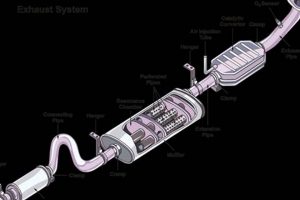

This term denotes a component employed within exhaust systems, typically in the context of automotive engineering or related mechanical applications. Its primary function involves mitigating the noise generated by internal combustion engines. For example, in a vehicle, this part is situated along the exhaust pathway, reducing the acoustic output before gases are expelled into the atmosphere.

The significance of this element lies in its contribution to environmental noise reduction and compliance with noise pollution regulations. Historically, advancements in the design and materials used in these parts have led to more efficient noise dampening while minimizing backpressure, thereby improving engine performance. Its use enhances the overall driving experience by decreasing unpleasant sounds and contributes to a quieter urban environment.

Understanding the principles of sound attenuation and the specific materials employed in these elements is essential for technicians, engineers, and anyone involved in the design, maintenance, or modification of exhaust systems. The following sections will delve deeper into the design variations, common issues, and maintenance procedures associated with this particular part of the exhaust system.

Operational Guidance for Exhaust Noise Reduction Devices

The following guidelines aim to optimize the performance and longevity of exhaust noise reduction devices commonly found in combustion engine applications. Adherence to these recommendations will contribute to consistent noise mitigation and overall system efficiency.

Tip 1: Material Selection: The selection of appropriate materials, such as stainless steel or aluminized steel, is crucial. Consider operating temperatures, corrosive elements in the exhaust stream, and the required lifespan of the device. Inappropriate material choices can lead to premature failure.

Tip 2: Regular Inspection: Conduct regular visual inspections for signs of corrosion, physical damage, or leaks. Early detection of such issues can prevent more significant problems and ensure continued compliance with noise regulations. Pay particular attention to weld points and areas prone to rust.

Tip 3: Proper Installation: Adherence to manufacturer specifications during installation is paramount. Incorrect mounting or misalignment can induce stress on the device, leading to cracks or premature wear. Utilize appropriate hangers and supports to minimize vibration and stress.

Tip 4: Exhaust System Alignment: Verify that the entire exhaust system is correctly aligned to prevent undue strain on the noise reduction device. Misalignment can result in stress fractures and decreased performance over time. Adjustments should be made as needed to ensure proper fit.

Tip 5: Avoiding Thermal Shock: Minimize exposure to rapid temperature fluctuations. Sudden cooling after extended operation can induce thermal stress, potentially leading to cracks or deformation. Allow for gradual cooling whenever possible.

Tip 6: Monitoring Backpressure: Regularly monitor exhaust backpressure to ensure it remains within acceptable limits. Excessive backpressure can indicate a blockage or degradation of the noise reduction device, potentially impacting engine performance and increasing emissions.

Tip 7: Addressing Leaks Promptly: Immediately address any detected exhaust leaks. Leaks not only compromise noise reduction but can also lead to increased emissions and potential safety hazards. Replace gaskets or repair leaks as soon as they are identified.

By consistently following these guidelines, users can maximize the effectiveness and durability of exhaust noise reduction devices, contributing to quieter operation, regulatory compliance, and prolonged system lifespan.

The subsequent discussion will explore specific failure modes and advanced diagnostic techniques related to these critical components.

1. Noise Attenuation Efficiency

Noise attenuation efficiency represents a primary performance metric for exhaust system components, including the device in question. Its measurement reflects the degree to which sound pressure levels are reduced as exhaust gases pass through the component. This is directly relevant to regulatory compliance and overall vehicle or machinery operation.

- Acoustic Absorption Materials

The incorporation of specific materials within the device’s internal structure significantly impacts its ability to absorb sound energy. Materials such as fiberglass, mineral wool, or specialized acoustic packing convert sound waves into heat through frictional losses. Higher density and strategically positioned materials enhance the attenuation of specific frequencies, leading to improved overall noise reduction. An example is the use of multi-layered packing configurations to target a broader range of sound frequencies.

- Chamber Design and Resonators

The internal chamber design and the implementation of resonators play a crucial role in noise cancellation. Chambers of specific sizes and shapes are designed to reflect and interfere with sound waves, leading to a reduction in amplitude. Resonators, often Helmholtz resonators, are tuned to specific frequencies to selectively cancel out dominant noise components. Automotive applications exemplify this approach, where chamber designs are optimized through computational fluid dynamics simulations to maximize attenuation efficiency.

- Perforated Tubes and Baffles

The use of perforated tubes and baffles within the device alters the path of exhaust gases and promotes sound wave scattering. Perforations create numerous small passages that disrupt the propagation of sound, while baffles force the gases to change direction, further dissipating sound energy. The arrangement and size of perforations, along with baffle geometry, are critical factors influencing attenuation performance. Examples include the application of staggered perforation patterns to broaden the frequency range of noise reduction.

- Flow Restriction and Backpressure Effects

While maximizing noise attenuation is the primary goal, minimizing flow restriction and backpressure is also essential. Excessive backpressure can negatively impact engine performance and fuel efficiency. Therefore, design considerations must balance acoustic performance with fluid dynamic properties. Modern designs often incorporate optimized flow paths and larger internal volumes to reduce backpressure while maintaining acceptable levels of noise attenuation. This is particularly important in high-performance engine applications where power output is a key consideration.

These facets underscore the multifaceted nature of noise attenuation efficiency within these devices. Effective design necessitates a comprehensive understanding of acoustics, fluid dynamics, and materials science to achieve optimal noise reduction without compromising engine performance. Continual advancements in these areas are essential for meeting increasingly stringent noise regulations and customer expectations for quieter operation.

2. Material Durability

Material durability, in the context of exhaust noise reduction devices, represents a pivotal factor affecting long-term performance and reliability. The selection of appropriate materials directly influences the device’s ability to withstand the harsh operating conditions within an exhaust system, ensuring consistent noise attenuation over its intended lifespan.

- Resistance to Corrosion

Exhaust gases contain corrosive compounds, including acids and water vapor, which can degrade metallic components over time. Materials exhibiting high corrosion resistance, such as stainless steel (particularly grades 304 and 316) or aluminized steel with protective coatings, are preferred to mitigate this degradation. The premature failure of a noise reduction device due to corrosion leads to increased noise emissions and necessitates costly replacements, directly impacting operational efficiency.

- Thermal Stability at Elevated Temperatures

Exhaust systems operate at high temperatures, often exceeding 500C (932F) during normal operation and potentially reaching significantly higher temperatures during periods of heavy load or engine malfunction. Materials must maintain their structural integrity and mechanical properties at these elevated temperatures to prevent deformation, cracking, or failure. The selection of materials with high melting points and low thermal expansion coefficients minimizes the risk of thermal stress-induced damage, ensuring continued effectiveness.

- Resistance to Mechanical Stress and Vibration

Exhaust systems are subjected to constant mechanical stress and vibration generated by the engine. The chosen material must possess sufficient fatigue strength and resistance to cracking to withstand these forces. Proper mounting and support systems are critical to minimize stress concentrations, but the inherent properties of the material play a vital role in preventing fatigue failure. The absence of adequate mechanical strength can lead to cracks and leaks, compromising noise reduction performance and potentially posing safety risks.

- Impact of Environmental Factors

External environmental factors, such as exposure to road salt, moisture, and debris, can further accelerate material degradation. Protective coatings and surface treatments can enhance resistance to these external factors, extending the lifespan of the device. Regular inspection and maintenance, including cleaning and application of protective coatings, can help mitigate the impact of environmental factors, preserving the material integrity and ensuring continued performance.

The correlation between material durability and exhaust device performance is undeniable. Careful consideration of these facets during the design and material selection process is essential for ensuring the long-term reliability and effectiveness of the device, contributing to reduced noise pollution and minimized maintenance costs.

3. Backpressure Optimization

Backpressure optimization within exhaust systems represents a critical design consideration that directly impacts both engine performance and noise attenuation. The term denotes the management of exhaust gas flow resistance to achieve a balance between minimizing power loss and maximizing the noise reduction capabilities of components such as specialized mufflers.

- Effects on Engine Efficiency

Excessive backpressure impedes the efficient expulsion of exhaust gases from the engine cylinders, increasing pumping losses and reducing volumetric efficiency. This leads to a decrease in power output and fuel economy. The careful design of the muffler, including internal geometry and flow paths, minimizes flow restriction while maintaining effective noise reduction. For instance, a straight-through muffler design offers minimal backpressure but may require more sophisticated sound-absorbing materials to achieve acceptable noise levels.

- Influence on Noise Attenuation

Conversely, insufficient backpressure can compromise noise attenuation effectiveness. In this part, internal baffles, chambers, and resonators are used to redirect and dissipate sound waves. These elements inherently introduce some level of flow restriction. The challenge lies in optimizing their design to maximize sound reduction while minimizing the associated backpressure. A balance between these two opposing forces is crucial for achieving regulatory compliance and customer satisfaction.

- Design Trade-offs and Material Selection

Backpressure optimization necessitates a series of design trade-offs, including the selection of appropriate materials. Larger muffler bodies and optimized flow paths can reduce backpressure but may increase size and weight. The choice of materials, such as stainless steel or aluminized steel, also impacts the overall system design and performance. Thinner gauge materials may reduce weight but compromise durability, requiring a careful balance between weight, durability, and backpressure considerations.

- Impact on Vehicle Performance

The cumulative effect of backpressure on vehicle performance is significant, particularly in high-performance applications. Optimized exhaust systems are designed to minimize backpressure, maximizing engine output and improving throttle response. In contrast, poorly designed systems can significantly restrict engine performance, leading to sluggish acceleration and reduced overall driving experience. Therefore, meticulous attention to backpressure optimization is paramount in achieving desired performance characteristics.

The interplay between engine efficiency, noise attenuation, design trade-offs, and material selection in the context of backpressure underscores the complex engineering considerations involved in designing specialized mufflers. The ability to effectively manage backpressure is integral to achieving both optimal performance and regulatory compliance, ultimately contributing to a superior product.

4. System Compatibility

System compatibility, in the context of exhaust noise reduction, centers on ensuring that a specific component, such as a specialized muffler, functions seamlessly with the overall exhaust system and the vehicle or machinery it serves. This entails considering various factors, including dimensional fit, flow characteristics, and material compatibility. A mismatch in any of these areas can lead to performance degradation, premature component failure, and potential safety hazards. For instance, installing a muffler designed for a low-displacement engine on a high-performance vehicle can create excessive backpressure, reducing power output and potentially damaging the engine over time. Conversely, utilizing a muffler constructed from incompatible materials may lead to accelerated corrosion due to galvanic reactions with other exhaust system components. The original equipment manufacturer (OEM) part serves as a benchmark for system compatibility, often dictating precise specifications for aftermarket replacements.

The practical significance of system compatibility extends beyond mere functionality. Regulatory compliance, particularly concerning noise emissions and emissions control, hinges on the proper integration of all exhaust system components. A muffler that effectively reduces noise but compromises emissions control systems may render the entire vehicle non-compliant, leading to legal repercussions. Furthermore, incorrect component selection can impact diagnostic capabilities. For example, an incompatible muffler may alter exhaust gas composition in a way that interferes with oxygen sensor readings, resulting in inaccurate diagnostic trouble codes and complicating troubleshooting efforts. Automotive repair shops routinely encounter issues stemming from system incompatibility, underscoring the need for careful component selection and adherence to manufacturer specifications.

In summary, system compatibility is not merely a desirable attribute but a fundamental requirement for the proper operation and longevity of exhaust noise reduction devices. Addressing potential compatibility issues proactively can mitigate the risk of performance degradation, regulatory non-compliance, and costly repairs. While aftermarket options offer cost-effective alternatives, careful attention must be paid to ensuring that these components meet or exceed the specifications of the original equipment to maintain system integrity. Continued advancements in component design and material science are essential for addressing the evolving demands of modern exhaust systems and ensuring ongoing system compatibility.

5. Installation Integrity

Installation integrity represents a cornerstone in the effective performance and longevity of an exhaust noise reduction device, specifically the component identified as a “charlotte muffler”. Proper installation directly influences noise attenuation, exhaust flow dynamics, and overall system reliability. Any deviation from established procedures can compromise these factors, leading to suboptimal performance or premature failure.

- Correct Mounting and Alignment

The proper mounting and alignment of the muffler are crucial for preventing undue stress on its structure. Misalignment can create stress concentrations, leading to cracks or weld failures. Utilizing appropriate hangers and supports, positioned according to manufacturer specifications, ensures even weight distribution and reduces vibration-induced stress. For instance, insufficient support can cause the muffler to sag, placing excessive strain on the inlet and outlet connections, potentially resulting in exhaust leaks and diminished noise reduction.

- Proper Sealing of Connections

Ensuring airtight seals at all connections is essential for preventing exhaust leaks. Leaks not only compromise noise attenuation but also introduce harmful exhaust gases into the environment. The use of new gaskets and appropriate sealing compounds is recommended to achieve a secure and leak-free connection. Overtightening fasteners can damage flanges or crush gaskets, while undertightening may result in leaks. Adhering to specified torque values is vital for achieving optimal sealing without causing damage.

- Avoidance of Mechanical Damage

Physical damage during installation, such as dents or scratches, can compromise the structural integrity and corrosion resistance of the muffler. Careful handling is necessary to prevent such damage. Using appropriate tools and avoiding forceful installation techniques minimizes the risk of dents or scratches. Any existing damage should be addressed prior to installation to prevent further degradation and potential failure.

- Compatibility with Existing System

Ensuring compatibility with the existing exhaust system is crucial for proper function and longevity. Mismatched pipe diameters, incorrect hanger positions, or incompatible materials can create stress points and accelerate corrosion. Verifying the muffler’s specifications against the vehicle’s or machinery’s requirements is essential for ensuring compatibility. Adapters or modifications may be necessary to achieve a proper fit and function in certain situations.

These facets highlight the multifaceted nature of installation integrity as it relates to the device. A meticulous approach to these elements during installation is paramount for ensuring the reliable performance and extended lifespan, contributing to reduced noise pollution and minimized maintenance requirements.

6. Maintenance Schedule

Adherence to a structured maintenance schedule is paramount to ensuring the sustained performance and longevity of exhaust noise reduction components. The component in question, like many similar parts, is subject to degradation from operational conditions and environmental factors. A well-defined maintenance schedule allows for the early detection and mitigation of potential issues, preventing costly repairs and ensuring continued compliance with noise regulations.

- Visual Inspection for Corrosion and Damage

Regular visual inspections should be conducted to identify signs of corrosion, physical damage, or exhaust leaks. Corrosion weakens the structural integrity of the part, while physical damage can compromise its noise attenuation capabilities. Exhaust leaks not only increase noise emissions but also pose safety hazards. These inspections should be performed at predetermined intervals, such as every oil change or during routine vehicle servicing. Early detection of these issues allows for timely repairs or replacements, preventing more extensive damage and ensuring continued functionality.

- Checking Mounting Hardware and Connections

The integrity of mounting hardware and connections is critical for maintaining the proper alignment and stability of the component. Loose or damaged mounting brackets can cause excessive vibration and stress, leading to premature failure. Connections should be inspected for signs of corrosion or leakage. Tightening loose connections and replacing damaged hardware are essential maintenance tasks that prevent costly repairs and ensure optimal performance. Recommended torque specifications for fasteners should be strictly adhered to during maintenance procedures.

- Assessment of Backpressure Levels

Monitoring backpressure levels provides valuable insight into the internal condition of the part. Excessive backpressure can indicate a blockage or deterioration of internal components, hindering exhaust flow and reducing engine efficiency. Regular backpressure measurements, performed using appropriate diagnostic equipment, can detect early signs of these issues, allowing for timely intervention. Deviations from established backpressure parameters necessitate further investigation and potential replacement of the component.

- Cleaning and Protective Coating Application

The accumulation of road debris, salt, and other environmental contaminants can accelerate corrosion and degradation of the part’s exterior. Regular cleaning to remove these contaminants, followed by the application of a protective coating, can significantly extend its lifespan. Specific cleaning agents and protective coatings should be selected based on the material composition of the component to ensure compatibility and effectiveness. This preventative maintenance measure helps to preserve the structural integrity and appearance of the part, contributing to its long-term performance.

Integrating these facets into a comprehensive maintenance schedule ensures the sustained efficacy and operational life of this particular component within the exhaust system. Consistent adherence to the recommended intervals and procedures enables proactive issue resolution, averting more significant complications and upholding consistent performance, thereby reducing overall operational costs and ensuring compliance with established noise emission standards.

Frequently Asked Questions Regarding Exhaust Noise Reduction Components

This section addresses prevalent inquiries concerning the functionality, maintenance, and performance characteristics of exhaust noise reduction components, offering clarification and practical insights.

Question 1: What are the primary factors influencing the lifespan of these components?

Material composition, operating temperature, exposure to corrosive substances, and adherence to recommended maintenance practices significantly impact the lifespan. Components constructed from higher-grade materials and properly maintained typically exhibit extended service intervals.

Question 2: How does backpressure affect engine performance when using these components?

Excessive backpressure impedes exhaust flow, reducing engine efficiency and power output. Optimal designs minimize backpressure while maintaining effective noise attenuation. Backpressure levels should be monitored to ensure they remain within acceptable parameters.

Question 3: What are the key indicators of a failing exhaust noise reduction component?

Increased exhaust noise, reduced engine performance, visible corrosion or damage, and exhaust leaks are indicative of a failing component. These symptoms warrant immediate inspection and potential replacement to prevent further complications.

Question 4: Can aftermarket options compromise the overall emissions system?

Improperly designed or incompatible aftermarket options can negatively impact emissions control systems, leading to non-compliance and potential fines. Aftermarket components should meet or exceed OEM specifications to ensure proper function and regulatory compliance.

Question 5: How frequently should exhaust system components be inspected?

A visual inspection should be conducted at least annually or during routine maintenance intervals. Components operating in harsh conditions may require more frequent inspections to identify potential issues early.

Question 6: What is the significance of proper installation techniques?

Incorrect installation can induce stress concentrations, leading to premature failure and diminished performance. Adhering to manufacturer specifications, utilizing appropriate mounting hardware, and ensuring proper alignment are critical for long-term reliability.

These answers offer foundational knowledge regarding the characteristics and maintenance of exhaust noise reduction devices. Proactive maintenance and informed decision-making are vital for ensuring optimal performance and longevity.

The subsequent discussion will address advanced diagnostic techniques for evaluating component performance and identifying potential issues.

Conclusion

The preceding exploration of “charlotte muffler” has elucidated its critical function within exhaust systems as a primary noise reduction element. Key points addressed include material durability, backpressure optimization, system compatibility, installation integrity, and the importance of a consistent maintenance schedule. Effective implementation of these principles directly impacts regulatory compliance, environmental noise reduction, and the overall performance of combustion engines.

The ongoing advancement in materials science and acoustic engineering will inevitably lead to further refinements in “charlotte muffler” design, enhancing both noise attenuation and operational efficiency. It is, therefore, incumbent upon engineers, technicians, and vehicle owners to remain informed of these developments and to prioritize the proper maintenance and selection of these components to ensure continued adherence to evolving environmental standards and optimal system performance. The responsible application of these technologies is paramount for minimizing the environmental impact of combustion engines.

![Richmond Muffler: Local Choice, Quiet Ride [Richmond, VA] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Richmond Muffler: Local Choice, Quiet Ride [Richmond, VA] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-108-300x200.jpg)