An exhaust component designed to reduce engine noise, this device plays a crucial role in vehicle emissions control and overall acoustic comfort. Its primary function is to attenuate the sound waves produced by the engine’s combustion process before they are released into the atmosphere. An example is its integration into the exhaust system of a passenger car.

The importance of this component stems from its dual contribution to environmental and social well-being. By minimizing noise pollution, it enhances the quality of life in urban environments and reduces stress on both drivers and residents. Furthermore, its contribution to efficient exhaust flow can indirectly impact fuel economy. Historically, advancements in its design have paralleled developments in engine technology and noise regulations.

Understanding the specific design characteristics, materials used in construction, and performance metrics are essential when evaluating the suitability of this component for particular applications. Subsequent sections will delve into these aspects, providing a detailed analysis of its functionality and potential variations.

Maintenance & Longevity Tips

The following guidelines will assist in maximizing the lifespan and performance of the exhaust system’s noise reduction component.

Tip 1: Regular Visual Inspection: Conduct routine examinations for signs of corrosion, physical damage, or leaks. Early detection can prevent extensive repairs.

Tip 2: Address Rust Promptly: Treat surface rust with appropriate rust inhibitors to prevent it from compromising the structural integrity of the component.

Tip 3: Avoid Short Trips: Frequent short trips do not allow the exhaust system to reach optimal operating temperature, leading to moisture buildup and accelerated corrosion. Longer drives periodically can mitigate this effect.

Tip 4: Proper Installation: Ensure correct installation according to manufacturer specifications. Improper installation can introduce undue stress and premature failure.

Tip 5: Promptly Replace Worn Hangers: Failing exhaust hangers can cause excessive vibration and stress on the system, reducing the lifespan of the noise reduction component.

Tip 6: Minimize Exposure to Road Salt: In regions where road salt is used, regular undercarriage washing can help prevent corrosion.

Implementing these measures contributes to extending the functional life of this critical exhaust component, mitigating the need for premature replacement and ensuring optimal vehicle performance.

The next section will address common issues and troubleshooting techniques.

1. Noise Reduction

Effective noise reduction is a primary function of a vehicular exhaust noise control device. The design and construction of the device directly determine its capacity to attenuate sound waves generated by engine combustion. Without effective noise reduction, vehicles would produce unacceptably high levels of environmental noise, contributing to noise pollution. As an example, regulations often dictate maximum allowable noise levels for vehicles, necessitating the inclusion of effective noise reduction technologies in the exhaust system.

The internal baffling and sound-absorbing materials are critical elements in achieving desired noise reduction levels. Specific designs use resonators and strategically placed chambers to cancel out certain frequencies, thereby lowering the overall sound pressure level. Furthermore, the materials used in construction, such as fiberglass packing or specialized alloys, play a vital role in absorbing sound energy. Manufacturers continually refine these designs and materials to meet stricter noise regulations and consumer expectations.

In summary, noise reduction is an indispensable function; it’s performance is directly linked to the component’s design, materials, and overall effectiveness in mitigating sound pollution. Achieving optimal noise reduction is crucial for compliance with environmental regulations and ensuring comfortable vehicle operation. The future developments in this area will focus on lighter materials, more efficient designs, and intelligent noise cancellation technologies.

2. Exhaust Flow

Exhaust flow, in the context of an exhaust silencing device, is a critical parameter influencing engine performance and efficiency. The device’s design must strike a balance between noise reduction and minimizing backpressure to optimize engine output.

- Restriction and Backpressure

Excessive restriction within the muffler impedes exhaust gas expulsion, creating backpressure. This elevated pressure counteracts piston movement during the exhaust stroke, reducing engine power and fuel efficiency. A less restrictive muffler design can mitigate this issue, but must still effectively attenuate noise.

- Internal Design

The internal configuration of the muffler, including the size and placement of baffles, perforations, and chambers, directly impacts exhaust flow characteristics. A poorly designed interior can create turbulence and flow restrictions, negating any potential benefits of reduced backpressure.

- Diameter of Piping

The diameter of the inlet and outlet pipes influences the overall flow capacity. An undersized pipe diameter can act as a bottleneck, restricting exhaust flow even if the internal muffler design is optimized. Conversely, an excessively large diameter can negatively affect exhaust gas velocity, potentially reducing scavenging efficiency.

- Scavenging Effect

Optimized exhaust flow can enhance the scavenging effect within the engine cylinders. Efficient removal of exhaust gases creates a vacuum that aids in drawing in the fresh air/fuel mixture during the intake stroke, potentially improving combustion efficiency and engine power.

The interplay between noise reduction and exhaust flow demonstrates a design trade-off. Achieving optimal performance requires careful consideration of the internal muffler design, pipe diameters, and the resulting backpressure characteristics. Balancing these factors is crucial for maximizing engine power, fuel efficiency, and minimizing emissions.

3. Material Durability

Material durability is a paramount consideration in the construction of this exhaust component. The operational environment presents significant challenges, including exposure to high temperatures, corrosive exhaust gases, road salts, and mechanical stresses from vibration and impact. Failure to select materials with adequate durability can result in premature component failure, leading to increased noise levels, reduced exhaust system efficiency, and the need for costly repairs or replacements. As an example, a muffler constructed from low-grade steel is susceptible to rapid corrosion in regions with harsh winters, ultimately compromising its structural integrity and acoustic performance. The selection of appropriate materials directly correlates with the lifespan and effectiveness of the exhaust component.

The choice of materials frequently involves a trade-off between cost, weight, and durability. While stainless steel offers excellent corrosion resistance and high-temperature strength, it is more expensive than aluminized steel. Aluminized steel provides a reasonable balance of corrosion resistance and cost, making it a common choice for original equipment manufacturers. However, in applications where extreme durability is required, such as in heavy-duty trucks or performance vehicles, stainless steel or other specialized alloys may be necessary. The design of the internal baffling and structural components also influences material selection, as these elements are subjected to high levels of thermal and mechanical stress. Therefore, design engineers must carefully analyze the specific application requirements to choose the most appropriate materials.

In summary, material durability is inextricably linked to the performance and longevity of an exhaust silencing device. The component’s ability to withstand the harsh operating environment directly affects its ability to effectively reduce noise and maintain exhaust system efficiency. Selecting materials that offer a suitable balance of corrosion resistance, strength, and cost is essential for ensuring the long-term reliability and value of the vehicle. The ongoing development of new materials and manufacturing processes will continue to play a significant role in improving the durability and performance of these critical automotive components.

4. Corrosion Resistance

Corrosion resistance is a crucial attribute of any exhaust system silencing device. The lifespan and effectiveness of this component are directly linked to its ability to withstand the corrosive elements present in the exhaust stream and the external environment. Consequently, material selection and manufacturing processes heavily emphasize corrosion mitigation.

- Exhaust Gas Composition

Exhaust gases contain water vapor, carbon dioxide, sulfur oxides, and nitrogen oxides, all of which can contribute to corrosion. These gases react with the metal surfaces of the muffler, leading to oxidation and the formation of rust or other corrosive byproducts. The specific composition of exhaust gases can vary depending on fuel type and engine operating conditions, influencing the rate and type of corrosion. For example, vehicles operating on fuels with high sulfur content will experience accelerated corrosion.

- Road Salt Exposure

In regions where road salt is used for de-icing, vehicles are exposed to highly corrosive salt spray. This salt accelerates the corrosion process, particularly on the exterior surfaces of the muffler. Salt penetrates into crevices and seams, promoting crevice corrosion and undermining protective coatings. Regular washing of the vehicle’s undercarriage can help mitigate the effects of road salt exposure.

- Material Selection

The choice of materials significantly influences the corrosion resistance of the muffler. Stainless steel alloys offer superior corrosion resistance compared to aluminized steel or mild steel. However, stainless steel is more expensive and may not be cost-effective for all applications. Aluminized steel provides a reasonable compromise between cost and corrosion resistance, offering a protective layer of aluminum that inhibits rust formation. The selection of appropriate materials is crucial for ensuring the long-term durability of the muffler.

- Protective Coatings

Protective coatings, such as ceramic coatings or powder coatings, can enhance the corrosion resistance of muffler components. These coatings create a barrier between the metal surface and the corrosive environment, slowing down the rate of corrosion. The effectiveness of the coating depends on its adhesion, thickness, and resistance to abrasion and chipping. Regular inspection and maintenance of these coatings are essential for maintaining their protective properties.

In conclusion, corrosion resistance is a primary determinant of the longevity and performance of an exhaust silencing device. The ability to withstand the corrosive environment encountered during operation is vital for maintaining exhaust system integrity and minimizing noise pollution. Material selection, protective coatings, and design considerations all play a critical role in achieving optimal corrosion resistance and extending the lifespan of this component.

5. Engine Compatibility

Engine compatibility is a critical factor influencing the selection and performance of any exhaust silencing device. A mismatch between the muffler’s specifications and the engine’s characteristics can lead to a range of adverse effects, including reduced engine power, decreased fuel efficiency, and accelerated component wear. The exhaust system, including the muffler, is engineered to manage the flow of exhaust gases efficiently. An incompatible muffler can create excessive backpressure, hindering the engine’s ability to expel exhaust gases effectively. This, in turn, can lead to incomplete combustion, increased emissions, and potential engine damage. For example, installing a muffler designed for a small displacement engine on a larger, more powerful engine will likely result in significant performance degradation due to increased backpressure.

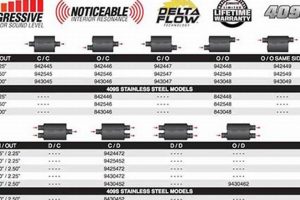

The engine’s displacement, horsepower rating, and exhaust gas volume are key parameters to consider when determining compatibility. Mufflers are typically designed to handle a specific range of exhaust flow rates. Exceeding these limits can cause the muffler to overheat, leading to premature failure of internal components. Similarly, using a muffler with insufficient flow capacity can restrict exhaust flow, negatively impacting engine performance. Furthermore, the physical dimensions of the muffler and its inlet/outlet configurations must align with the vehicle’s exhaust system layout to ensure proper installation and avoid modifications that could compromise structural integrity or exhaust system efficiency. Selecting the correct inlet and outlet diameter ensures optimal connection and minimal flow disruption.

In summary, engine compatibility is not merely a fitment issue but a critical performance and reliability consideration. Selecting a muffler designed to complement the engine’s specific characteristics is essential for maintaining optimal engine performance, fuel efficiency, and minimizing the risk of premature component failure. A thorough understanding of engine specifications and muffler design parameters is necessary to ensure a compatible and efficient exhaust system. Prioritizing engine compatibility safeguards against potential damage and maximizes the intended benefits of the exhaust silencing device.

6. Installation Complexity

Installation complexity is a significant consideration when integrating an exhaust silencing device into a vehicle. The ease or difficulty of this process can impact both the cost of the installation and the potential for errors that could compromise the device’s performance or the integrity of the exhaust system.

- Direct Fit vs. Universal Fit

Direct fit designs are engineered for specific vehicle makes and models, simplifying the installation process by matching existing mounting points and exhaust pipe diameters. Universal fit designs, conversely, require modification and fabrication to adapt to the vehicle’s exhaust system, increasing installation complexity and requiring specialized tools and skills. Using direct fit parts minimizes installation time and reduces the risk of improper connections.

- Welding Requirements

Some installations may necessitate welding to ensure secure and leak-free connections between the device and the exhaust piping. Welding adds complexity and expense to the installation process, requiring specialized equipment and expertise. Improper welding can result in exhaust leaks, reduced performance, and potential safety hazards. Clamping systems offer an alternative to welding, but may not provide the same level of durability or leak resistance.

- Accessibility and Clearance

The accessibility of the exhaust system components and the available clearance around the muffler can significantly impact installation difficulty. Limited space or obstructed access can make it challenging to maneuver the muffler into position and tighten mounting hardware. Vehicles with complex exhaust system layouts or aftermarket modifications may present additional installation challenges. Considering the available space and accessibility before commencing installation is advisable.

- Sensor Integration

Modern vehicles often incorporate oxygen sensors and other monitoring devices within the exhaust system. Proper integration of these sensors during muffler installation is crucial for maintaining accurate engine management and emissions control. Incorrectly installed or damaged sensors can trigger warning lights and negatively impact vehicle performance. Therefore, careful attention must be paid to sensor placement and wiring connections during the installation process.

Therefore, the complexity associated with its installation can influence the overall ownership experience. Proper research, careful planning, and the utilization of skilled technicians are essential for a successful and trouble-free integration. Selecting components designed for ease of installation can mitigate potential challenges and ensure optimal performance.

7. Emissions Impact

The environmental performance of a vehicle exhaust system, and specifically, its silencing component, is intrinsically linked to its ability to regulate harmful emissions. The design and condition of this component directly influence the levels of pollutants released into the atmosphere.

- Catalytic Converter Integration

The position of the silencing device in proximity to the catalytic converter affects the converter’s efficiency. If the silencing device creates excessive backpressure, it can impede the catalytic converter’s ability to function optimally, leading to increased emissions of hydrocarbons, carbon monoxide, and nitrogen oxides. The component must facilitate, not hinder, the converter’s performance.

- Backpressure Effects on Combustion

Excessive backpressure caused by a poorly designed or deteriorated silencing device negatively impacts engine combustion. Incomplete combustion results in higher emissions of unburned hydrocarbons and particulate matter. A well-designed silencing device minimizes backpressure, promoting efficient combustion and reducing the release of harmful pollutants.

- Noise Reduction vs. Flow Restriction Trade-off

The design of the silencing device must strike a balance between noise reduction and exhaust flow restriction. Aggressive noise reduction techniques can sometimes increase backpressure, leading to higher emissions. The ideal design minimizes noise without significantly impeding exhaust flow, achieving both acoustic comfort and environmental responsibility. For instance, some designs incorporate resonators that cancel specific frequencies without restricting overall flow.

- Material Degradation and Leakage

A corroded or damaged silencing device can leak exhaust gases, bypassing the catalytic converter and releasing untreated pollutants directly into the atmosphere. Material degradation reduces the component’s ability to effectively manage exhaust flow, contributing to increased emissions. Regular inspection and maintenance are crucial for preventing leaks and ensuring optimal emissions control.

Effective management of the emissions impact, therefore, demands a comprehensive approach that considers the design, integration, and maintenance of the exhaust silencing device. Its role in the overall emissions control system is undeniable; optimizing its performance contributes directly to reduced environmental pollution and improved air quality. The interplay of catalytic conversion, backpressure, and material integrity must be carefully considered to minimize a vehicle’s environmental footprint.

Frequently Asked Questions About Rogers Muffler Components

The following section addresses common inquiries regarding exhaust silencing devices, providing clarity on technical aspects and performance characteristics.

Question 1: What is the typical lifespan of a rogers muffler?

Lifespan varies significantly based on material composition, environmental conditions, and driving habits. Components constructed from stainless steel generally exhibit greater longevity than those fabricated from aluminized steel. Exposure to road salt and frequent short trips can accelerate corrosion and reduce lifespan. Under ideal conditions, a high-quality component may last upwards of seven years; however, more challenging environments can reduce this lifespan considerably.

Question 2: How does a rogers muffler affect engine performance?

A properly designed component minimizes backpressure, allowing the engine to expel exhaust gases efficiently. Excessive backpressure can reduce engine power and fuel economy. Aftermarket components marketed as “high-performance” often prioritize reduced backpressure; however, this may come at the expense of noise reduction. Matching the component to the engine’s specifications is crucial for optimal performance.

Question 3: What are the symptoms of a failing rogers muffler?

Common symptoms include increased exhaust noise, reduced fuel economy, and a visible presence of rust or physical damage. A rattling sound emanating from the exhaust system may indicate internal baffle damage. In severe cases, exhaust leaks may be detected, posing a safety hazard. Regular inspections can help identify these issues early.

Question 4: Can a rogers muffler be repaired?

Minor corrosion or small holes can sometimes be repaired using welding techniques or specialized patching compounds. However, extensive damage or significant corrosion typically necessitates replacement. Attempting to repair severely damaged components may compromise structural integrity and lead to further complications. A professional assessment is recommended to determine the feasibility of repair.

Question 5: Are all rogers mufflers created equal?

No. Variations in design, materials, and construction methods significantly impact the performance and durability of these components. Lower-priced options often utilize less durable materials and simplified designs, resulting in shorter lifespans and potentially compromised performance. Investing in a higher-quality component typically translates to improved reliability and longevity.

Question 6: How does a rogers muffler impact vehicle emissions?

While its primary function is noise reduction, a properly functioning component indirectly supports emissions control. By minimizing backpressure, it allows the engine and catalytic converter to operate more efficiently, reducing the release of harmful pollutants. A damaged or corroded component can negatively impact emissions by causing exhaust leaks and disrupting the exhaust flow.

In summary, understanding the function, maintenance, and potential issues associated with exhaust silencing devices is essential for ensuring optimal vehicle performance, environmental responsibility, and long-term reliability.

The subsequent section will provide a glossary of common terms.

Rogers Muffler

This exploration has underscored the multifaceted importance of exhaust silencing devices. The effectiveness in noise reduction, impact on engine performance, and contribution to emissions control represent critical considerations for vehicle owners and manufacturers alike. The choice of materials, design intricacies, and proper installation directly influence the device’s longevity and overall impact.

The continued evolution of automotive technology necessitates a commitment to informed decision-making regarding these essential components. Understanding their functionality and maintenance requirements will foster responsible vehicle ownership and contribute to a more sustainable transportation ecosystem. Prioritizing quality and compatibility ensures both optimal vehicle performance and a reduction in environmental impact.