An exhaust system component designed for enhanced performance and a distinctive sound profile, these devices modify the expulsion of exhaust gases from an internal combustion engine. Characterized by reduced backpressure and often constructed from high-grade materials, these units are favored in aftermarket automotive applications to potentially increase horsepower and torque. For example, a vehicle modified with such a system may exhibit improved acceleration and a more aggressive exhaust note.

The advantages of installing such an upgrade often encompass not only a potential improvement in engine efficiency, leading to increased power output, but also an alteration of the vehicle’s auditory characteristics. This can result in a more resonant and pronounced exhaust sound, appealing to enthusiasts seeking a sportier driving experience. Historically, demand for these systems has grown alongside the performance modification industry, mirroring advancements in engine technology and evolving consumer preferences for customized vehicles.

The subsequent discussion will delve into specific aspects of these exhaust components, including material considerations, installation procedures, and the implications of such modifications on vehicle emissions and regulatory compliance. Furthermore, the analysis will extend to performance metrics and objective assessments of the overall impact on vehicle dynamics and driver satisfaction.

Enhancing Vehicle Performance

This section outlines critical advice for those considering modifications to their vehicle’s exhaust system to optimize performance and manage sound output.

Tip 1: Material Selection: Prioritize stainless steel or titanium alloys for enhanced durability and resistance to corrosion. These materials offer a longer lifespan, especially in environments with harsh weather conditions or road salts. A high-quality material choice reduces the need for frequent replacements and maintains consistent performance over time.

Tip 2: Diameter Optimization: Select the appropriate pipe diameter to complement engine displacement and intended power goals. An improperly sized system can negatively impact exhaust flow, potentially reducing horsepower. Consult performance charts or seek professional advice to ensure proper sizing.

Tip 3: Minimize Backpressure: Reduce backpressure through efficient design and smooth bends in the exhaust piping. Excessive backpressure hinders engine efficiency and limits potential power gains. Aim for a system with minimal obstructions to facilitate optimal exhaust gas flow.

Tip 4: Catalytic Converter Considerations: Evaluate the catalytic converter’s impact on exhaust flow and emissions compliance. High-flow catalytic converters offer a balance between emissions regulations and performance. Ensure the selected converter meets local environmental standards and doesn’t unduly restrict exhaust flow.

Tip 5: Sound Level Management: Incorporate resonators or mufflers to control exhaust sound levels and minimize drone. Unwanted noise can lead to driver fatigue and potential noise ordinance violations. Evaluate different muffler designs to achieve the desired sound profile without compromising performance.

Tip 6: Professional Installation: Seek professional installation for optimal fitment and performance. A properly installed exhaust system ensures proper sealing, reduces the risk of leaks, and maximizes potential power gains. Incorrect installation can lead to performance issues and potential damage to the vehicle.

Tip 7: Emissions Compliance: Verify that any modifications comply with local emissions regulations. Illegal modifications can result in fines and mandatory vehicle inspections. Research and ensure that the chosen system meets all applicable legal requirements.

By adhering to these guidelines, owners can effectively enhance their vehicle’s performance and customize its auditory characteristics while maintaining reliability and adhering to regulatory standards.

The subsequent sections will explore real-world applications and performance analysis scenarios, providing a data-driven understanding of the impact of aftermarket exhaust systems.

1. Enhanced Exhaust Flow

Enhanced exhaust flow, a fundamental characteristic of effective exhaust systems, is critically linked to the performance capabilities of automotive exhaust components. A carefully designed system promotes efficient removal of exhaust gases, contributing to increased engine power and responsiveness.

- Reduced Backpressure

Reduced backpressure is a direct result of enhanced exhaust flow, facilitating easier expulsion of exhaust gases from the engine cylinders. This reduction minimizes the energy the engine expends pushing out exhaust, freeing up power to be used for propulsion. Systems featuring optimized designs, such as mandrel bends and larger diameter piping, contribute to lower backpressure. For example, a vehicle experiencing sluggish acceleration may benefit significantly from a system designed to minimize exhaust restriction.

- Improved Scavenging Efficiency

Enhanced exhaust flow promotes efficient scavenging, the process of drawing spent gases out of the combustion chamber and creating space for fresh air and fuel. More effective scavenging allows for a more complete combustion cycle, maximizing energy extraction from the fuel. Systems with strategically placed collectors and tuned pipe lengths can optimize scavenging efficiency, leading to increased horsepower and torque output.

- Thermal Management

Effective exhaust flow contributes to improved thermal management within the engine. Rapid evacuation of hot exhaust gases helps to prevent excessive heat buildup in the engine compartment, reducing the risk of overheating and component degradation. Systems constructed from materials with high thermal conductivity, coupled with efficient flow design, can significantly improve thermal management. For instance, during extended periods of high-performance driving, such a system aids in maintaining stable engine temperatures.

- Optimized Gas Velocity

Maintaining optimal gas velocity is crucial for ensuring efficient exhaust flow. While reduced backpressure is desirable, excessively large diameter piping can lead to a reduction in gas velocity, potentially hindering scavenging and overall performance. Systems designed with properly sized piping and strategic constrictions maintain an ideal balance between backpressure and gas velocity, maximizing engine efficiency across a wide range of operating conditions. An example includes systems employing stepped headers to maintain gas velocity as exhaust gases move through the system.

The combined effects of reduced backpressure, improved scavenging, enhanced thermal management, and optimized gas velocity demonstrate the significant impact of enhanced exhaust flow on overall vehicle performance. Systems designed to maximize these factors can provide noticeable improvements in horsepower, torque, and throttle response, leading to a more engaging driving experience. These elements underscore the importance of selecting a well-engineered exhaust system for optimizing engine function.

2. Performance Sound Tuning

Performance sound tuning is a critical aspect related to “top gun muffler” functionality, dictating the auditory characteristics produced by the exhaust system. The design and internal structure of a muffler directly influence the sound waves generated by the engine’s combustion process. These systems are engineered to attenuate specific frequencies, either amplifying or suppressing them to achieve a desired sonic signature. An improperly tuned system can lead to undesirable noise levels or frequencies, affecting the overall driving experience and potentially violating noise regulations. For example, a system focused solely on reducing backpressure might produce an excessively loud and abrasive exhaust note, negating the benefits of improved performance with a harsh and distracting sound.

The strategic implementation of resonators, baffles, and packing materials within the muffler body facilitates the selective manipulation of sound waves. Resonators, chambers tuned to specific frequencies, can cancel out droning noises often associated with certain engine speeds. Baffles, strategically positioned obstructions, redirect and diffuse sound waves, reducing their amplitude. Packing materials, typically fiberglass or steel wool, absorb sound energy, further attenuating unwanted frequencies. As an illustration, an aftermarket system designed for a sport utility vehicle might incorporate a Helmholtz resonator to eliminate low-frequency drone at highway cruising speeds, enhancing driver comfort without sacrificing performance or the system’s enhanced auditory profile.

In summary, performance sound tuning is not merely an aesthetic consideration but an integral component of an exhaust system, impacting both the subjective driving experience and regulatory compliance. The effectiveness of an exhaust system hinges on the precise manipulation of sound waves, achieved through strategic design and material selection. A well-engineered system balances performance gains with acceptable noise levels, demonstrating the importance of considering performance sound tuning as a critical element during the design and selection process of an aftermarket exhaust component. Improper tuning can not only lead to an undesirable sound but can also distract the driver and increase driver fatigue.

3. Durable Material Composition

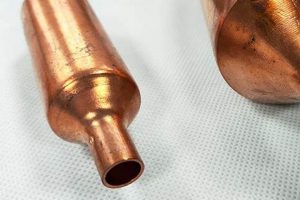

Durable material composition is a cornerstone in the construction of any exhaust system component, directly influencing longevity and sustained performance. The environment within an exhaust system is inherently corrosive, characterized by high temperatures, acidic gases, and exposure to road debris and moisture. Components manufactured from inferior materials are prone to rapid degradation, leading to premature failure and compromised functionality. Therefore, the selection of materials resistant to these conditions is essential for ensuring the continued effectiveness of the system.

The selection of premium-grade materials, such as T304 stainless steel or titanium alloys, provides exceptional resistance to corrosion and high-temperature oxidation. Stainless steel, owing to its chromium content, forms a protective oxide layer that prevents rust formation. Titanium alloys exhibit even greater strength-to-weight ratios and superior corrosion resistance. A “top gun muffler” constructed from these materials can withstand harsh operating conditions, extending its service life and maintaining consistent performance over time. For example, a system fabricated from aluminized steel might exhibit signs of corrosion within a year, whereas a stainless steel counterpart could remain structurally sound for upwards of five years or more. This difference translates directly to reduced maintenance costs and prolonged operational effectiveness.

In conclusion, durable material composition is not merely an aesthetic consideration but a fundamental attribute directly impacting the functionality and economic viability of an exhaust system. The long-term performance and reliability hinges on robust material selection. The correlation between superior materials and prolonged service life underscores the importance of investing in exhaust components constructed from high-grade alloys. This attention to material composition mitigates the risk of premature failure, reduces maintenance expenditures, and ensures the sustained effectiveness of the vehicle’s exhaust system.

4. Optimized Engine Output

Optimized engine output, a primary objective in automotive engineering, is inextricably linked to exhaust system efficiency. The performance of the exhaust components, particularly the system, significantly influences the engine’s capacity to generate power and torque. The system’s ability to facilitate the efficient removal of exhaust gases directly impacts the combustion process and overall engine function. When designed to reduce backpressure and optimize exhaust flow, the system effectively allows the engine to breathe more freely, leading to improved volumetric efficiency. An engine burdened by a restrictive exhaust system requires more energy to expel exhaust gases, effectively reducing the power available to drive the vehicle. Therefore, the relationship is one of cause and effect: a well-designed system contributes directly to increased engine output, while a poorly designed system hinders performance.

The system’s significance stems from its ability to modify the engine’s operating characteristics. For instance, an engine operating with a properly tuned system might exhibit increased horsepower across the RPM range, resulting in improved acceleration and overall drivability. Conversely, a poorly matched system, such as one with excessively large diameter pipes, might actually decrease low-end torque, resulting in a loss of responsiveness at lower engine speeds. Consider a scenario involving a turbocharged engine: the installation of a high-flow system can significantly reduce backpressure, allowing the turbocharger to spool up more quickly and efficiently, thus increasing power output. This increased output translates directly into tangible improvements in vehicle performance, such as reduced 0-60 mph acceleration times and increased top speed. This is the practical significance. Understanding this relationship enables informed decision-making regarding aftermarket exhaust modifications.

In summary, the connection between optimized engine output and the system is clear. The system serves as a crucial element in maximizing engine potential, influencing power delivery, throttle response, and overall vehicle performance. Addressing the challenges associated with system design, such as balancing backpressure and exhaust velocity, remains a critical area of focus for automotive engineers and performance enthusiasts. The ability to choose and properly install an optimized system directly impacts vehicle performance and the driver’s experience.

5. Aftermarket Customization Options

Aftermarket customization options afford vehicle owners a spectrum of enhancements to an exhaust system, extending beyond mere replacement of damaged components. These options cater to diverse performance objectives, aesthetic preferences, and budgetary considerations, directly influencing the functionality and appearance of a system.

- Muffler Style Variations

Muffler style variations present a wide array of options to alter both the sound and performance characteristics. Chambered mufflers, for instance, utilize internal chambers to cancel out specific frequencies, resulting in a quieter exhaust note. Straight-through mufflers offer minimal restriction, maximizing exhaust flow but often producing a louder sound. Turbo mufflers, designed with a specific internal flow path, strike a balance between performance and sound control. The choice of muffler style directly impacts the vehicle’s auditory profile and the potential for increased horsepower and torque. An owner prioritizing sound attenuation might select a chambered muffler, while an enthusiast seeking maximum performance may opt for a straight-through design.

- Tip Design and Finish

Tip design and finish contribute to the visual appeal, complementing or contrasting the vehicle’s overall aesthetic. Tips are available in a variety of shapes, sizes, and materials, including stainless steel, chrome, and carbon fiber. Angle-cut tips provide a sporty appearance, while rolled-edge tips offer a more refined look. The finish can range from polished to matte, allowing for customization to match the vehicle’s paint color or other exterior elements. While not directly influencing performance, tip design and finish represent an opportunity to personalize the vehicle’s style and enhance its visual impact. An understated vehicle might benefit from simple stainless-steel tips, while a high-performance car could be enhanced with aggressive carbon-fiber tips.

- Material Upgrades

Material upgrades, such as selecting stainless steel or titanium, provide increased durability and resistance to corrosion. Stainless steel offers superior corrosion resistance compared to aluminized steel, extending the lifespan of the exhaust system, especially in regions with harsh winter climates. Titanium, while more expensive, provides even greater weight reduction and corrosion resistance, making it a popular choice for high-performance applications. Material upgrades represent a long-term investment, reducing the need for frequent replacements and ensuring sustained performance. A vehicle exposed to road salt on a regular basis would benefit from a stainless-steel system, while a race car might benefit from the weight savings offered by a titanium system.

- Resonator Additions or Deletions

Resonator additions or deletions offer fine-tuning capabilities for exhaust sound characteristics, enabling control over drone and unwanted frequencies. Adding a resonator can help to dampen specific sound frequencies, reducing interior noise levels and improving driving comfort. Conversely, deleting a resonator can increase exhaust volume and produce a more aggressive sound. The decision to add or remove a resonator depends on the desired sound profile and the vehicle’s intended use. A daily driver might benefit from the addition of a resonator to reduce drone, while a weekend track car could benefit from its deletion to maximize exhaust volume.

These customization options highlight the flexibility available in configuring exhaust systems to meet individual needs. The degree of personalization allows for targeted improvements in performance, sound, and aesthetics. The selection process should involve a comprehensive assessment of driving habits, performance goals, and desired auditory and visual impact.

Frequently Asked Questions

This section addresses common inquiries regarding performance exhaust systems, offering concise and factual responses to provide clarity and assist in informed decision-making.

Question 1: What quantifiable performance gains can be expected from installing a “top gun muffler”?

Performance gains vary based on engine characteristics, existing modifications, and system design. Dyno testing is the most reliable method to determine power increases, but typical gains range from 5-15 horsepower for naturally aspirated engines and potentially more for turbocharged applications. Claims exceeding these figures warrant scrutiny.

Question 2: Does installing an aftermarket “top gun muffler” void a vehicle’s warranty?

The Magnuson-Moss Warranty Act protects consumers from unwarranted warranty denials. An aftermarket part does not automatically void the warranty; the manufacturer must prove the aftermarket part directly caused the failure. However, dealerships might attempt to attribute certain failures to the exhaust modification.

Question 3: What are the legal considerations regarding “top gun muffler” sound levels?

Sound level regulations vary by jurisdiction. Some areas have specific decibel limits, while others rely on subjective “excessive noise” clauses. It is the vehicle owner’s responsibility to ensure compliance with local laws. Consult local ordinances and consider investing in a sound level meter to monitor exhaust volume.

Question 4: How does pipe diameter affect exhaust system performance when using “top gun muffler”?

Pipe diameter influences exhaust gas velocity and backpressure. An excessively large diameter can reduce exhaust gas velocity, leading to decreased low-end torque. Conversely, an undersized diameter can create excessive backpressure, restricting high-RPM power. Proper sizing depends on engine displacement and intended use.

Question 5: What are the primary material choices for a “top gun muffler,” and what are their respective benefits?

Common materials include aluminized steel, stainless steel, and titanium. Aluminized steel offers cost-effectiveness but is susceptible to corrosion. Stainless steel provides superior corrosion resistance. Titanium offers the best strength-to-weight ratio and corrosion resistance but is the most expensive option.

Question 6: Can a “top gun muffler” improve fuel efficiency?

A properly designed system can contribute to improved fuel efficiency, primarily by reducing backpressure and improving engine breathing. However, any gains are typically marginal and depend heavily on driving style and engine tuning. Fuel efficiency should not be the primary motivation for installing such a system.

These answers provide a foundation for understanding critical aspects of performance exhaust systems. Further research and professional consultation are recommended before making any modifications.

The subsequent section will explore specific installation procedures and best practices for optimizing performance.

Concluding Remarks on Performance Exhaust Technology

The preceding analysis has explored various facets of performance exhaust systems, including the significance of exhaust flow, the mechanics of sound tuning, the importance of material durability, the impact on engine output, and the options available for customization. This investigation elucidates that optimizing performance requires a comprehensive understanding of each component and their synergistic relationship. The selection and implementation of a top gun muffler, therefore, demand careful consideration of the vehicle’s specific needs and intended application.

Ultimately, informed decision-making is paramount. Further research, professional consultation, and adherence to regulatory standards are crucial for realizing the full potential of exhaust modifications. As engine technology continues to advance, ongoing development and refinement of exhaust systems will undoubtedly remain central to enhancing both vehicle performance and the overall driving experience. Understanding these principles ensures responsible and effective vehicle modification.