A device designed to mitigate the sound produced by high-energy exhaust expulsion, often associated with combustion engines, finds application in various contexts. One prominent example is its use in automotive applications, where it reduces the noise generated by modified or performance-oriented vehicles. These engines, capable of generating substantial power, often produce significant exhaust noise that can be disruptive and even illegal in certain regions.

The incorporation of such a noise-reducing component offers numerous benefits. Beyond compliance with noise regulations, it can enhance the driving experience by reducing driver fatigue and minimizing disturbance to surrounding communities. Historically, the need for these devices grew alongside the increasing prevalence of high-performance vehicles and a greater awareness of environmental noise pollution. Their development represents a continuous effort to balance power and performance with social responsibility.

The following sections will delve into the specific design characteristics, operational principles, and performance metrics associated with exhaust noise reduction technology, exploring the factors that influence its effectiveness and the considerations involved in its selection and implementation.

Optimizing Performance and Compliance

Effective utilization of an exhaust sound reduction device requires careful consideration of several factors. These guidelines aim to assist in maximizing performance while ensuring regulatory adherence.

Tip 1: Selection Based on Engine Characteristics: Choosing a device appropriate for the specific engine displacement and power output is critical. An undersized unit may be ineffective, while an oversized unit may impede performance. Consult manufacturer specifications for optimal pairing.

Tip 2: Material Selection for Longevity: Consider the material composition of the device. Stainless steel or other corrosion-resistant materials are recommended for prolonged use, particularly in environments with high moisture or salt exposure.

Tip 3: Professional Installation Recommended: Proper installation is crucial for optimal performance and to prevent exhaust leaks. Seek professional assistance to ensure correct alignment and secure mounting.

Tip 4: Regular Inspection for Damage: Periodically inspect the device for signs of damage, such as cracks, rust, or loose connections. Promptly address any issues to maintain effectiveness and prevent system failure.

Tip 5: Adherence to Local Noise Regulations: Familiarize yourself with local noise ordinances and ensure that the chosen device complies with these regulations. Penalties for excessive noise can be significant.

Tip 6: Consider Backpressure Implications: Be aware that some devices can increase backpressure, potentially impacting engine performance. Opt for designs that minimize backpressure while effectively reducing noise.

Employing these strategies can lead to a more efficient and compliant exhaust system, balancing performance enhancements with environmental responsibility.

The concluding section will summarize the key benefits of utilizing effective sound reduction technology and highlight potential areas for future innovation.

1. Noise reduction efficiency

Noise reduction efficiency, when considered in the context of an exhaust sound reduction device, directly quantifies its capability to attenuate sound pressure levels. This metric is paramount in determining the suitability of a given device for specific applications, particularly where noise pollution is a concern or where strict regulatory limits are enforced. Higher efficiency translates to a greater reduction in decibel levels, mitigating the propagation of unwanted sound waves generated by the engine’s exhaust. The inherent design characteristics and internal structure contribute significantly to the overall noise reduction efficiency. For instance, multi-chamber designs or those incorporating sound-absorbing materials are typically more effective than simpler, straight-through configurations.

The significance of noise reduction efficiency extends beyond mere regulatory compliance. In residential areas, effective noise reduction minimizes disturbance to the surrounding community, fostering a more harmonious environment. Furthermore, reduced noise levels contribute to a more comfortable driving experience, particularly for long journeys, by mitigating driver fatigue and improving overall vehicle acoustics. A practical example can be seen in aftermarket automotive applications, where enthusiasts often prioritize power enhancements. However, without adequate noise reduction, these modifications can lead to excessive noise, resulting in legal repercussions and social disapproval. Therefore, selecting a device with appropriate noise reduction capabilities becomes a critical factor in achieving both performance gains and responsible vehicle operation.

In summary, noise reduction efficiency is a fundamental performance characteristic of any exhaust sound mitigation solution. Its importance lies not only in meeting regulatory requirements but also in promoting social responsibility and enhancing the overall driving experience. Challenges remain in optimizing noise reduction while minimizing backpressure and maintaining durability. Ongoing research and development efforts are focused on achieving this delicate balance, ensuring that future designs offer improved performance and environmental compatibility. This focus is essential for the continued advancement of noise reduction technology and its effective application across various industries.

2. Backpressure impact

The backpressure impact associated with an exhaust noise reduction device directly influences engine performance characteristics. Devices that generate excessive backpressure restrict the flow of exhaust gases, impeding the engine’s ability to expel spent combustion products efficiently. This restriction can lead to a decrease in horsepower and torque, particularly at higher engine speeds. The internal design of the device plays a crucial role in determining the level of backpressure generated. Complex internal structures with numerous baffles or restrictions, while potentially effective at noise reduction, can contribute to increased backpressure. A real-world example is observed when replacing a factory exhaust system with an aftermarket system; if the aftermarket system significantly reduces noise but introduces excessive backpressure, the anticipated performance gains may not materialize, or may even result in a net performance loss.

The relationship between backpressure and performance is further complicated by engine type and tuning. Turbocharged engines, for example, are generally more sensitive to backpressure than naturally aspirated engines. An exhaust system that generates minimal backpressure is typically preferred for turbocharged applications to maximize turbocharger efficiency and reduce turbo lag. Conversely, some naturally aspirated engines may benefit from a small amount of backpressure, as it can help improve low-end torque. The choice of an exhaust sound reduction device must therefore be carefully considered in relation to the specific engine characteristics and intended usage. Performance testing and dyno tuning are often employed to assess the actual impact of a given device on engine output.

In summary, the backpressure impact is a critical consideration when selecting an exhaust noise reduction solution. Excessive backpressure can negate performance gains and potentially damage the engine, while insufficient backpressure may not effectively reduce noise. The ideal solution represents a balance between noise reduction and minimal backpressure, tailored to the specific engine and application. Understanding this relationship is essential for optimizing both performance and compliance with noise regulations. Future designs should prioritize minimizing backpressure while maintaining effective noise reduction capabilities, potentially through the use of advanced materials and innovative internal geometries.

3. Material durability

Material durability constitutes a critical design parameter in the efficacy and longevity of an exhaust noise reduction device. The operational environment, characterized by high temperatures, corrosive gases, and vibrational forces, necessitates the selection of materials capable of withstanding these harsh conditions. Premature failure due to corrosion, fatigue, or thermal degradation can render the device ineffective, leading to increased noise levels and potential regulatory non-compliance. The choice of materials, therefore, directly impacts the overall performance and lifespan of the system. For instance, a mild steel component, while cost-effective, exhibits limited resistance to corrosion, especially in regions with high road salt usage, resulting in reduced service life and increased replacement frequency. Conversely, stainless steel alloys provide superior corrosion resistance, thereby extending the operational lifespan and minimizing maintenance requirements.

The significance of material durability extends beyond cost considerations. Failure of the internal components due to material degradation can lead to structural damage, potentially releasing fragments into the exhaust stream, which could damage downstream components or even compromise engine performance. Furthermore, the device’s ability to effectively attenuate noise is directly dependent on the integrity of its internal structure; corrosion or deformation can alter the acoustic properties and reduce noise reduction efficiency. Practical applications, such as heavy-duty trucking or off-road vehicles, which operate in particularly demanding environments, underscore the need for robust material selection to ensure reliable performance and minimize downtime. The selection process must consider not only the inherent material properties but also the manufacturing processes employed, as welding techniques and surface treatments can significantly affect the overall durability.

In conclusion, material durability is inextricably linked to the long-term performance and reliability of exhaust noise reduction technology. The selection of appropriate materials, coupled with robust manufacturing processes, is essential for ensuring that these devices can withstand the rigors of the operational environment and maintain their effectiveness over an extended service life. Addressing the challenges associated with material degradation is crucial for achieving optimal noise reduction and minimizing the environmental impact of vehicular emissions. Future advancements in material science may lead to the development of even more durable and cost-effective solutions, further enhancing the performance and sustainability of these essential components.

4. Installation complexity

Installation complexity directly correlates with the ease and efficiency with which an exhaust sound reduction device can be integrated into a vehicle’s exhaust system. The design of the device, the accessibility of the exhaust system components, and the required tools all contribute to the overall installation difficulty. Complex installation procedures can increase labor costs, extend downtime, and heighten the risk of improper installation, potentially compromising performance and safety. For example, a universal-fit device may require significant modification to the existing exhaust system, including cutting, welding, and custom fabrication, thereby demanding specialized skills and equipment. Conversely, a direct-fit replacement is designed to seamlessly integrate with the existing system, minimizing the need for modifications and simplifying the installation process.

The installation complexity of an exhaust sound reduction component directly impacts its adoption rate and long-term maintenance requirements. A complex installation procedure can deter potential users, particularly those without specialized mechanical skills, limiting the market reach of the device. Furthermore, improperly installed components can lead to exhaust leaks, reduced noise reduction efficiency, and even damage to other vehicle systems. In contrast, a well-designed device with straightforward installation instructions and minimal required modifications promotes user confidence and reduces the likelihood of installation-related issues. The integration of detailed diagrams, video tutorials, and readily available technical support can further mitigate installation challenges and enhance user satisfaction. In the context of aftermarket modifications, selecting a device with manageable installation requirements is often a primary consideration for vehicle enthusiasts.

In summary, the installation complexity of exhaust sound reduction devices significantly affects cost, user satisfaction, and long-term reliability. Minimizing installation complexity through thoughtful design, clear instructions, and readily available support is crucial for promoting widespread adoption and ensuring optimal performance. Future development efforts should prioritize ease of installation, enabling users to efficiently integrate these devices into their vehicles with minimal specialized knowledge or equipment. Addressing installation challenges enhances accessibility and promotes the responsible use of exhaust sound reduction technology.

5. Regulatory compliance

Regulatory compliance represents a critical aspect in the design, manufacture, and use of exhaust sound reduction technology. It dictates the permissible noise levels emitted by vehicles and imposes penalties for exceeding these limits. Adherence to these regulations is paramount to avoid legal ramifications and to promote responsible vehicle operation.

- Noise Emission Standards

Noise emission standards, established by governing bodies, define the maximum allowable sound pressure levels for vehicles operating in specific areas. These standards often vary based on vehicle type, time of day, and geographic location. Devices intended for use in vehicles must be engineered to meet these standards to ensure legal compliance and minimize noise pollution. For example, certain jurisdictions impose stricter noise limits in residential zones compared to industrial areas. The effectiveness of the noise reduction device in meeting these specific standards is a primary consideration during regulatory evaluations.

- Type Approval and Certification

Many regions require exhaust sound reduction devices to undergo type approval and certification processes. These processes involve rigorous testing to verify that the device meets the prescribed noise emission standards. Certification marks, such as those issued by regulatory agencies, indicate that the device has been independently verified and approved for legal use. Without proper certification, the device may be deemed illegal, resulting in fines and potential vehicle impoundment. Obtaining type approval involves submitting the device to accredited testing facilities for comprehensive evaluation.

- Enforcement and Penalties

Enforcement of noise regulations typically involves law enforcement agencies utilizing sound level meters to measure vehicle noise levels. Vehicles exceeding the permissible limits are subject to penalties, including fines, repair orders, and vehicle impoundment. Repeat offenders may face more severe consequences, such as license suspension. The severity of the penalties often depends on the magnitude of the noise level exceedance and the specific regulations of the jurisdiction. Effective enforcement mechanisms are crucial for deterring non-compliance and maintaining acceptable noise levels in communities.

- Aftermarket Modifications and Legal Implications

Aftermarket modifications to exhaust systems, including the installation of noise reduction devices, are subject to the same regulatory requirements as original equipment. Modifying an exhaust system in a manner that increases noise levels beyond the permissible limits constitutes a violation of noise regulations. Vehicle owners are responsible for ensuring that any aftermarket modifications comply with applicable laws and regulations. Ignorance of these regulations is not an acceptable defense against enforcement actions. Choosing certified and compliant devices is essential to avoid potential legal issues arising from aftermarket modifications.

In conclusion, regulatory compliance is a non-negotiable aspect of exhaust sound reduction technology. Adherence to noise emission standards, obtaining type approval, and understanding the legal implications of aftermarket modifications are crucial for ensuring responsible vehicle operation and avoiding penalties. Effective enforcement mechanisms and readily available information about noise regulations contribute to a quieter and more sustainable environment.

6. Engine compatibility

Engine compatibility represents a foundational element in the effective deployment of an exhaust sound reduction device. The selection of a noise reduction component without considering the specific characteristics of the engine can result in suboptimal performance, potential damage, or regulatory non-compliance. The engine’s displacement, power output, and operating RPM range significantly influence the design parameters required for effective sound attenuation without negatively impacting engine efficiency. A device designed for a small displacement engine, if installed on a high-performance engine, may create excessive backpressure, reducing power output and potentially leading to overheating. Conversely, a device designed for a high-performance engine may not provide sufficient noise reduction when installed on a smaller, quieter engine. An understanding of these interactions is crucial for ensuring that the chosen sound reduction component functions as intended without compromising engine integrity.

Practical significance of engine compatibility is evident in the automotive aftermarket. Modifications intended to enhance performance often involve alterations to the exhaust system. However, indiscriminately installing components without regard for engine specifications can lead to adverse outcomes. For instance, replacing a factory exhaust system with a larger diameter system without accounting for the engine’s scavenging requirements may result in a loss of low-end torque. In these situations, matching the sound reduction device’s flow characteristics to the engine’s needs is essential. Utilizing data from dyno testing and consulting with qualified technicians can help ensure proper component matching and optimize engine performance while minimizing noise emissions.

In conclusion, engine compatibility is not merely a desirable feature but a fundamental prerequisite for the successful application of exhaust sound reduction devices. Failing to consider engine specifications can result in performance degradation, engine damage, and regulatory violations. Therefore, a thorough understanding of engine characteristics and the sound reduction component’s design parameters is essential for achieving optimal noise attenuation and maintaining engine integrity. Future advancements in exhaust system design should prioritize engine-specific solutions, offering greater flexibility and performance optimization across a wider range of applications.

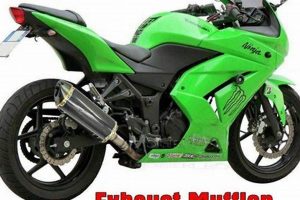

Frequently Asked Questions About Cannon Mufflers

This section addresses common inquiries regarding exhaust sound reduction devices, focusing on their functionality, applications, and implications for vehicle performance and regulatory compliance.

Question 1: What is the primary function of a cannon muffler?

The primary function is to attenuate noise generated by the exhaust system of an internal combustion engine. It reduces the amplitude of sound waves, thereby decreasing the overall noise level emitted by the vehicle.

Question 2: How does a cannon muffler affect engine performance?

A properly designed one minimizes backpressure, ensuring optimal engine performance. Excessive backpressure can impede exhaust flow, reducing horsepower and torque. The device should balance noise reduction with exhaust flow efficiency.

Question 3: Are cannon mufflers legal for street use?

Legality varies by jurisdiction. Many regions have noise regulations that specify maximum permissible decibel levels. Compliance requires selecting a device that meets these standards and adhering to local regulations regarding exhaust modifications.

Question 4: What materials are commonly used in their construction?

Common materials include stainless steel and aluminized steel. Stainless steel offers superior corrosion resistance and durability, making it a preferred choice for longevity. Aluminized steel provides a more cost-effective alternative but may have a shorter lifespan.

Question 5: Can I install a cannon muffler myself, or is professional installation required?

While self-installation is possible, professional installation is generally recommended. Proper installation ensures correct alignment, secure mounting, and the prevention of exhaust leaks. Improper installation can compromise performance and safety.

Question 6: How do I choose the right one for my vehicle?

Selection should be based on engine size, power output, and intended use. Consult manufacturer specifications and seek advice from qualified technicians to ensure compatibility and optimal performance. Consider noise level requirements and regulatory compliance.

Understanding these key aspects is crucial for making informed decisions regarding exhaust sound reduction technology and its application to specific vehicles and driving conditions.

The concluding section will summarize the core benefits and potential drawbacks associated with various exhaust sound reduction technologies.

Conclusion

This exploration of the cannon muffler has illuminated its role in mitigating exhaust noise, underscoring the critical balance between sound reduction, engine performance, and regulatory adherence. The device’s effectiveness hinges on careful selection of materials, appropriate design for specific engine characteristics, and proper installation to ensure optimal functionality. Consideration of noise reduction efficiency, backpressure impact, material durability, installation complexity, and engine compatibility is paramount.

The cannon muffler, when strategically implemented, can contribute to a more sustainable and responsible automotive environment. Its continued development and refinement are essential for navigating the evolving landscape of noise regulations and performance expectations. Prudent implementation requires informed decision-making and adherence to best practices to maximize its potential while minimizing adverse effects on engine operation and regulatory compliance.