This automotive component, often found in mountainous terrain, plays a crucial role in reducing engine noise and managing exhaust emissions. For example, vehicles operating at high altitudes often require specially designed units to compensate for the thinner air and varying atmospheric pressures.

The significance of this part lies in its ability to contribute to a quieter environment and compliance with noise regulations, particularly important in residential or environmentally sensitive areas. Historically, advancements in materials and design have led to more efficient and durable versions, enhancing overall vehicle performance and longevity.

The remainder of this discussion will delve into the specific characteristics, performance considerations, and maintenance practices related to this important aspect of vehicular systems.

Considerations for Optimal Performance

The following points outline essential factors to consider in maximizing the operational effectiveness and lifespan of the exhaust silencing device, particularly in challenging environments.

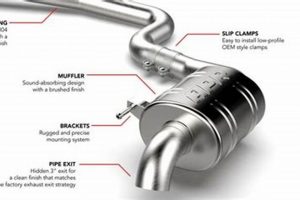

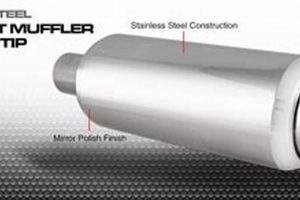

Tip 1: Material Selection: Employ corrosion-resistant materials, such as stainless steel, to mitigate the effects of harsh weather and road salts common in mountainous regions. Premature degradation can significantly reduce the component’s effectiveness.

Tip 2: Proper Installation: Adherence to manufacturer specifications during installation is paramount. Incorrect mounting can introduce undue stress, leading to cracks and premature failure. Verify all connections are secure and properly aligned.

Tip 3: Regular Inspection: Conduct routine visual inspections for signs of damage, such as rust, dents, or leaks. Early detection of these issues allows for timely repairs, preventing more extensive and costly problems.

Tip 4: Avoid Short Trips: Frequent short journeys can contribute to condensation buildup within the system, accelerating corrosion. Allow sufficient operating time for the system to reach optimal temperature, facilitating the evaporation of moisture.

Tip 5: Monitor Engine Performance: Issues with engine performance, such as misfires or excessive fuel consumption, can place undue stress on the exhaust system. Address any underlying engine problems promptly to prevent consequential damage.

Tip 6: Professional Maintenance: Schedule periodic maintenance with a qualified technician to ensure optimal operation and identify potential issues before they escalate. This includes checking for exhaust leaks and assessing the condition of supporting hardware.

Implementing these recommendations will contribute to extended operational life, reduced maintenance costs, and consistent performance within a vehicle’s exhaust system.

The succeeding sections will address advanced troubleshooting techniques and potential upgrade options.

1. Altitude Impact Considerations

Operating conditions in mountainous regions present unique challenges to exhaust systems. Changes in atmospheric pressure and air density directly influence the performance and longevity of components designed for exhaust noise reduction. These factors necessitate specific design adaptations to ensure optimal function.

- Reduced Air Density

At higher altitudes, the reduced air density affects combustion efficiency, resulting in altered exhaust gas composition. This impacts the effectiveness of the silencing element, potentially leading to increased noise levels. Furthermore, lower air density reduces cooling efficiency for exhaust components.

- Changes in Backpressure

The altered air density also influences the backpressure within the exhaust system. Excessive backpressure can reduce engine performance and fuel efficiency, while insufficient backpressure can affect emissions control. A properly designed system compensates for these variations.

- Thermal Cycling Stress

Fluctuations in ambient temperature at higher elevations induce greater thermal cycling stress on exhaust components. Repeated expansion and contraction can accelerate material fatigue and lead to premature failure, requiring robust material selection and design considerations.

- Moisture Accumulation

The combination of temperature variations and potential for increased precipitation at higher altitudes can lead to moisture accumulation within the exhaust system. This moisture promotes corrosion, especially in systems not utilizing corrosion-resistant materials.

These altitude-related factors necessitate design modifications to ensure long-term reliability. For example, modifications may include the use of higher-grade materials, optimized internal baffling, and improved drainage to mitigate the effects of altitude on vehicle systems operating in mountainous environments.

2. Material Corrosion Resistance

Material corrosion resistance is a critical factor in the longevity and performance of vehicular exhaust systems, particularly those operating in mountainous terrain. The harsh environmental conditions prevalent in these regions accelerate the degradation of components, necessitating the use of robust, corrosion-resistant materials.

- Road Salt Exposure

Mountainous areas often experience heavy snowfall and ice, leading to the extensive use of road salts for de-icing. These salts are highly corrosive and can rapidly degrade standard steel exhaust systems. The resulting corrosion compromises structural integrity and leads to exhaust leaks, diminishing performance and increasing noise levels.

- Temperature Fluctuations

Significant temperature variations, common at high altitudes, induce thermal stress in exhaust systems. This constant expansion and contraction exacerbate corrosion, as the resulting micro-cracks provide entry points for corrosive agents. Materials with high thermal stability and resistance to fatigue are essential to mitigate these effects.

- Moisture Accumulation

Higher precipitation levels and frequent temperature inversions in mountainous areas contribute to increased moisture accumulation within exhaust systems. This trapped moisture, often combined with corrosive byproducts of combustion, accelerates the corrosion process, particularly in areas with inadequate drainage.

- Material Selection Importance

The selection of appropriate materials, such as stainless steel or aluminized steel, is paramount in ensuring the long-term durability of exhaust silencing devices operating in mountainous environments. These materials offer superior resistance to corrosion compared to standard carbon steel, significantly extending the component’s lifespan and maintaining optimal performance.

In summary, the effective selection and implementation of corrosion-resistant materials is vital for maintaining the structural integrity, noise reduction capabilities, and overall lifespan of exhaust systems operating in the demanding conditions characteristic of mountainous regions. Neglecting this aspect leads to premature failure, increased maintenance costs, and compromised performance.

3. Exhaust Noise Reduction

Exhaust noise reduction is a primary function inherent in the design and operation of the “mt muffler.” This automotive component mitigates sound generated by the rapid expulsion of combustion gases from an internal combustion engine. Without effective noise reduction, vehicles operating in mountainous environments, often characterized by noise-sensitive areas, would contribute significantly to noise pollution. The design incorporates a series of chambers and baffles that redirect and attenuate sound waves, reducing their amplitude before exiting the exhaust system. This directly addresses the impact of engine operation on the surrounding environment.

The effectiveness of the noise reduction is directly related to the internal design and material properties of the muffler. For example, a well-designed unit uses resonance and interference to cancel out specific frequencies associated with engine operation. Furthermore, the selection of sound-absorbing materials contributes to damping higher-frequency noises. The practical application of these principles is evident in vehicles operating near residential areas or protected wildlife habitats, where stringent noise regulations are enforced. Failure to adequately reduce exhaust noise can result in fines and operational restrictions.

In summary, exhaust noise reduction is an indispensable component of the “mt muffler’s” function, addressing both environmental and regulatory concerns. The challenge lies in balancing noise reduction with the need to minimize backpressure, which can negatively impact engine performance. Achieving this balance requires careful design and selection of materials, contributing to the overall efficiency and environmental responsibility of vehicle operation in varied terrains.

4. Backpressure Optimization

Backpressure optimization is an intrinsic element in the design and functionality of an “mt muffler.” The device, fundamentally, aims to reduce exhaust noise. This process, however, inherently introduces resistance to the flow of exhaust gases, a factor directly influencing engine performance. Optimizing backpressure entails striking a precise balance between noise reduction and unrestricted exhaust flow, thus maximizing engine efficiency and power output.

Excessive backpressure restricts the scavenging of exhaust gases from the combustion chamber, leading to reduced volumetric efficiency and potential power loss. Conversely, insufficient backpressure can negatively impact low-end torque and fuel economy. An “mt muffler” designed with optimized backpressure, therefore, incorporates specific internal configurations such as pipe diameter, chamber volume, and baffle design to achieve an ideal equilibrium. For instance, vehicles used in mountainous environments, frequently subjected to varied engine loads and inclines, benefit significantly from optimized backpressure which provides consistent power delivery and prevents engine strain. Aftermarket performance units provide examples where poor designs caused engine backpressure, causing damages in engine.

Effective backpressure optimization in an “mt muffler” contributes directly to engine longevity, fuel efficiency, and overall vehicle performance. The intricacies of achieving this delicate balance underscore the importance of careful design and engineering considerations. In conclusion, understanding and prioritizing backpressure optimization are crucial in maximizing the benefits derived from exhaust systems and ensuring vehicle reliability.

5. Thermal Stress Management

Thermal stress management is an indispensable aspect of “mt muffler” design and operation, particularly vital due to the extreme temperature fluctuations encountered in mountainous environments. The exhaust system experiences rapid heating and cooling cycles, inducing expansion and contraction within its constituent materials. Without effective thermal stress management, components are susceptible to fatigue, cracking, and premature failure. The “mt muffler,” therefore, requires design features and material selection strategies that mitigate the adverse effects of these thermal cycles.

One primary approach to thermal stress management involves the incorporation of expansion joints. These flexible connections accommodate thermal expansion and contraction, preventing the buildup of stress within the system. Material selection also plays a crucial role; for instance, using high-grade stainless steel alloys with low coefficients of thermal expansion reduces the magnitude of stress induced by temperature changes. Furthermore, proper insulation can minimize temperature gradients within the “mt muffler,” thus reducing thermal stress concentrations. An example of this is observed in high-performance vehicles operating at elevated altitudes, where sophisticated exhaust systems with advanced thermal management features are standard to ensure reliability under demanding conditions.

In summary, thermal stress management is not merely an ancillary consideration but rather an integral component of the “mt muffler.” Failing to address this factor effectively compromises the durability, longevity, and performance of the system, especially in the challenging conditions presented by mountainous terrain. A comprehensive understanding of thermal stress principles, coupled with appropriate design implementations and material choices, is essential for ensuring the reliable operation of vehicles and equipment operating in these environments. Prioritizing thermal stress management translates directly into reduced maintenance costs, increased vehicle uptime, and enhanced overall operational efficiency.

Frequently Asked Questions about “mt muffler”

The following questions address common inquiries regarding the application, maintenance, and performance characteristics of exhaust silencing devices, particularly in mountainous regions.

Question 1: What constitutes an “mt muffler,” and how does it differ from a standard muffler?

An “mt muffler” is designed to operate in mountainous terrain; differing from a standard muffler, it incorporates specific design features to compensate for altitude-induced variations in air density and temperature. These modifications typically involve optimized backpressure characteristics and enhanced corrosion resistance due to increased exposure to road salts and moisture.

Question 2: How does altitude affect the performance of an “mt muffler”?

Altitude affects exhaust gas density and flow. Lower air density at higher elevations can reduce the effectiveness of noise reduction and influence backpressure. Designs mitigate this by optimizing exhaust flow and employing materials resistant to thermal stress caused by temperature fluctuations.

Question 3: What materials are best suited for “mt muffler” construction?

Stainless steel and aluminized steel are preferred for “mt muffler” construction. These materials offer superior corrosion resistance, essential for withstanding the harsh conditions encountered in mountainous environments, including exposure to road salts and moisture.

Question 4: How frequently should an “mt muffler” be inspected and maintained?

Inspection should be conducted at least annually, or more frequently in areas with severe weather conditions. Maintenance includes checking for rust, leaks, and damage to mounting hardware. Prompt repairs are crucial to prevent performance degradation and potential system failure.

Question 5: Can a damaged “mt muffler” negatively impact engine performance?

Yes, a damaged “mt muffler” can adversely affect engine performance. Exhaust leaks and increased backpressure resulting from corrosion or structural damage can reduce fuel efficiency and power output, and, therefore, require immediate repair or replacement.

Question 6: Are there specific regulations regarding exhaust noise levels in mountainous regions?

Many mountainous regions are subject to strict noise regulations to protect both human populations and wildlife. The “mt muffler” plays a critical role in complying with these regulations, as excessive exhaust noise can result in fines and operational restrictions.

Proper understanding and maintenance of the exhaust silencing device, considering the particular characteristics of mountainous environments, are critical for optimal performance, regulatory compliance, and environmental protection.

The following section will explore advanced topics relating to exhaust systems in high-altitude environments.

Conclusion

This exploration has underscored the critical function of the mt muffler in mountainous environments. From material selection and thermal stress management to backpressure optimization and noise reduction, the intricate design and operation of this component directly impact vehicle performance, environmental compliance, and overall operational efficiency. Altitude-related factors, such as reduced air density and increased corrosion exposure, necessitate specialized designs and maintenance practices to ensure long-term reliability.

The information presented herein underscores the importance of prioritizing the selection, maintenance, and proper function of the mt muffler. As environmental awareness grows and regulatory standards become more stringent, the role of effective exhaust systems in mitigating noise pollution and optimizing engine performance will only increase in significance. Continued research and development in this area are essential to ensuring that vehicles operating in mountainous regions do so responsibly and sustainably.

![Secure Exhaust: Best Stainless Muffler Clamp [Durable] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Secure Exhaust: Best Stainless Muffler Clamp [Durable] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-113-300x200.jpg)