A component of a vehicle’s exhaust system, this part reduces noise generated by the engine. Its construction typically involves joining metal pieces permanently through a fusion process. This manufacturing method creates a sealed unit designed to redirect and dampen sound waves, contributing to a quieter operational experience.

The durability and longevity of this type of exhaust component are significant advantages. The robust nature of the joins formed during its construction allows it to withstand vibrations, temperature fluctuations, and corrosive elements encountered during regular vehicle operation. Furthermore, its widespread adoption in automotive manufacturing reflects its effectiveness in meeting noise regulations and enhancing driver and passenger comfort. Its development is intertwined with the evolution of automotive technology and the increasing emphasis on environmental and noise pollution control.

The following sections will delve into specific types of these components, exploring their design variations, installation procedures, common issues, and potential maintenance strategies for optimizing performance and lifespan. Further investigation into material selection and advanced manufacturing techniques employed will also be presented.

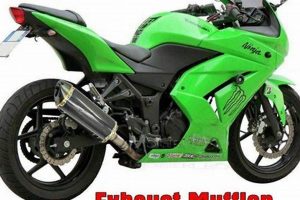

Guidance on Exhaust Noise Reduction Devices

This section provides practical recommendations for ensuring optimal performance and longevity of exhaust noise reduction devices installed using fusion techniques.

Tip 1: Material Inspection: Prior to installation, verify the metallurgical compatibility of the exhaust component with the existing exhaust system materials. Dissimilar metals can accelerate corrosion due to galvanic reactions.

Tip 2: Joint Integrity Assessment: Thoroughly examine the fusion points for any signs of porosity, cracks, or incomplete penetration. These flaws can lead to premature failure and exhaust leaks.

Tip 3: Proper Alignment: Ensure precise alignment of the exhaust system during installation to minimize stress on the component. Misalignment can induce fatigue and shorten the lifespan of the joints.

Tip 4: Corrosion Protection: Apply a high-temperature anti-seize compound to all bolts and fittings to prevent corrosion and facilitate future removal.

Tip 5: Vibration Dampening: Utilize rubber isolators or hangers to reduce the transmission of engine vibrations to the exhaust system. Excessive vibration can compromise the integrity of the joins.

Tip 6: Regular Inspections: Conduct periodic visual inspections to identify any signs of corrosion, damage, or exhaust leaks. Address any issues promptly to prevent further degradation.

Tip 7: Avoid Abrasive Cleaning: Refrain from using abrasive cleaning methods, as these can damage protective coatings and accelerate corrosion. Opt for mild detergents and soft cloths.

Implementing these recommendations can significantly extend the service life and maintain the performance of exhaust noise reduction components, resulting in reduced maintenance costs and improved vehicle operation.

The following section presents a summary of the key considerations discussed in this article.

1. Durability

The operational lifespan of an exhaust system component is significantly determined by its ability to withstand the harsh conditions of the vehicle environment. Durability, therefore, represents a critical consideration in the design, manufacturing, and material selection processes for exhaust noise reduction devices that employ fusion techniques.

- Material Selection and Corrosion Resistance

The choice of materials directly affects the ability of the exhaust component to resist corrosion, a primary cause of failure. Stainless steel alloys, for instance, offer superior protection against rust and degradation compared to standard carbon steel. The presence of road salts, moisture, and extreme temperature variations further exacerbate corrosive effects, highlighting the necessity of selecting materials with inherent resilience.

- Joint Integrity and Fatigue Resistance

The method of joining metal pieces to create the component must ensure long-term structural integrity. Well-executed fusions are resistant to fatigue cracking caused by constant vibration and thermal cycling. Deficiencies such as porosity, incomplete penetration, or improper filler metal selection can compromise the joint’s strength, leading to premature failure.

- Thickness and Reinforcement

The gauge of the metal used, as well as any reinforcement structures incorporated into the design, contribute to the component’s ability to withstand physical impacts from road debris and internal pressure fluctuations. Thicker materials and strategically placed supports enhance resistance to deformation and prolong the component’s service life.

- Protective Coatings and Treatments

The application of coatings or surface treatments can further enhance corrosion resistance and extend the component’s lifespan. Aluminizing, ceramic coatings, and other protective layers create a barrier against environmental elements, reducing the rate of degradation and preserving the structural integrity of the component.

In summation, the ability of an exhaust noise reduction device utilizing fusion techniques to endure long-term operational stresses is fundamentally tied to material quality, joint construction, design features, and protective measures. Optimizing these aspects leads to increased longevity and reduces the frequency of replacements, ultimately lowering vehicle maintenance costs.

2. Material Compatibility

The longevity and performance of an exhaust noise reduction device utilizing fusion techniques are directly dependent on the compatibility of the materials employed in its construction. Incompatible materials can lead to accelerated corrosion, weakening of fused joints, and premature failure. This compatibility extends beyond the device itself and includes consideration of the materials used in the existing exhaust system to which it will be attached. For example, attaching a stainless steel component to a mild steel exhaust system can result in galvanic corrosion, where the mild steel corrodes at an accelerated rate due to the electrochemical potential difference between the two metals. Similarly, using incompatible filler metals during the fusion process can create weak or brittle joints susceptible to cracking under thermal stress.

Real-world examples illustrate the practical significance of material compatibility. Many original equipment manufacturers (OEMs) specify particular grades of stainless steel for their exhaust systems to ensure resistance to corrosion and high-temperature oxidation. Aftermarket installations involving incompatible materials often lead to significantly reduced lifespans. Furthermore, the expansion coefficients of different metals must be considered. If materials with vastly different expansion rates are joined, thermal cycling can induce stresses that weaken the fused connections. Selecting appropriate materials for the base metal and filler metal that are chemically compatible and have similar thermal expansion rates is critical to ensuring the device’s structural integrity.

In summary, careful consideration of material compatibility is paramount for achieving durable and reliable exhaust components utilizing fusion techniques. Failure to address this aspect can result in premature failure, increased maintenance costs, and potential safety hazards. Understanding the electrochemical properties, thermal expansion rates, and mechanical strengths of different materials is essential for engineers and technicians involved in the design, fabrication, and installation of these components. Adherence to established industry standards and best practices ensures optimized performance and extended service life.

3. Joint Integrity

The sustained functionality of an exhaust noise reduction device created using fusion techniques is intrinsically linked to the structural integrity of the joints formed during its manufacture. Weaknesses or defects in these areas can lead to premature failure, compromised performance, and potential safety hazards.

- Weld Quality and Material Fatigue

The execution of a fusion process dictates the susceptibility of joints to material fatigue. Poor weld quality characterized by porosity, incomplete penetration, or slag inclusions creates stress concentration points. These imperfections act as initiation sites for cracks under cyclical loading, leading to eventual failure. Proper welding techniques, including appropriate pre-heating, interpass temperature control, and post-weld heat treatment, are crucial for mitigating these risks.

- Corrosion Resistance at the Weld Zone

The area where the fusion occurred may become more vulnerable to corrosion. The heat-affected zone (HAZ) can undergo microstructural changes that alter its corrosion resistance compared to the base metal. Furthermore, the use of dissimilar filler metals can create galvanic couples, accelerating corrosion in the weld region. Employing filler metals with comparable corrosion resistance to the base metal and applying protective coatings to the weld zone are strategies for mitigating these issues.

- Stress Distribution and Joint Design

The design of a fusion joint significantly influences the distribution of stresses under operational conditions. Sharp corners and abrupt transitions create stress concentrations, increasing the likelihood of cracking. Optimizing joint geometry to promote more uniform stress distribution enhances the joint’s ability to withstand mechanical and thermal loads. Finite element analysis (FEA) can assist in identifying and mitigating stress concentrations during the design phase.

- Inspection and Non-Destructive Testing

Rigorous inspection procedures are essential for verifying the integrity of the joints. Visual inspection, dye penetrant testing, radiographic testing, and ultrasonic testing are non-destructive methods used to detect surface and subsurface defects. These techniques provide valuable information about weld quality, enabling the identification and repair of flawed joints before they lead to in-service failures.

Ultimately, achieving optimal performance and extending the service life of a fabricated exhaust component necessitates meticulous attention to detail throughout the welding process, from material selection and joint design to welding technique and inspection protocols. Compromises in joint integrity can negate the benefits of advanced materials and sophisticated designs, leading to unsatisfactory results and increased maintenance costs.

4. Noise Reduction

The primary function of an exhaust noise reduction device incorporating fusion techniques is to mitigate the sound generated by an internal combustion engine. The effectiveness of this component in achieving substantial noise reduction directly influences a vehicle’s compliance with noise regulations and contributes significantly to the comfort of both the vehicle’s occupants and the surrounding environment. The internal architecture of this device, characterized by chambers, baffles, and resonating components, is carefully engineered to redirect and attenuate sound waves propagating through the exhaust system. As exhaust gases pass through the component, sound waves encounter these designed features, causing them to reflect, interfere, and dissipate energy. The efficiency with which this occurs determines the overall reduction in noise levels achieved. Failures or deficiencies in the welds compromise the integrity of the internal chambers, allowing exhaust gases to bypass the intended flow paths and reducing the effectiveness of sound attenuation. The practical significance of this relationship is evident in the performance of vehicles failing noise emission tests, which often correlate with damaged or poorly manufactured devices.

Real-world applications showcase the importance of effective noise reduction. Heavy-duty vehicles, such as trucks and buses, are frequently equipped with large-capacity units designed to meet stringent noise standards in urban environments. Similarly, performance vehicles may utilize sophisticated designs to balance noise reduction with minimal exhaust backpressure, optimizing engine performance while maintaining acceptable sound levels. Modifications to the exhaust system that compromise the integrity of the fusion points or alter the internal configuration often result in increased noise levels, potentially leading to legal penalties or vehicle inspection failures. The development and refinement of internal designs continue to push the boundaries of noise reduction technologies, striving for optimal performance without sacrificing engine efficiency.

In summary, the ability of a constructed exhaust device to effectively reduce noise is paramount to its functionality and societal impact. Maintained joint integrity is essential for achieving intended noise reduction targets. Proper material selection and precise manufacturing techniques are pivotal to a device’s long-term performance. As environmental awareness grows and noise regulations become stricter, the role of effective and durable devices employing fusion techniques will only increase in importance. Challenges remain in balancing noise reduction with other factors, such as engine efficiency and cost, but the continuous pursuit of innovative designs and advanced materials will drive future advancements in this field.

5. Exhaust Flow

The efficiency of exhaust flow through a welded muffler directly influences engine performance and emissions. Restrictions within the muffler, often caused by design flaws, internal obstructions resulting from poor fusion techniques, or corrosion, impede the free passage of exhaust gases. This impedance generates backpressure, requiring the engine to expend additional energy to expel exhaust. The increased backpressure reduces engine power output, especially at higher revolutions per minute, and can negatively impact fuel economy. Real-world examples include aftermarket mufflers with complex internal geometries that, while aimed at specific sound characteristics, often create substantial flow restrictions. Engines equipped with such restrictive components exhibit a noticeable reduction in horsepower and torque compared to their original configurations. The performance differential highlights the necessity of optimizing flow characteristics in the design and manufacturing of welded mufflers.

Optimal exhaust flow is achieved through careful consideration of internal passage diameters, the arrangement and geometry of baffles, and the smoothness of welded joints. Sharp angles, rough surfaces, and excessive weld penetration into the exhaust passage can all create turbulence and increase flow resistance. A well-designed welded muffler will minimize these restrictions, allowing exhaust gases to exit the engine with minimal impedance. The significance of this consideration extends beyond performance; reduced backpressure also contributes to lower engine operating temperatures and reduced stress on engine components. An efficient exhaust system, therefore, enhances both the performance and the longevity of the engine.

In summary, exhaust flow constitutes a vital performance factor in any welded muffler. Flow restrictions negatively influence engine power, fuel efficiency, and overall engine health. The design, manufacturing process, and installation practices significantly determine the actual flow performance. Efforts to improve flow characteristics should be prioritized to maximize engine capabilities and ensure regulatory compliance with emissions standards, while maintaining desired noise reduction levels.

6. Structural Stability

The capacity of a welded muffler to maintain its physical form and integrity under operational stresses is crucial for its long-term performance and reliability. Structural stability, therefore, is a paramount design consideration that directly impacts the component’s ability to withstand vibrations, thermal stresses, and physical impacts encountered during vehicle operation.

- Material Selection and Thickness

The type and gauge of materials used in the muffler’s construction significantly influence its structural integrity. High-strength alloys, such as stainless steel, offer superior resistance to deformation and cracking compared to mild steel. The thickness of the metal must be sufficient to withstand internal pressures and external forces without yielding or fracturing. Insufficient material thickness compromises the overall structural integrity, leading to premature failure.

- Welding Technique and Joint Design

The quality of the welded joints directly affects the structural stability of the muffler. Proper welding techniques, including adequate penetration, fusion, and filler metal selection, are essential for creating strong, durable joints. Poorly executed welds characterized by porosity, incomplete fusion, or slag inclusions weaken the structure, making it susceptible to fatigue cracking and eventual failure. The design of the joints themselves also plays a crucial role, with overlapping or reinforced joints providing greater strength and resistance to stress concentrations.

- Internal Baffle and Chamber Support

The internal components of the muffler, such as baffles and chambers, require adequate support to prevent collapse or deformation under exhaust pressure and thermal stress. These supports are typically achieved through internal braces, welded connections, or interlocking designs that distribute loads evenly throughout the structure. Insufficient support can lead to vibration-induced fatigue and eventual failure of the internal components, reducing the muffler’s noise reduction effectiveness and potentially creating exhaust restrictions.

- External Reinforcement and Mounting

External reinforcement features, such as ribs or gussets, can enhance the muffler’s resistance to physical impacts and vibrations. Proper mounting hardware and techniques are also essential for maintaining structural stability. Securely attaching the muffler to the vehicle’s chassis with properly sized hangers and isolators minimizes stress on the welded joints and prevents excessive movement or vibration that can lead to fatigue cracking. Neglecting proper mounting procedures compromises the muffler’s structural integrity and increases the risk of premature failure.

The integration of robust materials, sound welding practices, and well-engineered support structures ensures the muffler retains its structural integrity throughout its service life. Compromising these elements can lead to premature failure, reduced performance, and potential safety hazards. Therefore, structural stability remains a critical factor in the design and manufacturing of effective and durable welded mufflers.

7. Corrosion Resistance

Corrosion resistance is a crucial performance parameter for exhaust system components employing fusion techniques. The operational environment exposes these devices to a multitude of corrosive agents, ranging from atmospheric moisture and road salts to acidic byproducts of combustion. The ability of the device to withstand these corrosive influences directly determines its service life and overall cost-effectiveness.

- Material Composition and Alloy Selection

The selection of appropriate alloys constitutes a fundamental aspect of corrosion resistance. Stainless steel alloys, characterized by their chromium content, form a passive oxide layer on their surface, providing inherent protection against corrosion. In contrast, carbon steel is highly susceptible to rust, particularly in the presence of moisture and electrolytes. The choice of alloy significantly impacts the device’s ability to withstand long-term exposure to corrosive environments. For example, a device constructed from 304 stainless steel exhibits greater resistance to chloride-induced pitting corrosion than a comparable device made from 409 stainless steel.

- Fusion Technique and Heat-Affected Zone (HAZ)

The fusion process employed during manufacture influences corrosion behavior, particularly within the heat-affected zone (HAZ). Elevated temperatures associated with fusion can alter the microstructure of the base metal, potentially reducing its corrosion resistance. The formation of chromium carbides in the HAZ of stainless steel reduces the chromium content available for passivation, rendering the region more susceptible to corrosion. Proper welding techniques and post-weld heat treatments minimize these detrimental effects and restore corrosion resistance in the HAZ. For example, controlled welding parameters and the use of appropriate filler metals can mitigate carbide precipitation and maintain corrosion resistance in the weld zone.

- Surface Treatments and Coatings

The application of surface treatments and coatings provides an additional layer of protection against corrosion. Aluminizing, ceramic coatings, and specialized paints create a barrier between the metal surface and the corrosive environment, slowing down the rate of degradation. These coatings are particularly effective in protecting against oxidation at elevated temperatures. For instance, an aluminized device demonstrates significantly improved resistance to oxidation compared to an uncoated device exposed to the same high-temperature exhaust gases. Protective coatings must exhibit excellent adhesion, thermal stability, and resistance to abrasion to maintain their effectiveness over the component’s lifespan.

- Galvanic Compatibility and Dissimilar Metal Joints

When joining dissimilar metals, galvanic corrosion becomes a significant concern. If an exhaust device is constructed from, or connected to, components made of different metals, an electrochemical potential difference can drive corrosion of the more anodic metal. This effect is particularly pronounced in the presence of electrolytes, such as road salts. Careful material selection and the use of insulating materials or sacrificial anodes mitigate galvanic corrosion. For instance, using a stainless steel clamp to connect a carbon steel exhaust pipe to a stainless steel device will likely result in accelerated corrosion of the carbon steel pipe. Strategies to prevent galvanic corrosion are essential for ensuring the long-term integrity of exhaust systems comprising dissimilar metals.

The facets discussed highlight the complex relationship between corrosion resistance and these specialized exhaust components. The selection of appropriate materials, the execution of controlled welding processes, the application of protective coatings, and the consideration of galvanic compatibility are all critical factors influencing the device’s longevity and performance in corrosive operating conditions. Addressing these factors is essential for ensuring the reliability and cost-effectiveness of exhaust systems.

Frequently Asked Questions

This section addresses common inquiries regarding this component, providing clear and concise answers to enhance understanding of its functionality, durability, and maintenance requirements.

Question 1: What are the primary advantages of a welded muffler over other types?

A structure made by fusion generally offers enhanced structural integrity and resistance to leaks compared to mechanically joined components. The seamless connections minimize the risk of exhaust gas escape and contribute to increased durability.

Question 2: How does the material composition affect the lifespan of a welded muffler?

The material used determines its corrosion resistance. Stainless steel provides superior protection against rust and degradation compared to standard carbon steel, extending the component’s operational life.

Question 3: What factors contribute to the premature failure of a welded muffler?

Common causes include corrosion due to exposure to road salts and moisture, fatigue cracking from engine vibrations, and damage from physical impacts with road debris.

Question 4: Can a damaged welded muffler be repaired?

Minor damage, such as small cracks or leaks, may be repairable through re-welding. However, extensive damage often necessitates replacement of the entire component to ensure proper performance and safety.

Question 5: How does this component influence vehicle performance?

Its design affects exhaust flow. Restrictions can increase backpressure, reducing engine power and fuel efficiency. A well-designed muffler minimizes these restrictions, optimizing performance.

Question 6: What are the key considerations during the installation of a welded muffler?

Proper alignment of the exhaust system is essential to minimize stress on the muffler and its joints. Using appropriate mounting hardware and ensuring secure connections prevent premature failure due to vibration.

Understanding these aspects of this structure assists in making informed decisions about its selection, maintenance, and overall contribution to vehicle operation.

The subsequent section will provide a detailed summary encapsulating all essential aspects of the exhaust component.

Welded Muffler

The preceding exploration has illuminated the multifaceted attributes of the exhaust component. Its durability, material compatibility, joint integrity, noise reduction capabilities, exhaust flow characteristics, structural stability, and corrosion resistance are critical determinants of its performance and longevity. These factors collectively influence its effectiveness in mitigating noise pollution, optimizing engine efficiency, and ensuring compliance with regulatory standards. Neglecting any of these aspects can compromise the component’s functionality, leading to increased maintenance costs, reduced vehicle performance, and potential environmental consequences.

The enduring importance of the exhaust component in automotive engineering necessitates continued research and development efforts focused on material science, manufacturing techniques, and design optimization. As environmental regulations become more stringent and consumer demands for quieter vehicles increase, the need for robust, efficient, and durable exhaust devices will only intensify. The responsible design, manufacture, and maintenance of these components are essential for promoting sustainable transportation and safeguarding public health.