A professionally installed and dependable exhaust silencing device is a critical component in modern vehicles. Such a device effectively reduces engine noise, contributing to a more comfortable driving experience and minimizing environmental sound pollution. For example, a well-engineered unit will noticeably decrease the loudness emanating from the vehicle’s tailpipe.

The importance of a robust and effectively functioning noise reduction system extends beyond mere comfort. It plays a vital role in maintaining compliance with local noise ordinances and ensuring responsible vehicle operation. Historically, advancements in materials science and engineering have led to significant improvements in the durability and performance of these systems, offering extended lifespans and enhanced sound dampening capabilities.

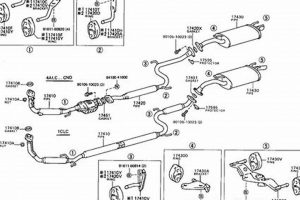

Understanding the specific characteristics, installation procedures, and maintenance requirements of this essential automotive part is paramount. The following sections will explore these aspects in detail, providing comprehensive information on selecting, using, and preserving a high-quality exhaust silencing solution.

Guidance for Optimal Exhaust System Performance

The following guidelines address factors related to maximizing the lifespan and effectiveness of an exhaust noise reduction component. Adherence to these practices can lead to improved vehicle operation and reduced maintenance costs.

Tip 1: Material Selection is Critical. When selecting a component, prioritize corrosion-resistant materials like stainless steel or aluminized steel. These materials offer enhanced longevity, particularly in environments with harsh road conditions or exposure to corrosive substances.

Tip 2: Proper Installation Prevents Premature Failure. Ensure correct alignment and secure mounting during installation. Misalignment or loose connections can introduce stress points, leading to cracking and exhaust leaks, significantly reducing the component’s effectiveness and lifespan.

Tip 3: Regular Inspections Identify Potential Issues. Conduct routine visual inspections for signs of rust, damage, or leaks. Early detection of these issues allows for timely repairs, preventing more extensive and costly problems later.

Tip 4: Address Exhaust Leaks Promptly. Exhaust leaks not only degrade noise reduction but can also introduce harmful fumes into the vehicle’s cabin. Address any detected leaks immediately by repairing or replacing the affected components.

Tip 5: Consider Professional Installation. While DIY installation may seem appealing, professional installation ensures proper fitment and sealing, maximizing the component’s performance and lifespan. Professionals possess the expertise and tools to address potential issues that may arise during installation.

Tip 6: Optimize Driving Habits. Avoid frequent short trips, as they do not allow the exhaust system to reach optimal operating temperature, increasing the risk of condensation and corrosion. Longer trips promote the evaporation of moisture, extending the system’s lifespan.

Tip 7: Shielding and Protective Coatings. Consider applying protective coatings or installing heat shields to mitigate the effects of extreme temperatures and road debris, further enhancing the component’s durability.

By implementing these guidelines, vehicle owners can significantly improve the reliability and longevity of their exhaust systems, contributing to a more comfortable and environmentally responsible driving experience.

The subsequent sections will delve into specific maintenance procedures and troubleshooting techniques, providing further insight into ensuring the optimal performance of this essential vehicle component.

1. Expert Installation

The professional installation of an exhaust silencing device directly correlates with its long-term dependability and effectiveness. Incorrect installation procedures can introduce stresses on the component, leading to premature failure, reduced noise reduction, and potential exhaust leaks. For instance, improper welding techniques or inadequate support hangers can cause stress fractures in the muffler body, significantly shortening its lifespan and compromising its ability to effectively dampen engine noise. The outcome of a poor fitment or incorrect mounting are exhaust leaks, resulting in elevated noise levels and the potential release of harmful gases into the environment.

Proper installation, conversely, ensures optimal alignment, secure connections, and the correct application of necessary sealing compounds. These factors contribute to a gas-tight seal, preventing leaks and maximizing the muffler’s noise reduction capabilities. A professionally installed unit also benefits from the installer’s expertise in identifying and addressing potential issues, such as exhaust system interference or the need for additional support brackets. A practical example involves ensuring adequate clearance between the muffler and other vehicle components, such as the fuel tank or suspension components, preventing heat damage or physical abrasion that could lead to premature failure. Furthermore, an expert installer will utilize appropriate tools and techniques to avoid damaging the muffler during installation, ensuring its structural integrity is maintained.

In summary, expert installation is not merely a procedural step; it is a foundational element that underpins the reliability and performance of a professionally chosen exhaust silencing device. Neglecting this aspect can lead to significant performance degradation, increased maintenance costs, and potential safety hazards. Therefore, investing in professional installation services is a crucial component of ensuring long-term satisfaction and maximizing the value of the investment in a reliable muffler. Challenges may involve locating qualified and experienced installers, but the benefits of doing so far outweigh the potential risks associated with improper installation.

2. Material Durability

Material durability stands as a cornerstone in the definition and performance of a reliable exhaust silencing device. The correlation is direct: the selection of durable materials dictates the lifespan, operational effectiveness, and overall value of the unit. Components subjected to constant exposure to high temperatures, corrosive exhaust gases, road salts, and physical impacts require robust construction to maintain structural integrity and functional performance. Insufficient material strength or inadequate corrosion resistance will invariably lead to premature failure, necessitating frequent replacements and increased operational costs. For instance, a muffler constructed from low-grade steel will quickly succumb to rust in regions with harsh winter conditions where road salt is commonly used, while a stainless-steel counterpart would exhibit significantly greater longevity. Similarly, the internal baffles and chambers within the muffler, responsible for sound attenuation, must withstand constant vibration and thermal stress. Failure of these internal components can lead to a significant increase in exhaust noise and a decrease in the system’s overall effectiveness.

The implementation of advanced materials and manufacturing techniques directly influences the durability and reliability of these noise reduction systems. For example, using thicker gauge steel or employing reinforced welding techniques can enhance structural integrity, making the muffler more resistant to physical damage from road debris. Coatings and surface treatments can further improve corrosion resistance, prolonging the lifespan of the component, especially in challenging environmental conditions. Furthermore, advancements in exhaust gas temperature management can reduce the thermal stresses on the material, contributing to increased durability. As an illustration, some high-performance vehicles employ ceramic coatings or heat shields to protect the exhaust system from excessive heat, reducing the risk of material degradation and component failure.

In summary, the selection of durable materials is not merely a matter of cost; it represents a critical investment in the long-term performance and reliability of an exhaust silencing device. A commitment to high-quality materials, coupled with sound manufacturing practices, ensures that the component can withstand the rigors of daily use, providing consistent noise reduction, preventing costly repairs, and minimizing environmental impact. Although upfront costs may be higher for durable components, the long-term savings in maintenance and replacement, combined with the peace of mind knowing the component will perform reliably, make it a worthwhile investment. The primary challenge involves accurately assessing the long-term value and identifying components manufactured with verifiable material specifications and quality control processes.

3. Noise Reduction

Effective noise reduction is a core function and defining characteristic of a professionally designed and dependable exhaust silencing device. The primary purpose of such a device is to mitigate the sound pressure levels generated by the internal combustion engine as exhaust gases are expelled. Without adequate noise reduction, vehicle operation would contribute significantly to environmental noise pollution and compromise passenger comfort. A well-designed muffler achieves this noise reduction through a combination of sound wave interference, absorption, and redirection, resulting in a substantial decrease in the audible output from the tailpipe. For instance, a vehicle equipped with a malfunctioning or absent muffler can produce noise levels exceeding legal limits, subjecting the operator to fines and requiring immediate corrective action. In contrast, a properly functioning system keeps noise within acceptable boundaries, ensuring regulatory compliance and promoting a more pleasant acoustic environment.

The specific design elements incorporated into the muffler directly influence its noise reduction capabilities. Chambered mufflers, for example, utilize a series of strategically placed chambers and baffles to reflect and cancel out sound waves, reducing their amplitude. Absorption mufflers, on the other hand, employ sound-absorbing materials like fiberglass or steel wool to dissipate sound energy as it passes through the muffler. Hybrid designs combine both chambered and absorption techniques to achieve optimal noise reduction across a wider range of frequencies. Automotive manufacturers often invest significant resources in acoustic engineering to develop muffler designs that effectively minimize noise without compromising engine performance. A practical demonstration of this principle is apparent in luxury vehicles, where extensive soundproofing measures, including advanced muffler designs, contribute to a significantly quieter cabin environment compared to economy models. Moreover, the design of the exhaust system as a whole, including the placement of resonators and catalytic converters, can also influence noise reduction effectiveness.

In summary, noise reduction is not merely a desirable feature of a professionally implemented and reliable exhaust silencing device; it is its fundamental purpose. The degree of noise reduction achieved directly impacts the vehicle’s compliance with noise regulations, the comfort of vehicle occupants, and the overall quality of the acoustic environment. Challenges remain in balancing optimal noise reduction with other performance considerations, such as backpressure and fuel efficiency, requiring ongoing innovation in muffler design and materials science. This understanding underscores the critical role of a well-engineered muffler in promoting responsible vehicle operation and environmental stewardship.

4. Emissions Compliance

Emissions compliance constitutes a critical regulatory requirement for all modern vehicles, directly impacting the design, functionality, and selection of exhaust system components, including the noise reduction device. A properly functioning exhaust system, incorporating a reliable muffler, plays a vital role in minimizing the release of harmful pollutants into the atmosphere, adhering to stringent environmental standards.

- Catalytic Converter Integration

The exhaust silencing device often resides downstream of the catalytic converter, which chemically transforms pollutants into less harmful substances. A poorly functioning muffler can create excessive backpressure, hindering the converter’s performance and increasing emissions. The location and design must not impede the converter’s functionality.

- Backpressure Management

Exhaust backpressure, the resistance to exhaust gas flow, significantly affects engine performance and emissions. A reliable muffler is engineered to minimize backpressure while still providing adequate noise reduction. Excessive backpressure can reduce fuel efficiency, increase emissions, and even damage engine components. Careful design considerations are crucial to optimize these competing factors.

- Leak Prevention

Exhaust leaks, whether from the muffler itself or its connections, allow uncombusted hydrocarbons and other pollutants to escape into the atmosphere. A durable and well-sealed muffler is essential to prevent such leaks. Regular inspections and proper installation techniques are necessary to maintain a leak-free system.

- Material Compatibility

The materials used in the construction of the exhaust silencing device must be compatible with the chemical composition of exhaust gases and the operating temperatures of the exhaust system. Incompatible materials can degrade over time, releasing contaminants into the environment and reducing the muffler’s effectiveness. Corrosion-resistant materials are therefore vital for ensuring long-term emissions compliance.

The interplay between these facets highlights the necessity of selecting an exhaust silencing device designed with emissions compliance as a primary consideration. Failure to address these elements can result in increased pollution, regulatory penalties, and compromised vehicle performance. A high-quality, professionally installed, and reliable muffler is therefore an indispensable component of a vehicle’s emissions control system.

5. Longevity Maximization

Longevity maximization, in the context of a professionally installed and dependable exhaust silencing device, represents a concerted effort to extend the operational lifespan and maintain the functional effectiveness of the unit over an extended period. It encompasses a range of factors from material selection to maintenance practices, all contributing to the long-term value and performance of the component.

- Corrosion Resistance Prioritization

The selection of corrosion-resistant materials, such as stainless steel or aluminized steel, is paramount in maximizing the lifespan of the device. These materials resist the corrosive effects of exhaust gases, road salts, and moisture, which are primary contributors to premature failure. In regions with harsh winter conditions, the difference in lifespan between a low-grade steel muffler and a stainless steel counterpart can be significant, with the latter exhibiting several times the service life. This proactive approach minimizes the need for frequent replacements, reducing both cost and environmental impact.

- Robust Construction and Welding Techniques

The structural integrity of the muffler is directly linked to its ability to withstand physical stresses and vibrations over time. Robust construction, incorporating reinforced welds and thicker gauge materials, enhances the component’s resistance to damage from road debris, thermal cycling, and mechanical fatigue. Poorly executed welds or inadequate material thickness can lead to cracking and premature failure, negating any potential cost savings from cheaper materials. Proper construction methods ensure that the muffler maintains its structural integrity and functional performance throughout its service life.

- Proper Installation and Alignment Practices

Correct installation practices are essential for preventing undue stress on the muffler and its associated components. Misalignment, inadequate support hangers, or improperly tightened connections can introduce stress points that lead to premature failure. Proper alignment ensures that the muffler is not subjected to excessive vibration or strain, while adequate support hangers prevent sagging or movement that can damage the component. Following manufacturer-recommended installation procedures and utilizing qualified technicians are crucial steps in maximizing the lifespan of the muffler.

- Regular Inspection and Preventative Maintenance

Routine visual inspections and preventative maintenance practices are essential for identifying and addressing potential issues before they escalate into major problems. Inspections should focus on identifying signs of corrosion, damage, leaks, or loose connections. Promptly addressing any identified issues, such as repairing leaks or replacing worn-out hangers, can prevent more extensive damage and extend the muffler’s lifespan. Regular cleaning to remove accumulated debris and applying protective coatings can further enhance its durability.

These interconnected elements highlight the multifaceted nature of longevity maximization in relation to a professionally installed and dependable exhaust silencing device. A holistic approach that incorporates careful material selection, robust construction, proper installation, and routine maintenance is essential for achieving the maximum possible lifespan and ensuring consistent performance. This proactive strategy translates into long-term cost savings, reduced environmental impact, and a more reliable and enjoyable driving experience. In contrast, neglecting these factors will invariably lead to premature failure, increased maintenance costs, and compromised vehicle performance.

6. Performance Consistency

Performance consistency, in relation to an exhaust silencing device, denotes the sustained ability of the component to maintain its operational parameters within acceptable tolerances over its designed lifespan. This reliability is paramount, as deviations from expected performance can impact vehicle emissions, fuel efficiency, noise reduction, and overall operational safety.

- Stable Noise Attenuation

A pro reliable muffler ensures consistent noise reduction throughout its operational life. This implies minimal degradation in its sound-dampening capabilities due to internal component wear, material fatigue, or environmental corrosion. In contrast, a lower-quality muffler might exhibit a noticeable increase in exhaust noise over time, indicating a breakdown in its internal baffling or sound-absorbing materials. Stable noise attenuation levels correlate directly with the quality of materials and the precision of manufacturing processes used in its construction.

- Consistent Backpressure Levels

Maintaining consistent exhaust backpressure is crucial for optimal engine performance and fuel efficiency. A professionally engineered muffler is designed to provide a specific level of backpressure within the exhaust system. Deviations from this design can lead to reduced horsepower, increased fuel consumption, and potentially, damage to engine components. Reliable mufflers maintain this designed backpressure level over time, despite exposure to high temperatures and corrosive exhaust gases, demonstrating the stability of its internal structure and flow dynamics.

- Durability Under Varying Conditions

A reliable exhaust silencing device withstands a wide range of operating conditions, including extreme temperatures, exposure to road salts, and physical impacts. Performance consistency implies that the muffler’s noise reduction and backpressure characteristics remain stable even under these challenging circumstances. For example, a muffler that experiences significant performance degradation after exposure to a single winter season would be considered inconsistent and unreliable.

- Predictable Lifespan

While complete predictability is unattainable, a pro reliable muffler exhibits a predictable lifespan based on its design, materials, and expected operating conditions. This predictability allows for proactive maintenance and replacement planning, minimizing unexpected breakdowns and associated costs. In contrast, a low-quality muffler might fail prematurely and without warning, resulting in vehicle downtime and potentially more extensive repairs.

These elements illustrate how performance consistency is integral to the overall reliability and value proposition of an exhaust silencing device. The ability to maintain intended performance levels under diverse conditions and over a predictable lifespan translates directly to reduced maintenance costs, improved fuel efficiency, and minimized environmental impact, underscoring the importance of choosing a professionally engineered and dependable muffler. These points are more critical to consider and observe for safety measures.

7. Cost-Effectiveness

The assessment of cost-effectiveness in the context of an exhaust silencing device extends beyond the initial purchase price. It encompasses the long-term operational costs, potential repair expenses, and the overall lifespan of the component. A seemingly inexpensive muffler may prove more costly in the long run if it requires frequent replacement or leads to decreased fuel efficiency and increased emissions.

- Extended Lifespan and Reduced Replacement Costs

A key aspect of cost-effectiveness is the expected lifespan of the muffler. A professionally installed, reliable unit constructed from durable materials, such as stainless steel, typically exhibits a significantly longer service life compared to cheaper alternatives. This extended lifespan translates directly into reduced replacement costs, as the unit requires less frequent replacement over the vehicle’s operational life. For example, a stainless-steel muffler might last for ten years or more, while a low-grade steel muffler might require replacement every two to three years, resulting in substantially higher cumulative costs.

- Fuel Efficiency and Reduced Operating Expenses

A properly functioning exhaust system, including a reliable muffler, contributes to optimal engine performance and fuel efficiency. Excessive backpressure, caused by a poorly designed or damaged muffler, can reduce engine power and increase fuel consumption. A cost-effective muffler is engineered to minimize backpressure while still providing adequate noise reduction, resulting in improved fuel economy and reduced operating expenses. Over the course of several years, the fuel savings resulting from a properly functioning muffler can significantly offset the initial cost of a higher-quality unit. In contrast, a poorly designed or malfunctioning muffler can lead to increased fuel consumption and higher operating costs.

- Minimized Repair and Maintenance Expenses

A reliable muffler is less prone to damage and failure, resulting in reduced repair and maintenance expenses. Components constructed from durable materials and installed according to manufacturer specifications are less susceptible to corrosion, leaks, and structural damage. This decreased susceptibility translates into fewer trips to the repair shop and lower overall maintenance costs. For example, a muffler with reinforced welds and robust construction is less likely to develop cracks or leaks, reducing the need for welding repairs or component replacement.

- Avoidance of Regulatory Penalties

A properly functioning exhaust system, including a reliable muffler, ensures compliance with local noise regulations and emissions standards. Non-compliance can result in fines and penalties, adding to the overall cost of vehicle operation. A cost-effective muffler helps to avoid these regulatory penalties by maintaining noise levels within acceptable limits and ensuring that the vehicle meets emissions requirements. By investing in a high-quality muffler, vehicle owners can mitigate the risk of incurring fines and penalties associated with non-compliance.

These facets demonstrate that cost-effectiveness, in the context of a reliable muffler, is not solely determined by the initial purchase price. Instead, it encompasses a broader perspective that considers the long-term operational costs, potential repair expenses, and the overall lifespan of the component. A higher initial investment in a professionally installed and dependable unit often translates into significant long-term savings due to reduced replacement costs, improved fuel efficiency, minimized repair expenses, and avoidance of regulatory penalties.

Frequently Asked Questions About Exhaust Silencing Devices

The following section addresses common inquiries and clarifies prevailing misconceptions regarding exhaust noise reduction components, aiming to provide a clear understanding of their functionality, selection, and maintenance.

Question 1: What constitutes a “pro reliable muffler,” and why is it necessary?

A “pro reliable muffler” denotes a high-quality exhaust silencing device engineered for consistent performance and extended lifespan. Its necessity stems from regulatory requirements for noise reduction, the need for optimized engine efficiency, and the desire for a comfortable driving experience.

Question 2: How does the material composition impact the performance of a pro reliable muffler?

The material composition significantly impacts a muffler’s durability and resistance to corrosion. Stainless steel and aluminized steel are commonly utilized due to their superior resistance to exhaust gases and environmental elements, leading to enhanced longevity compared to lower-grade materials.

Question 3: What are the potential consequences of neglecting proper muffler maintenance?

Neglecting muffler maintenance can result in diminished noise reduction, reduced fuel efficiency due to increased backpressure, potential exhaust leaks leading to hazardous fume inhalation, and eventual component failure necessitating costly repairs or replacements.

Question 4: How does professional installation contribute to the longevity of an exhaust silencing device?

Professional installation ensures correct alignment, secure mounting, and proper sealing, minimizing stress on the component and preventing exhaust leaks. Trained technicians can identify and address potential issues during installation, maximizing the muffler’s lifespan and performance.

Question 5: What role does a reliable muffler play in vehicle emissions compliance?

While catalytic converters are primary, a functioning muffler ensures proper exhaust flow and prevents leaks that could release harmful pollutants into the atmosphere. Excessive backpressure from a failing muffler can also impede catalytic converter performance, leading to increased emissions.

Question 6: Is a higher initial investment in a pro reliable muffler justified, considering the available alternatives?

A higher initial investment is often justified due to the extended lifespan, improved fuel efficiency, reduced maintenance costs, and ensured emissions compliance associated with a reliable, professionally installed muffler. The long-term cost of ownership is typically lower compared to repeatedly replacing cheaper, less durable alternatives.

In summary, understanding the intricacies of exhaust silencing devices, prioritizing quality components, and adhering to proper maintenance practices are paramount for ensuring optimal vehicle performance, environmental responsibility, and long-term cost-effectiveness.

The subsequent sections will delve into specific selection criteria and offer guidance on identifying reputable manufacturers and installation services.

Conclusion

The preceding analysis has underscored the multifaceted benefits of prioritizing a pro reliable muffler in vehicle maintenance and operation. From ensuring regulatory compliance with noise and emissions standards to optimizing engine performance and minimizing long-term ownership costs, the selection of a high-quality exhaust silencing device represents a sound investment.

Moving forward, continued advancements in materials science and acoustic engineering promise to further enhance the performance and durability of these essential automotive components. Therefore, vehicle owners and maintenance professionals should remain informed about emerging technologies and best practices to ensure the continued effective and responsible operation of motor vehicles.