective and sustainable materials that can withstand the harsh operating conditions and meet increasingly stringent noise regulations. Continued research in material science is essential for advancing the performance and extending the lifespan of these critical components in exhaust systems.

6. Application

The successful integration of high-capacity exhaust silencing devices is fundamentally driven by the intended application. Varied operational requirements across industries necessitate tailored solutions to effectively mitigate noise pollution while maintaining optimal system performance and adhering to regulatory standards. The following delineates specific facets of this integration.

- Power Generation Facilities

In power generation, “mega muffler” are crucial for large diesel or gas turbine engines. These facilities often operate continuously, generating substantial noise. Silencing systems must be designed to handle high exhaust volumes and temperatures while meeting stringent noise level regulations to protect surrounding communities. For example, a power plant near a residential area requires a system that achieves significant noise reduction across a broad frequency range, necessitating advanced reactive and absorptive silencing techniques. The application demands reliability, durability, and compliance with environmental standards.

- Marine Propulsion Systems

Large marine vessels, such as cargo ships and tankers, utilize powerful engines that produce considerable exhaust noise. The application of exhaust silencing systems in these vessels is essential for crew comfort, port noise regulations, and minimizing underwater noise pollution that can affect marine life. These applications demand corrosion-resistant materials and designs capable of withstanding the harsh marine environment. Furthermore, weight and space constraints on ships necessitate compact and efficient silencing solutions. Marine applications also often require adherence to international maritime noise standards.

- Heavy-Duty Vehicle Fleets

Large trucks, buses, and construction equipment generate significant noise pollution, particularly in urban environments. Integration of “mega muffler” into these vehicles is necessary to comply with noise ordinances and improve the quality of life for residents. The demands in this application are for systems that balance noise reduction with minimal impact on engine performance and fuel efficiency. Durability is also paramount, as these vehicles operate in demanding conditions and require robust silencing solutions that can withstand vibration, impact, and exposure to road debris. Retrofit programs frequently involve upgrading existing exhaust systems with more effective silencing technology.

- Industrial Processing Plants

Many industrial processes, such as those in chemical plants or refineries, utilize large engines or turbines that generate substantial exhaust noise. Silencing systems are critical for protecting workers’ hearing, complying with occupational safety regulations, and preventing community noise complaints. These applications often require specialized materials and designs to resist corrosive chemicals and extreme temperatures. Furthermore, safety considerations, such as spark arrestors and explosion-proof designs, may be necessary in certain industrial settings. The application necessitates a focus on both noise reduction and process safety.

These diverse applications highlight the importance of tailoring “mega muffler” to specific operational and environmental contexts. Effective integration requires a comprehensive understanding of the noise source characteristics, regulatory requirements, and the unique challenges presented by each application. Continuous advancements in materials, design, and simulation techniques are driving the development of more efficient and effective exhaust silencing solutions for a wide range of industries.

Frequently Asked Questions About Mega Muffler Systems

The following questions address common concerns and misconceptions regarding high-capacity exhaust silencing systems. The information provided is intended to offer clarity and promote informed decision-making.

Question 1: What constitutes a “mega muffler,” and how does it differ from a standard muffler?

A “mega muffler” denotes an exhaust silencing system designed for high-volume, high-power applications, such as large engines in power generation, marine propulsion, or heavy industrial machinery. Standard mufflers are typically smaller and designed for automotive or light-duty applications. The differentiating factors include size, capacity, durability, and the level of noise attenuation provided.

Question 2: What are the primary factors influencing the performance of an advanced exhaust silencing system?

The performance of a “mega muffler” is influenced by several key factors, including the materials used in construction, the internal design (baffle configuration, chamber volume), the capacity to handle exhaust flow without creating excessive backpressure, and the system’s ability to attenuate noise across a broad frequency range. Proper integration with the engine and exhaust system is also crucial.

Question 3: How does backpressure affect engine performance when using a high-capacity muffler?

Excessive backpressure generated by any exhaust silencing system, including “mega muffler,” can negatively impact engine performance, fuel efficiency, and emissions. A well-designed system minimizes backpressure while achieving the required noise reduction. Computational fluid dynamics (CFD) simulations are often used to optimize internal geometries and ensure adequate flow capacity.

Question 4: What materials are commonly used in the construction of “mega muffler,” and why?

Stainless steel alloys are frequently employed due to their resistance to corrosion, high-temperature strength, and durability. Specific grades, such as 316L, may be selected for enhanced resistance to chloride-induced pitting in marine environments. Other materials, such as specialized insulation and acoustic damping materials, are used to enhance noise attenuation.

Question 5: What are the typical maintenance requirements for large-scale exhaust silencing systems?

Regular inspections are essential to identify and address any signs of wear, corrosion, or damage. Periodic cleaning may be necessary to remove soot and debris that can accumulate within the system. Repairs should be performed promptly to prevent minor issues from escalating into more significant problems. The frequency of maintenance depends on the operating environment and the specific design of the silencing system.

Question 6: How can one determine the appropriate size and capacity of a “mega muffler” for a specific application?

Determining the appropriate size and capacity requires a detailed analysis of the engine’s specifications, including exhaust gas flow rate, temperature, and pressure. Regulatory noise limits and environmental factors must also be considered. Consulting with a qualified acoustic engineer is recommended to ensure proper selection and integration of the silencing system.

Understanding these fundamental aspects is crucial for effective noise mitigation and optimal performance in high-capacity exhaust applications.

The next section will explore case studies demonstrating successful implementations of “mega muffler” across various industries.

Conclusion

This exploration of “mega muffler” systems has underscored their critical role in managing noise pollution from high-capacity engines. From material selection and internal design to flow dynamics and application-specific considerations, the effectiveness of these systems hinges on a comprehensive understanding of acoustic principles and engineering best practices. The diverse applications, ranging from power generation to marine propulsion, demand tailored solutions that balance noise reduction with engine performance and regulatory compliance.

As environmental awareness and noise regulations continue to tighten, the demand for advanced exhaust silencing technologies will only intensify. Further research and development in material science, acoustic engineering, and computational modeling are essential to push the boundaries of noise attenuation performance while minimizing operational costs and environmental impact. The future of sustainable power generation and transportation depends, in part, on the continued innovation and responsible deployment of effective “mega muffler” solutions. Organizations are encouraged to prioritize robust silencing strategies to ensure both environmental stewardship and operational efficiency.