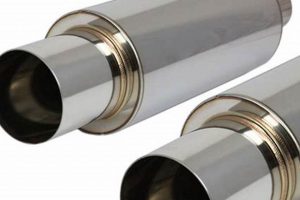

These components are bands or fasteners specifically designed to secure a vehicle’s exhaust noise reduction device to the undercarriage. Often constructed from durable materials such as steel or reinforced rubber, they are engineered to withstand exposure to heat, vibration, and environmental elements. For example, a damaged or corroded retaining mechanism could lead to the exhaust system dragging on the road, causing significant damage and potential safety hazards.

The integrity of these mounting devices is paramount for maintaining vehicle safety and compliance with noise regulations. A secure exhaust system prevents excessive noise pollution and ensures proper emission control. Historically, simpler methods were used for exhaust attachment, but modern designs incorporate advanced materials and engineering to enhance durability and longevity, contributing to reduced maintenance and improved vehicle performance.

The following sections will delve into the various types available, common failure points, proper installation techniques, and best practices for maintaining these critical automotive parts. Understanding these aspects will empower vehicle owners and technicians to ensure the safe and efficient operation of their vehicle’s exhaust system.

Maintenance and Optimization Strategies

Proper care and attention to exhaust mounting hardware significantly extend the lifespan of the exhaust system and ensure vehicle safety. The following guidelines offer practical advice for maintaining these essential components.

Tip 1: Regular Inspection: Conduct routine visual checks for signs of corrosion, cracking, or detachment. Early detection of these issues prevents more significant problems and potential system failure. For instance, a small crack can rapidly expand due to temperature fluctuations and vibration.

Tip 2: Material Compatibility: When replacing these components, ensure the new parts are compatible with the vehicle’s exhaust system material. Dissimilar metals can accelerate corrosion through galvanic reactions. Refer to the vehicle’s service manual or consult a qualified technician for guidance.

Tip 3: Proper Torque Application: When tightening fasteners, adhere strictly to the manufacturer’s recommended torque specifications. Over-tightening can strip threads or damage the mounting hardware; under-tightening can lead to loosening and eventual failure.

Tip 4: Vibration Dampening: Utilize vibration-dampening materials or insulators when installing or replacing mounting hardware. These materials reduce the transmission of vibration from the exhaust system to the vehicle chassis, mitigating stress and extending the lifespan of the components.

Tip 5: Rust Prevention: Apply a rust-inhibiting compound to the mounting hardware and surrounding areas, particularly in regions with harsh weather conditions or road salt exposure. This proactive measure protects against corrosion and prolongs the life of the system.

Tip 6: Professional Installation: For complex installations or repairs, seek the assistance of a qualified automotive technician. Professional installation ensures proper alignment, secure fastening, and adherence to safety standards.

Tip 7: Avoid Excessive Loads: Ensure that the exhaust system is not subjected to excessive weight or stress. Avoid driving over large obstacles or off-road conditions that could damage the exhaust system or its mounting hardware.

Implementing these strategies minimizes the risk of exhaust system failure, ensuring optimal performance, safety, and regulatory compliance. Prioritizing these maintenance practices reduces long-term repair costs and enhances vehicle reliability.

The subsequent sections will further explore troubleshooting techniques and long-term maintenance solutions for exhaust systems, ensuring continued vehicle performance and safety.

1. Secure Attachment

Secure attachment is paramount to the function and longevity of a vehicle’s exhaust system, directly impacting the effectiveness and safety of its operation. The reliable retention of the exhaust assembly, particularly through properly functioning retaining mechanisms, ensures consistent performance and prevents damage to both the exhaust components and the vehicle itself.

- Load Distribution

Effective load distribution is achieved when the retaining mechanisms distribute the weight of the exhaust system evenly across the designated mounting points. This prevents stress concentrations that could lead to premature failure of the system or its supporting hardware. For example, poorly distributed load could result in cracking of the exhaust manifold or detachment of the tailpipe.

- Vibration Mitigation

Vehicle operation inevitably generates significant vibrations, which, if not properly managed, can cause loosening or fatigue of the support hardware. Properly designed and installed mechanisms incorporate vibration-damping materials and secure locking mechanisms to minimize the effects of these forces. The absence of effective vibration mitigation can result in excessive noise, rattling, and potential system damage.

- Corrosion Protection

The undercarriage of a vehicle is exposed to harsh environmental conditions, including road salt, moisture, and extreme temperatures, all of which contribute to corrosion. Secure attachment relies on corrosion-resistant materials and coatings to maintain the integrity of the retaining mechanisms over time. Corrosion can weaken the hardware, leading to failure and detachment of the exhaust system.

- Proper Alignment

Correct alignment between the exhaust system and the vehicle’s chassis is essential for ensuring secure attachment. Misalignment can introduce stress and strain on the support hardware, leading to premature wear and failure. Careful attention to alignment during installation and subsequent maintenance is critical for maintaining the stability and security of the exhaust system.

These facets of secure attachment are interconnected and interdependent. A failure in one area, such as inadequate corrosion protection, can compromise the overall security of the exhaust system. By addressing each of these aspects proactively, vehicle owners and technicians can ensure the reliable performance and extended lifespan of their vehicles’ exhaust systems.

2. Material Durability

Material durability is a critical consideration in the design and performance of retaining devices for exhaust systems. The selection of appropriate materials dictates the lifespan and reliability of these components, particularly in the face of harsh operating conditions.

- Tensile Strength

Tensile strength, the resistance of a material to breaking under tension, is paramount. These components are constantly subjected to gravitational forces pulling downward on the exhaust system, coupled with dynamic stresses from road vibrations. Materials lacking sufficient tensile strength will deform or fracture prematurely. Stainless steel, for example, offers superior tensile strength compared to standard carbon steel, making it a preferred choice in demanding applications.

- Corrosion Resistance

Exposure to road salt, moisture, and exhaust gases necessitates high corrosion resistance. Corroded fasteners weaken structurally, compromising their ability to securely hold the exhaust system. Materials like galvanized steel or stainless steel provide enhanced protection against corrosion compared to uncoated steel, extending the service life of the retaining mechanisms.

- Heat Resistance

Exhaust systems operate at elevated temperatures, requiring retaining mechanisms to withstand thermal degradation. Materials with poor heat resistance can become brittle or lose their structural integrity, leading to failure. High-temperature alloys and reinforced polymers are employed to mitigate these effects, ensuring the fastener maintains its strength even at elevated temperatures.

- Fatigue Resistance

Constant vibration and fluctuating stress levels induce fatigue in the components. Materials with high fatigue resistance can withstand repeated stress cycles without cracking or breaking. Spring steel, often used in clamp designs, exhibits excellent fatigue resistance, enabling it to maintain clamping force over extended periods.

The interplay of these material properties directly impacts the reliability and longevity of exhaust retaining devices. Selection of materials optimized for tensile strength, corrosion resistance, heat resistance, and fatigue resistance is essential for ensuring safe and effective exhaust system operation. Failure to consider these factors can result in premature component failure, leading to costly repairs and potential safety hazards.

3. Vibration Dampening

Effective vibration dampening is essential to the performance and longevity of exhaust systems, and specifically, to the efficacy of retaining mechanisms. Undamped vibrations contribute to premature wear, material fatigue, and potential structural failure. Mitigation of these vibrations enhances the reliability and operational lifespan of the entire exhaust system.

- Material Selection

The selection of appropriate materials for retaining mechanisms significantly impacts vibration dampening. Rubber or polymer-based insulators, incorporated into the design, absorb vibrational energy, preventing its transmission to the vehicle chassis. Using materials with inherently high damping characteristics reduces stress on the system and the retaining devices, extending their service life. An example includes incorporating rubber grommets between the exhaust hanger and the vehicle frame, which minimizes the transfer of vibrational forces.

- Design Configuration

Design configurations of the retaining hardware directly influence vibration dampening capabilities. Incorporating flexible joints or isolating mounts allows for controlled movement of the exhaust system, accommodating vibrational forces. Strategically placed flexible hangers minimize the transmission of vibration from the exhaust to the vehicle’s structural components. A design that allows for slight movement of the exhaust relative to the vehicle chassis can significantly reduce stress on retaining hardware.

- Frequency Tuning

Exhaust systems vibrate at specific frequencies. By tuning the retaining hardware to dampen these frequencies, engineers can minimize the effects of resonance. This involves careful selection of materials and design to ensure that the natural frequency of the retaining mechanism is out of phase with the primary vibration frequencies of the exhaust. This tuned dampening reduces stress concentration and material fatigue.

- Proper Installation

Effective vibration dampening is contingent on proper installation techniques. Retaining mechanisms must be securely fastened, but not over-tightened, to allow for necessary movement and vibration absorption. Over-tightening compromises the dampening capabilities of flexible mounts. Correct installation ensures that the design features intended for vibration reduction are fully realized.

These facets of vibration dampening, when effectively implemented, contribute to a more durable and reliable exhaust system. By minimizing the destructive forces of vibration, the components experience less stress and fatigue, resulting in extended service life and reduced maintenance requirements. Proper vibration dampening ultimately safeguards the vehicle, ensuring safer and more efficient operation.

4. Corrosion Resistance

Corrosion resistance is a paramount attribute of effective exhaust support mechanisms. These components are consistently exposed to a corrosive environment, including moisture, road salts, and exhaust byproducts. Degradation due to corrosion weakens the material structure, ultimately compromising the integrity of the exhaust mounting. For instance, steel retaining bands, unprotected against rust, will gradually corrode, losing their ability to securely hold the exhaust system, leading to potential detachment and damage.

The selection of corrosion-resistant materials and protective coatings directly influences the lifespan and reliability of these crucial parts. Stainless steel, aluminized steel, and specialized coatings are employed to mitigate corrosion. Consider the practical example of a vehicle operating in a region with frequent snowfall and road salting; retaining bands constructed from uncoated steel would require replacement much more frequently than those made from stainless steel. Furthermore, proper surface treatments such as galvanization or powder coating provide an additional layer of protection, extending the service life and reducing maintenance costs.

In summary, corrosion resistance is not merely a desirable feature but a fundamental requirement for ensuring the long-term effectiveness and safety of exhaust support mechanisms. The selection of appropriate materials and the application of protective coatings are critical to preventing corrosion-related failures, safeguarding the exhaust system, and maintaining vehicle operability. Prioritizing corrosion resistance in the design and maintenance of these components results in reduced repair costs, enhanced safety, and prolonged vehicle lifespan.

5. Proper Installation

Proper installation of exhaust support mechanisms, especially including retaining bands, directly influences their effectiveness and longevity. Incorrect installation introduces stress points, reduces vibration dampening, and accelerates corrosion, thereby diminishing the intended performance. A loosely fitted fastener, for example, allows excessive movement of the exhaust system, leading to metal fatigue and potential detachment. Conversely, an overtightened fastener can crush the exhaust pipe or damage the retaining mechanism itself, causing premature failure. The correct application of torque, adhering to manufacturer specifications, ensures the support is secure yet not excessively strained. The consequences of improper installation are not limited to the retaining band itself but extend to the entire exhaust system, potentially affecting vehicle performance and safety.

Consider the practical example of replacing a corroded retainer on an exhaust system. If the new retaining band is not properly aligned with the exhaust pipe and muffler, the resulting stress will concentrate at the point of misalignment. This concentrated stress can cause the new retaining band to fail prematurely, potentially leading to an exhaust leak or complete system detachment. Furthermore, neglecting to clean the mating surfaces of the exhaust pipe and muffler before installing the new retaining band can introduce contaminants that accelerate corrosion and reduce the grip of the fastener. The correct procedure includes thoroughly cleaning the surfaces, properly aligning the components, and tightening the fastener to the specified torque, all contributing to a robust and durable connection.

In summary, proper installation is not merely a procedural step but an integral factor in the function and lifespan of exhaust supports. By adhering to established installation guidelines, technicians and vehicle owners can mitigate the risks associated with improper installation, ensuring secure attachment, optimal performance, and prolonged service life. Addressing the complexities involved in installation reinforces the value of precise execution and reinforces the importance of proper understanding of all supporting component roles.

6. System Alignment

System alignment is intrinsically linked to the functionality and longevity of exhaust retaining mechanisms. Misalignment introduces undue stress on these components, leading to premature failure and potential damage to the exhaust system and surrounding vehicle structures. When the exhaust system is not properly aligned, the retaining bands bear uneven loads, concentrating stress at specific points. This concentration weakens the metal over time, increasing the likelihood of cracking or complete failure. A real-world example is an exhaust system that has been improperly reinstalled after repairs. If the system is not aligned correctly, the retaining bands are forced to compensate for the misalignment, placing them under constant strain.

The influence of alignment extends beyond just the retaining components; it affects the performance of the entire exhaust system. An improperly aligned exhaust system can restrict exhaust flow, reducing engine efficiency and potentially damaging catalytic converters. Furthermore, vibrations are amplified when the system is misaligned, accelerating wear on all components, including hangers, pipes, and mufflers. Proper alignment, conversely, ensures that all components operate within their design parameters, maximizing performance and minimizing stress. Routine inspections and adjustments are critical to maintaining optimal alignment and preventing costly repairs.

Maintaining correct system alignment presents challenges, particularly given the harsh operating environment under a vehicle. Temperature fluctuations, road debris, and corrosion all contribute to misalignment over time. Addressing these challenges requires durable retaining designs and proactive maintenance. Regular inspections, professional repairs, and using appropriately sized and aligned components contribute to overall system health. These practices safeguard not only the supports but the entire exhaust assembly, which contributes to a safer and more efficient vehicle operation.

Frequently Asked Questions

The following questions address common inquiries regarding the selection, maintenance, and functionality of exhaust support mechanisms.

Question 1: What constitutes a suitable material for exhaust mounting components?

Optimal materials exhibit high tensile strength, corrosion resistance, and thermal stability. Stainless steel and aluminized steel are common choices due to their durability and ability to withstand harsh environmental conditions.

Question 2: How frequently should exhaust retention devices be inspected?

Visual inspections should occur at least annually, or more frequently in regions with severe weather conditions or excessive road salt usage. Early detection of corrosion or damage prevents more significant issues.

Question 3: What are the implications of improper exhaust alignment?

Misalignment introduces undue stress on retaining devices, leading to premature failure. Additionally, it can restrict exhaust flow and negatively impact engine performance.

Question 4: Is professional installation of exhaust hardware necessary?

While some installations may appear straightforward, professional expertise ensures proper alignment, torque application, and overall system integrity. Complex installations and welding repairs should always be performed by qualified technicians.

Question 5: What factors contribute to premature failure of retaining bands?

Common causes include corrosion, excessive vibration, improper installation, and exposure to extreme temperatures. Addressing these factors through proper maintenance prolongs component lifespan.

Question 6: Are aftermarket solutions for vibration dampening effective?

High-quality aftermarket vibration dampeners can effectively reduce stress on the exhaust system and its retaining components. Ensure compatibility with the vehicle’s specific make and model.

Proper understanding and proactive maintenance of exhaust system support mechanisms contribute to vehicle safety, performance, and longevity.

The subsequent section explores troubleshooting common exhaust system issues and implementing long-term maintenance solutions.

Conclusion

Throughout this exploration, the critical role of muffler straps in securing and maintaining exhaust systems has been underscored. Proper material selection, installation, maintenance, and alignment are paramount in ensuring their functionality. The consequences of neglecting these aspects range from increased noise pollution and compromised vehicle safety to premature exhaust system failure and costly repairs.

Effective management and proactive maintenance of muffler straps and related components are indispensable for the reliable and efficient operation of any vehicle. By acknowledging their significance and implementing the strategies outlined, vehicle owners and technicians alike can enhance vehicle safety, prolong exhaust system life, and contribute to a reduction in noise pollution.