A vehicle-specific exhaust component designed to reduce noise emitted from the engine of a four-wheel drive automobile. It integrates into the exhaust system, employing chambers and baffling to attenuate sound waves produced during combustion. Models vary in design and construction materials, such as aluminized steel or stainless steel, influencing durability and performance.

The purpose is multifaceted. Beyond noise reduction, which is legally mandated in many regions, such a component can impact engine performance and fuel efficiency. Historically, rudimentary designs focused solely on sound suppression. Modern iterations, however, are often engineered to minimize backpressure, potentially enhancing horsepower and torque. Choosing a suitable variant involves balancing these competing factors alongside considerations of corrosion resistance and longevity.

The following sections will delve into the selection criteria for these components, examining aspects such as material composition, design variations (including aftermarket performance options), installation procedures, and potential troubleshooting scenarios. Furthermore, the regulatory landscape governing noise emissions from motor vehicles will be addressed to provide a comprehensive understanding of this essential automotive element.

Essential Considerations for Replacement of Exhaust Noise Dampeners in Four-Wheel Drive Vehicles

The subsequent guidelines offer critical insights when replacing an exhaust noise dampener in a four-wheel drive vehicle, emphasizing performance, durability, and regulatory compliance.

Tip 1: Material Selection: Prioritize stainless steel construction for optimal corrosion resistance, especially in environments with high road salt exposure. Aluminized steel represents a more economical alternative but exhibits reduced lifespan.

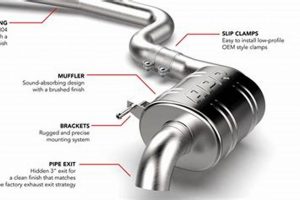

Tip 2: Design Considerations: Evaluate internal design based on desired performance characteristics. Chambered designs offer superior sound suppression, while straight-through designs prioritize minimal backpressure for potential power gains.

Tip 3: Regulatory Compliance: Ensure the replacement unit meets local noise emission standards. Non-compliant components may result in fines or vehicle inspection failures.

Tip 4: Installation Procedures: Adhere to manufacturer-recommended torque specifications during installation to prevent leaks and ensure proper alignment with the exhaust system.

Tip 5: Aftermarket Performance: When considering aftermarket performance options, research reputable brands and verify compatibility with the specific vehicle model to avoid adverse effects on engine performance or reliability.

Tip 6: Welding Considerations: If welding is required during installation, employ appropriate welding techniques and materials to ensure a secure and leak-free connection. Improper welding can compromise structural integrity and lead to premature failure.

Tip 7: Exhaust Leaks: Conduct a thorough inspection for exhaust leaks after installation. Leaks can reduce fuel efficiency, decrease engine performance, and pose potential safety hazards.

Adherence to these guidelines will facilitate a successful replacement, ensuring optimal performance, regulatory compliance, and long-term durability. Selecting the appropriate exhaust component contributes significantly to the vehicle’s overall operational efficiency and environmental impact.

The following sections will delve into troubleshooting common problems and maintenance practices for prolonging the lifespan of this crucial component.

1. Sound Reduction

Sound reduction is a primary function inextricably linked to the purpose of a vehicle-specific exhaust noise damper. The component’s design centers on attenuating the high-intensity sound waves generated by internal combustion. Without effective noise abatement, these engines would produce unacceptably loud noise levels, violating noise regulations and impacting public well-being. The effectiveness is directly correlated with the internal structure, material composition, and overall integrity of the assembly.

The design achieves sound reduction through a combination of reflection, absorption, and interference. Chambers and baffles within the unit redirect sound waves, causing them to collide and cancel each other out. The choice of materials, such as packed fiberglass or specific metal alloys, further influences the absorption of sound energy. A poorly functioning unit, resulting from corrosion or damage, loses its ability to attenuate sound, leading to increased noise emissions. A direct result of failing is typically observed in noise complaints, vehicle inspection failures, and reduced driver comfort.

In summary, effective sound reduction is not merely a desirable feature, but a core requirement for the proper operation of a road-going motor vehicle. The design and maintenance of exhaust noise dampeners are critical for complying with noise regulations, preserving community tranquility, and ensuring a comfortable driving experience. A compromised muffler invariably leads to increased noise pollution and potential legal repercussions, underscoring the importance of this component.

2. Exhaust Flow

Exhaust flow constitutes a critical parameter influencing engine performance and efficiency, particularly concerning the exhaust system of a four-wheel drive automobile. The design and condition of the exhaust noise damper directly affect the rate at which exhaust gases are expelled, impacting power output and fuel economy.

- Backpressure Effects

Excessive backpressure, caused by a restrictive exhaust noise damper, impedes the efficient expulsion of exhaust gases. This can lead to reduced engine horsepower and torque, particularly at higher RPMs. A clogged or poorly designed muffler significantly increases backpressure, diminishing overall vehicle performance. The impact is noticeable through decreased acceleration and reduced fuel efficiency.

- Diameter and Design

The internal diameter and design of the exhaust noise damper influence exhaust flow. Straight-through designs, often found in aftermarket performance options, minimize restrictions and maximize flow. However, they may also provide less effective sound suppression. Conversely, chambered designs prioritize sound reduction but can introduce greater resistance to exhaust flow. Choosing between these designs involves a trade-off between performance and noise reduction.

- Material and Corrosion

Corrosion within the exhaust system, particularly inside the exhaust noise damper, can severely restrict exhaust flow. Rust and debris accumulate, narrowing the internal passages and increasing backpressure. Regular inspections and preventative maintenance, such as rust inhibitors, help maintain optimal exhaust flow and prolong the lifespan of the components. A corroded unit requires replacement to restore proper engine performance.

- Scavenging Effect

Optimized exhaust flow can enhance the scavenging effect, where the outgoing exhaust gases help draw out the remaining exhaust from the cylinder. This effect improves combustion efficiency and increases power output. Aftermarket systems, including high-flow mufflers, are designed to maximize this effect, contributing to improved engine performance. The design and condition are directly influence the cylinder charge and fuel use.

In conclusion, exhaust flow is intrinsically linked to engine performance, and it’s affected by the design, material, and condition. The selection of an appropriate exhaust noise damper, as well as regular maintenance, is essential for maintaining optimal engine efficiency, power output, and fuel economy. Poor maintenance and selection reduces engine power and can cause damage.

3. Vehicle Compatibility

Ensuring vehicle compatibility is paramount when selecting a replacement exhaust component for a four-wheel drive vehicle. A mismatch between the component and the vehicle’s specifications can lead to diminished performance, installation difficulties, and potential damage to the exhaust system or engine.

- Model-Specific Design

Exhaust systems are often designed with specific vehicle models in mind. The exhaust noise damper, or muffler, must align perfectly with the existing piping, mounting points, and exhaust routing. A component designed for a different model may not physically fit or may require extensive modifications, compromising the integrity of the exhaust system. For example, a component intended for a Wrangler will likely be incompatible with a Grand Cherokee due to variations in chassis design and exhaust system layout.

- Engine Configuration

Engine configuration dictates the exhaust flow characteristics and, consequently, the design requirements of the exhaust system. A V6 engine, for instance, will typically necessitate a different exhaust system design compared to an inline-four engine. Selecting a component designed for the wrong engine configuration can result in improper backpressure, leading to reduced engine performance and potential damage. For example, installing a component designed for a 4.0L inline-six engine on a 3.6L V6 engine would likely lead to suboptimal exhaust flow and decreased efficiency.

- Year of Manufacture

Even within the same vehicle model, exhaust system designs can vary across different model years. Facelifts, engine updates, and changes to emissions regulations can necessitate modifications to the exhaust system. Therefore, it is crucial to select a component specifically designed for the vehicle’s year of manufacture. A component intended for an earlier model year may not be compatible with a later model due to alterations in exhaust system design or mounting points. For example, the design for the 2010 JK Wrangler may differ from the 2018 JL Wrangler.

- Trim Level Considerations

Different trim levels within a single vehicle model may feature variations in exhaust systems. A performance-oriented trim level may incorporate a different component design compared to a standard trim level. Neglecting trim level considerations during component selection can result in incompatibilities and reduced performance. For example, a Rubicon trim level may feature a different system than a Sahara trim level, necessitating careful selection of the replacement component. These models can often use different suspension system and exhaust components.

Proper assessment of vehicle-specific design, engine configuration, year of manufacture, and trim level is essential for selecting a compatible exhaust noise damper. Failure to consider these factors can lead to installation difficulties, diminished engine performance, and potential damage to the exhaust system. Accurate identification of the vehicle’s specifications is critical for ensuring optimal performance and compatibility when replacing any exhaust system component.

4. Material Durability

Material durability is a critical factor influencing the lifespan and performance of an exhaust noise dampener in a four-wheel drive vehicle. The operating environment of these vehicles often exposes the exhaust system to harsh conditions, including moisture, road salt, and extreme temperatures, demanding robust material selection for long-term reliability.

- Corrosion Resistance

The selection of corrosion-resistant materials is paramount in regions with high road salt usage or exposure to marine environments. Stainless steel offers superior protection against corrosion compared to aluminized steel. While aluminized steel provides a cost-effective alternative, it is more susceptible to rust and degradation, particularly in areas with frequent exposure to corrosive elements. Premature failure due to corrosion can lead to exhaust leaks, increased noise levels, and the need for frequent replacements.

- Thermal Stress Resistance

Exhaust systems experience significant temperature fluctuations during vehicle operation. Materials must withstand repeated heating and cooling cycles without succumbing to thermal fatigue. The ability to resist thermal stress is particularly important in high-performance engines or vehicles subjected to heavy use. Materials with low thermal expansion coefficients and high heat resistance are preferred for minimizing the risk of cracking or distortion under extreme temperature variations.

- Mechanical Strength

The exhaust system is subjected to mechanical stresses from vibration, impacts from road debris, and the weight of the exhaust components themselves. The material must possess sufficient mechanical strength to withstand these forces without fracturing or deforming. Thicker gauge materials and robust welding techniques contribute to increased mechanical strength and resistance to damage. Impacts from rocks or debris, particularly common in off-road driving, can compromise the integrity of a component constructed from less durable materials.

- Weld Integrity

Welding is a critical process in the fabrication and installation of exhaust systems. The quality of the welds directly affects the overall durability and longevity. Poorly executed welds are prone to cracking and failure, particularly under thermal stress or vibration. Selecting welding materials and techniques compatible with the base metal is essential for ensuring strong, durable welds that resist corrosion and mechanical stress. Professional welding services are often recommended to ensure weld integrity and prevent premature failure.

The selection of appropriate materials, coupled with proper fabrication and installation techniques, plays a pivotal role in determining the lifespan and performance. Prioritizing material durability ensures long-term reliability, reduced maintenance costs, and optimal performance, even in demanding operating environments. Regular inspection of the material ensures proper operation.

5. Regulatory Compliance

The intersection of regulatory compliance and exhaust noise dampeners directly influences the legality and operational acceptance of a modified four-wheel drive vehicle. Governing bodies establish noise emission standards to mitigate noise pollution and maintain community tranquility. A failure to adhere to these standards can result in fines, vehicle inspection failures, and legal restrictions on vehicle operation.

An exhaust noise dampener must effectively attenuate engine noise to levels below the specified legal limits. These limits vary by jurisdiction and often depend on the vehicle’s weight class and year of manufacture. Aftermarket exhaust systems, in particular, must demonstrate compliance through testing and certification to ensure they meet the applicable noise emission standards. For instance, California requires aftermarket components to bear a CARB (California Air Resources Board) Executive Order number, indicating that they have been tested and approved for use on specific vehicle models. The absence of such certification can render the vehicle non-compliant and subject to penalties during vehicle inspections.

In conclusion, selecting a compliant exhaust noise dampener is not merely a matter of personal preference but a legal imperative. Understanding and adhering to local noise emission regulations is crucial for avoiding penalties, ensuring vehicle legality, and promoting responsible vehicle operation. Failure to comply with these regulations can result in significant financial and legal ramifications, emphasizing the importance of thorough research and careful selection of exhaust system components.

6. Installation Integrity

The operational effectiveness and longevity of a vehicle-specific exhaust noise damper are intrinsically linked to the integrity of its installation. Improper installation procedures can compromise the component’s ability to reduce noise, affect engine performance, and lead to premature failure, thereby negating the benefits of even the highest-quality units. The structural soundness of the exhaust system, including the integrity of joints, hangers, and mounting points, is paramount for ensuring the unit functions as intended.

One primary concern is the creation of exhaust leaks due to poorly sealed connections. Even small leaks can drastically increase noise levels, defeating the purpose of the noise-dampening component. Furthermore, leaks can introduce harmful exhaust gases into the vehicle’s cabin, posing a health hazard to occupants. Incorrectly torqued bolts on flanges or improperly applied sealant can create such leaks. Another critical aspect is the correct alignment and support of the exhaust system. Insufficient or improperly installed hangers can cause undue stress on the unit, leading to cracking or breakage, particularly in off-road driving conditions. For instance, a Wrangler driven over rough terrain with inadequately supported exhaust system components is highly susceptible to damage and subsequent failure of the noise dampener.

In summary, the successful integration depends not only on the quality of the components but also on meticulous installation practices. Proper sealing of joints, secure mounting of the system, and adherence to manufacturer-recommended torque specifications are crucial for maximizing performance and lifespan. Neglecting installation integrity can result in increased noise, reduced engine performance, safety hazards, and premature replacement of the components, ultimately undermining the investment in a quality part.

Frequently Asked Questions

This section addresses common inquiries regarding exhaust noise dampeners in four-wheel drive vehicles, providing objective and informative answers to enhance understanding of this essential component.

Question 1: What is the expected lifespan of an exhaust noise dampener?

The lifespan varies based on material composition, driving conditions, and maintenance practices. Stainless steel units typically outlast aluminized steel counterparts, particularly in corrosive environments. Regular inspections for corrosion and damage are recommended to prolong component life. In standard driving conditions, and with proper vehicle maintenance, expect roughly 5 to 7 years of useful function.

Question 2: How can the compliance of an aftermarket exhaust component be verified?

Compliance is typically indicated by markings or documentation from regulatory bodies. In California, a CARB Executive Order number signifies compliance with state emission standards. It is essential to verify the certification for the specific vehicle model and year to ensure legality.

Question 3: Does an aftermarket exhaust component enhance engine performance?

Some aftermarket components are designed to improve exhaust flow and potentially increase horsepower and torque. However, performance gains are not guaranteed and can vary depending on the design and engine configuration. A component must be properly matched to the engine for any increase in engine performance.

Question 4: What are the signs of a failing unit?

Common indicators of a failing unit include increased exhaust noise, reduced fuel efficiency, visible corrosion or damage, and potential exhaust leaks. A hissing sound or unusual engine performance may also indicate a problem.

Question 5: Can a damaged component be repaired?

Minor damage, such as small leaks, may be repairable through welding or patching. However, extensive corrosion or structural damage typically necessitates replacement of the entire unit. Attempts to repair a severely compromised muffler will likely yield a quick but unsatisfactory result.

Question 6: Is professional installation recommended for exhaust components?

Professional installation is generally recommended, particularly for complex exhaust systems or when welding is required. A qualified technician possesses the expertise and equipment to ensure proper alignment, sealing, and support, minimizing the risk of future problems. Installation is crucial in the long run for best performance.

These frequently asked questions aim to provide clarity regarding the selection, maintenance, and performance aspects of exhaust noise dampeners in four-wheel drive vehicles. Understanding these factors facilitates informed decision-making and contributes to optimal vehicle operation.

The following sections will explore potential troubleshooting scenarios and maintenance practices for prolonging the lifespan of this critical component.

Muffler for Jeep

The preceding exploration of exhaust noise dampeners, specifically concerning “muffler for jeep” applications, underscores the multifaceted nature of this critical automotive component. Aspects of design, material science, regulatory mandates, and installation practices demonstrate the interconnected factors that determine performance, longevity, and legal conformity. From corrosion resistance to sound attenuation and the optimization of exhaust flow, careful consideration of these elements is essential for responsible vehicle operation.

The ongoing development of material technologies and exhaust system designs promises to further refine the efficiency and durability of future components. Continued adherence to evolving regulatory standards and a commitment to proper maintenance will ensure that this essential element continues to play a vital role in mitigating noise pollution and promoting environmentally conscious vehicle operation. Therefore, diligent attention to the condition and selection of this component remains paramount for maintaining vehicle functionality and upholding environmental responsibility.