The device, associated with a specific individual, functions to reduce the noise emitted by an internal combustion engine. It achieves this by channeling exhaust gases through a series of chambers and passages designed to dampen sound waves. For example, an automotive vehicle might employ this kind of mechanism to comply with local noise ordinances and enhance the driving experience.

The implementation of such a component is crucial for maintaining environmental sound quality and public health by minimizing noise pollution. Its development reflects a history of engineering advancements aimed at balancing engine performance with societal well-being, playing a key role in the evolution of quieter and more socially responsible transportation technologies. Effective noise reduction also contributes to improved vehicle performance, potentially increasing fuel efficiency and extending the lifespan of other exhaust system components.

Understanding its purpose and function lays the groundwork for a broader discussion regarding exhaust systems, emission control technologies, and automotive maintenance best practices. Further exploration will involve examining different designs, materials, and repair methodologies associated with this essential part. This sets the stage for a deeper examination of how these components influence vehicle operation and environmental impact.

Maintenance and Longevity Tips

Proper care and maintenance are essential to maximize the lifespan and performance of exhaust noise reduction systems. Implementing these strategies can significantly reduce the likelihood of premature failure and ensure continued compliance with noise regulations.

Tip 1: Regular Visual Inspection: Conduct periodic visual inspections for signs of rust, corrosion, or physical damage. Early detection of these issues allows for timely repairs and prevents more extensive damage.

Tip 2: Promptly Address Exhaust Leaks: Any exhaust leaks, indicated by unusual noises or reduced engine performance, should be addressed immediately. Leaks can compromise noise reduction effectiveness and potentially lead to safety hazards.

Tip 3: Proper Engine Tuning: Ensure the engine is properly tuned. An improperly tuned engine can produce excessive exhaust temperatures, accelerating wear on the noise reduction device and other exhaust components.

Tip 4: Avoid Short Trips: Frequent short trips can lead to the accumulation of condensation within the exhaust system, promoting corrosion. Longer trips allow the system to heat up sufficiently to evaporate this moisture.

Tip 5: Use Quality Replacement Parts: When replacement is necessary, use high-quality parts that meet or exceed original equipment manufacturer (OEM) specifications. Inferior parts may not provide adequate noise reduction or durability.

Tip 6: Professional Installation: Ensure that installation of new or replacement components is performed by a qualified technician. Improper installation can lead to leaks, damage, and reduced effectiveness.

Tip 7: Consider Protective Coatings: Applying a heat-resistant, anti-corrosion coating can significantly extend the lifespan of the system, particularly in environments with high road salt exposure.

Adhering to these preventative maintenance practices will contribute to the longevity, efficiency, and overall performance of the exhaust noise reduction apparatus. Consistent upkeep minimizes potential disruptions and ensures continued compliance with environmental standards.

The next section will detail common troubleshooting techniques associated with these parts, providing practical guidance for identifying and resolving typical operational issues.

1. Noise reduction effectiveness

Noise reduction effectiveness represents a primary performance metric for the device in question. It quantifies the degree to which the component reduces the sound pressure levels generated by an internal combustion engine’s exhaust. Without adequate noise reduction, the engine’s operation would create excessive noise pollution, violating local noise ordinances and diminishing the quality of life for individuals in proximity to the vehicle. The design and construction directly influence this characteristic, with factors like internal chamber size, baffle placement, and insulation material impacting overall sound attenuation. A decrease in effectiveness implies the device is degrading, signifying potential internal damage or corrosion that is impeding its ability to dissipate sound waves effectively. The decibel level is measured.

The performance of the system is vital not only for environmental compliance but also for enhancing the driving experience. Excessive engine noise can be distracting and fatiguing for the driver and passengers, particularly on long journeys. By effectively minimizing noise, the driver can experience a more comfortable and focused driving environment, leading to increased safety and reduced stress. Example, a faulty system that causes increased noise will affect the nearby community.

In summary, noise reduction capability is critical to the device. A properly functioning system contributes to both environmental responsibility and improved user experience. Maintaining optimal performance through regular inspections and timely repairs is essential to ensure continued compliance with noise regulations and to mitigate potential negative impacts on public health and well-being. Furthermore, advancements in noise reduction technology continue to drive the development of more efficient and environmentally friendly vehicles.

2. Material Durability

Material durability is intrinsically linked to the lifespan and performance of the exhaust noise reduction component. The harsh operating environment, characterized by high temperatures, corrosive exhaust gases, and exposure to road debris and moisture, necessitates the use of robust materials capable of withstanding these conditions. A failure in material integrity can lead to premature degradation of the noise reduction capabilities, rendering the device ineffective and potentially creating safety hazards. For instance, the selection of low-grade steel can result in rapid corrosion, leading to exhaust leaks and increased noise emissions, negating the intended benefits of the device. Such a failure would also lead to non-compliance with noise regulations.

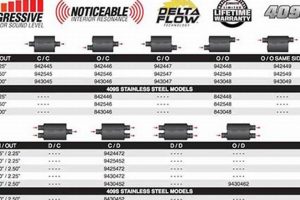

The choice of materials, therefore, constitutes a critical design consideration. Stainless steel, aluminized steel, and specialized alloys are frequently employed due to their superior resistance to corrosion and high-temperature degradation. The thickness of the material also plays a crucial role, with thicker gauges providing increased resistance to physical damage from impacts and vibrations. Furthermore, the quality of welds and joints must be high to prevent premature failure due to stress concentration and corrosion. The implementation of a durable, high-quality material ensures the function will continue to maintain noise reduction effectivness.

In conclusion, material durability is paramount for ensuring the long-term functionality and reliability of the noise reduction system. Selecting appropriate materials and employing robust manufacturing techniques are essential for minimizing the risk of premature failure and maintaining compliance with environmental regulations. Prioritizing material quality represents a cost-effective strategy, reducing the need for frequent replacements and minimizing potential disruptions caused by system malfunctions. Understanding the material properties is key to creating the best product for noise reduction.

3. Exhaust flow optimization

Exhaust flow optimization within a muffler assembly, such as the one associated with the name “bobby,” directly influences engine performance and efficiency. The primary function of the muffler is to attenuate noise generated by the engine’s combustion process. However, this noise reduction should not come at the expense of increased backpressure, which impedes the expulsion of exhaust gases. Optimized exhaust flow aims to minimize this backpressure while still achieving desired sound levels. A poorly designed muffler can create excessive restriction, leading to reduced engine power, increased fuel consumption, and potential engine overheating. The design of internal baffles and chambers is crucial to achieving this balance. For example, a straight-through muffler design generally offers better flow than a chambered design, but it may not provide the same level of noise reduction.

Real-world applications demonstrate the practical significance of this understanding. Automotive engineers invest considerable resources in Computational Fluid Dynamics (CFD) simulations to model exhaust gas flow within muffler designs. This allows them to optimize internal geometries to minimize backpressure and turbulence, while simultaneously achieving target noise reduction levels. Aftermarket performance mufflers often advertise improved exhaust flow, claiming horsepower gains resulting from reduced restriction. However, it is essential to note that the actual gains may vary depending on the specific engine and vehicle modifications. Optimizing flow requires balancing the amount of chamber and perforations.

In summary, exhaust flow optimization is an integral component of muffler design, directly impacting engine performance, fuel efficiency, and noise levels. While mufflers are essential for meeting noise regulations and enhancing driving comfort, their design must carefully consider the trade-offs between noise reduction and exhaust flow restriction. Advancements in simulation and manufacturing technologies continue to improve muffler designs, enabling engineers to achieve better performance and environmental compliance. Understanding the dynamics is key to improved performance.

4. Corrosion resistance

Corrosion resistance is a critical attribute for any exhaust system component, particularly a muffler, due to its constant exposure to harsh environmental conditions. The longevity and effective performance of “bobby’s muffler” are directly contingent upon its ability to withstand corrosive forces.

- Material Selection and Protective Coatings

The choice of materials, such as stainless steel or aluminized steel, dictates the inherent corrosion resistance of the muffler. These materials form a passive oxide layer, impeding further oxidation. Additionally, protective coatings, such as ceramic-based paints or specialized polymer coatings, are frequently applied to provide an extra barrier against corrosion. For example, a stainless-steel muffler with a ceramic coating will exhibit superior corrosion resistance compared to a mild steel muffler with no coating.

- Internal Condensation and Acidic Byproducts

During engine operation, combustion byproducts, including water vapor and acidic gases (e.g., sulfur dioxide), are produced. When the exhaust system cools, water vapor condenses, forming a corrosive liquid. The acidic components exacerbate this effect, accelerating the corrosion process. The internal design of the muffler should facilitate drainage to minimize the accumulation of corrosive condensates. For instance, strategically placed drain holes can prevent the pooling of liquids, thereby extending the lifespan of the muffler.

- Road Salt and Environmental Exposure

In regions where road salt is used for de-icing, the exhaust system is subjected to increased corrosive attack. Road salt, typically sodium chloride, readily dissolves in water and creates an electrolyte solution that accelerates the corrosion of metals. Furthermore, atmospheric pollutants and humidity contribute to corrosion. Regular washing of the vehicle, especially during winter months, can mitigate the accumulation of road salt and reduce its corrosive effects on the muffler.

- Welding and Fabrication Techniques

The quality of welds and fabrication techniques significantly impacts corrosion resistance. Improper welding can create crevices and stress concentrations, which are susceptible to corrosion. The use of proper welding procedures, such as gas tungsten arc welding (GTAW), and the application of corrosion-resistant welding consumables are essential. Post-weld treatments, such as passivation, can further enhance corrosion resistance by removing surface contaminants and promoting the formation of a protective oxide layer. For instance, poorly executed welds can become preferential sites for corrosion initiation, leading to premature muffler failure.

The interplay of these factors underscores the importance of corrosion resistance in ensuring the durability and reliable performance of “bobby’s muffler”. Proper material selection, design considerations, and maintenance practices are crucial for mitigating corrosion and maximizing the lifespan of the exhaust system component.

5. Legal compliance

Legal compliance, regarding exhaust systems, constitutes a critical aspect of automotive operation and environmental stewardship. Regulations governing noise emissions and exhaust modifications directly impact the design, maintenance, and legality of components such as a muffler.

- Noise Emission Standards

Noise emission standards, established by federal, state, and local authorities, dictate the maximum permissible sound levels produced by a vehicle. Mufflers play a crucial role in attenuating engine noise to comply with these regulations. Exceeding noise limits can result in fines, vehicle impoundment, or mandatory repairs. For instance, an aftermarket exhaust system lacking adequate muffling capabilities may render a vehicle non-compliant, leading to legal repercussions during vehicle inspections or roadside enforcement.

- Anti-Tampering Laws

Anti-tampering laws prohibit the modification or removal of emission control devices, including mufflers, if such alterations compromise the vehicle’s compliance with emission standards. Replacing a factory-installed muffler with a straight pipe, which eliminates noise reduction, would violate these laws in many jurisdictions. Violations can result in substantial penalties for both the vehicle owner and any involved repair facilities.

- State and Local Ordinances

Specific state and local ordinances may impose additional restrictions on vehicle exhaust systems. These may include limitations on the type of modifications permitted, restrictions on vehicle operation during certain hours, or specific requirements for muffler design. For example, some jurisdictions may prohibit the use of “cutouts” or bypass valves that allow exhaust gases to bypass the muffler, thereby increasing noise levels. Non-compliance can result in fines or the requirement to restore the exhaust system to its original configuration.

- Inspection and Enforcement

Vehicle inspections, conducted periodically by authorized agencies, often include assessments of the exhaust system to ensure compliance with noise and emission regulations. Inspectors may visually examine the muffler for modifications, test noise levels using calibrated equipment, or verify the presence of required emission control components. Failure to pass inspection can prevent vehicle registration renewal or require the owner to undertake corrective repairs to achieve compliance. Therefore, retaining documentation that proves the muffler meets applicable legal guidelines is an ideal measure for protection.

The interplay of noise and emission standards, anti-tampering laws, state and local ordinances, and enforcement mechanisms underscores the significance of legal compliance in relation to vehicle exhaust systems. Modifying or neglecting the device can result in significant penalties and compromise the vehicle’s legality. Adherence to these regulations is paramount for responsible vehicle ownership and environmental protection.

6. Engine performance impact

The operational characteristics of exhaust noise reduction devices, such as a muffler, directly influence engine performance. A primary function of this component is to attenuate noise generated by the combustion process. However, this noise reduction can introduce backpressure within the exhaust system. Excessive backpressure impedes the efficient expulsion of exhaust gases from the engine cylinders, diminishing volumetric efficiency and, consequently, reducing power output. The internal design of a specific design, including baffle configuration and chamber dimensions, governs the extent of backpressure. The magnitude of this effect depends on both the design of the component itself and the characteristics of the engine it is paired with. For example, a high-performance engine, generating a significant volume of exhaust gases, may be more sensitive to backpressure than a low-output engine.

The implementation of carefully optimized designs can mitigate negative impacts on engine performance. Straight-through muffler designs, characterized by a relatively unobstructed flow path, minimize backpressure while still providing a degree of noise reduction. Computer-aided design and computational fluid dynamics (CFD) are employed to model exhaust gas flow within muffler designs, enabling engineers to optimize internal geometries for minimal restriction. The aftermarket automotive industry provides numerous examples of performance mufflers claiming horsepower gains resulting from reduced backpressure. However, independent testing is often required to validate these claims, as the actual gains can vary significantly depending on factors such as engine modifications and overall exhaust system design. The size of the chamber affects the performance.

In summary, understanding the relationship between exhaust noise reduction components and engine performance is crucial for optimizing both sound attenuation and power output. While mufflers are necessary for legal compliance and driver comfort, their design must carefully balance the conflicting demands of noise reduction and exhaust flow restriction. Employing advanced design techniques and selecting appropriate components can minimize negative impacts on engine performance and ensure efficient operation. Further study should evaluate design and the performance.

7. Proper Installation

Correct mounting procedures are paramount for the long-term performance and reliability of the part. Incorrect installation can lead to a cascade of detrimental effects, ranging from compromised noise reduction to accelerated wear and potential safety hazards. The design and construction of the component are predicated on precise fitment within the vehicle’s exhaust system. Deviations from specified installation guidelines can introduce stresses, misalignments, and leaks that undermine its intended function. As a tangible example, an improperly secured part may vibrate excessively, leading to premature fatigue and eventual failure of the mounting hardware or even the device itself. Furthermore, exhaust leaks resulting from inadequate sealing not only diminish noise reduction but also introduce the risk of carbon monoxide exposure.

Ensuring correct installation requires adherence to manufacturer specifications, utilization of appropriate tools and techniques, and verification of proper alignment and sealing. Torque specifications for fasteners must be meticulously followed to avoid over-tightening or under-tightening, both of which can compromise the integrity of the connection. Gaskets and sealing compounds should be applied correctly to prevent exhaust leaks. In addition, the alignment of the exhaust system must be checked to ensure that the newly installed device is not subjected to undue stress. Professional installation by a qualified technician is often recommended, particularly for individuals lacking the requisite skills and experience.

In summary, proper installation is an indispensable element of “bobby’s muffler’s” overall performance and longevity. Failure to adhere to specified installation procedures can negate the benefits of even the highest-quality component, leading to diminished performance, accelerated wear, and potential safety risks. A meticulous approach to installation, encompassing adherence to specifications, utilization of appropriate tools, and verification of proper alignment and sealing, is essential for ensuring that this design functions as intended and contributes to a safe and environmentally responsible vehicle operation.

Frequently Asked Questions about “bobby’s muffler”

The following addresses frequently raised inquiries concerning noise reduction systems. These points are intended to clarify common misconceptions and provide comprehensive insight.

Question 1: What is the expected lifespan of a noise reduction mechanism?

Lifespan varies considerably based on material composition, operating conditions, and maintenance practices. Components fabricated from stainless steel and operated under moderate conditions may last upwards of 10 years. Conversely, those constructed from less durable materials or subjected to extreme operating environments may require replacement within 3 to 5 years.

Question 2: Does the modification of exhaust systems affect a vehicle’s warranty?

Modifications to the exhaust system may, under certain circumstances, void portions of the vehicle’s warranty. It is advisable to consult the vehicle manufacturer’s warranty documentation or seek clarification from an authorized dealer to determine the potential impact of such modifications.

Question 3: How does a faulty noise reduction mechanism affect fuel efficiency?

A malfunctioning noise reduction device, typically due to increased backpressure, can negatively affect fuel efficiency. Excessive backpressure hinders the efficient expulsion of exhaust gases, forcing the engine to work harder, thereby increasing fuel consumption. This can be addressed by improving the functionality of the part.

Question 4: What are the auditory indicators of a failing noise reduction system?

Common auditory indicators of a failing system include increased exhaust noise, rattling sounds, or hissing noises emanating from the undercarriage. These sounds typically suggest leaks, internal damage, or component degradation, warranting prompt inspection and repair.

Question 5: Is it possible to enhance the noise reduction capabilities of an existing system?

Enhancement options are limited and often depend on the design and condition of the existing system. The addition of supplemental noise reduction devices or the replacement with a higher-performing component may yield marginal improvements; however, complete replacement often yields the most substantial gains.

Question 6: What are the legal ramifications of operating a vehicle with an excessively loud exhaust?

Operating a vehicle with an exhaust system that exceeds permissible noise levels can result in fines, citations, or mandatory vehicle inspections. Noise regulations vary by jurisdiction, necessitating adherence to local ordinances and statutes.

Understanding these critical points equips individuals with the necessary knowledge to maintain their vehicles responsibly and in accordance with relevant regulations.

The subsequent section provides detailed guidance on selecting an optimal system for specific vehicle applications.

Conclusion

This discourse has comprehensively examined the function, maintenance, and regulatory considerations surrounding “bobby’s muffler.” Key areas of focus have included noise reduction effectiveness, material durability, exhaust flow optimization, and legal compliance. These facets underscore the component’s pivotal role in mitigating noise pollution, maintaining vehicle performance, and adhering to environmental regulations. Understanding the intricacies of its function is paramount for effective vehicle maintenance and responsible environmental stewardship.

Given the critical function this element serves in both vehicle operation and environmental protection, continued awareness and responsible upkeep are imperative. Further research and technological advancements should focus on enhancing material durability and optimizing designs to achieve greater noise reduction with minimal impact on engine performance. Prioritizing responsible vehicle maintenance and remaining informed about evolving regulations are essential for ensuring continued compliance and promoting environmental well-being.