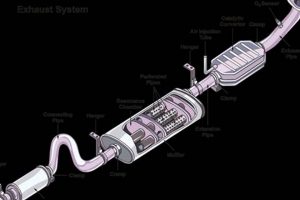

An automotive exhaust component designed to reduce noise emissions from a single source is the focus. This device, typically integrated into the exhaust system, functions by attenuating sound waves generated by the engine’s combustion process. For example, it might be used in a single-cylinder engine application or in a customized exhaust setup where noise reduction on one specific outlet is paramount.

The significance of such a component lies in its ability to meet regulatory noise standards, enhance vehicle operator and bystander comfort, and contribute to overall environmental well-being by minimizing noise pollution. Historically, these devices have evolved significantly, from simple expansion chambers to sophisticated multi-chambered and absorption-based designs, driven by increasingly stringent noise control regulations and advancements in materials science.

Considering the fundamental purpose of individual sound suppression, subsequent discussions will delve into specific types of noise reduction technologies, the materials used in their construction, and the factors influencing their performance and durability within an automotive exhaust system.

Guidance on Individual Exhaust Sound Attenuation

The following advice provides insight into optimizing noise reduction from a singular exhaust source. Implementing these recommendations can improve performance, longevity, and compliance with noise regulations.

Tip 1: Material Selection: Choose materials resistant to corrosion and high temperatures. Stainless steel or aluminized steel offer enhanced durability compared to standard steel, extending the device’s lifespan in harsh environments.

Tip 2: Proper Sizing: Ensure the device’s dimensions are appropriate for the engine’s displacement and exhaust flow rate. Undersized components may create excessive backpressure, hindering engine performance, while oversized units might not effectively attenuate sound.

Tip 3: Correct Installation: Adhere to manufacturer’s installation guidelines to prevent leaks and ensure optimal performance. Improper installation can lead to reduced noise reduction and potential exhaust system damage.

Tip 4: Regular Inspection: Conduct routine visual inspections for signs of damage, such as rust, cracks, or loose connections. Addressing minor issues promptly can prevent more significant problems and costly repairs.

Tip 5: Acoustic Damping Material: Utilize high-quality acoustic damping material internally for enhanced sound absorption. Fiberglass or specialized sound-deadening wraps can improve overall noise reduction capabilities.

Tip 6: Sealing Integrity: Verify the integrity of all seals and connections within the exhaust system. Exhaust leaks can significantly compromise noise reduction effectiveness and create potentially hazardous conditions.

Proper selection, installation, and maintenance are critical for ensuring the effectiveness and longevity of individual exhaust sound attenuation devices. Adherence to these guidelines will contribute to improved performance and reduced noise emissions.

In conclusion, consistent attention to these details offers an optimized approach to managing exhaust noise, leading to improved operational characteristics and minimizing environmental impact. The subsequent sections will elaborate on specific technologies employed in individual exhaust sound attenuation.

1. Material Durability

Material durability is a critical factor in the performance and longevity of an exhaust sound attenuation device on a single exhaust outlet. The harsh environment within an exhaust system, characterized by high temperatures, corrosive gases, and vibration, necessitates robust material selection to ensure operational integrity and prevent premature failure.

- Corrosion Resistance

The primary threat to exhaust system components is corrosion, arising from the condensation of acidic byproducts of combustion. Materials like stainless steel (particularly 304 or 316 grades) offer superior corrosion resistance compared to aluminized or mild steel. This property is crucial in extending the lifespan of the device, especially in regions with high humidity or road salt usage.

- Thermal Fatigue Resistance

Exhaust systems undergo significant temperature fluctuations during vehicle operation. Repeated heating and cooling cycles induce thermal stress, leading to fatigue and potential cracking. Materials with high thermal fatigue resistance, such as certain grades of stainless steel or specialized alloys, are essential for maintaining structural integrity over extended periods.

- Mechanical Strength at Elevated Temperatures

The exhaust system experiences high temperatures, potentially exceeding 500C near the engine. Materials must retain sufficient mechanical strength at these temperatures to withstand the pressure and vibration generated by the exhaust flow. The selection of materials with appropriate high-temperature strength is critical for preventing deformation or failure.

- Abrasion Resistance

Road debris and particulate matter in the exhaust gas can cause abrasion of the device’s internal components. Selecting materials with high abrasion resistance, or incorporating protective coatings, can mitigate wear and tear, preserving the sound attenuation performance and structural integrity over time.

In summary, the material composition of an individual exhaust sound attenuation device directly impacts its ability to withstand the rigors of the exhaust environment. Selecting durable, high-quality materials is paramount for ensuring long-term performance, minimizing maintenance requirements, and complying with noise regulations. The initial investment in robust materials often translates to significant cost savings over the lifecycle of the vehicle.

2. Sound Attenuation

Sound attenuation represents the core function of a “muffler for one,” denoting the reduction of noise emitted from a single exhaust outlet. The design and effectiveness of the device are directly proportional to its sound attenuation capabilities. The cause-and-effect relationship is straightforward: optimized design leads to greater decibel reduction. For instance, a motorcycle exhaust system might employ a specifically designed device to meet community noise ordinances. In this case, understanding the principles of sound attenuation is paramount to the device’s success in achieving compliance.

The methods of sound attenuation employed within a “muffler for one” can vary. Absorption techniques use materials to convert sound energy into heat, while reactive techniques employ chambers and baffles to cancel out sound waves. A real-world example is an aftermarket single-exit exhaust system for a performance car, which often incorporates a combination of these methods to achieve both a desirable exhaust note and reduced overall noise levels. The practical significance lies in balancing performance with regulatory requirements and driver comfort.

Effective sound attenuation in a “muffler for one” is crucial for noise regulation compliance and environmental considerations. Challenges exist in maintaining performance while minimizing backpressure, which can negatively impact engine efficiency. Ultimately, the integration of advanced sound attenuation technologies within such devices contributes to quieter vehicles and a more sustainable transportation ecosystem. Understanding and implementing these technologies is essential for future automotive developments.

3. Backpressure

Backpressure, the resistance to exhaust flow created by the exhaust system, is an unavoidable characteristic directly influenced by the design of an individual noise reduction device. Its presence dictates the engine’s ability to expel exhaust gases efficiently, thus affecting overall engine performance and fuel economy. The magnitude of backpressure introduced by a “muffler for one” is a critical design consideration, necessitating a balance between noise attenuation and exhaust flow optimization.

- Backpressure and Engine Efficiency

Excessive backpressure impedes the expulsion of exhaust gases, requiring the engine to expend more energy during the exhaust stroke. This increased energy expenditure reduces volumetric efficiency, leading to decreased power output and increased fuel consumption. The impact is most pronounced at higher engine speeds where exhaust flow rates are greatest. A well-designed “muffler for one” minimizes backpressure while effectively reducing noise.

- Design Considerations for Backpressure Reduction

The internal structure of the noise reduction device dictates the level of backpressure it generates. Straight-through designs, characterized by minimal obstructions to exhaust flow, offer the lowest backpressure. Chambered designs, while potentially providing superior noise attenuation, often introduce higher levels of backpressure due to the redirection and expansion of exhaust gases. The selection of design is often a compromise between noise reduction targets and performance requirements.

- Impact on Forced Induction Engines

Engines equipped with turbochargers or superchargers are particularly sensitive to backpressure. The turbine in a turbocharger relies on exhaust gas flow to spin and compress intake air. Excessive backpressure downstream of the turbine hinders its operation, reducing boost pressure and negating the benefits of forced induction. In these applications, minimizing backpressure is paramount.

- Measurement and Monitoring of Backpressure

Backpressure can be measured using pressure sensors installed in the exhaust system. Monitoring backpressure levels provides valuable information regarding the health and performance of the engine and exhaust system. Abnormally high backpressure readings may indicate a clogged or restricted exhaust system, necessitating inspection and repair. Periodic monitoring can prevent performance degradation and potential engine damage.

The relationship between backpressure and “muffler for one” is a crucial aspect of exhaust system design. Minimizing backpressure is essential for maintaining engine efficiency and performance, particularly in forced induction applications. Careful consideration of design, material selection, and regular monitoring are necessary to optimize exhaust flow and ensure long-term operational effectiveness. The trade-offs between noise attenuation and backpressure must be carefully evaluated to achieve optimal vehicle performance and regulatory compliance.

4. Flow Capacity

Flow capacity, representing the volume of exhaust gases that can pass through a “muffler for one” within a specific timeframe, directly impacts engine performance. If the flow capacity is insufficient, the device creates excessive backpressure, hindering the engine’s ability to expel exhaust gases efficiently. This, in turn, reduces volumetric efficiency, resulting in diminished power output and increased fuel consumption. For example, an undersized noise reduction device installed on a high-performance engine can severely restrict exhaust flow, negating any potential performance gains from other modifications. Therefore, selecting a “muffler for one” with adequate flow capacity is paramount for maintaining optimal engine performance.

The design of the “muffler for one” significantly influences its flow capacity. Straight-through designs, characterized by minimal internal obstructions, typically offer the highest flow rates. Chambered designs, while potentially providing superior noise attenuation, often exhibit reduced flow capacity due to the redirection and expansion of exhaust gases. The choice between these designs represents a trade-off between noise reduction and performance. Manufacturers often specify the flow capacity of their devices, allowing informed decisions based on engine displacement and performance requirements. Practical applications, such as selecting an appropriate noise reduction device for a turbocharged engine, demonstrate the necessity of matching flow capacity with engine demands to avoid power restrictions.

Understanding the relationship between flow capacity and “muffler for one” is essential for optimizing engine performance and ensuring long-term reliability. Selecting a device with inadequate flow capacity can lead to detrimental consequences, including reduced power, increased fuel consumption, and potential engine damage. The challenges lie in accurately assessing engine exhaust flow requirements and selecting a device that meets those demands without compromising noise reduction goals. Further development in noise reduction technologies seeks to enhance flow capacity while maintaining or improving sound attenuation, thereby contributing to a more efficient and environmentally responsible transportation ecosystem.

5. Installation

Proper installation is critical to the functionality and longevity of a “muffler for one.” The process directly affects the device’s performance, structural integrity, and compliance with applicable regulations. Incorrect installation can negate the intended noise reduction benefits, compromise exhaust system sealing, and potentially damage the engine. For example, misaligned connections can lead to exhaust leaks, increasing noise emissions and creating potentially hazardous conditions within the vehicle’s cabin. The installation phase, therefore, represents a pivotal step in realizing the intended performance of a single exhaust outlet noise reduction device. Attention to detail and adherence to manufacturer specifications are paramount.

The practical significance of a correct “muffler for one” installation extends beyond immediate performance. A properly installed device reduces stress on other exhaust system components, minimizing the likelihood of premature failures. Conversely, improper installation can introduce undue stress, accelerating wear and tear on adjacent parts. Real-world scenarios underscore this point; a muffler supported inadequately during installation can suffer from vibration-induced cracking, necessitating costly repairs. Further, ensuring proper sealing at connection points prevents exhaust leaks that can damage sensitive engine components and impact emissions testing results. The skill and precision applied during installation contribute directly to the overall reliability and lifespan of the entire exhaust system.

In conclusion, the installation of a “muffler for one” is not merely a procedural task but a critical determinant of its effectiveness and durability. Challenges arise from variations in vehicle models and exhaust system designs, requiring installers to possess specific knowledge and experience. Addressing these challenges through proper training and adherence to manufacturer guidelines contributes significantly to the successful implementation of noise reduction strategies and the overall performance of the vehicle. Future advancements may focus on simplified installation methods to minimize potential errors and ensure consistent results across a broader range of vehicles.

6. Regulations

Noise emission regulations significantly influence the design, manufacturing, and use of individual exhaust sound attenuation devices. Governmental bodies and international organizations establish limits on permissible noise levels generated by vehicles, necessitating the incorporation of effective sound suppression technologies. Compliance with these regulations is not merely a legal requirement but a societal expectation, aimed at mitigating noise pollution and improving quality of life. For example, the European Union’s noise emission standards (UNECE R41) mandate specific noise limits for vehicles, directly impacting the design and construction of individual exhaust components intended for use within the EU. This regulatory framework ensures that vehicles operating within member states adhere to acceptable noise levels. Consequently, the manufacturer is forced to incorporate a “muffler for one” as part of their product to comply with UNECE R41 regulations.

The practical significance of noise emission regulations lies in their direct impact on automotive engineering and development. Manufacturers must invest in research and development to create innovative noise reduction solutions that meet regulatory requirements without compromising vehicle performance or fuel efficiency. These regulations drive technological advancements in areas such as acoustic damping materials, exhaust system design, and active noise cancellation systems. The United States Environmental Protection Agency (EPA) also sets noise standards for medium and heavy-duty trucks. A real-world application is the retrofitting of older vehicles to comply with current standards, a task that often involves upgrading or replacing individual exhaust components to achieve the necessary noise reduction. The understanding of existing regulations is critical for any automotive mechanic working in this sector.

In summary, noise emission regulations play a central role in shaping the design and application of exhaust sound attenuation devices. Meeting these regulations is not only essential for legal compliance but also for fostering a quieter and more sustainable transportation environment. The ongoing evolution of noise regulations presents ongoing challenges for the automotive industry, stimulating innovation and encouraging the development of advanced noise reduction technologies. As society becomes more aware of the harmful effects of noise pollution, the importance of robust and effective regulations will only continue to grow, further driving the need for sophisticated individual exhaust sound attenuation solutions.

Frequently Asked Questions

This section addresses common inquiries regarding noise attenuation from a single exhaust outlet, providing clarity on technical aspects and practical considerations.

Question 1: What constitutes an individual exhaust noise reduction device, and where is it typically employed?

An individual exhaust noise reduction device, often referred to as a “muffler for one,” is a component designed to reduce noise emanating from a single exhaust outlet. This device is frequently implemented in single-cylinder engine applications, custom exhaust systems, or scenarios where focused noise reduction on a specific exhaust port is required.

Question 2: What are the primary mechanisms by which these devices attenuate sound?

Sound attenuation is achieved through various methods, including absorptive and reactive techniques. Absorptive techniques utilize materials to convert sound energy into heat, while reactive techniques employ chambers and baffles to manipulate sound waves, causing destructive interference and reducing noise levels.

Question 3: How does the flow capacity of an individual exhaust noise reduction device affect engine performance?

The flow capacity of the device is crucial. Insufficient flow capacity can create excessive backpressure, hindering the engine’s ability to expel exhaust gases efficiently. This reduced efficiency can lead to diminished power output and increased fuel consumption. A correctly sized device optimizes exhaust flow while effectively reducing noise.

Question 4: What materials are commonly used in the construction of these devices, and why?

Common materials include stainless steel, aluminized steel, and mild steel. Stainless steel offers superior corrosion resistance and durability, making it ideal for harsh exhaust environments. Aluminized steel provides a cost-effective alternative with moderate corrosion resistance. Mild steel, while less durable, is sometimes used in non-critical applications.

Question 5: How does improper installation impact the performance and longevity of the device?

Improper installation can compromise the device’s sealing, leading to exhaust leaks and reduced noise attenuation. Additionally, it can introduce undue stress on the device and surrounding components, accelerating wear and potentially causing premature failure. Adherence to manufacturer specifications is essential for proper installation.

Question 6: What are the regulatory considerations regarding noise emissions from individual exhaust outlets?

Noise emission regulations set limits on permissible noise levels generated by vehicles. Compliance with these regulations is mandatory and requires the implementation of effective sound suppression technologies. Regulations vary by jurisdiction, necessitating that manufacturers and installers be aware of applicable standards.

The effectiveness of any device, or “muffler for one,” depends upon adherence to design specifications, flow capacity requirements, installation accuracy, and regular maintenance.

Further sections will delve into specific applications of these noise reduction devices across diverse vehicle types and operational contexts.

Muffler for One

This exploration has detailed the intricacies of noise reduction from a single exhaust outlet. Critical aspects, including material durability, sound attenuation methodologies, backpressure management, flow capacity considerations, installation protocols, and regulatory compliance, have been examined. The effectiveness of a “muffler for one” is contingent upon a holistic understanding and application of these elements.

The ongoing pursuit of quieter and more efficient transportation systems necessitates continued advancements in individual exhaust noise reduction technologies. Rigorous adherence to established guidelines and a commitment to innovation will ensure the effective mitigation of noise pollution and contribute to a more sustainable automotive future. Further research and development remain crucial to optimize the performance and longevity of these devices.

![Richmond Muffler: Local Choice, Quiet Ride [Richmond, VA] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Richmond Muffler: Local Choice, Quiet Ride [Richmond, VA] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-108-300x200.jpg)