A high-performance exhaust component designed for off-road vehicles, specifically ATVs and UTVs, enhances engine output and modifies exhaust acoustics. These components typically replace the original equipment manufacturer (OEM) exhaust system to improve airflow and reduce backpressure. An example is a system installed on a sport ATV to increase horsepower and torque.

The advantages of these systems include potential increases in engine power, improved throttle response, and a reduction in overall vehicle weight compared to stock systems. Historically, aftermarket exhaust systems have been developed to address limitations in OEM designs, often focusing on improving performance and providing customizable sound profiles for enthusiasts.

The following sections will delve into specific aspects related to the construction, performance characteristics, and maintenance considerations of these aftermarket exhaust solutions.

Optimizing Performance with Aftermarket Exhaust Systems

The following tips provide guidance on maximizing the benefits and ensuring the longevity of performance-enhancing exhaust components. Adherence to these recommendations contributes to optimal vehicle performance and reduces the risk of premature component failure.

Tip 1: Select the Appropriate System: Choose a system designed specifically for the vehicle make, model, and intended use. Verify compatibility and ensure the system meets regulatory requirements, if applicable.

Tip 2: Proper Installation is Critical: Follow the manufacturer’s installation instructions precisely. Incorrect installation can lead to exhaust leaks, reduced performance, and potential engine damage. Consider professional installation if lacking mechanical expertise.

Tip 3: Regular Inspection: Periodically inspect the system for signs of damage, such as cracks, dents, or corrosion. Address any issues promptly to prevent further degradation and maintain optimal performance.

Tip 4: Monitor Exhaust System Fasteners: Exhaust systems are subject to significant temperature fluctuations and vibration. Check and tighten all fasteners regularly to prevent loosening and potential exhaust leaks.

Tip 5: Utilize Proper Maintenance Procedures: Clean the exhaust system regularly to remove dirt, debris, and contaminants. Apply a high-temperature protectant to prevent corrosion, particularly in harsh environments.

Tip 6: Adjust Fuel Mapping as Needed: Modifying the exhaust system can alter the engine’s air/fuel ratio. Consider using a fuel controller or having the ECU remapped to optimize performance and prevent engine damage caused by a lean condition.

Tip 7: Sound Level Monitoring: Be mindful of noise regulations in your operating area. Consider using exhaust inserts or sound-dampening materials to comply with local ordinances and minimize disturbance to others.

Following these guidelines ensures the user receives the full performance benefits of an aftermarket exhaust system while minimizing potential issues. These practices promote reliability and long-term enjoyment of the vehicle.

The subsequent sections will explore frequently asked questions and potential troubleshooting scenarios related to these exhaust modifications.

1. Performance enhancement

The core objective of these aftermarket exhaust systems centers on elevating the operational capabilities of off-road vehicles. This enhancement stems from modifications to the exhaust flow dynamics, reducing backpressure and enabling the engine to expel exhaust gases more efficiently. The resulting effect is an increase in horsepower and torque, translating to improved acceleration and overall engine responsiveness. A practical example is observed when an ATV equipped with such a system demonstrates enhanced hill-climbing ability and quicker acceleration compared to its stock configuration.

Performance improvement achieved through the integration of these systems is contingent upon several factors, including the design of the system, the engine’s characteristics, and the accuracy of fuel mapping adjustments. Improper installation or inadequate fuel tuning can negate the intended benefits and potentially lead to engine damage. A specific instance involves installing a high-flow exhaust on an engine without corresponding adjustments to the fuel injection system, resulting in a lean air-fuel mixture and potential engine overheating.

In summary, the correlation between these exhaust systems and performance enhancement is predicated on the system’s design efficacy, proper installation, and appropriate fuel management. While the potential for increased power and responsiveness exists, realizing these gains requires a comprehensive understanding of the engine’s requirements and careful attention to detail during installation and tuning. Failure to address these factors can negate the advantages and potentially compromise engine reliability.

2. Sound Modulation

Sound modulation represents a critical aspect of exhaust system design, influencing both the auditory experience and regulatory compliance. In the context of performance exhaust components for off-road vehicles, sound modulation strategies are deliberately engineered to strike a balance between enhanced exhaust note and acceptable noise levels.

- Internal Baffling Design

The internal structure of the exhaust system, particularly the baffling configuration, plays a primary role in shaping the emitted sound. Baffles strategically redirect and impede exhaust flow, attenuating certain frequencies and altering the overall sound profile. A denser baffle arrangement generally results in a quieter exhaust note, while a more open design yields a louder, more aggressive sound. Manufacturers often experiment with various baffle shapes and placements to achieve a specific sound characteristic.

- Resonator Implementation

Resonators are chambers within the exhaust system designed to cancel out specific sound frequencies. They operate on the principle of acoustic interference, where sound waves of opposite phase are used to neutralize undesirable noise components. Incorporating resonators into the exhaust system allows manufacturers to target and eliminate specific frequencies that contribute to drone or harshness, resulting in a more refined and pleasing exhaust note.

- Exhaust Tip Configuration

The design of the exhaust tip, including its shape, size, and material, can influence the sound emitted from the system. A flared tip, for example, can amplify the exhaust note, while a downturned tip can direct the sound downwards, reducing its perceived loudness. The tip’s construction material also contributes to the sound’s tonal quality. Stainless steel tips often produce a brighter, more metallic sound compared to ceramic-coated tips.

- Acoustic Packing Materials

Acoustic packing materials, such as fiberglass or stainless steel wool, line the inside of the exhaust canister and absorb sound energy. These materials reduce the overall noise level by converting sound waves into heat through friction. The type, density, and placement of acoustic packing influence the exhaust’s sound absorption characteristics. Over time, these materials can degrade, leading to an increase in exhaust noise.

These sound modulation techniques are integral to the design and performance characteristics of aftermarket exhaust systems. The selection and implementation of these methods determine the final auditory signature, influencing both the operator’s experience and compliance with noise regulations. The careful engineering of sound modulation strategies is crucial for achieving the desired balance between performance enhancement and responsible operation.

3. Material Durability

Material durability is a critical attribute directly impacting the operational lifespan and performance consistency of a high-performance exhaust component. These systems, designed for demanding environments such as off-road vehicle applications, are subjected to substantial stresses including extreme temperatures, vibrations, and exposure to corrosive elements like water, mud, and road salts. The choice of materials therefore has a direct cause-and-effect relationship with the exhaust system’s ability to withstand these rigors and maintain its structural integrity and functional effectiveness over time.

The utilization of high-grade materials is not merely a cosmetic enhancement but rather a fundamental necessity for ensuring longevity and reliable performance. For instance, stainless steel alloys, such as 304 or 316, are frequently employed due to their superior corrosion resistance and high-temperature strength. These alloys form a protective oxide layer that inhibits rust formation, a common failure mode in exhaust systems. Titanium, while more expensive, offers an exceptional strength-to-weight ratio and superior heat dissipation, making it suitable for high-performance applications where weight reduction and thermal management are paramount. Conversely, lower-grade materials or inadequate manufacturing processes can lead to premature failure, manifested as cracks, leaks, or complete structural collapse. These failures not only compromise performance but can also pose safety hazards. Consider the example of an exhaust system constructed from mild steel in a coastal environment; the rapid corrosion caused by salt spray will significantly shorten its lifespan compared to a stainless steel counterpart.

In conclusion, material durability is an indispensable design consideration, not simply a desirable feature. The long-term reliability and consistent performance of a high-performance exhaust component are fundamentally linked to the quality of materials used in its construction and the manufacturing processes employed. Selecting systems constructed from durable, corrosion-resistant materials is a key factor in ensuring a worthwhile investment and avoiding costly repairs or replacements in the long run. Neglecting this aspect can lead to compromised performance, reduced lifespan, and potential safety risks, ultimately undermining the benefits expected from an aftermarket exhaust upgrade.

4. Installation Complexity

The installation of an aftermarket performance exhaust component is a multifaceted procedure with varying degrees of difficulty depending on the vehicle, the specific system design, and the installer’s mechanical aptitude. The complexity of this process directly impacts the time required, tools necessary, and the potential need for professional assistance.

- Direct-Fit Replacement vs. Universal Modifications

Systems designed as “direct-fit” replacements aim for simplified installation by matching the mounting points and dimensions of the OEM exhaust. This minimizes the need for fabrication or modification. Conversely, universal systems often require cutting, welding, and custom fitting to adapt to the vehicle chassis. Direct-fit systems generally decrease installation complexity, reducing time and skill requirements. An example is a bolt-on system for a specific ATV model versus a universal exhaust requiring extensive modification.

- Component Accessibility and Disassembly

The ease of access to the existing exhaust system and the complexity of its removal significantly influence the overall installation difficulty. Vehicles with readily accessible exhaust components and straightforward mounting hardware present fewer challenges than those requiring extensive disassembly of surrounding parts or the use of specialized tools. For instance, removal of a rusted exhaust manifold can substantially increase installation time and complexity.

- Requirement for Specialized Tools and Equipment

Some installations necessitate specialized tools such as exhaust pipe cutters, welders, oxygen sensor wrenches, or diagnostic equipment for fuel mapping adjustments. The need for these tools increases the complexity and may necessitate professional installation if the installer lacks the required equipment or expertise. An example includes systems requiring welding for proper fitment or oxygen sensor recalibration.

- Post-Installation Adjustments and Calibration

Proper installation often extends beyond the physical mounting of the exhaust system. Many performance systems necessitate adjustments to the engine’s fuel mapping to optimize performance and prevent lean conditions. This may involve installing a fuel controller or re-flashing the ECU, tasks that require specialized knowledge and equipment. Failing to address these adjustments can lead to suboptimal performance or engine damage.

The varying levels of installation complexity demand careful consideration. A seemingly straightforward exhaust upgrade can quickly become a challenging project if unforeseen obstacles arise or specialized skills are needed. It is imperative to accurately assess one’s mechanical abilities and access to necessary tools before attempting the installation. Professional installation, while incurring additional cost, often mitigates the risks associated with improper installation and ensures optimal performance.

5. Maintenance requirements

The operational longevity and sustained performance of aftermarket exhaust systems are inextricably linked to consistent adherence to prescribed maintenance procedures. Neglecting these requirements can precipitate premature component degradation, leading to diminished performance and potential system failure. The exhaust component is exposed to harsh operating conditions, including extreme temperature fluctuations, corrosive exhaust gases, and environmental contaminants. These factors collectively contribute to wear and tear, necessitating proactive maintenance to mitigate their adverse effects.

Regular maintenance activities encompass several critical aspects. Periodic inspection for signs of corrosion, cracks, or physical damage is paramount. Promptly addressing any identified issues prevents further degradation and potentially costly repairs. Cleaning the exhaust system to remove accumulated carbon deposits and debris maintains optimal flow characteristics and prevents restriction. The application of high-temperature protective coatings inhibits corrosion and extends the lifespan of the component. Furthermore, ensuring that all mounting hardware remains properly tightened minimizes vibration-induced stress and prevents exhaust leaks. As a tangible example, consider an exhaust system subjected to frequent off-road use in muddy conditions. Without regular cleaning, accumulated mud and debris can accelerate corrosion and impede heat dissipation, leading to premature failure.

In summary, diligent maintenance practices are essential for realizing the full potential and maximizing the lifespan of the exhaust system. Ignoring these requirements not only diminishes performance but also increases the risk of system failure and costly repairs. A proactive maintenance regimen, incorporating regular inspections, cleaning, and protective measures, ensures continued optimal performance and preserves the investment in the aftermarket exhaust system. Adhering to these guidelines is paramount for sustaining the performance benefits and ensuring the long-term reliability of the exhaust modification.

Frequently Asked Questions

The following addresses common inquiries concerning the operational characteristics and practical considerations of aftermarket exhaust components.

Question 1: Does this exhaust modification void the vehicle’s warranty?

The impact on a vehicle’s warranty depends on various factors, including the specific warranty terms, the nature of the modification, and applicable laws. In many jurisdictions, a modification will only void the warranty if the manufacturer can demonstrate that the modification directly caused the failure of a covered component. Routine maintenance and non-related repairs remain covered. Consult the vehicle’s warranty documentation and relevant legal precedents for clarification.

Question 2: What performance gains can be expected from this exhaust upgrade?

Performance gains vary based on engine characteristics, exhaust system design, and supporting modifications. Expect modest gains in horsepower and torque, particularly in the mid-range. A professionally dyno-tuned vehicle will demonstrate the most substantial improvements. Claims of significant power increases exceeding 15% should be viewed with skepticism unless substantiated by independent testing.

Question 3: Are fuel mapping adjustments necessary after installation?

Fuel mapping adjustments are highly recommended, especially with high-flow exhaust systems. Altering exhaust flow can disrupt the engine’s air-fuel ratio, potentially leading to a lean condition and engine damage. A fuel controller or ECU remapping ensures optimal performance and prevents engine damage. Consult with a qualified tuner for proper calibration.

Question 4: What is the expected lifespan of this aftermarket exhaust?

Lifespan is dependent on material quality, environmental conditions, and maintenance practices. Stainless steel systems, properly maintained, can last for many years. Exposure to harsh chemicals or neglect can significantly shorten the system’s lifespan. Regular inspection and cleaning are critical for longevity.

Question 5: Does this exhaust system comply with noise regulations?

Noise regulations vary by jurisdiction. It is the operator’s responsibility to ensure compliance with local noise ordinances. Some systems include sound inserts or baffles to reduce noise levels. Confirm compliance before operating the vehicle in noise-sensitive areas.

Question 6: Can this exhaust system be repaired if damaged?

Repair options depend on the nature and extent of the damage. Minor cracks or leaks can often be repaired by welding. Severe damage or corrosion may necessitate replacement of the entire system or affected components. Consult with a qualified exhaust repair specialist for assessment.

Understanding these aspects will empower the owner to make informed decisions about aftermarket exhaust modifications.

The subsequent section delves into troubleshooting common issues related to these systems.

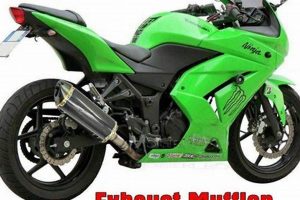

hmf muffler

This exploration detailed the multifaceted nature of this performance component, encompassing performance enhancement, sound modulation, material durability, installation considerations, and maintenance requirements. Proper selection, installation, and upkeep are crucial to realizing the intended benefits and ensuring the system’s longevity. Neglecting any of these aspects can lead to suboptimal performance, premature failure, and potential safety concerns.

Therefore, a comprehensive understanding of these factors is essential for responsible ownership and operation. Continued adherence to best practices, coupled with a commitment to informed decision-making, will maximize the return on investment and contribute to a positive and safe operating experience. Furthermore, staying abreast of evolving technologies and regulatory standards remains crucial for navigating the dynamic landscape of performance exhaust modifications.