These aftermarket components are designed to be placed within a vehicle’s exhaust system. Typically cylindrical or conical in shape, they modify the flow of exhaust gases, thereby altering the sound characteristics of the vehicle. For instance, installing one in a motorcycle’s exhaust can significantly reduce its decibel output.

Their incorporation offers several advantages. Primarily, they provide a means of controlling exhaust noise, which is crucial in adhering to legal sound restrictions and improving community relations. Historically, these devices emerged as a response to increasing noise pollution concerns stemming from modified exhaust systems, offering a balance between performance and responsible sound management.

The subsequent sections will delve into the various types available, explore their installation methods, discuss performance implications, and address regulatory considerations relevant to their use.

Guidance on Utilizing Exhaust Sound Dampeners

Proper implementation of these devices requires careful consideration to ensure both optimal sound reduction and minimal performance compromise. The following points offer guidance for their selection and integration.

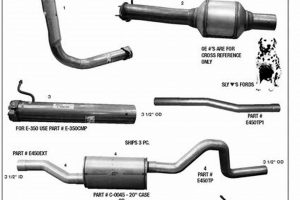

Tip 1: Assess Exhaust System Compatibility: Prior to acquisition, verify dimensional compatibility with the existing exhaust piping. Precise measurements of the inner diameter are essential to ensure a secure and effective fit.

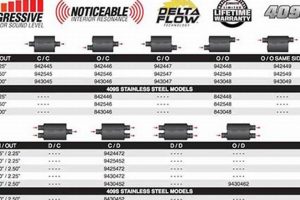

Tip 2: Evaluate Material Composition: Consider the material composition’s resistance to heat and corrosion. Stainless steel offers superior durability compared to less robust materials.

Tip 3: Account for Backpressure Effects: Be cognizant of the potential increase in backpressure resulting from the installation. Excessive backpressure may negatively impact engine efficiency.

Tip 4: Comply with Local Regulations: Research and adhere to local noise ordinances and regulations concerning vehicle sound levels. Ensure the selected device brings the vehicle into compliance.

Tip 5: Implement Secure Installation Practices: Employ secure fastening methods, such as welding or robust bolting, to prevent dislodgement due to vibration or exhaust pressure.

Tip 6: Consider the Desired Sound Profile: Recognize that different designs produce varying sound attenuation characteristics. Select a model that aligns with the desired acoustic outcome.

Tip 7: Monitor Performance After Installation: Regularly observe engine performance indicators, such as fuel economy and throttle response, to identify any adverse effects. Adjustments may be necessary.

Effective application of these guidelines will contribute to achieving a balance between noise reduction and vehicle performance, while ensuring legal compliance. Neglecting these considerations may lead to undesirable outcomes.

The subsequent sections will elaborate on specific applications and troubleshooting techniques related to these components.

1. Noise Reduction

The primary function of a muffler insert is the attenuation of exhaust noise. This noise reduction is achieved through a combination of sound wave interference, absorption, and redirection. The insert’s internal structure, typically incorporating baffles, chambers, and/or sound-absorbing materials, forces exhaust gases to navigate a convoluted path, diminishing the amplitude of sound waves emitted from the tailpipe. For instance, residential areas with strict noise ordinances necessitate vehicles equipped with inserts that demonstrably lower decibel levels to comply with regulations. Failure to manage exhaust sound can result in legal penalties or restrictions on vehicle usage.

The effectiveness of noise reduction is directly proportional to the design and construction of the insert. Denser, more complex internal structures generally yield greater sound suppression, albeit often at the cost of increased backpressure. Consider a situation where a motorcycle owner installs an insert designed for racing applications in a residential area. The minimally restricted airflow may provide marginally increased performance, but the inadequate noise reduction would likely lead to complaints and potential legal repercussions, illustrating the importance of matching the insert’s noise reduction capabilities to the environment.

In summary, the noise reduction capabilities of muffler inserts are critical for responsible vehicle operation. The practical significance lies in ensuring compliance with legal standards, minimizing disturbance to communities, and promoting harmonious coexistence between vehicle enthusiasts and the general public. The ongoing challenge resides in developing designs that achieve optimal noise attenuation without unduly compromising engine performance.

2. Backpressure Influence

The installation of a muffler insert inevitably affects the backpressure within an exhaust system. Backpressure refers to the resistance to exhaust gas flow. These components, by their very nature, restrict the free passage of exhaust gases, thus increasing pressure upstream. This alteration in backpressure can have demonstrable effects on engine performance. For example, an excessively restrictive insert can impede the efficient scavenging of exhaust gases from the cylinders, potentially leading to reduced horsepower and fuel economy. Conversely, insufficient backpressure, while less common with inserts, can also negatively impact engine torque, particularly at lower RPMs. The selection of an appropriate insert, therefore, necessitates a balanced consideration of noise reduction and its influence on engine performance characteristics. The practical significance lies in understanding that an insert designed solely for maximum noise reduction may inadvertently compromise the vehicle’s overall drivability.

The magnitude of the backpressure effect is dependent on several factors, including the engine’s displacement, the exhaust system’s original design, and the specific geometry of the insert. A larger engine, for instance, will generally exhibit a more pronounced sensitivity to changes in backpressure than a smaller engine. Furthermore, the internal structure of the insert the size and number of perforations, the presence of baffles, and the overall flow path will dictate the extent to which exhaust gases are restricted. As a practical example, consider a high-performance motorcycle equipped with a free-flowing exhaust system. The addition of a highly restrictive insert may noticeably diminish throttle response and overall power output, while a less restrictive model might offer a more acceptable compromise between sound reduction and performance preservation.

In summary, the backpressure influence of muffler inserts is a critical consideration in their application. It is imperative to recognize that these components are not merely noise reduction devices but rather integral elements of the exhaust system, capable of affecting engine performance in both positive and negative ways. The challenge resides in striking a balance between achieving desired sound levels and maintaining optimal engine efficiency, requiring informed decision-making based on an understanding of the interrelationship between insert design, engine characteristics, and desired vehicle performance.

3. Material Durability

The service life of a muffler insert is directly correlated to the durability of the materials used in its construction. Exposure to high exhaust gas temperatures, corrosive combustion byproducts, and mechanical vibrations creates a harsh operating environment. Premature failure of an insert, due to material degradation, necessitates replacement, increasing maintenance costs and potentially compromising noise reduction effectiveness. For instance, inserts fabricated from low-carbon steel are susceptible to rapid oxidation and structural weakening, especially in regions with high humidity or road salt usage. The practical implication is that a seemingly inexpensive insert, if manufactured from an inferior material, can prove more costly in the long term due to its reduced lifespan.

Stainless steel, particularly grades 304 and 316, offers significantly enhanced corrosion resistance and elevated temperature stability compared to carbon steel alternatives. These materials resist oxidation, minimizing structural degradation and maintaining dimensional integrity under prolonged exposure to exhaust gases. Titanium, although providing superior strength-to-weight ratio and excellent corrosion resistance, is a more expensive option, typically reserved for high-performance applications where weight reduction is paramount. Consider the scenario of a commercial vehicle operating in a region with frequent exposure to de-icing salts. An insert constructed from stainless steel would demonstrably outlast one made from mild steel, reducing downtime and replacement costs.

In conclusion, material durability constitutes a critical determinant of the longevity and overall value of muffler inserts. Selection of appropriate materials, considering the operating environment and intended application, is paramount for ensuring long-term performance, minimizing maintenance expenses, and maintaining consistent noise reduction. The enduring challenge lies in balancing material cost with the required level of durability to achieve optimal cost-effectiveness and reliable performance throughout the vehicle’s service life.

4. Installation Method

The installation method of muffler inserts is inextricably linked to their effectiveness and longevity. A properly executed installation ensures secure placement, optimal noise reduction, and prevents damage to both the insert and the exhaust system. Conversely, improper installation can lead to reduced performance, premature failure, and potential safety hazards.

- Welding Integration

Welding permanently affixes the insert to the exhaust pipe. This method provides a robust and leak-proof seal, preventing rattling and ensuring optimal noise reduction. However, welding necessitates specialized equipment and expertise, and renders the insert non-removable without cutting. An example would be a custom exhaust system where the insert is specifically tailored and welded in place for maximum performance and sound control.

- Bolt-On Securing

Bolt-on installations utilize mechanical fasteners to secure the insert. This approach offers greater flexibility for removal and adjustment, facilitating experimentation with different inserts or fine-tuning of exhaust sound. However, bolt-on methods are susceptible to loosening due to vibration, potentially leading to exhaust leaks and reduced noise attenuation. Routine inspection and tightening of fasteners are essential to maintain a secure connection. A common example is an aftermarket insert secured with bolts through pre-drilled holes in the exhaust pipe.

- Friction Fitting with Clamps

Friction fitting relies on the insert’s tight fit within the exhaust pipe, often supplemented with clamps for added security. This method is relatively simple and requires minimal tools. However, the effectiveness of friction fitting is highly dependent on the dimensional accuracy of both the insert and the exhaust pipe. Inadequate clamping force or dimensional discrepancies can result in slippage or dislodgement, particularly under high exhaust pressure. A small motorbike or scooter is often the situation for this sort of insert installation.

- Professional vs. DIY Installation

Professional installation, performed by experienced technicians, ensures adherence to best practices and proper torque specifications. This minimizes the risk of damage to the exhaust system and maximizes the insert’s performance and lifespan. DIY installation, while potentially cost-effective, requires careful attention to detail and access to appropriate tools. Improper techniques, such as over-tightening fasteners or neglecting to use sealant, can compromise the integrity of the installation. Professional services offer expertise and warranty-backed workmanship.

In summary, the chosen installation method significantly impacts the performance, reliability, and safety of muffler inserts. Selecting the appropriate method depends on factors such as the type of insert, the vehicle’s exhaust system, and the installer’s skill level. Regardless of the method employed, meticulous attention to detail and adherence to manufacturer’s instructions are crucial for achieving optimal results.

5. Compatibility

Ensuring congruence between a muffler insert and the host vehicle’s exhaust system is paramount for effective noise reduction and uncompromised engine performance. A mismatch can negate the intended benefits, potentially causing damage or regulatory non-compliance.

- Dimensional Compatibility

Precise measurements of the exhaust pipe’s inner diameter and the insert’s outer diameter are essential. An insert that is too large will be impossible to install, while one that is too small will fail to provide adequate noise reduction and may vibrate or dislodge. Manufacturers typically provide dimensional specifications to facilitate accurate selection. A scenario involving a motorcycle owner purchasing an insert without verifying dimensions illustrates the importance of this aspect. The owner’s incorrect assumption of a standard size led to a frustrating and ultimately futile installation attempt.

- Engine Displacement Matching

Inserts are often designed for specific engine displacement ranges. Using an insert intended for a smaller engine on a larger one may result in inadequate noise reduction. Conversely, an insert designed for a large engine may create excessive backpressure on a smaller engine, negatively impacting performance. Manufacturers’ guidelines typically specify recommended engine displacement ranges. Installing an insert designed for a high-displacement V8 engine on a small four-cylinder car, for instance, could lead to a significant loss of power and fuel efficiency.

- Exhaust System Type Alignment

Variations exist in exhaust system designs (e.g., single vs. dual, straight-through vs. baffled). An insert designed for one type may not function effectively, or even be compatible, with another. For example, an insert intended for a straight-through exhaust may not fit or function correctly in a baffled system, and can create exhaust flow issues. Before purchase, verify that the insert is appropriate for the specific exhaust system configuration. Attempting to adapt an insert designed for a single exhaust system to a dual exhaust system is likely to produce uneven noise reduction and potential performance imbalances.

- Regulatory Compliance Verification

Different regions and jurisdictions have varying noise regulations. An insert that complies with regulations in one area may not meet the requirements in another. Before installation, verify that the selected insert meets all applicable local, state, and federal noise standards. Modifying a vehicle with an unapproved device could lead to fines or vehicle impoundment.

These facets underscore the critical role of compatibility in the successful application of muffler inserts. Inadequate attention to these considerations can result in compromised performance, regulatory violations, or even equipment damage. Careful evaluation and adherence to manufacturer recommendations are essential for realizing the intended benefits of these devices.

Frequently Asked Questions Regarding Muffler Inserts

The following addresses common inquiries and misconceptions surrounding the utilization of these devices within vehicle exhaust systems. The intent is to provide clear and objective information to facilitate informed decision-making.

Question 1: What defines the primary function?

The core purpose lies in attenuating exhaust noise, thereby reducing the decibel level emitted by the vehicle.

Question 2: Does installation affect engine performance?

Introduction can influence engine performance, primarily through alterations in backpressure. Excessive backpressure may negatively impact horsepower and fuel economy.

Question 3: What materials are most suitable for their construction?

Stainless steel is generally preferred due to its superior corrosion resistance and elevated temperature stability compared to carbon steel alternatives.

Question 4: Is professional installation mandatory?

Professional services are recommended, particularly for welding applications, to ensure proper fitment and prevent damage to the exhaust system.

Question 5: How does one ensure compatibility with a specific vehicle?

Compatibility verification involves confirming dimensional congruence between the insert and the exhaust pipe, aligning with the engine displacement range, and ensuring that it’s right for the exhaust system type.

Question 6: Are there legal implications associated with their usage?

Adherence to local, state, and federal noise regulations is essential. Modifying a vehicle with an unapproved device could lead to legal penalties.

The preceding responses offer a concise overview of critical considerations related to these components. Diligent adherence to these guidelines will facilitate responsible and effective utilization.

The subsequent sections will provide illustrative case studies and practical troubleshooting tips.

Conclusion

This exploration has underscored the multifaceted nature of muffler inserts. Their implementation involves considerations beyond mere noise reduction, encompassing engine performance implications, material durability, installation methodologies, and strict adherence to regulatory frameworks. Selecting and deploying these components demands a comprehensive understanding of these interrelated factors to achieve optimal outcomes.

The responsible application of muffler inserts necessitates ongoing awareness of evolving technologies and regulatory landscapes. A commitment to informed decision-making ensures both legal compliance and the preservation of vehicle performance characteristics, ultimately contributing to a harmonious balance between individual vehicle operation and community well-being.