A vehicle exhaust system component sold and serviced in Canby, Oregon, is designed to reduce engine noise and safely vent exhaust gases away from the vehicle’s occupants. For example, a damaged or corroded component in this system can lead to increased noise levels and potential safety hazards.

Properly functioning components contribute to a vehicle’s overall performance and fuel efficiency while also complying with local noise ordinances. Historically, these systems have evolved from simple pipes to sophisticated assemblies incorporating catalytic converters and resonators to minimize pollution and noise.

The remainder of this article will delve into the selection, maintenance, and repair considerations for this specific type of vehicle exhaust component within the Canby, Oregon, area, outlining key factors for vehicle owners to consider.

Guidance Regarding Exhaust Systems in Canby

This section offers practical guidance concerning the selection, upkeep, and troubleshooting of exhaust systems, with a focus on residents of Canby, Oregon.

Tip 1: Routine Inspections: Regular visual inspections of the exhaust system are crucial. Examine for signs of corrosion, rust, or physical damage. Early detection can prevent costly repairs.

Tip 2: Address Unusual Noises: Any changes in exhaust sound, such as rattling, hissing, or roaring, should be promptly investigated. These noises often indicate leaks or component failures.

Tip 3: Professional Assessment: Seek a qualified mechanic for a comprehensive exhaust system evaluation, particularly if persistent issues are observed or suspected.

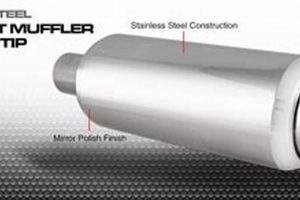

Tip 4: Consider Material Quality: When replacing components, prioritize materials known for durability and resistance to corrosion, such as stainless steel, to ensure longevity.

Tip 5: Confirm Local Compliance: Ensure that any modifications or replacements meet the noise level regulations and emissions standards mandated by the city of Canby and the state of Oregon.

Tip 6: Understand System Components: Familiarize yourself with the various parts of your vehicle’s exhaust system, including the manifold, catalytic converter, resonator, and tailpipe, to better understand potential issues.

Tip 7: Document Maintenance: Maintain a record of all exhaust system inspections, repairs, and replacements. This documentation aids in tracking the system’s health and identifying recurring problems.

Adhering to these guidelines will contribute to optimal vehicle performance, enhanced safety, and compliance with local regulations. Prioritizing preventative maintenance can significantly extend the lifespan of the vehicle’s exhaust system.

The subsequent sections of this article will explore specific repair scenarios and preventative strategies in greater detail, providing further insights into exhaust system management.

1. Local Availability

Local availability directly influences the cost and timeliness of exhaust system repairs and replacements in Canby, Oregon. The presence of local suppliers and service providers specializing in vehicle exhaust systems allows for quicker access to necessary parts and expertise. Conversely, limited local options can result in increased lead times for parts procurement and potentially higher service costs due to reduced competition. For example, if a specific vehicle model requires a specialized exhaust component not readily available in Canby, it may necessitate ordering from external suppliers, adding to the overall repair duration and expense. This has a cascading effect on vehicle down time and availability of transportation.

The importance of local availability extends beyond immediate repair needs. A strong local network of suppliers fosters a competitive market, potentially driving down prices for both parts and labor. Furthermore, local service providers are often more familiar with the specific challenges posed by the regional climate and driving conditions, enabling them to offer tailored maintenance recommendations. As an illustration, exhaust systems in the Pacific Northwest are often more susceptible to corrosion due to high humidity and frequent rainfall, prompting local mechanics to recommend specific preventative measures.

Understanding the interplay between local availability and exhaust system maintenance is practically significant for Canby residents. By considering local options for parts and service, vehicle owners can optimize repair costs and minimize downtime. Maintaining a proactive approach to exhaust system inspection and addressing issues promptly can further reduce the reliance on external suppliers and ensure the continued availability of transportation. The efficient and effective maintenance of these components relies, in part, on robust local resources.

2. Noise reduction

Noise reduction constitutes a primary function of vehicle exhaust systems, particularly relevant to the Canby, Oregon locale, where community noise ordinances impact vehicle operation.

- Compliance with Local Ordinances

Canby’s noise regulations dictate permissible sound levels for vehicle operation. Effective noise reduction ensures vehicles meet these standards, preventing potential fines or legal issues. The specific design of an exhaust system, including its muffling capabilities, directly contributes to compliance. For instance, older vehicles retrofitted with modern, noise-reducing components can achieve compliance that would otherwise be unattainable.

- Component Design and Function

The internal construction of components within the exhaust system, such as resonators and baffles, is engineered to attenuate sound waves. These components work by creating interference patterns that cancel out or dampen noise produced by the engine. The choice of materials and the specific arrangement of internal structures significantly influence the noise reduction effectiveness. As an example, a system employing multiple resonating chambers achieves greater noise reduction than a simpler, single-chamber design.

- Impact on Vehicle Operation

Noise reduction not only contributes to regulatory compliance but also enhances the overall driving experience. Reduced exhaust noise minimizes driver fatigue and improves passenger comfort. Furthermore, excessive exhaust noise can indicate underlying mechanical issues, such as leaks or failing components, which can negatively impact engine performance and fuel efficiency. Addressing noise issues promptly can therefore lead to improved vehicle operation and longevity.

- Material Degradation and Noise Levels

Over time, the materials within the exhaust system can degrade due to corrosion and thermal stress, leading to a reduction in noise reduction capabilities. This degradation can result in increased exhaust noise, signaling the need for component replacement or repair. For example, a rusted or damaged system may exhibit significantly higher noise levels than a properly functioning one. Regular inspections and maintenance are therefore crucial for preserving optimal noise reduction performance.

The interplay between noise reduction, component design, and material durability underlines the importance of selecting appropriate exhaust systems and implementing routine maintenance practices. Such considerations are particularly relevant for Canby residents seeking to comply with local ordinances, maintain vehicle performance, and ensure a comfortable driving experience. Ignoring these factors can result in regulatory infractions, diminished vehicle performance, and increased operational costs.

3. Exhaust venting

Effective exhaust venting is a critical safety and performance characteristic intrinsically linked to the proper function of exhaust systems in Canby, Oregon. The primary function of a vehicle’s exhaust system, beyond noise reduction, involves channeling harmful combustion byproducts away from the vehicle’s occupants and into the atmosphere. A malfunctioning system can lead to the accumulation of carbon monoxide within the passenger compartment, posing a serious health risk. Properly functioning exhaust components ensure these gases are expelled efficiently, mitigating the potential for exposure. For example, a rusted or cracked exhaust manifold, often a precursor to system failure, can allow exhaust gases to leak into the engine compartment and subsequently enter the cabin through the ventilation system. The correct installation and maintenance of the exhaust system contributes to reliable exhaust venting, thereby protecting vehicle occupants.

The design and integrity of the exhaust system, including its connections and seals, directly affect the efficacy of exhaust venting. Leaks at any point in the system compromise the ability to effectively channel gases away from the vehicle. For instance, damaged or improperly installed gaskets connecting sections of the exhaust pipe can create escape routes for exhaust fumes. Routine inspection and maintenance procedures, such as checking for leaks and replacing worn-out components, are essential for maintaining optimal exhaust venting performance. A local auto mechanic in Canby, specializing in exhaust systems, would typically conduct a pressure test to identify leaks not visible to the naked eye.

In conclusion, exhaust venting is an indispensable safety feature inseparable from the proper functioning of vehicle exhaust systems. The consequences of compromised exhaust venting range from reduced engine performance to severe health risks for vehicle occupants. Regular maintenance and prompt repair of exhaust system components are crucial for ensuring the continued integrity of the venting process. The awareness of this relationship highlights the necessity of addressing exhaust system issues with due diligence, thereby contributing to vehicle safety and environmental responsibility within the Canby community.

4. System Inspection

System inspection, particularly within the context of exhaust systems in locations like Canby, Oregon, is a crucial element in maintaining vehicle safety, regulatory compliance, and operational efficiency. The following aspects detail key considerations regarding inspection procedures.

- Corrosion Assessment

Exhaust systems are inherently susceptible to corrosion due to exposure to high temperatures, moisture, and road salts. Inspection routines must meticulously assess the extent of corrosion, focusing on welds, joints, and areas prone to moisture accumulation. Untreated corrosion compromises structural integrity, leading to leaks and potential system failure. Early detection through inspection allows for timely intervention, preventing more extensive and costly repairs. For instance, a seemingly minor surface rust patch on the muffler can quickly escalate into a significant hole, necessitating complete replacement if left unaddressed.

- Leak Detection

Exhaust leaks pose both safety and performance concerns. Leaks compromise the system’s ability to efficiently vent exhaust gases, potentially exposing vehicle occupants to harmful substances like carbon monoxide. Furthermore, leaks negatively impact engine performance and fuel efficiency. Inspection protocols must include methods for identifying leaks, such as visual examination for soot deposits or the use of specialized leak detection equipment. Leaks at joints, flanges, or welds require immediate attention to restore proper system function.

- Component Integrity

Exhaust system components, including the manifold, catalytic converter, muffler, and tailpipe, must be inspected for physical damage, such as dents, cracks, or distortions. Damage to these components can impede exhaust flow, reduce system efficiency, and potentially create safety hazards. For example, a severely dented muffler can restrict exhaust flow, leading to increased backpressure and reduced engine power. The inspection process must encompass a thorough evaluation of each component’s structural integrity to ensure optimal performance.

- Mounting and Support Systems

Exhaust systems are typically suspended from the vehicle’s undercarriage using hangers and supports. These mounting systems are subject to wear and tear, potentially leading to system sagging or detachment. Inspection procedures must evaluate the condition of hangers, brackets, and rubber insulators, ensuring they are securely attached and free from damage. A loose or damaged mounting system can cause the exhaust system to vibrate excessively, increasing stress on other components and potentially leading to premature failure.

The aforementioned considerations underscore the vital role of systematic inspection in maintaining the health and functionality of vehicle exhaust systems, including those serviced in Canby. By adhering to rigorous inspection protocols, potential issues can be identified and addressed proactively, minimizing the risk of safety hazards, performance degradation, and costly repairs.

5. Material durability

Material durability serves as a cornerstone in the longevity and overall effectiveness of exhaust components in the Canby, Oregon, area. The environmental conditions prevalent in the Pacific Northwest, characterized by high humidity and frequent precipitation, accelerate corrosion processes. Consequently, the selection of materials resistant to these conditions directly impacts the lifespan of exhaust systems. For example, exhaust systems constructed from aluminized steel, while offering an initial cost advantage, exhibit a lower resistance to corrosion compared to those fabricated from stainless steel. This disparity in material durability translates to a shorter service life for aluminized steel components, necessitating more frequent replacements and increased long-term costs for vehicle owners. The choice of materials, therefore, represents a critical factor in the economic and operational viability of vehicle ownership in Canby.

The correlation between material composition and the functional performance of exhaust systems is also significant. As materials degrade due to corrosion, the system’s ability to effectively reduce noise and vent exhaust gases diminishes. A compromised exhaust system, resulting from material failure, can lead to increased noise levels, potentially violating local ordinances, and can also allow harmful exhaust gases to leak into the vehicle cabin, posing a safety hazard. Stainless steel, with its superior resistance to corrosion, maintains its structural integrity and functional performance for a longer duration, thereby mitigating these risks. The increased initial investment in durable materials translates to reduced maintenance costs and enhanced safety over the life of the vehicle.

In summation, the link between material durability and exhaust system performance in Canby is undeniable. The selection of appropriate materials, particularly those resistant to corrosion, directly impacts the system’s longevity, functional effectiveness, and the overall cost of vehicle ownership. Prioritizing material durability, although potentially involving a higher initial investment, offers substantial long-term benefits, including reduced maintenance costs, enhanced safety, and compliance with local regulations. This understanding underscores the importance of informed decision-making when selecting and maintaining exhaust systems in the region.

Frequently Asked Questions Regarding Exhaust System Components in Canby, Oregon

The following questions and answers address common inquiries concerning the selection, maintenance, and troubleshooting of vehicle exhaust systems within the Canby, Oregon, area.

Question 1: What constitutes evidence of exhaust system failure?

Indications of a failing exhaust system include, but are not limited to, excessive noise, a noticeable decrease in fuel efficiency, the presence of unusual odors within the vehicle cabin, and visible signs of corrosion or physical damage to exhaust components.

Question 2: How frequently should an exhaust system undergo professional inspection?

A professional exhaust system inspection is recommended at least annually, or more frequently if any of the aforementioned symptoms of failure are observed.

Question 3: What are the ramifications of neglecting exhaust system repairs?

Deferring necessary exhaust system repairs can result in reduced vehicle performance, increased fuel consumption, potential exposure to hazardous exhaust gases, and non-compliance with local noise ordinances.

Question 4: What factors influence the cost of exhaust system repairs or replacements?

The cost of repairs or replacements is determined by the extent of the damage, the specific components requiring attention, the type of materials used for replacement parts, and the labor rates of the chosen service provider.

Question 5: Are there specific noise regulations applicable to vehicle exhaust systems in Canby, Oregon?

Yes, the City of Canby enforces noise ordinances that regulate permissible sound levels for vehicle operation. Exhaust systems must comply with these regulations to avoid potential fines or legal action.

Question 6: What materials are best suited for replacement exhaust system components in the Pacific Northwest climate?

Stainless steel components offer superior resistance to corrosion in the region’s damp climate, providing enhanced durability and longevity compared to aluminized steel alternatives.

Maintaining a properly functioning exhaust system is crucial for vehicle safety, performance, and regulatory compliance. Addressing exhaust system issues promptly and seeking professional assistance when necessary can mitigate potential risks and ensure optimal vehicle operation.

The subsequent section will delve into preventative maintenance strategies designed to extend the lifespan of exhaust systems and minimize the need for costly repairs.

canby muffler

This exploration has emphasized the critical role of vehicle exhaust systems within Canby, Oregon, focusing on factors directly impacting their performance, safety, and regulatory compliance. Key aspects addressed include the importance of local availability of parts and services, the function of noise reduction mechanisms, the necessity of effective exhaust venting, the significance of regular system inspections, and the value of durable materials in resisting corrosion. These elements collectively contribute to the responsible operation and maintenance of vehicles within the community.

Vehicle owners are strongly encouraged to prioritize proactive maintenance and address exhaust system issues promptly. Neglecting these responsibilities can lead to diminished vehicle performance, increased operational costs, potential safety hazards, and regulatory infractions. A commitment to responsible vehicle maintenance ensures both individual well-being and the preservation of environmental quality within Canby and beyond.

![Secure Exhaust: Best Stainless Muffler Clamp [Durable] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Secure Exhaust: Best Stainless Muffler Clamp [Durable] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-113-300x200.jpg)

![[Guide] Muffler Sizing: Find The Right Size Muffler For Your Car Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades [Guide] Muffler Sizing: Find The Right Size Muffler For Your Car | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-110-300x200.jpg)

![Richmond Muffler: Local Choice, Quiet Ride [Richmond, VA] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Richmond Muffler: Local Choice, Quiet Ride [Richmond, VA] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-108-300x200.jpg)