A replacement exhaust component designed for specific Ram 1500 models, ensuring seamless installation without requiring modifications like cutting or welding. The component aligns with the vehicle’s existing exhaust system mounting points. As an example, a 2016 Ram 1500 with a particular engine configuration may require a distinctly designed replacement part for optimal performance and fit.

The advantage of such a component lies in its ease of installation, potentially reducing labor costs for vehicle owners. Historically, exhaust system repairs often involved custom fabrication. These systems negate the need for such custom work, saving time and ensuring a proper seal, crucial for exhaust gas management and noise reduction. Furthermore, a correctly installed component maintains the vehicle’s intended emissions standards.

Subsequent sections will delve into the selection criteria for choosing a suitable replacement, potential performance enhancements achievable with aftermarket options, and maintenance tips to prolong the lifespan of this crucial exhaust system component.

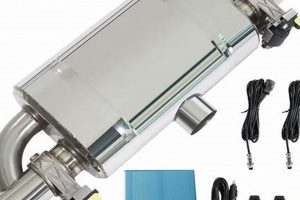

Ram 1500 Direct Fit Muffler

Proper selection and maintenance contribute significantly to the longevity and performance of a replacement exhaust component. The following points outline key considerations.

Tip 1: Verify Compatibility. Always confirm the replacement component’s compatibility with the specific Ram 1500 year, model, engine size, and cab configuration. Utilize online parts catalogs or consult with automotive professionals to ensure accurate matching.

Tip 2: Prioritize Material Quality. Opt for components constructed from durable materials such as stainless steel or aluminized steel. These materials offer increased resistance to corrosion, extending the lifespan of the replacement part.

Tip 3: Inspect Welds and Seams. Examine the quality of welds and seams on the new component. Consistent and robust welds indicate superior manufacturing processes, reducing the likelihood of leaks or premature failures.

Tip 4: Ensure Proper Installation. Adhere strictly to the manufacturer’s installation guidelines. Incorrect installation can lead to exhaust leaks, reduced performance, and potential damage to other vehicle components.

Tip 5: Regularly Inspect for Corrosion. Periodically inspect the exhaust system, including the muffler, for signs of rust or corrosion. Address minor issues promptly to prevent more significant and costly repairs.

Tip 6: Address Exhaust Leaks Immediately. If unusual noises or exhaust fumes are detected, promptly inspect for exhaust leaks. Leaks can compromise fuel efficiency, reduce engine performance, and pose a safety hazard.

Tip 7: Consider Professional Installation. If lacking experience with exhaust system repairs, consider entrusting the installation to a qualified mechanic. Professional installation ensures proper fitment and reduces the risk of complications.

Adherence to these guidelines maximizes the effectiveness and lifespan of the replacement exhaust component, contributing to the vehicle’s overall performance and reliability.

The subsequent section details common performance enhancements associated with aftermarket replacement options and provides a comprehensive conclusion.

1. Vehicle Compatibility

Vehicle compatibility is paramount when selecting a replacement exhaust component. Mismatched parts can lead to installation difficulties, reduced performance, and potential damage to the vehicle. For the Ram 1500, ensuring the replacement component is specifically designed for the vehicle’s year, model, engine type, and cab configuration is critical.

- Engine Configuration Matching

Different Ram 1500 engine options, such as the 3.6L V6, 5.7L V8, or 3.0L diesel, necessitate distinct exhaust system designs. A component intended for a V6 engine will not properly fit or function on a V8 model due to variations in exhaust port configurations and exhaust flow requirements. Therefore, precise engine specification matching is essential.

- Model Year Specificity

Ram 1500 models undergo design modifications across model years. Exhaust system routing and mounting points can vary, even within the same engine type. A component designed for a 2010 Ram 1500 may not be compatible with a 2019 model due to changes in chassis design or emissions control systems. Verifying model year compatibility is crucial for seamless integration.

- Cab and Bed Configuration Considerations

Cab and bed configurations, such as Regular Cab, Quad Cab, Crew Cab, and different bed lengths, influence exhaust system length and routing. A replacement component designed for a Crew Cab model with a short bed may not fit a Regular Cab model with a long bed due to differences in frame length and exhaust hanger locations. Accounting for cab and bed configuration is vital for proper fitment.

- Emissions Standards Compliance

Exhaust systems are integral to meeting emissions standards. A replacement component must be compliant with the applicable emissions regulations for the vehicle’s model year and location. Using a non-compliant part can result in failed emissions tests and potential fines. Ensuring the replacement component meets or exceeds emissions standards is imperative.

In conclusion, the selection of a replacement component for the Ram 1500 hinges on precise vehicle compatibility. Failure to account for engine configuration, model year, cab and bed configuration, and emissions standards can lead to installation problems, reduced performance, and regulatory non-compliance. Therefore, thorough verification of compatibility is paramount before procurement and installation.

2. Material Durability

Material durability is a critical attribute directly impacting the service life and overall performance of a replacement exhaust component for the Ram 1500. The exhaust system, positioned underneath the vehicle, is constantly exposed to harsh environmental conditions, including road salt, moisture, extreme temperatures, and physical impacts from road debris. A component constructed from inferior materials is prone to premature corrosion, cracking, and failure, leading to exhaust leaks, reduced engine efficiency, and the need for frequent replacements. For example, a replacement fabricated from standard steel in a region with heavy winter salting might only last a few years, whereas a stainless-steel equivalent could endure for a decade or more.

The selection of durable materials directly influences the exhaust components ability to withstand these stressors. Stainless steel, aluminized steel, and titanium represent increasingly robust options, each offering varying levels of corrosion resistance and heat tolerance. Stainless steel provides a high degree of protection against rust and oxidation, while aluminized steel offers a more economical alternative with enhanced corrosion resistance compared to standard steel. Titanium, though more expensive, delivers exceptional strength-to-weight ratio and resistance to extreme temperatures. The practical implication of choosing a durable material lies in reduced maintenance costs, improved vehicle reliability, and a prolonged service life for the exhaust system.

Therefore, material durability constitutes a fundamental consideration when evaluating replacement exhaust components for the Ram 1500. Compromising on material quality to save on initial cost can result in significantly higher expenses over the vehicle’s lifespan due to repeated replacements and potential engine damage. Selecting a component constructed from a corrosion-resistant material, appropriate for the operating environment, is a sound investment that contributes to the long-term reliability and value of the vehicle.

3. Ease of Installation

The primary design objective of a “ram 1500 direct fit muffler” centers on simplifying the replacement process. This design philosophy directly impacts installation time and required tools, potentially reducing labor costs if a professional mechanic is not employed. The direct fit characteristic implies the replacement part replicates the dimensions and mounting points of the original equipment manufacturer (OEM) component, eliminating the need for cutting, welding, or custom fabrication. For example, a mechanic replacing a rusted muffler on a 2015 Ram 1500 should, ideally, only need to unbolt the old component and bolt on the new one, using existing hardware or supplied replacements.

Achieving “Ease of Installation” involves precise manufacturing and quality control. Deviations from OEM specifications, even minor ones, can negate the direct fit benefit. If bolt holes are misaligned or pipe diameters differ slightly, the installer faces challenges requiring modification, which increases labor and the potential for improper sealing. Furthermore, a truly “direct fit” muffler includes all necessary hardware (gaskets, clamps, bolts) and clear, concise installation instructions. The absence of these elements diminishes the “Ease of Installation” benefit, adding to the complexity and potentially affecting the outcome.

Ultimately, the value of a “ram 1500 direct fit muffler” is significantly enhanced by its ease of installation. A part that genuinely adheres to this principle saves time, reduces costs, and minimizes the risk of installation errors. This attribute is particularly beneficial for do-it-yourself (DIY) mechanics, providing a more accessible means of maintaining or upgrading their vehicle’s exhaust system. Consequently, the “Ease of Installation” aspect serves as a critical differentiator among competing products.

4. Exhaust Flow

Exhaust flow, the measure of how efficiently exhaust gases exit an engine, directly correlates with the performance of a replacement exhaust component. The primary function of the muffler, a key component of the exhaust system, is to attenuate noise. However, this noise reduction must be achieved without significantly impeding exhaust flow. A poorly designed muffler can create excessive backpressure, hindering the engine’s ability to expel exhaust gases. This, in turn, reduces engine power, fuel efficiency, and overall performance. A “ram 1500 direct fit muffler,” therefore, must strike a balance between sound reduction and exhaust flow optimization to maintain or improve upon the vehicle’s original performance characteristics. For example, a restrictive muffler on a modified Ram 1500 with increased engine output would negate the benefits of those modifications by choking the engine.

Aftermarket replacement mufflers often emphasize increased exhaust flow as a selling point. These performance-oriented mufflers typically employ designs that minimize internal restrictions, allowing exhaust gases to exit more freely. Examples include straight-through designs or those with larger internal diameters. While these mufflers can enhance engine power, particularly in modified vehicles, the increased exhaust flow often comes at the expense of louder exhaust noise. The selection of a “ram 1500 direct fit muffler” requires a consideration of the trade-offs between performance gains and noise level. Furthermore, modifications to the exhaust system, including muffler replacement, must comply with local noise regulations to avoid legal issues.

In summary, exhaust flow represents a critical performance parameter directly influenced by the design of a “ram 1500 direct fit muffler.” Understanding the relationship between muffler design, exhaust flow, and overall engine performance is essential for selecting a replacement component that meets the vehicle owner’s specific needs and preferences. Challenges arise in balancing noise reduction with performance enhancement, requiring careful consideration of design features and potential trade-offs. Compliance with noise regulations adds another layer of complexity to the selection process.

5. Sound Reduction

Sound reduction is a primary function of the muffler within the exhaust system and represents a crucial consideration when selecting a “ram 1500 direct fit muffler.” The effectiveness of sound reduction directly impacts the vehicle’s compliance with noise regulations and the driving experience.

- Muffler Design and Sound Attenuation

Muffler design dictates the degree of sound attenuation achieved. Baffled mufflers, chambered mufflers, and absorption mufflers represent common designs. Baffled mufflers utilize internal partitions to reflect and cancel sound waves, offering effective sound reduction but potentially restricting exhaust flow. Chambered mufflers employ resonating chambers to cancel specific frequencies, providing a balance between sound reduction and flow. Absorption mufflers, packed with sound-absorbing materials like fiberglass, offer minimal flow restriction but may degrade over time. The selection of a “ram 1500 direct fit muffler” necessitates an understanding of these design principles and their impact on sound reduction characteristics.

- Material Composition and Noise Dampening

The material composition of the muffler contributes to noise dampening. Heavier gauge steel and the inclusion of sound-deadening materials reduce resonance and shell noise. A “ram 1500 direct fit muffler” constructed with higher-quality materials exhibits improved noise dampening properties, resulting in a quieter exhaust note. The impact of material composition extends beyond sound reduction, influencing the overall durability and lifespan of the muffler.

- Frequency Cancellation and Harmonic Resonance

Advanced muffler designs employ frequency cancellation techniques to target specific exhaust frequencies. By creating interference patterns within the muffler, certain frequencies are selectively attenuated, resulting in a more controlled and less intrusive exhaust sound. Harmonic resonance, a phenomenon where certain frequencies are amplified within the exhaust system, can be mitigated through careful muffler design and placement. A “ram 1500 direct fit muffler” designed to address frequency cancellation and harmonic resonance contributes to a more refined and less obtrusive driving experience.

The ability of a “ram 1500 direct fit muffler” to effectively reduce exhaust noise directly influences driver comfort, vehicle compliance, and overall customer satisfaction. Selecting a muffler that effectively balances sound reduction with other performance characteristics is a critical consideration for Ram 1500 owners.

6. Emissions Compliance

Adherence to emissions standards is a critical aspect of automotive maintenance and modification. The exhaust system, including the muffler, plays a pivotal role in ensuring a vehicle meets legally mandated limits on pollutant output. A replacement “ram 1500 direct fit muffler” must not compromise the vehicle’s original emissions control capabilities.

- Catalytic Converter Compatibility

The catalytic converter, situated upstream of the muffler, is the primary device for reducing harmful emissions. A replacement muffler must not impede the catalytic converter’s function. Backpressure created by a poorly designed muffler can decrease the converter’s efficiency, leading to increased emissions of hydrocarbons, carbon monoxide, and nitrogen oxides. A “ram 1500 direct fit muffler” should be engineered to minimize backpressure and maintain optimal converter performance. For instance, a muffler with excessive internal baffling can restrict exhaust flow, negatively impacting the catalytic converter’s effectiveness. Selecting a replacement muffler that adheres to OEM specifications, or those designed to enhance exhaust flow without increasing emissions, is crucial.

- Oxygen Sensor Functionality

Oxygen sensors, located in the exhaust stream, provide feedback to the engine control unit (ECU) regarding exhaust gas composition. This feedback enables the ECU to adjust the air-fuel mixture for optimal combustion and minimal emissions. An exhaust leak caused by a poorly fitted or damaged “ram 1500 direct fit muffler” can introduce ambient air into the exhaust stream, skewing oxygen sensor readings. Inaccurate readings can disrupt the ECU’s ability to properly regulate the air-fuel mixture, leading to increased emissions and decreased fuel efficiency. Ensuring a tight, leak-free seal is vital for maintaining accurate oxygen sensor readings and optimal emissions control.

- Sound Level Regulations

While not directly related to chemical emissions, sound level regulations often indirectly impact muffler selection. Many jurisdictions impose limits on vehicle noise levels. A “ram 1500 direct fit muffler” marketed as “performance-enhancing” may produce exhaust noise exceeding legal limits. While such a muffler might improve engine output, its non-compliance with noise regulations can result in fines or vehicle inspection failures. Therefore, compliance with sound level regulations represents an important aspect of overall emissions compliance, albeit an indirect one.

- CARB Compliance

In regions following California Air Resources Board (CARB) regulations, aftermarket parts, including mufflers, require CARB certification to be legally installed on vehicles operated on public roads. CARB certification signifies that the part has been tested and proven not to increase vehicle emissions beyond permissible levels. A “ram 1500 direct fit muffler” lacking CARB certification may be illegal to install on a Ram 1500 registered in California or other states adhering to CARB standards. Verifying CARB compliance prior to purchase is essential for ensuring legal operation within these jurisdictions.

The selection of a replacement “ram 1500 direct fit muffler” necessitates a thorough understanding of its impact on the vehicle’s emissions control system. Compatibility with the catalytic converter and oxygen sensors, adherence to sound level regulations, and CARB certification (where applicable) are crucial factors to consider. Failure to address these factors can lead to increased emissions, regulatory non-compliance, and potential penalties.

Frequently Asked Questions

The following questions address common concerns and misconceptions regarding replacement exhaust components designed for specific Ram 1500 models. The information provided aims to clarify key considerations for informed decision-making.

Question 1: Is a “direct fit” component truly bolt-on, requiring no welding or cutting?

A genuine “direct fit” component is engineered to seamlessly integrate with the existing exhaust system, utilizing factory mounting points. Welding or cutting should not be necessary. However, existing hardware (bolts, clamps) may be corroded and require replacement.

Question 2: Does a replacement affect the vehicle’s emissions?

A properly functioning replacement component should not increase emissions. The component must maintain or improve upon the original exhaust system’s efficiency and be compatible with the catalytic converter. Modifications that remove or alter emissions control devices are illegal.

Question 3: Will a performance component void the vehicle’s warranty?

The installation of an aftermarket component may not automatically void the entire vehicle warranty. However, if the component causes damage to related systems, warranty claims for those specific repairs may be denied. Consult the vehicle warranty documentation for details.

Question 4: What materials offer the best corrosion resistance?

Stainless steel provides superior corrosion resistance compared to aluminized steel or standard steel. Titanium offers exceptional resistance but is significantly more expensive. The optimal choice depends on the operating environment and budget.

Question 5: How does a muffler impact fuel economy?

A restrictive muffler can increase backpressure, reducing engine efficiency and negatively impacting fuel economy. A properly designed replacement component should maintain or improve upon the vehicle’s original fuel economy.

Question 6: Can a “direct fit” component be installed by a novice?

While the “direct fit” design simplifies the installation process, experience with automotive repairs is recommended. Incorrect installation can lead to exhaust leaks and potential damage. If lacking experience, professional installation is advisable.

These FAQs highlight essential considerations when selecting a replacement exhaust component. Understanding these points contributes to informed decision-making and ensures optimal performance and compliance.

The following section will offer a final summary and conclusion of the points covered in this article.

Ram 1500 Direct Fit Muffler

This exploration has detailed the significance of selecting an appropriate exhaust component replacement. Vehicle compatibility, material durability, ease of installation, optimized exhaust flow, effective sound reduction, and strict emissions compliance emerged as key factors. The “ram 1500 direct fit muffler,” when properly chosen, ensures seamless integration with the vehicle’s existing exhaust system, mitigating potential performance degradation and maintaining regulatory adherence.

The information presented underscores the necessity of diligent research and informed decision-making. The long-term performance and reliability of the Ram 1500 depend on selecting components engineered for optimal function and durability. Therefore, vehicle owners should prioritize verified compatibility and quality construction to safeguard their investment and ensure continued compliance with relevant standards.