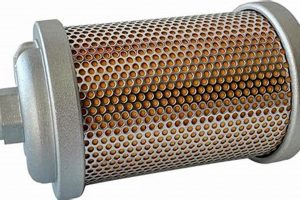

A device attached to the exhaust system of a combustion engine designed to reduce the acoustic intensity of the engine’s exhaust. Primarily utilized in motorcycles and automobiles, it functions by attenuating sound waves through a series of chambers and baffles, absorbing and deflecting the pressure pulses generated by the engine’s combustion process.

The reduction in exhaust noise contributes to regulatory compliance, enhanced rider or driver comfort, and a decrease in environmental noise pollution. Throughout the automotive and motorcycle industries, manufacturers and aftermarket suppliers have continually developed designs to optimize noise reduction capabilities while striving to minimize backpressure, which can negatively impact engine performance. The development of these components has often paralleled advancements in engine technology and noise control engineering.

The subsequent sections will delve into the specifics of design variations, performance characteristics, materials used in construction, and factors to consider when selecting a suitable option for a given application.

M4 Muffler

Proper selection, installation, and maintenance of a device of this type can significantly impact vehicle performance, sound levels, and lifespan. Adherence to the following guidelines is recommended.

Tip 1: Confirm Compatibility: Prior to purchase, ensure the chosen unit is explicitly designed for the target vehicle’s make, model, and year. Incompatible models can negatively affect exhaust flow and engine operation.

Tip 2: Evaluate Materials: Stainless steel and titanium are prevalent materials due to their durability and corrosion resistance. Consider the operating environment and select a material accordingly.

Tip 3: Assess Sound Output: Evaluate the desired sound level. Options range from street-legal, quieter versions to race-oriented, louder configurations. Local regulations regarding noise emissions must be considered.

Tip 4: Inspect Welding Quality: Examine the welding seams for uniformity and integrity. Poor welding can lead to premature failure and exhaust leaks.

Tip 5: Ensure Proper Installation: Follow the manufacturer’s installation instructions precisely. Incorrect installation can compromise performance and structural integrity.

Tip 6: Conduct Regular Inspections: Periodically inspect the unit for signs of damage, corrosion, or leaks. Address any issues promptly to prevent further deterioration.

Tip 7: Clean Periodically: Depending on the environment, regular cleaning may be necessary to remove road debris and prevent corrosion. Use appropriate cleaning products designed for the specific material.

Following these guidelines will contribute to the longevity, optimal performance, and regulatory compliance of this exhaust system component.

The subsequent section will address troubleshooting common issues associated with these systems and provide potential solutions.

1. Sound Attenuation and Exhaust Systems

Sound attenuation, the reduction of acoustic energy, is a primary function of an exhaust system component designed to mitigate noise generated by internal combustion engines. The efficacy of this component is intrinsically linked to its ability to control and diminish exhaust noise to meet regulatory standards and enhance user experience.

- Internal Baffle Design

The arrangement of internal baffles within the component is critical for sound attenuation. These baffles create a complex pathway for exhaust gases, causing sound waves to reflect, interfere destructively, and dissipate energy as heat. The specific design including baffle shape, size, and placement directly influences the frequency and amplitude of sound waves that are attenuated. For example, a chambered design may target specific frequencies to reduce droning at cruising speeds, while a perforated core promotes broader frequency attenuation for overall noise reduction.

- Acoustic Absorption Materials

Many designs incorporate sound-absorbing materials, such as fiberglass packing or steel wool, within the muffler body. These materials convert acoustic energy into thermal energy through friction and viscous damping. The type and density of the absorption material significantly affect the muffler’s ability to attenuate sound. Over time, these materials can degrade, reducing their effectiveness and requiring replacement. A performance design might use tightly packed, high-temperature-resistant materials for extended durability.

- Resonance Chamber Tuning

Some components employ resonance chambers, strategically sized cavities designed to cancel out specific frequencies through destructive interference. The size and shape of the resonance chamber are carefully calculated to target dominant frequencies in the exhaust noise spectrum. Proper tuning of the resonance chamber is essential for effective noise cancellation. An improperly tuned chamber can actually amplify certain frequencies, increasing overall noise levels. This approach is common in systems designed to eliminate specific droning noises.

- Exhaust Gas Flow Dynamics

The design of the component must balance sound attenuation with minimal restriction of exhaust gas flow. Excessive backpressure can reduce engine performance, negating the benefits of noise reduction. A well-designed system minimizes flow restriction while maximizing sound attenuation through optimized internal geometries and flow paths. The trade-off between noise reduction and performance is a crucial consideration in the design and selection of the component. A system with a larger diameter and straighter flow path will generally offer less sound attenuation but higher performance.

In summary, the capacity to effectively attenuate sound hinges on a multifaceted design approach that integrates internal baffle configurations, acoustic absorption materials, resonance chamber tuning, and exhaust gas flow dynamics. Optimizing these elements allows for the creation of components that effectively control exhaust noise while minimizing adverse impacts on engine performance. The selection of this component involves a careful consideration of application-specific requirements and desired performance characteristics.

2. Flow Optimization

Flow optimization within the design of an exhaust component directly impacts engine performance and efficiency. The minimization of exhaust gas restriction is a critical objective, as excessive backpressure can impede the engine’s ability to expel exhaust gases efficiently, resulting in reduced power output and increased fuel consumption. The subsequent points delineate key facets of flow optimization in relation to these exhaust system components.

- Core Design and Diameter

The internal diameter of the core, and its overall design, significantly influences exhaust gas flow. A larger diameter and a smoother internal surface minimize flow resistance. Perforated cores, common in some designs, must balance the need for sound attenuation with the need for unrestricted flow. The size and density of perforations directly affect backpressure. Performance-oriented designs often prioritize a larger diameter and a more direct flow path to reduce backpressure at the expense of some sound attenuation.

- Baffle Configuration

The arrangement and design of internal baffles play a crucial role in controlling exhaust gas flow. Baffles that create abrupt changes in direction or restrict the flow path can increase backpressure. Optimized baffle designs incorporate smooth curves and gradual expansions to minimize flow resistance while still providing effective sound attenuation. The number of baffles, their shape, and their placement within the unit all contribute to the overall flow characteristics. A design with fewer baffles and a more streamlined configuration will generally offer better flow.

- Welding and Joint Integrity

The quality of welding and the design of joints within the component are critical for maintaining smooth, unobstructed flow. Poorly executed welds or misaligned joints can create turbulence and increase flow resistance. Smooth, consistent welds and properly aligned joints minimize flow disruptions, contributing to improved engine performance. Robotic welding and precise manufacturing processes are often employed to ensure consistent weld quality and joint alignment.

- Material Selection and Surface Finish

The material used in construction and its surface finish can influence flow characteristics. Smoother internal surfaces reduce friction and improve gas flow. Polished stainless steel or ceramic coatings can further reduce friction, enhancing flow efficiency. Corrosion-resistant materials are also important to prevent the buildup of rust or scale, which can roughen the internal surface and increase flow resistance. Some high-performance designs utilize specialized coatings to minimize friction and improve flow characteristics.

The design must strike a balance between effective sound attenuation and minimal flow restriction to optimize engine performance. Careful consideration of core design, baffle configuration, welding integrity, and material selection is essential for achieving this balance. A well-optimized component will deliver both reduced noise levels and enhanced engine efficiency, contributing to an improved driving or riding experience.

3. Material Durability

Material durability is a critical factor influencing the longevity, performance, and overall value of an exhaust component. The harsh operating environment to which this component is subjected necessitates the selection of materials capable of withstanding extreme temperatures, corrosive substances, and mechanical stresses.

- Stainless Steel Composition

The specific grade of stainless steel utilized directly affects its resistance to corrosion and oxidation. Austenitic stainless steels, such as 304 and 316, are commonly employed due to their high chromium and nickel content, which provides excellent corrosion protection. Lower grades of stainless steel may exhibit susceptibility to rust and degradation, particularly in regions with high salt concentrations or exposure to road salts. For instance, a unit constructed from 304 stainless steel in a northern climate may exhibit superior resistance to corrosion compared to a unit made from a lower-grade steel in the same environment.

- Titanium Alloys

Titanium alloys offer exceptional strength-to-weight ratios and superior corrosion resistance compared to stainless steel. However, titanium components are typically more expensive. The high heat resistance of titanium makes it a suitable choice for high-performance applications where exhaust gas temperatures are elevated. A titanium system on a racing motorcycle, for example, can withstand extreme heat and stress while minimizing weight, contributing to improved performance.

- Weld Integrity and Technique

The quality of welds significantly impacts the structural integrity and durability of the component. Poorly executed welds can create stress concentrations and points of failure, leading to premature cracking and exhaust leaks. Gas Tungsten Arc Welding (GTAW), also known as TIG welding, is often preferred for its precision and ability to create strong, durable welds. A well-executed GTAW weld will exhibit uniform penetration and minimal porosity, ensuring a robust and leak-free joint.

- Protective Coatings and Treatments

Coatings and surface treatments can enhance the durability of the component by providing an additional layer of protection against corrosion and heat. Ceramic coatings, for example, can improve heat resistance and reduce surface temperatures. Powder coating provides a durable and aesthetically pleasing finish while offering some degree of corrosion protection. These coatings can extend the lifespan of the component, particularly in harsh environments.

The material composition, weld integrity, and application of protective coatings are all integral to the overall durability of an exhaust system component. The selection of appropriate materials and manufacturing techniques is essential for ensuring long-term performance and reliability under demanding operating conditions. Failure to prioritize material durability can result in premature failure, increased maintenance costs, and compromised performance.

4. Vehicle Compatibility

Vehicle compatibility is paramount when considering the integration of an exhaust system component. The selection of a component that aligns with the vehicle’s specific make, model, year, and engine configuration is essential for proper fitment, optimal performance, and regulatory compliance.

- Exhaust Port Geometry

The geometry of the exhaust port on the engine and the inlet flange of the component must be congruent. Discrepancies in port shape, size, or bolt patterns can prevent a secure and leak-free connection. Adapters may be available in some instances, but their use can compromise exhaust flow and increase the risk of leaks. A component designed for a specific engine family, such as a Honda K-series engine, will feature an inlet flange that precisely matches the exhaust port configuration of that engine family.

- Chassis and Suspension Clearance

The component must be designed to provide adequate clearance with the vehicle’s chassis, suspension components, and other undercarriage elements. Insufficient clearance can lead to contact between the exhaust system and other components, resulting in noise, vibration, and potential damage. The routing of the exhaust piping and the positioning of the component are critical considerations to ensure proper clearance throughout the vehicle’s range of motion. A system designed for a lowered vehicle, for example, will typically feature shorter hangers and a more compact design to prevent ground contact.

- Sensor Placement and Compatibility

Modern vehicles often incorporate oxygen sensors and other exhaust gas monitoring devices. The component must be designed to accommodate these sensors in their proper locations. Failure to properly integrate sensors can result in inaccurate readings, triggering check engine lights and potentially affecting engine performance. Sensor bungs must be positioned correctly and be of the appropriate thread size to ensure compatibility with the vehicle’s sensors. The absence of sensor bungs or improperly sized bungs can render a component incompatible with a particular vehicle.

- Emissions Compliance

The component must comply with applicable emissions regulations for the target vehicle and region. Modifications to the exhaust system that alter emissions control devices may be illegal and can result in fines or failed inspections. Some components are specifically designed to meet the requirements of California’s Air Resources Board (CARB) and are designated as 50-state legal. It is imperative to verify that the component is compliant with all relevant emissions regulations before installation.

Ensuring vehicle compatibility necessitates a meticulous assessment of port geometry, chassis clearance, sensor placement, and emissions compliance. Failure to adhere to these considerations can result in installation difficulties, performance degradation, regulatory non-compliance, and potential damage to the vehicle. Prior to purchase, verification of compatibility with the target vehicle is paramount to ensure a successful and trouble-free installation.

5. Installation Precision

The successful integration of an exhaust component hinges critically on installation precision. Deviations from specified procedures or tolerances can compromise performance, structural integrity, and compliance with regulatory standards. Precise installation ensures the component functions as intended, delivering the designed sound attenuation, exhaust flow characteristics, and durability.

- Torque Specification Adherence

Fasteners securing the component to the exhaust manifold and supporting brackets must be tightened to manufacturer-specified torque values. Under-tightening can lead to leaks and vibrations, while over-tightening can damage threads and compromise the integrity of the joint. Correct torque application ensures a secure and leak-free connection. For example, utilizing a calibrated torque wrench to achieve the exact specified torque on exhaust flange bolts prevents exhaust leaks that could degrade engine performance and increase noise levels.

- Alignment and Clearance Verification

The component must be properly aligned with the exhaust system to prevent stress on joints and hangers. Insufficient clearance between the component and other vehicle components, such as the chassis or suspension, can result in noise, vibration, and potential damage. Verification of proper alignment and clearance throughout the vehicle’s range of motion is essential. A misaligned or poorly supported component can develop cracks or leaks due to stress, compromising its ability to attenuate sound and efficiently channel exhaust gases.

- Gasket and Seal Integrity

Exhaust gaskets and seals are critical for preventing leaks at connection points. These components must be properly seated and in good condition to ensure a tight seal. Damaged or improperly installed gaskets can result in exhaust leaks, which degrade engine performance and increase noise levels. Replacing worn or damaged gaskets during installation is crucial. A new gasket installed correctly will create a tight seal, preventing exhaust leaks and ensuring that the component functions as designed to reduce noise and optimize exhaust flow.

- Hanger and Mounting Point Security

The component relies on secure mounting points and hangers to support its weight and prevent excessive vibration. Worn or damaged hangers can allow the component to move excessively, leading to stress on joints and potential failure. Proper installation includes inspecting and replacing worn hangers and ensuring that mounting points are securely fastened. Correctly installed hangers minimize vibration and stress on the system, extending its lifespan and ensuring consistent performance in terms of noise reduction and exhaust flow.

These facets highlight the importance of meticulous attention to detail during the installation process. Proper torque application, alignment verification, gasket integrity, and hanger security are all essential for ensuring that the component functions as designed, delivering the intended performance benefits and maintaining long-term durability.

6. Regulatory Compliance

The design, manufacture, and application of exhaust system components are often governed by stringent regulations aimed at mitigating noise pollution and controlling exhaust emissions. Adherence to these regulations is a critical consideration for both manufacturers and end-users of such components. Compliance ensures legal operation and minimizes the environmental impact of vehicles equipped with these systems.

- Noise Emission Standards

Many jurisdictions impose limits on the permissible noise levels emitted by vehicles. Exhaust systems are a primary source of vehicle noise, and components must be designed to attenuate sound within these regulatory limits. Testing protocols and certification procedures are often required to demonstrate compliance. For example, certain aftermarket components may require certification from organizations such as the Society of Automotive Engineers (SAE) to verify that they meet specified noise standards. Exceeding noise limits can result in fines, vehicle impoundment, or restrictions on vehicle operation.

- Emissions Control Device Compatibility

Exhaust systems in modern vehicles are integral to emissions control. Altering or removing emissions control devices, such as catalytic converters, is often prohibited by law. Components must be designed to be compatible with existing emissions control systems and must not compromise their effectiveness. Replacing a factory-installed system with a non-compliant aftermarket component can result in increased emissions and potential violations of environmental regulations. Some components are specifically designed and certified to maintain or improve emissions performance while providing desired sound characteristics.

- Type Approval and Certification

Some jurisdictions require exhaust system components to undergo type approval testing and certification to ensure they meet specific performance and safety standards. This process involves independent testing and verification of the component’s design and manufacturing quality. Components that have been type-approved are typically marked with a certification number or symbol, indicating their compliance with applicable regulations. The absence of type approval can render a component illegal for use on public roads in certain regions.

- Tampering Regulations

Many regulations prohibit tampering with or modifying emissions control systems. This includes alterations to the exhaust system that could increase emissions or noise levels. Manufacturers and installers of components must ensure that their products and services do not violate these anti-tampering provisions. Altering an exhaust system to bypass or disable emissions control devices can result in significant penalties and legal repercussions.

Navigating the complex landscape of regulations governing exhaust systems requires careful consideration of noise emission standards, emissions control device compatibility, type approval requirements, and anti-tampering provisions. Choosing components that are certified and compliant with applicable regulations ensures legal operation and minimizes the environmental impact. Compliance with these regulations is a shared responsibility of manufacturers, installers, and vehicle owners.

7. Performance Impact

The performance impact of an exhaust system component on an internal combustion engine is a multifaceted consideration involving a complex interplay between noise attenuation and exhaust gas flow dynamics. The modifications enacted by these components can exert both positive and negative influences on engine power output, fuel efficiency, and overall vehicle responsiveness. The extent and nature of this impact are contingent upon the component’s design, materials, and the specific characteristics of the engine to which it is mated. An improperly designed unit can induce excessive backpressure, impeding the efficient expulsion of exhaust gases and thereby diminishing engine performance. Conversely, a carefully engineered component can optimize exhaust flow, potentially unlocking gains in horsepower and torque.

A common scenario involves the installation of an aftermarket component on a motorcycle, intended to enhance the auditory experience and visual aesthetics. However, if the component’s internal baffling design is overly restrictive, it can impede exhaust gas flow, particularly at higher engine speeds. This restriction can manifest as a perceptible reduction in power and throttle response, negating the intended benefits of the modification. Conversely, a performance-oriented component, meticulously designed with a larger diameter core and optimized baffling, can reduce backpressure and facilitate more efficient exhaust gas evacuation. This can translate into tangible improvements in engine performance, especially when coupled with complementary engine management tuning. For example, a sportbike equipped with a high-flow component and a corresponding fuel map adjustment might exhibit a noticeable increase in horsepower and improved acceleration.

In conclusion, the performance impact of such a component is not a monolithic entity but rather a variable outcome influenced by design considerations and engine-specific factors. While these components can contribute to enhanced auditory experiences and aesthetic appeal, their impact on engine performance warrants careful consideration. A judicious approach involves selecting components that balance noise attenuation with optimized exhaust flow characteristics, potentially leading to tangible improvements in power, efficiency, and overall vehicle responsiveness. Prior to installation, it is advisable to research the component’s design specifications and seek feedback from experienced users to ascertain its likely effect on the intended vehicle’s performance profile.

Frequently Asked Questions Regarding Exhaust System Components

This section addresses common inquiries and misconceptions surrounding these exhaust system components. The information presented aims to provide clarity and assist in informed decision-making.

Question 1: Does the installation of an aftermarket unit automatically increase horsepower?

The installation of an aftermarket unit does not guarantee an increase in horsepower. Performance gains are contingent upon the component’s design and its compatibility with the vehicle’s engine. An improperly designed unit can, in fact, reduce horsepower.

Question 2: Are all units street legal?

Not all units are street legal. Compliance with noise emission regulations varies by jurisdiction. It is the responsibility of the vehicle owner to ensure the component meets local regulations prior to installation.

Question 3: How often should a unit be inspected for damage?

Inspection frequency depends on driving conditions and environmental factors. A visual inspection should be conducted at least every six months, with more frequent inspections in harsh environments.

Question 4: What materials offer the best durability?

Stainless steel and titanium alloys offer superior durability due to their resistance to corrosion and high temperatures. Titanium alloys provide an excellent strength-to-weight ratio, but typically at a higher cost.

Question 5: Can a damaged unit be repaired?

Repair feasibility depends on the extent and nature of the damage. Minor cracks and leaks may be repairable by a qualified welder. Significant damage may necessitate replacement of the unit.

Question 6: Does the unit affect fuel efficiency?

An improperly designed unit that creates excessive backpressure can negatively impact fuel efficiency. A well-designed unit that optimizes exhaust flow may, in some cases, improve fuel efficiency.

These FAQs provide a general overview of common concerns. Consulting with a qualified mechanic or exhaust system specialist is recommended for specific applications.

The subsequent section will offer a concluding summary of the key aspects discussed within this article.

Conclusion

The preceding discussion has provided a comprehensive exploration of the function, selection, maintenance, and impact of “m4 muffler” within the context of internal combustion engine exhaust systems. Emphasis has been placed on key attributes such as sound attenuation, flow optimization, material durability, vehicle compatibility, installation precision, regulatory compliance, and performance implications. Each of these factors contributes to the overall effectiveness and suitability of this component for specific applications.

The informed selection and diligent maintenance of an appropriate “m4 muffler” contribute significantly to both vehicle performance and environmental responsibility. Further research and development in materials science and acoustic engineering will likely lead to even more efficient and durable solutions in the future. Therefore, remaining abreast of advancements in this area is crucial for optimizing vehicle operation and minimizing environmental impact.