A critical component of an internal combustion engine’s exhaust system, a device is designed to reduce the acoustic intensity of the sound produced by the engine. This reduction is achieved through a series of internal chambers and tubes that cause sound waves to reflect and cancel each other out, thereby diminishing the overall noise level emitted from the vehicle. For example, a typical automotive application employs one or more of these devices to ensure compliance with local noise regulations.

The functional significance of this component extends beyond mere noise abatement. By minimizing exhaust backpressure, it can contribute to improved engine performance and fuel efficiency. Historically, early iterations were rudimentary, often involving simple baffles or expansion chambers. However, modern designs are sophisticated, utilizing advanced materials and engineering principles to optimize both sound reduction and exhaust flow. The benefits include a more comfortable driving experience and reduced environmental noise pollution.

Understanding the function and design of this essential automotive part is crucial for various topics, including vehicle maintenance, performance tuning, and environmental impact assessments. Further discussion will delve into specific types, maintenance considerations, and the role it plays in overall vehicle emissions control.

Muffler Maintenance and Optimization Tips

Proper maintenance and informed selection of a vehicle’s exhaust silencing device contribute significantly to its longevity, performance, and compliance with noise regulations. The following guidelines offer practical advice for maximizing the effectiveness and lifespan of this crucial component.

Tip 1: Regular Inspection for Corrosion: The exhaust system, including the silencing device, is susceptible to corrosion due to exposure to heat, moisture, and road salts. Conduct routine visual inspections, particularly in regions with harsh winter conditions, to identify and address rust or deterioration early on.

Tip 2: Prompt Repair of Exhaust Leaks: Exhaust leaks not only increase noise levels but also compromise engine efficiency and potentially introduce harmful gases into the vehicle cabin. Address any detected leaks immediately by repairing or replacing the affected components.

Tip 3: Consider Material Upgrades: When replacement is necessary, explore options constructed from corrosion-resistant materials such as stainless steel or aluminized steel. These materials offer significantly extended lifespan compared to standard steel.

Tip 4: Optimize Exhaust Flow: The internal design of the silencing device influences exhaust flow and, consequently, engine performance. Consult with automotive professionals to select a design appropriate for the vehicle’s specific engine and performance requirements.

Tip 5: Be Mindful of Aftermarket Modifications: Modifications to the exhaust system, including the silencing device, can impact both performance and compliance with noise regulations. Ensure that any aftermarket components meet relevant legal standards and do not negatively affect engine efficiency.

Tip 6: Professional Installation Recommended: While some maintenance tasks can be performed independently, the installation of a new silencing device is best left to qualified technicians. Proper installation ensures optimal performance and prevents potential exhaust leaks.

Adhering to these guidelines ensures the ongoing effectiveness of this noise reduction device, contributing to a quieter, more efficient, and environmentally responsible vehicle operation.

These maintenance considerations are essential for ensuring the long-term functionality of the device and optimizing overall vehicle performance. The subsequent sections will address specific types and their impact on emissions control.

1. Noise Reduction

The core function of a common automotive component centers on the imperative of noise reduction. This component, a key element within a vehicle’s exhaust system, is specifically engineered to attenuate the sound generated by the internal combustion engine. The connection between this device and noise reduction is thus one of direct cause and effect: the device is the instrument, and diminished acoustic output is the intended consequence. Noise reduction’s significance stems from its role in ensuring regulatory compliance, environmental responsibility, and occupant comfort. Real-world examples demonstrate the practical impact; for instance, stringent noise ordinances in urban areas necessitate effective noise reduction strategies, making the performance of this device a crucial factor in vehicle certification and operation. Furthermore, the quality of the noise reduction directly influences the driving experience, contributing to a less fatiguing and more pleasant environment for both the driver and passengers.

The practical application of noise reduction principles within the design of this component involves intricate internal structures and acoustic dampening materials. These elements work synergistically to manipulate sound waves, causing them to interfere destructively, thereby reducing their amplitude and perceived loudness. Different designs prioritize various aspects of noise reduction, balancing performance characteristics with cost considerations and vehicle-specific requirements. For example, larger vehicles with more powerful engines often necessitate more robust devices capable of handling higher exhaust volumes and generating greater levels of sound attenuation. Moreover, advancements in material science have led to the development of lighter and more durable components, further enhancing both the effectiveness and longevity of noise reduction systems in automobiles.

In summary, effective noise reduction is not merely a desirable attribute but an essential requirement for modern vehicles, dictated by legal standards, environmental concerns, and consumer expectations. The component in question plays a pivotal role in achieving this goal, utilizing sophisticated engineering principles and materials to minimize engine noise. Challenges remain in balancing noise reduction performance with factors such as engine efficiency and cost-effectiveness. Future advancements will likely focus on optimizing these trade-offs, leading to even quieter and more environmentally sound transportation solutions. The critical relationship between the component and noise abatement underscores its continued importance in automotive engineering and environmental stewardship.

2. Exhaust System

The exhaust system is an interconnected series of components responsible for channeling exhaust gases away from an internal combustion engine. A core element within this system is a specifically designed device responsible for reducing acoustic output. This device directly influences the characteristics of the exhaust flow, shaping its path and attenuating sound waves generated during combustion. Its integration within the exhaust system is not merely additive, but essential for the system’s overall function. A deficient or improperly functioning device compromises the system’s ability to effectively manage exhaust noise, potentially leading to violations of noise pollution regulations and decreased occupant comfort. For instance, many modern automobiles utilize sophisticated exhaust systems designed to minimize emissions while simultaneously reducing noise levels, thus relying heavily on the proper performance of the noise reduction device.

The practical significance of understanding this interconnection lies in effective vehicle maintenance and emission control. Regular inspections of the exhaust system, including this noise reduction device, enable early detection of corrosion, leaks, or structural damage. Addressing these issues promptly prevents performance degradation and ensures compliance with environmental standards. Further, modifications to the exhaust system, such as installing aftermarket components, require careful consideration of their impact on both exhaust flow dynamics and noise attenuation. An ill-advised modification could negatively affect engine performance, increase noise levels, and potentially violate emission regulations. The interdependency of the system’s components necessitates a holistic approach to maintenance and upgrades.

In summary, this sound reduction device is an indispensable element within the broader exhaust system. Its function directly impacts the system’s ability to control noise emissions and maintain regulatory compliance. Proper understanding of this interconnection, coupled with diligent maintenance practices, ensures optimal performance and contributes to a quieter, more environmentally responsible vehicle operation. The challenge lies in continually optimizing designs to balance noise reduction with other critical factors such as engine efficiency and emission control. Future innovations will likely focus on creating more compact, durable, and efficient components that seamlessly integrate within advanced exhaust system architectures.

3. Engine Performance

A critical aspect of internal combustion engine operation is engine performance, which is intricately linked to the design and functionality of a sound-dampening device integrated within the exhaust system. This device directly influences engine performance by modulating exhaust backpressure. Excessive backpressure can impede the efficient expulsion of exhaust gases, leading to reduced volumetric efficiency, increased pumping losses, and diminished power output. Conversely, insufficient backpressure can negatively affect cylinder scavenging and combustion efficiency, particularly at lower engine speeds. Therefore, the selection and configuration of this sound reduction device must carefully balance noise attenuation requirements with the need to maintain optimal engine performance characteristics. Examples include selecting a straight-through design for high-performance applications to minimize backpressure, or employing a baffled design for quieter operation in standard vehicles, each prioritizing different aspects of engine function.

The practical significance of understanding this relationship lies in effective vehicle maintenance, performance tuning, and component selection. Replacing a damaged or corroded device with one that introduces excessive backpressure can significantly reduce engine power and fuel economy. Similarly, modifying the exhaust system to achieve a desired sound characteristic without properly accounting for backpressure effects can lead to suboptimal engine performance and potential long-term damage. Moreover, advanced engine control systems often rely on feedback from exhaust gas sensors to optimize combustion parameters. Deviations from expected exhaust flow characteristics, induced by a poorly designed sound attenuation device, can disrupt the control system’s operation and compromise engine efficiency. The interplay is nuanced, demanding a holistic understanding of exhaust gas dynamics.

In summary, engine performance is directly influenced by the exhaust system component designed to reduce noise. The optimization challenge involves achieving acceptable noise reduction levels without compromising engine power, fuel efficiency, or emission control. Future advancements will likely focus on developing adaptive devices that can dynamically adjust backpressure based on engine operating conditions, thereby maximizing both performance and noise attenuation across a wider range of vehicle applications. A thorough comprehension of the cause-and-effect relationship between this component and engine behavior is essential for ensuring optimal vehicle operation and longevity.

4. Material Durability

Material durability is a paramount consideration in the design and lifespan of a device intended to reduce sound emitted from a vehicle’s exhaust system. This device is subjected to a harsh operating environment, characterized by elevated temperatures, corrosive exhaust gases, exposure to road salts and moisture, and mechanical stresses resulting from vibrations and impacts. Consequently, the selection of materials directly impacts the component’s ability to withstand these conditions and maintain its functionality over an extended period. The use of inferior materials inevitably leads to premature failure, necessitating replacement and increasing maintenance costs. A real-world example is the contrast between standard steel and stainless steel: the former is highly susceptible to rust and corrosion, while the latter offers superior resistance, significantly extending the device’s service life. The practical significance of understanding this relationship lies in making informed decisions regarding replacement parts and preventative maintenance strategies.

Further analysis reveals the importance of material properties such as tensile strength, yield strength, and resistance to thermal fatigue. The device must be able to withstand the mechanical stresses induced by exhaust pressure and vehicle vibrations without experiencing structural failure. Moreover, resistance to thermal fatigue is crucial, as the component undergoes repeated heating and cooling cycles during engine operation. The choice of materials also influences the device’s ability to maintain its acoustic performance over time. Corrosion or degradation of internal components can alter the sound absorption characteristics, leading to increased noise levels and potential regulatory non-compliance. For instance, some high-performance devices utilize exotic alloys or ceramic coatings to enhance both durability and thermal management, further improving their overall effectiveness. These specialized materials offer an edge in demanding applications.

In summary, material durability is intrinsically linked to the long-term performance and reliability of a vehicle’s exhaust silencing device. The operating environment imposes stringent demands on the materials used in its construction, requiring careful consideration of factors such as corrosion resistance, mechanical strength, and thermal stability. The key challenge lies in balancing material costs with the desired level of durability and performance, necessitating informed engineering decisions and a thorough understanding of material science principles. Future advancements will likely focus on developing lighter, stronger, and more corrosion-resistant materials that can withstand even more extreme operating conditions, ensuring quieter and more reliable vehicle operation.

5. Legal Compliance

Legal compliance is directly related to devices designed to reduce sound emitted from vehicles. Noise regulations, often established at local, state, and federal levels, mandate maximum permissible sound levels for operating motor vehicles. The sound-reducing device is a primary component used to ensure vehicles meet these regulations. Failure to comply with noise ordinances can result in fines, vehicle impoundment, or operational restrictions. For example, many jurisdictions conduct roadside noise level checks, where vehicles exceeding the established decibel limits are issued citations. The device’s function is thus not merely a matter of comfort or preference, but a legal requirement for vehicle operation. The practical significance of understanding this connection lies in avoiding penalties and ensuring the vehicle’s continued legal operation.

Further analysis reveals the complexity of noise regulations. Some regulations specify different permissible sound levels based on vehicle type, speed, or time of day. In such cases, the sound-reducing device must be carefully selected and maintained to ensure compliance under various operating conditions. Modifications to the exhaust system that increase noise levels beyond legal limits are also frequently prohibited and subject to penalties. Vehicle manufacturers must design and equip their vehicles with sound-reducing devices that meet all applicable regulations at the time of sale. The continuous evolution of these regulations necessitates ongoing monitoring and adaptation to maintain legal compliance. The device’s sound-dampening properties serve as a key benchmark for regulatory adherence.

In summary, legal compliance is a critical driver in the design, installation, and maintenance of sound-reducing devices in motor vehicles. Noise regulations impose enforceable limits on vehicle sound emissions, making the function of this device a legal imperative. The challenge lies in achieving effective noise reduction while balancing other factors, such as engine performance and cost. Staying informed about evolving noise regulations and ensuring the sound-reducing device is functioning correctly are essential for avoiding legal penalties and maintaining responsible vehicle operation.

6. Backpressure Impact

The design and functionality of a device intended to attenuate sound within an exhaust system critically influence exhaust backpressure. This backpressure, a resistance to the flow of exhaust gases, directly affects engine performance characteristics. Understanding the nuances of this relationship is essential for optimizing engine efficiency and power output.

- Engine Efficiency and Power Loss

Excessive backpressure impedes the evacuation of exhaust gases from the cylinders, resulting in reduced volumetric efficiency. This leads to incomplete combustion, increased pumping losses, and a measurable reduction in engine power and fuel economy. An improperly designed or clogged exhaust silencing device can significantly contribute to this detrimental effect. For example, a device with overly restrictive internal passages creates a bottleneck, hindering the free flow of exhaust gases and negatively impacting engine performance.

- Cylinder Scavenging and Combustion

The pressure dynamics within the exhaust system also play a crucial role in cylinder scavenging, the process of removing spent gases from the cylinder before the intake stroke. Inadequate backpressure can disrupt this scavenging process, leading to residual exhaust gases remaining in the cylinder. This contaminates the incoming air-fuel mixture, resulting in less efficient combustion and increased emissions. A properly tuned exhaust system, including a carefully selected device, ensures optimal scavenging for improved engine performance and reduced emissions.

- Torque Characteristics and Engine Response

The level of backpressure influences the torque characteristics of the engine, particularly at lower engine speeds. Excessive backpressure can improve low-end torque in some engine designs, but at the expense of high-end power. Conversely, insufficient backpressure can reduce low-end torque, resulting in sluggish engine response. A properly designed exhaust device balances these trade-offs to optimize engine performance across the entire operating range. Engine response dictates acceleration.

- Catalytic Converter Functionality

The efficiency of the catalytic converter, a vital component for emissions control, can be influenced by exhaust backpressure. Excessive backpressure can elevate exhaust gas temperatures, potentially damaging the catalytic converter and reducing its ability to effectively convert harmful pollutants into less harmful substances. Maintaining optimal backpressure levels is therefore crucial for ensuring both engine performance and environmental compliance. The device must not only perform the primary role of dampening sound, but it must also allow the gases to be effectively filtered.

In summary, the backpressure generated by this device is a critical factor influencing engine performance, emissions, and overall vehicle efficiency. Balancing noise attenuation with minimal backpressure requires careful design and selection of appropriate internal structures and materials. Understanding these interdependencies is essential for optimizing exhaust system performance and ensuring long-term engine health.

7. Maintenance Requirements

The operational lifespan and effectiveness of a noise reduction device are intrinsically linked to adherence to specific maintenance requirements. These requirements stem from the device’s constant exposure to harsh operating conditions, including high temperatures, corrosive exhaust gases, and physical stresses from road debris and vehicle vibrations. Neglecting maintenance results in diminished noise reduction performance, potential engine inefficiency, and eventual component failure. For example, corrosion, if left unaddressed, weakens the device’s structural integrity, leading to exhaust leaks and increased noise emissions. Regular inspection and prompt remediation of such issues are critical. The practical significance of understanding these maintenance demands lies in preventing costly repairs and ensuring continued compliance with noise regulations.

Further analysis reveals specific maintenance tasks essential for preserving the device’s functionality. Visual inspections for rust, cracks, and physical damage should be conducted periodically. Exhaust leaks, often indicated by unusual noises or decreased fuel efficiency, warrant immediate attention. In regions with harsh winter conditions, rinsing the undercarriage of the vehicle to remove road salts minimizes corrosion. Replacement of worn or corroded mounting hardware prevents vibrations and ensures proper alignment. Additionally, considering the device’s lifespan and usage patterns, proactive replacement before complete failure mitigates potential performance degradation and associated consequences. These practices exemplify proactive maintenance strategies that enhance component longevity.

In summary, diligent attention to maintenance requirements is indispensable for maintaining the performance and extending the lifespan of a vehicle’s noise reduction device. Regular inspections, prompt repairs, and preventative measures such as corrosion protection and timely replacement are essential for ensuring optimal function and compliance with noise regulations. The primary challenge lies in raising awareness among vehicle owners regarding the importance of this often-overlooked aspect of vehicle maintenance, ultimately contributing to quieter and more environmentally responsible transportation. The relationship between the device and its upkeep highlights the broader theme of responsible vehicle ownership and maintenance.

Frequently Asked Questions About a Sound-Reducing Exhaust System Component

This section addresses common inquiries and dispels misconceptions regarding a critical automotive component designed to attenuate engine noise. The following questions and answers provide a comprehensive overview of its functionality, maintenance, and importance.

Question 1: What precisely does this component do within a vehicle?

The primary function of this component is to reduce the sound intensity emanating from the engine’s exhaust. This is accomplished through a series of internal chambers and passageways that manipulate sound waves, causing them to cancel each other out, thereby diminishing the overall noise level.

Question 2: How does a malfunctioning device affect engine performance?

A device that is damaged, clogged, or improperly designed can increase exhaust backpressure, impeding the efficient expulsion of exhaust gases. This can lead to reduced engine power, decreased fuel economy, and potential engine damage over time.

Question 3: What are the key indicators of a failing or deficient component?

Common indicators include an increase in exhaust noise, a rattling sound emanating from the exhaust system, visible corrosion or damage to the device, and a decrease in fuel efficiency. A qualified mechanic can perform a thorough inspection to diagnose the issue.

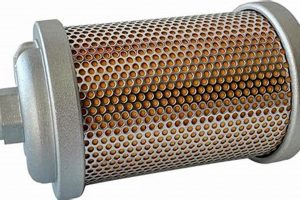

Question 4: Are there different types of these sound-dampening devices, and how do they differ?

Yes, several types exist, each employing different noise reduction techniques. Baffled devices use a series of partitions to reflect sound waves, while absorption devices utilize sound-absorbing materials to dampen noise. Straight-through designs offer minimal backpressure but may provide less noise reduction. The choice depends on the vehicle’s requirements and desired performance characteristics.

Question 5: Is it possible to enhance the performance of this sound reduction device?

While modifications are possible, it is crucial to ensure that any changes comply with local noise regulations and do not negatively impact engine performance. Selecting a higher-quality replacement device or optimizing exhaust flow can improve overall performance, but professional installation is recommended.

Question 6: What are the environmental implications of a poorly functioning sound-reducing device?

A device that fails to adequately reduce exhaust noise contributes to noise pollution, impacting the quality of life in surrounding areas. Additionally, if the device’s malfunction affects engine performance, it can lead to increased fuel consumption and higher emissions of harmful pollutants.

Understanding these fundamental aspects contributes to informed decision-making regarding vehicle maintenance and environmental responsibility. This knowledge empowers owners to ensure optimal vehicle performance while minimizing negative impacts.

The subsequent section will explore advanced designs and future trends in sound reduction technology.

Conclusion

This exploration has elucidated the function, maintenance, and significance of a noise-reducing device within a vehicle’s exhaust system. Its pivotal role in attenuating engine noise, impacting engine performance, ensuring legal compliance, and contributing to environmental responsibility has been thoroughly examined. The multifaceted aspects of this component, from material durability to backpressure impact, underscore its importance in the overall automotive ecosystem.

Recognizing the complex interdependencies associated with this system allows for informed decisions regarding vehicle maintenance, performance optimization, and environmental stewardship. Continued innovation and diligent upkeep of this vital component remain essential for fostering quieter, more efficient, and environmentally conscious transportation solutions. Its continued evolution will further contribute to the balance between noise reduction, performance requirements, and regulatory standards.