A crucial component in the exhaust system of the Ford F-150, this device mitigates engine noise. It operates by using internal chambers and baffling to redirect sound waves, causing them to cancel each other out. A defective or absent one will result in a significantly louder vehicle operation.

The effectiveness directly impacts driver and passenger comfort, as well as compliance with noise regulations in many jurisdictions. The implementation of efficient sound dampening contributes to a more pleasant driving experience and can prevent legal issues related to excessive vehicle noise. Historically, advancements in vehicle acoustic engineering have continually improved the design and function of these sound-reducing components.

Considering options for replacement, upgrade, or repair involves understanding various types, materials, and performance characteristics, each influencing sound level, exhaust flow, and overall lifespan. Subsequent sections will detail these factors, aiding in informed decision-making for F-150 owners.

Maintenance and Selection Guidance

Optimal performance and longevity of the sound-reducing component on a Ford F-150 relies on informed selection and diligent maintenance practices. The following recommendations are designed to maximize the effectiveness and lifespan of the original or replacement unit.

Tip 1: Material Assessment: When selecting a replacement, consider the material composition. Stainless steel offers superior corrosion resistance compared to aluminized steel, extending the service life, particularly in environments with frequent exposure to road salt.

Tip 2: Regular Inspection: Conduct routine visual inspections for signs of corrosion, damage, or leaks. Early detection allows for timely repairs, preventing more extensive and costly replacements.

Tip 3: Secure Mounting: Verify that all mounting hardware is correctly installed and tightened. Loose or damaged hangers can lead to premature failure due to excessive vibration and stress.

Tip 4: Exhaust System Alignment: Ensure proper alignment of the entire exhaust system. Misalignment can place undue stress on the sound-reducing component, potentially causing cracks or leaks.

Tip 5: Performance Considerations: Evaluate performance requirements based on driving style and environmental conditions. High-performance options often prioritize exhaust flow, potentially increasing noise levels compared to standard units. A balance between noise reduction and performance is critical.

Tip 6: Professional Installation: Unless possessing advanced mechanical skills, seek professional installation services. Correct installation ensures proper sealing, alignment, and secure mounting, optimizing performance and preventing future issues.

Following these guidelines facilitates consistent performance, extends the lifespan of the sound-reducing component, and ensures adherence to noise regulations. These practices contribute to a quieter, more reliable, and legally compliant F-150.

The subsequent sections will elaborate on specific product types and detailed installation procedures.

1. Sound Attenuation

Sound attenuation, the reduction of noise intensity, is a primary function of exhaust components in the Ford F-150. The effectiveness of this sound dampening directly influences the vehicle’s compliance with noise regulations and the comfort of its occupants.

- Internal Chamber Design

The architecture of internal chambers within the device manipulates sound waves, promoting destructive interference. This design reduces the amplitude of sound, thereby lowering overall noise levels. For example, baffles force sound waves to travel through convoluted paths, increasing opportunities for cancellation. Inefficient chamber design leads to inadequate sound dampening.

- Material Properties

The materials utilized in construction contribute to sound absorption and vibration damping. Dense, layered materials can effectively absorb sound energy, converting it into thermal energy. For instance, fiberglass packing within the component absorbs high-frequency sound components. Suboptimal materials reduce the ability to diminish sounds, resulting in a noisier vehicle.

- Resonance Frequency

Resonance within the exhaust system can amplify certain frequencies, counteracting the intended sound attenuation. Exhaust systems are designed to minimize resonance at frequencies that are most noticeable or annoying. The design must avoid amplifying the frequency that are near F-150 engine.

- Perforation Patterns

Perforated tubes within the device contribute to sound attenuation by altering the way sound waves propagate through the system. The size, density, and arrangement of these perforations can be tuned to target specific frequency ranges. For example, smaller perforations are more effective at attenuating higher frequencies. Ineffective perforation patterns undermine the sound reducing component’s purpose.

These facets of sound attenuation underscore the importance of quality in components selected for the Ford F-150. Proper design and material selection ensure optimal noise reduction, enhancing the driving experience and contributing to legal compliance. Variations in these factors directly correlate with differences in noise levels and overall performance of the exhaust system.

2. Material Durability

The longevity and reliability of a Ford F-150’s exhaust component are intrinsically linked to the durability of its constituent materials. The operating environment subjects these parts to significant thermal stress, corrosive chemicals, and physical impacts, necessitating robust construction. Material failure leads to compromised sound reduction, exhaust leaks, and potential engine damage. For example, a component constructed from low-grade steel is susceptible to rapid corrosion in regions with heavy road salt usage, whereas stainless steel would provide superior resistance.

The selection of appropriate materials significantly impacts the maintenance schedule and overall cost of ownership. Aluminized steel represents a compromise between cost and durability, offering improved corrosion resistance compared to mild steel, but less than stainless steel. Titanium exhaust systems, although offering exceptional strength-to-weight ratio and corrosion resistance, are substantially more expensive. Therefore, selection requires balancing budget constraints with anticipated environmental exposure and desired lifespan. Proper material choice delays the need for frequent replacements, reducing labor expenses and downtime.

In conclusion, material durability is a key determinant of the effectiveness and longevity of a Ford F-150’s exhaust sound-reduction device. Careful consideration of environmental factors and performance requirements during material selection directly translates into reduced maintenance costs and enhanced vehicle reliability. Neglecting this aspect leads to premature component failure and increased operational expenses.

3. Exhaust Flow and Ford F-150 Mufflers

Exhaust flow, the rate at which exhaust gases are expelled from an engine, is significantly influenced by the design and condition of the mufflers installed on a Ford F-150. A restrictive one impedes exhaust flow, leading to increased backpressure within the engine, potentially diminishing performance, fuel efficiency, and even increasing engine wear. Conversely, a high-flow unit reduces backpressure, potentially improving these aspects. The degree of influence depends on engine characteristics, overall exhaust system design, and driving conditions. For instance, a heavily modified F-150 engine with increased displacement and forced induction benefits more from a high-flow unit than a stock engine.

The internal construction determines the degree of restriction. Baffled mufflers, using chambers and deflectors to reduce sound, typically present more flow resistance than straight-through designs. Straight-through mufflers, often found in performance applications, prioritize flow over maximum sound reduction. When selecting an aftermarket option, it is important to consider the trade-offs between performance gains and desired noise level. A unit that allows a higher rate of flow might increase horsepower, especially in higher RPMs, but could also lead to a significant increase in noise, potentially violating local sound ordinances. A practical example involves a contractor using an F-150 for towing; a performance unit with improved flow may enhance towing performance, but the increased noise could become detrimental during long workdays.

Therefore, optimizing exhaust flow through appropriate sound-reduction components is crucial for maximizing the performance and lifespan of a Ford F-150’s engine. Careful consideration must be given to balancing the need for reduced backpressure with the desire for noise control and legal compliance. The ideal selection depends on the specific application, engine configuration, and individual preferences regarding sound and performance characteristics. Furthermore, routine maintenance and inspection are required to ensure proper flow, as internal corrosion or damage can restrict flow and diminish performance over time.

4. Installation Compatibility

Installation compatibility, regarding Ford F-150 exhaust components, encompasses the degree to which a replacement unit seamlessly integrates with the existing vehicle infrastructure. Proper compatibility ensures efficient installation, optimal performance, and prevents potential damage to other vehicle systems.

- Mounting Point Alignment

The physical location and configuration of mounting points on a replacement unit must precisely match those on the F-150’s chassis and exhaust system. Mismatched mounting points necessitate modifications, potentially compromising structural integrity or leading to exhaust leaks. For example, if the hanger brackets on the replacement part are located in different positions, it will require either fabricating new mounting points or modifying the existing ones, both of which introduce potential weaknesses.

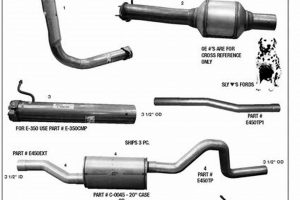

- Pipe Diameter and Configuration

The inlet and outlet pipe diameters, as well as their configuration (straight, angled, etc.), must align with the existing exhaust piping on the F-150. Diameter discrepancies lead to flow restrictions or require the use of adapters, increasing complexity and potential leak points. An undersized inlet pipe restricts exhaust flow, reducing engine performance, while an oversized pipe might create turbulence and affect exhaust scavenging.

- Sensor Port Integration

Modern F-150 models incorporate sensors within the exhaust system, such as oxygen sensors. A compatible replacement must include properly located and threaded ports for these sensors. Failure to integrate sensors correctly results in incorrect engine readings, leading to poor fuel economy, reduced performance, and potential damage to the catalytic converter. Omission of or improperly sized sensor ports render a unit incompatible.

- Overall Length and Clearance

The overall length and physical dimensions must allow for proper clearance within the F-150’s undercarriage. Interference with other components, such as the driveshaft, suspension components, or fuel lines, poses safety risks and compromises functionality. A unit that is too long could scrape on speed bumps or off-road obstacles, causing damage to both the unit and the vehicle.

These facets of installation compatibility highlight the importance of selecting components specifically designed for the Ford F-150. Deviation from original equipment specifications can result in a compromised exhaust system, leading to decreased performance, potential safety hazards, and increased maintenance costs. Cross-referencing part numbers and verifying compatibility with the specific F-150 model year and engine configuration is critical.

5. Noise regulations

Noise regulations impose legally mandated limits on vehicle sound emissions, directly affecting the design, maintenance, and aftermarket modifications related to the exhaust system. Ford F-150 owners are obligated to adhere to these standards, the stringency of which varies depending on locale. A properly functioning muffler is crucial for compliance. States and municipalities often set decibel limits for vehicle operation, with enforcement ranging from roadside inspections to fines. Failure to meet these standards results in penalties. For example, California Vehicle Code Section 27150 prohibits modifications that amplify vehicle noise beyond specified levels. A malfunctioning muffler, or the installation of an illegal aftermarket exhaust system, leads to non-compliance.

The implications extend beyond individual vehicle operation. Consistent enforcement of noise regulations contributes to community well-being by mitigating noise pollution. This has prompted manufacturers to engineer quieter vehicles and muffler designs. Aftermarket muffler manufacturers also produce components specifically designed to meet established noise standards. Therefore, adherence to sound output mandates plays a critical role in civic planning efforts. For example, residential areas located near major roadways benefit significantly from vehicles that adhere to enforced noise levels.

Understanding the interconnection between legal sound restrictions and the mechanical function of a sound-reducing component is essential for F-150 owners. Regular inspection and maintenance of the stock unit, or the selection of compliant aftermarket replacements, facilitates adherence to applicable regulations, averting fines and contributing to broader societal goals related to noise mitigation. Ignoring this connection leads to legal ramifications and diminished quality of life in affected areas.

6. Performance gains

Performance enhancements are a potential outcome when optimizing the sound-reducing component within a Ford F-150’s exhaust system. This relates directly to exhaust flow. A stock sound-reducing component is designed to meet noise regulations and provide acceptable performance for a broad range of driving conditions. However, it often presents a degree of restriction to the exhaust flow. Replacing the original with a less restrictive, performance-oriented component can lead to tangible improvements. These can manifest as increased horsepower and torque, particularly at higher engine speeds. Real-world examples include F-150 owners experiencing enhanced acceleration and improved throttle response after installing a high-flow system. This is especially noticeable in models equipped with forced induction or larger displacement engines, where minimizing backpressure is paramount for optimal output.

The type of replacement directly influences the degree of improvement. Straight-through designs, characterized by minimal internal obstructions, generally offer the greatest potential for increased flow. Chambered designs, while typically providing better sound attenuation, may present more resistance. Careful selection of components, matching the engine’s characteristics and intended use, is vital. For instance, an F-150 primarily used for towing benefits from a unit that maximizes low-end torque, whereas a truck used for performance driving may prioritize top-end horsepower. Moreover, modifying or removing the sound-reducing component without considering the overall exhaust system design can yield unpredictable results, potentially negating any performance gains and even causing detrimental effects.

In conclusion, while replacement of the original sound-reducing component on a Ford F-150 holds the potential for performance gains, the magnitude and nature of these enhancements are dependent on several factors. These include the specific unit selected, the engine’s configuration, and the interplay with the broader exhaust system. Success requires a careful and informed decision-making process, balancing the desire for improved output with considerations for noise levels, regulatory compliance, and overall vehicle reliability. The challenge lies in achieving optimal flow without sacrificing noise control or violating established sound standards.

7. Longevity expectations

The anticipated lifespan of a sound-reducing component installed on a Ford F-150 is a critical consideration for owners, influencing purchase decisions, maintenance planning, and overall cost of ownership. Multiple factors contribute to the service life of this component, demanding careful evaluation.

- Material Composition

The material from which the unit is manufactured is a primary determinant of its longevity. Stainless steel, aluminized steel, and mild steel represent different tiers of corrosion resistance, directly impacting lifespan. Stainless steel units withstand corrosive road salts and atmospheric moisture more effectively than aluminized or mild steel, extending their service life significantly. Conversely, a mild steel unit installed in a region with frequent snow and road salting will exhibit a considerably shorter lifespan due to accelerated corrosion.

- Environmental Conditions

The operating environment to which the vehicle is exposed plays a pivotal role in component degradation. Frequent exposure to road salt, extreme temperatures, and high humidity accelerates corrosion and weakens the structural integrity. An F-150 regularly driven on unpaved roads is also subject to increased physical impact from rocks and debris, potentially damaging the unit and shortening its lifespan. Vehicles operating in arid climates experience less corrosion compared to those in coastal regions, thereby extending the units service life.

- Driving Habits

Driving habits influence the thermal stress placed upon the sound-reducing component. Frequent short trips do not allow the exhaust system to reach optimal operating temperature, promoting moisture accumulation within the muffler and accelerating internal corrosion. Conversely, sustained high-speed driving exposes the unit to elevated temperatures, potentially leading to material fatigue and premature failure. Moderate and consistent driving habits contribute to a more stable operating environment and a longer lifespan.

- Maintenance Practices

Regular inspection and timely repair of minor damage contribute significantly to extending the service life. Addressing corrosion early, securing loose mounting hardware, and ensuring proper exhaust system alignment prevent further damage and prolong the component’s functionality. Neglecting maintenance allows minor issues to escalate, resulting in accelerated degradation and premature failure. For example, addressing a small exhaust leak promptly prevents it from expanding and causing significant damage to adjacent components.

These factors collectively determine the anticipated longevity of the sound-reducing component on a Ford F-150. Understanding and addressing these influences are essential for maximizing the units lifespan, reducing maintenance costs, and ensuring continued compliance with noise regulations. Strategic material selection, attentive driving habits, and proactive maintenance contribute to a significantly longer service life and overall vehicle reliability.

Frequently Asked Questions

This section addresses common inquiries regarding exhaust components for the Ford F-150, providing detailed and informative answers.

Question 1: What constitutes a muffler failure on a Ford F-150?

A failed exhaust component typically manifests as increased exhaust noise, reduced engine performance, or visible physical damage, such as corrosion or holes. Internal baffling disintegration or external rust compromising structural integrity are common indicators.

Question 2: Is it permissible to operate a Ford F-150 with a damaged exhaust system?

Operating a vehicle with a damaged exhaust system is generally inadvisable and potentially illegal. Increased noise pollution violates noise ordinances, and exhaust leaks pose health and safety risks. Furthermore, it may negatively impact engine performance and fuel economy.

Question 3: What are the potential benefits of upgrading the factory-installed exhaust system on a Ford F-150?

Upgrading the original exhaust component may yield improvements in engine performance, fuel efficiency, and exhaust sound. High-flow units reduce backpressure, potentially increasing horsepower and torque. However, these benefits must be balanced against potential increases in noise levels.

Question 4: How does climate affect the lifespan of an exhaust sound-reduction device on a Ford F-150?

Climatic conditions significantly influence longevity. Regions with high humidity and road salting accelerate corrosion, reducing lifespan. Conversely, arid climates typically prolong the service life.

Question 5: What are the key considerations when selecting a replacement unit for a Ford F-150?

Material composition, internal design, and compatibility with the existing exhaust system are paramount. Stainless steel offers superior corrosion resistance. The design should balance noise reduction with desired exhaust flow. Verify compatibility with the specific F-150 model year and engine configuration.

Question 6: Does replacing the original exhaust unit automatically void the Ford F-150’s warranty?

Replacing the exhaust unit may not automatically void the entire vehicle warranty. However, if the aftermarket unit causes damage to other components, those specific repairs may not be covered under the manufacturer’s warranty. Consult warranty documentation and a qualified mechanic for clarification.

Understanding these key aspects of exhaust system components ensures informed decision-making regarding maintenance, repair, and upgrades, thereby maximizing vehicle performance and longevity.

The subsequent section will provide a comparative analysis of aftermarket unit options for the Ford F-150.

In Summary

This exploration of muffler options for the Ford F-150 underscored several critical elements. Material selection, internal design, and installation compatibility profoundly impact performance, longevity, and regulatory compliance. Owners must weigh the trade-offs between sound attenuation and exhaust flow to optimize their vehicle’s function and adherence to noise standards. Maintenance and informed selection are essential for maximizing the lifespan of this critical component.

Continued diligence in monitoring exhaust system health will ensure optimal performance and prevent costly repairs. Future advancements in material science and acoustic engineering promise further enhancements in muffler design, potentially yielding both improved sound control and increased engine efficiency. Vehicle owners should remain informed of these developments to make optimal decisions regarding their F-150’s exhaust system.