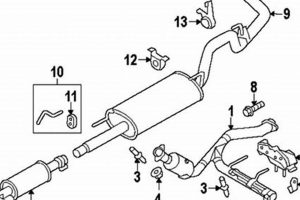

Components augmenting an exhaust system’s noise reduction and performance are integral to vehicle operation. These include items such as exhaust tips, clamps, hangers, and heat shields, all designed to enhance functionality and longevity. For example, a stainless steel exhaust tip can improve the appearance of a vehicle while also offering protection against corrosion.

Properly functioning exhaust systems are vital for minimizing noise pollution and ensuring efficient engine operation. The aforementioned components play a significant role in maintaining the system’s integrity, preventing leaks, and controlling vibration. Historically, advancements in materials and design have led to more durable and effective parts, contributing to improved vehicle performance and regulatory compliance.

The following sections will delve into specific categories of these components, examining their function, material composition, installation procedures, and factors influencing their selection.

Enhancing Exhaust Systems

The following recommendations offer guidance on optimizing exhaust system performance and longevity through careful selection and maintenance of supplementary components.

Tip 1: Material Selection: Opt for stainless steel or aluminized steel components to resist corrosion, particularly in regions with harsh weather conditions or road salt application. This choice extends the lifespan of the exhaust system.

Tip 2: Proper Installation: Ensure correct alignment and secure fastening of all components during installation. Improper fitment can lead to leaks, vibrations, and premature wear.

Tip 3: Regular Inspection: Conduct routine visual inspections to identify signs of damage, corrosion, or loose connections. Addressing these issues promptly prevents further degradation.

Tip 4: Heat Shield Utilization: Employ heat shields to protect surrounding components from excessive heat, thereby preventing damage to undercarriage elements and improving overall vehicle safety.

Tip 5: Clamp Selection: Utilize high-quality clamps with appropriate torque specifications to ensure a secure and leak-free seal at all connection points. Regular tightening may be required.

Tip 6: Vibration Dampening: Incorporate rubber hangers or isolators to minimize vibration transmission to the vehicle chassis, reducing noise and enhancing driving comfort.

Tip 7: Exhaust Tip Considerations: Select exhaust tips that not only enhance aesthetics but also provide adequate drainage to prevent water accumulation and corrosion.

Implementing these guidelines can significantly improve the performance, durability, and overall value of a vehicle’s exhaust system.

The subsequent section will provide a detailed analysis of troubleshooting common issues related to supplementary components.

1. Enhanced Noise Reduction

The primary function of an exhaust system is to expel combustion byproducts while mitigating engine noise. Supplementary components significantly contribute to achieving optimal sound dampening. The effectiveness of the primary noise reduction device, the muffler, is greatly enhanced by employing the right supporting elements.

- Acoustic Packing Materials

Internal muffler design relies on packing materials, such as fiberglass or steel wool, to absorb sound waves. Replacing or supplementing degraded packing within the muffler body can restore its original noise reduction capabilities. The choice of material impacts the frequency range that is effectively dampened. Regular inspection and replacement, if necessary, are vital for sustained performance.

- Resonators

Resonators, often installed inline with the muffler, are designed to cancel specific frequencies. Adding or replacing a resonator targets problem noise levels and provides additional sound control beyond the muffler’s capabilities. The placement and internal design of the resonator determine its effectiveness in suppressing particular sound frequencies.

- Exhaust Tips

While primarily aesthetic, certain exhaust tip designs can subtly alter exhaust note. Tips with baffled interiors or specific outlet shapes can diffuse sound waves, contributing to a reduction in perceived noise. However, the impact on noise reduction is often secondary to their visual appeal.

- Heat Shields and Dampers

These components minimize the transmission of vibrations and noise from the exhaust system to the vehicle chassis. Properly installed heat shields dampen structural vibrations, preventing them from amplifying exhaust noise within the vehicle cabin. Regular inspection is critical to ensure that mounting points are not compromised.

Effective noise reduction relies on the synergistic effect of these elements. Addressing individual components can improve the overall performance and meet noise regulations and driver preferences. Selecting high-quality materials, ensuring proper installation, and scheduling routine maintenance are all essential to maximizing sound dampening.

2. Improved Exhaust Flow

The efficiency of an internal combustion engine is inextricably linked to its ability to expel exhaust gases. Components supplementing the primary exhaust system elements can significantly influence the rate and smoothness of this gas expulsion, thereby impacting engine performance. Restrictions in exhaust flow create backpressure, reducing engine power and fuel economy. Certain elements are designed to mitigate these restrictions and enhance flow characteristics.

For instance, high-flow exhaust tips with flared designs can reduce turbulence at the exhaust outlet, promoting a smoother exit of gases. Similarly, mandrel-bent exhaust piping, characterized by its consistent diameter throughout bends, minimizes flow restriction compared to crush-bent piping. Furthermore, performance exhaust headers, when used in conjunction with the standard system, optimize gas scavenging from the cylinders, contributing to a more efficient combustion cycle. The impact is readily observable in dyno testing, where vehicles equipped with these components often exhibit measurable gains in horsepower and torque compared to stock configurations. Replacing stock exhaust manifolds and mufflers with less restrictive components is a common modification to improve exhaust flow in cars.

The practical significance of understanding the link between these components and exhaust flow lies in the ability to tailor exhaust systems to specific performance goals. Whether optimizing for fuel efficiency, maximizing horsepower, or achieving a desired exhaust note, the selection and integration of these elements play a critical role. While modifications must adhere to regulatory noise restrictions and emissions standards, the strategic utilization of these components can unlock significant potential improvements in engine performance and overall vehicle efficiency.

3. Corrosion Resistance

Corrosion poses a significant threat to the longevity and performance of exhaust systems. The selection of corrosion-resistant components is paramount in mitigating the adverse effects of environmental exposure and extending the lifespan of the entire system.

- Stainless Steel Construction

Stainless steel alloys, particularly grades 304 and 409, offer superior resistance to oxidation and chemical attack compared to mild steel. Employing these materials in the construction of exhaust tips, clamps, and hangers significantly reduces the likelihood of rust formation, even in harsh operating environments. For example, stainless steel exhaust tips maintain their structural integrity and aesthetic appearance over extended periods, unlike chrome-plated steel, which is prone to pitting and corrosion.

- Protective Coatings

Coatings such as ceramic-based thermal barriers and aluminized finishes provide an additional layer of protection against corrosion. These coatings create a physical barrier between the metal substrate and corrosive elements, preventing or slowing down the degradation process. An aluminized finish on exhaust piping, for example, provides sacrificial protection, corroding preferentially to the underlying steel and extending the pipe’s lifespan.

- Proper Drainage Design

The design of exhaust components should incorporate features that promote efficient water drainage. Water accumulation within the exhaust system can accelerate corrosion, particularly in areas with stagnant airflow. Exhaust tips with weep holes, for instance, allow water to escape, preventing it from pooling and causing rust. Similarly, the orientation of clamps and hangers should minimize the potential for water entrapment.

- Material Compatibility

When combining different materials within the exhaust system, it is crucial to consider their electrochemical compatibility. Galvanic corrosion can occur when dissimilar metals are in contact in the presence of an electrolyte, such as road salt. Selecting compatible materials or using insulating gaskets can mitigate this risk. For example, using aluminum hangers with a stainless steel exhaust system could lead to accelerated corrosion of the aluminum if not properly isolated.

The selection of corrosion-resistant components and the implementation of appropriate protective measures are essential for maintaining the structural integrity and performance of exhaust systems. The long-term cost savings associated with reduced maintenance and replacement outweigh the initial investment in high-quality, corrosion-resistant parts.

4. Secure Mounting

The operational integrity of any exhaust system hinges on the reliability of its mounting hardware. Failure to ensure secure attachment of all components, including the muffler and associated supports, can lead to a cascade of problems affecting both performance and safety.

- Hanger Design and Material

Exhaust hangers, typically constructed from steel or rubber, are responsible for supporting the weight of the exhaust system and isolating vibrations from the vehicle chassis. The design of these hangers must accommodate thermal expansion and contraction, as well as road-induced shocks. The material composition dictates its resistance to corrosion and fatigue. For instance, using reinforced rubber hangers in areas subject to high temperatures can prevent premature failure and maintain secure positioning of the muffler.

- Clamp Selection and Torque Specification

Clamps are essential for creating leak-proof connections between exhaust components. The selection of appropriate clamp types, such as band clamps or U-bolt clamps, must align with the specific application and pipe diameter. Adhering to precise torque specifications during installation is critical to ensure a secure seal without damaging the pipe. Under-torquing can result in exhaust leaks, while over-torquing can deform the pipe and compromise the connection. For example, using a T-bolt clamp with a specified torque value on a slip-fit joint ensures a tight seal that can withstand exhaust pressure and temperature variations.

- Mounting Point Integrity

The structural integrity of the vehicle’s mounting points for exhaust hangers is paramount. Corrosion or damage to these mounting points can weaken the support structure and increase the risk of exhaust system failure. Regular inspection of these points and timely repair or reinforcement are essential for maintaining secure mounting. Neglecting corroded mounting points, for example, can lead to hanger detachment and potential damage to the exhaust system and surrounding components.

- Isolator Function and Placement

Vibration isolators, typically made of rubber or polyurethane, are strategically placed to dampen vibrations transmitted from the exhaust system to the vehicle chassis. Proper placement of these isolators minimizes noise and prevents fatigue damage to the exhaust components. Deteriorated or improperly installed isolators can result in increased noise levels and accelerated wear on the exhaust system. Using high-durometer polyurethane isolators in performance applications, for instance, can provide enhanced vibration damping and durability.

Collectively, these elements ensure the exhaust system remains securely mounted, preventing leaks, reducing noise, and safeguarding against premature component failure. Periodic inspection and maintenance of mounting hardware are crucial for preserving the operational effectiveness and longevity of the entire exhaust system.

5. Heat Dissipation

Elevated temperatures within an exhaust system present a significant challenge to component longevity and vehicle safety. Efficient heat dissipation is crucial for preventing damage to adjacent components, maintaining optimal operating temperatures, and minimizing the risk of thermal-related failures. Elements contributing to this heat management are integral to the exhaust system’s overall functionality. Exhaust wraps, heat shields, and ceramic coatings are examples of such components designed to mitigate the impact of extreme heat. For instance, a heat shield positioned between the exhaust manifold and a plastic fuel line can prevent fuel vaporization and potential engine misfires caused by excessive heat transfer. The effectiveness of heat dissipation directly influences the durability of exhaust system elements, preventing premature degradation and ensuring optimal performance.

The strategic application of these components requires careful consideration of material properties, placement, and environmental factors. Exhaust wraps, typically made of fiberglass or ceramic materials, insulate the exhaust piping, reducing radiant heat transfer. Heat shields, constructed from aluminum or stainless steel, reflect heat away from sensitive areas. Ceramic coatings, applied directly to the exhaust components, provide a thermal barrier and enhance corrosion resistance. The selection of the appropriate component depends on the specific application and the level of heat protection required. In high-performance applications, ceramic coatings are often preferred due to their superior thermal insulation properties. In contrast, heat shields may be more suitable for protecting specific components from localized heat sources.

Effective heat dissipation extends the lifespan of exhaust components, improves vehicle safety, and enhances engine performance. The proper selection and installation of heat-dissipating elements are essential for mitigating the detrimental effects of elevated exhaust temperatures. Addressing thermal management challenges contributes to the overall reliability and efficiency of the vehicle, reducing the risk of costly repairs and ensuring optimal operating conditions. The principles of heat management are applied not only to enhance vehicle performance but also to ensure safety and component integrity, making it an important part of “muffler accessories”.

6. Aesthetic Customization

The visual appeal of a vehicle is often enhanced through modifications to the exhaust system. While functionality remains paramount, the selection of supplementary components offers opportunities for aesthetic customization, allowing owners to personalize the appearance of their vehicles.

- Exhaust Tip Designs

Exhaust tips serve as a prominent visual element, with various designs available to complement a vehicle’s style. Options range from polished stainless steel to black chrome finishes, with variations in shape, size, and angle. A dual-outlet tip, for example, can add a sporty appearance to a vehicle, while a downturned tip may offer a more subtle, understated look. The choice of exhaust tip can significantly influence the overall visual impression of the vehicle’s rear end.

- Hanger Finishes and Styles

While primarily functional, exhaust hangers can also contribute to the overall aesthetic. Stainless steel or powder-coated hangers offer a cleaner, more refined appearance compared to standard black rubber hangers. The style of the hanger, such as a polished or brushed finish, can complement other visual elements of the vehicle. Replacing worn or corroded hangers with aesthetically pleasing alternatives can improve the overall impression of the exhaust system.

- Heat Shield Materials and Textures

Heat shields, designed to protect surrounding components from heat, can also be selected for their aesthetic qualities. Aluminum heat shields with brushed or polished finishes offer a visually appealing alternative to plain steel shields. The texture of the heat shield, such as a diamond plate pattern, can add a touch of customization. While the primary function is heat protection, the aesthetic aspects of the heat shield can enhance the overall appearance of the exhaust system.

- Clamp Styles and Finishes

Clamps are essential for securing exhaust components, and their appearance can contribute to the overall aesthetic. Stainless steel clamps offer a cleaner, more durable alternative to standard steel clamps. Clamp styles, such as band clamps or T-bolt clamps, can also influence the visual impression. Selecting clamps with a consistent finish and style can enhance the appearance of the exhaust system, especially in areas where the clamps are visible.

The integration of aesthetic customization options into the exhaust system allows vehicle owners to express their individual style preferences. While performance and functionality remain primary considerations, the selection of visually appealing supplementary components can enhance the overall appearance of the vehicle.

7. Prolonged System Life

The service life of an exhaust system is significantly influenced by the selection and utilization of supplementary components. These elements, often overlooked, play a critical role in mitigating factors that contribute to premature wear and failure, thereby extending the system’s overall lifespan.

- Corrosion-Resistant Materials

The utilization of materials such as stainless steel or aluminized steel in components like exhaust tips, clamps, and hangers directly impacts resistance to corrosion. Environments with high exposure to road salt or moisture accelerate the degradation of exhaust systems constructed from standard steel. Stainless steel accessories provide a barrier against rust and oxidation, substantially prolonging the life of the exhaust system. For instance, a stainless steel exhaust tip, as opposed to a chrome-plated one, maintains structural integrity and visual appeal over extended periods.

- Vibration Dampening

Excessive vibration can cause fatigue and cracking in exhaust system components, particularly at welded joints and mounting points. The incorporation of rubber isolators or flexible couplings reduces the transmission of vibration from the engine to the exhaust system. These vibration-dampening elements minimize stress concentrations and prevent premature failure. A properly installed rubber hanger, for example, can significantly extend the lifespan of the muffler by absorbing vibrations that would otherwise be transferred directly to the muffler casing.

- Thermal Management

The cyclical heating and cooling of exhaust systems induce thermal stress, contributing to metal fatigue and eventual failure. Heat shields and thermal wraps help to regulate temperature fluctuations, reducing thermal stress and preventing localized hot spots. A heat shield positioned between the exhaust manifold and other components prevents excessive heat transfer, safeguarding adjacent components from damage and prolonging the lifespan of the exhaust system as a whole. Ceramic coatings also play a significant role in lowering underhood temperatures in sports or race cars.

- Proper Installation and Maintenance

The correct installation and routine maintenance of exhaust system components are crucial for maximizing system life. Misaligned components, loose connections, or damaged hangers can create stress points and accelerate wear. Regular inspection and timely replacement of worn or damaged parts prevent further degradation. Tightening loose clamps, replacing corroded hangers, and addressing exhaust leaks promptly can substantially extend the lifespan of the entire system.

The interconnectedness of these facets underscores the importance of a holistic approach to exhaust system maintenance. The strategic selection and proper maintenance of these supplementary components offer a cost-effective means of maximizing system longevity, reducing the need for frequent repairs or replacements, and ensuring optimal performance over an extended period. These points about extended system life also play an important part in “muffler accessories”.

Frequently Asked Questions

This section addresses common inquiries regarding components augmenting the primary exhaust system.

Question 1: What constitutes a supplementary exhaust system component?

Supplementary components encompass items such as exhaust tips, clamps, hangers, heat shields, resonators, and specialized packing materials used within mufflers. These elements enhance the functionality, performance, and aesthetic appeal of the core exhaust system.

Question 2: What is the expected lifespan of a typical exhaust hanger?

The lifespan of an exhaust hanger depends significantly on material and environmental conditions. Rubber hangers typically last 2-5 years, while stainless steel hangers can exceed 10 years. Exposure to road salt and extreme temperatures accelerates degradation.

Question 3: Does the selection of exhaust tip material impact sound characteristics?

While primarily aesthetic, exhaust tip material can subtly influence the exhaust note. Stainless steel tips tend to produce a brighter, more resonant sound, whereas tips with baffled interiors may slightly reduce perceived noise levels.

Question 4: What are the implications of using mismatched clamp sizes on exhaust connections?

Utilizing mismatched clamp sizes can lead to exhaust leaks, reduced system efficiency, and potential component damage. Improper clamping force compromises the seal, resulting in noise pollution and reduced engine performance. Correct sizing and torque specifications are crucial.

Question 5: What maintenance procedures are recommended for maximizing exhaust system longevity?

Recommended maintenance includes routine visual inspections for corrosion and damage, periodic tightening of clamps and fasteners, and timely replacement of worn or damaged components such as hangers and heat shields. Addressing issues promptly prevents further degradation.

Question 6: Can the addition of supplementary components void a vehicle’s warranty?

The impact on a vehicle’s warranty depends on the specific component and the manufacturer’s policies. Generally, components that do not directly alter the engine’s calibration or emissions control systems are less likely to void the warranty. Consult the vehicle’s warranty documentation and local regulations.

In conclusion, the judicious selection, proper installation, and diligent maintenance of supplementary exhaust system components are essential for optimizing performance, extending lifespan, and ensuring regulatory compliance.

The subsequent section will delve into troubleshooting common issues associated with these components.

Conclusion

The preceding analysis demonstrates the crucial role of supplementary components in optimizing exhaust system performance, longevity, and aesthetic appeal. From enhancing noise reduction and improving exhaust flow to ensuring corrosion resistance and secure mounting, these elements collectively contribute to a well-functioning and durable system. Strategic selection, proper installation, and diligent maintenance of these components are paramount for maximizing their benefits.

The ongoing evolution of materials and design principles suggests continued advancements in supplementary exhaust system technology. A comprehensive understanding of these advancements, coupled with adherence to best practices in component selection and maintenance, will enable vehicle owners and technicians to realize the full potential of their exhaust systems, ensuring sustained performance and regulatory compliance for years to come. Continued research in this area is encouraged.