The exhaust component responsible for reducing noise emanating from the engine of a popular sport utility vehicle is the focus. This part, designed to attenuate sound waves produced by combustion, plays a critical role in maintaining acceptable noise levels. Its functionality relies on a series of internal baffles and chambers which redirect and dampen the exhaust pulses before they exit the tailpipe. For instance, a failing component can result in a noticeable increase in vehicle loudness.

The significance of this component extends beyond mere noise reduction. It contributes to compliance with local noise ordinances, enhancing the driving experience for both the operator and surrounding environment. Historically, the development of these systems has paralleled advancements in engine technology, with designs evolving to address the increasing noise output of modern powerplants. A properly functioning system also ensures optimal backpressure, which is essential for efficient engine operation and fuel economy.

This article will further examine the construction materials, common failure points, replacement procedures, and aftermarket options related to this key element of a vehicle’s exhaust system. Factors such as the impact of corrosion, the role of catalytic converters, and the influence of different driving conditions on its lifespan will also be discussed.

Essential Considerations for the Exhaust Noise Reduction System

Maintaining the vehicle’s exhaust noise reduction system is crucial for both performance and regulatory compliance. The following points provide practical guidance regarding this critical component.

Tip 1: Regular Inspection for Corrosion: Corrosion is a primary cause of degradation. Conduct routine visual inspections, particularly in regions with road salt usage, to identify and address rust before it compromises structural integrity.

Tip 2: Promptly Address Unusual Noises: Rattling, hissing, or excessively loud exhaust sounds often indicate internal damage or leaks. Delaying repairs can lead to increased noise levels and potential exhaust system failure.

Tip 3: Verify Hanger Integrity: Exhaust system hangers provide support and prevent stress on the component. Ensure these are intact and properly secured to prevent premature wear and potential damage from vibrations.

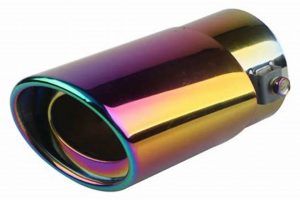

Tip 4: Consider Material Upgrades: When replacement is necessary, explore options crafted from stainless steel or aluminized steel for enhanced longevity, especially in corrosive environments. These materials offer superior resistance to rust and degradation compared to standard steel.

Tip 5: Evaluate Aftermarket Options Carefully: While aftermarket systems may offer performance gains or aesthetic enhancements, confirm that any replacement meets or exceeds original equipment manufacturer (OEM) specifications for noise reduction and emissions compliance. Ensure compatibility and proper fitment.

Tip 6: Professional Installation is Recommended: Unless possessing the necessary expertise and tools, entrust replacement to a qualified mechanic. Improper installation can lead to leaks, reduced performance, and potential safety hazards.

Tip 7: Regular Engine Maintenance: Ensure that the engine is running efficiently. Problems like misfires can cause excessive stress on the emission components, reducing lifespan.

Adhering to these recommendations can extend the lifespan of the exhaust noise reduction component, ensuring optimal performance, compliance with noise regulations, and a comfortable driving experience.

The next section will address common problems and troubleshooting techniques related to this vital vehicle system.

1. Noise Reduction Effectiveness

The primary function of the specifically designed component within the vehicle’s exhaust system centers on attenuating engine noise. Noise Reduction Effectiveness, therefore, is a direct measure of its operational efficacy. A properly functioning system significantly diminishes the decibel level emitted by the vehicle, contributing to a more comfortable in-cabin experience and adherence to municipal noise ordinances. The internal design, comprising strategically placed baffles and resonance chambers, dictates the extent to which sound waves are dampened. For instance, a component with a complex baffle system will generally offer superior noise reduction compared to a simpler, straight-through design.

Variations in Noise Reduction Effectiveness are discernible across different replacement options. Aftermarket components, while potentially offering performance advantages, may compromise noise attenuation for increased exhaust flow. Conversely, premium OEM replacements are engineered to replicate the original noise reduction capabilities, ensuring compliance with factory specifications. The implications of inadequate noise reduction extend beyond audibility; excessive noise pollution can lead to fines, vehicle inspection failures, and decreased property values in residential areas. The selection of a replacement system, therefore, requires careful consideration of its impact on overall sound output.

In conclusion, Noise Reduction Effectiveness is an indispensable characteristic of the aforementioned vehicle’s exhaust component. Its degradation or compromise can trigger a cascade of adverse consequences, impacting both the driver’s experience and the broader environment. Careful selection and maintenance, with an emphasis on noise attenuation capabilities, are essential for maximizing the lifespan of the system and mitigating potential problems. Choosing a component with verified noise reduction performance, aligned with regulatory standards, is paramount.

2. Material Durability

The service life of the specified exhaust component is inextricably linked to the material from which it is constructed. Material Durability directly influences the components resistance to environmental factors, specifically corrosion caused by road salts, moisture, and exhaust gases. Premature failure resulting from inadequate material choices necessitates replacement, impacting both vehicle operating costs and potential environmental consequences. For example, a component constructed from standard low-carbon steel will degrade far more rapidly than one fabricated from stainless steel, particularly in regions where road de-icing agents are frequently deployed. This difference translates directly into the frequency of replacements and associated labor costs.

The practical significance of Material Durability extends beyond mere longevity. The structural integrity of the exhaust system is paramount for controlling emissions and maintaining engine efficiency. A corroded or compromised component can lead to exhaust leaks, negatively impacting catalytic converter performance and potentially triggering fault codes within the vehicle’s onboard diagnostic system. Furthermore, the type of material employed affects the component’s ability to withstand thermal stresses generated by exhaust gases. Materials with higher thermal resistance are less prone to cracking and deformation under extreme temperature fluctuations, preserving their functionality over a longer period.

In summary, Material Durability is a critical determinant of the long-term performance and reliability of the vehicle’s exhaust noise reduction component. Selecting replacement parts constructed from corrosion-resistant and thermally stable materials is essential for minimizing maintenance costs, ensuring emissions compliance, and optimizing engine operation. Neglecting material considerations in favor of lower initial costs can result in significantly higher expenses over the vehicle’s lifespan, making a durable material choice a cost-effective investment.

3. Exhaust Backpressure Impact

The flow of exhaust gases through a vehicle’s exhaust system, specifically interacting with the noise reduction device, has a measurable effect on engine performance. This “Exhaust Backpressure Impact” constitutes a critical design parameter considered by automotive engineers and impacts the overall efficiency and longevity of the powertrain.

- Optimal Backpressure and Engine Efficiency

Engine efficiency is influenced by the degree of resistance to exhaust gas flow created by the device. An ideal level of backpressure contributes to efficient cylinder scavenging, where exhaust gases are effectively removed from the combustion chamber. Excessive backpressure, conversely, hinders this process, leading to reduced power output and decreased fuel economy. The internal structure of the vehicle’s device is designed to achieve this balance.

- Backpressure and Catalytic Converter Performance

The exhaust system, including the noise reduction device, directly influences the operating temperature and efficiency of the catalytic converter. Excessive backpressure can elevate exhaust gas temperatures, potentially damaging the converter or reducing its effectiveness in controlling emissions. Proper backpressure contributes to optimal converter function, ensuring compliance with emission standards.

- Backpressure and Engine Longevity

Inappropriate backpressure levels exert undue stress on engine components. Excessive backpressure can increase internal engine temperatures and pressures, potentially leading to premature wear and tear on valves, pistons, and other critical parts. Maintaining appropriate backpressure, through a properly functioning noise reduction device and overall exhaust system, contributes to extended engine lifespan.

- Aftermarket Systems and Backpressure Considerations

Replacement systems, particularly those designed for performance enhancement, can significantly alter backpressure characteristics. While some aftermarket systems may reduce backpressure for increased horsepower, they can also negatively impact low-end torque or emissions compliance. It’s essential to consider backpressure characteristics when selecting a replacement system to ensure compatibility with the vehicle’s engine management system and emissions requirements.

The effect of exhaust backpressure on a common sport utility vehicle is multifaceted. Its interplay with engine efficiency, catalytic converter performance, and engine longevity underscores the importance of maintaining the integrity of the exhaust system and carefully selecting replacement parts. Altering the backpressure characteristics without careful consideration can lead to unintended consequences, affecting both performance and long-term reliability.

4. Proper Fitment

Achieving a precise alignment and secure installation of the exhaust noise reduction component is critical for optimal vehicle operation. Proper Fitment ensures both performance and safety of the system. Deviations from specified dimensions or improper installation techniques can result in a cascade of negative consequences impacting vehicle operation.

- Leak Prevention and Noise Control

Accurate alignment of the mating surfaces between the vehicle’s exhaust part and the exhaust pipes is essential for creating a gas-tight seal. Improper fitment can lead to exhaust leaks, resulting in increased noise levels, reduced engine performance, and potential exposure to harmful exhaust gases. A properly fitted part eliminates these risks by maintaining the integrity of the exhaust system’s sealed environment.

- Vibration Dampening and Structural Integrity

The exhaust system is subjected to constant vibrations and thermal expansion during vehicle operation. Proper Fitment ensures that the support hangers and mounting points align correctly, effectively dampening vibrations and preventing undue stress on the component. Misalignment can lead to premature failure of the system, necessitating costly repairs and replacements.

- Emissions Compliance and Engine Performance

A correctly fitted exhaust noise reduction component contributes to optimal engine performance and emissions compliance. Exhaust leaks resulting from improper fitment can disrupt the oxygen sensor readings, leading to inefficient fuel combustion and increased emissions. A properly installed component ensures that the exhaust gases flow through the system as designed, allowing the catalytic converter to function optimally.

- Safety Considerations and Component Longevity

A securely fitted exhaust system minimizes the risk of component detachment or damage due to road debris or impacts. Improperly fitted components are more susceptible to damage, potentially posing a safety hazard to the vehicle occupants and other drivers. Proper Fitment extends the lifespan of the component by preventing undue stress and potential damage.

In conclusion, achieving Proper Fitment when installing the exhaust noise reduction component on the specified vehicle is paramount for ensuring safe, efficient, and compliant vehicle operation. Adherence to manufacturer specifications and utilization of proper installation techniques are essential for maximizing the component’s performance and longevity, while also mitigating potential risks associated with exhaust leaks, structural damage, and emissions non-compliance. Correct fitment contributes directly to the overall driving experience and minimizes long-term maintenance costs.

5. Regulatory Compliance

The exhaust noise reduction system is subject to stringent regulatory oversight at both the federal and state levels. Regulatory Compliance, therefore, is a critical consideration for vehicle manufacturers, repair facilities, and owners alike, particularly concerning the replacement or modification of the originally equipped system. This overview addresses key facets of regulatory alignment.

- Noise Emission Standards

Federal noise emission standards, enforced by the Environmental Protection Agency (EPA), place limits on the permissible noise levels generated by motor vehicles. Replacement units must meet or exceed these standards to ensure continued compliance. Altering the exhaust system in a manner that increases noise output beyond acceptable limits can result in fines and mandatory corrective actions. State and local ordinances may impose further restrictions, necessitating careful adherence to local regulations.

- Emissions Control System Integrity

The exhaust system plays a vital role in controlling emissions, particularly through its interaction with the catalytic converter. Modifying or replacing the exhaust device in a way that compromises the catalytic converter’s performance can lead to increased emissions of regulated pollutants, such as hydrocarbons, carbon monoxide, and nitrogen oxides. Tampering with the emissions control system is a federal offense, punishable by significant penalties.

- State Inspection and Maintenance Programs

Many states operate inspection and maintenance (I/M) programs that include visual inspections of the exhaust system and emissions testing. A modified or non-compliant system will likely fail inspection, preventing vehicle registration renewal. Technicians conducting inspections are trained to identify modifications that could impair emissions control or increase noise levels.

- Aftermarket Part Certification

Certain aftermarket components are certified as compliant with federal emissions and noise regulations. This certification, often indicated by an EPA or CARB (California Air Resources Board) stamp, provides assurance that the part meets the required standards. Using certified parts can help vehicle owners avoid potential regulatory issues and demonstrate due diligence in maintaining their vehicle’s compliance.

Maintaining compliance with applicable regulations is essential for ensuring the continued legal operation of the sport utility vehicle. Modifications or replacements that compromise emissions control or exceed noise limits can have significant consequences, including fines, inspection failures, and legal penalties. Vehicle owners and repair facilities should exercise caution and ensure that any alterations to the exhaust system adhere to all relevant federal, state, and local regulations.

Frequently Asked Questions

The following section addresses common inquiries regarding the exhaust component responsible for noise reduction in the specified sport utility vehicle. The information is intended to provide clarity on maintenance, replacement, and regulatory considerations.

Question 1: What are the primary indicators of a failing exhaust noise reduction component?

A noticeable increase in exhaust noise, rattling sounds emanating from the undercarriage, or the presence of visible rust or corrosion on the exhaust system are common indicators. Additionally, a decrease in fuel efficiency or the illumination of the check engine light may signify a problem.

Question 2: How often should this component be inspected?

A visual inspection is recommended at least annually or during routine vehicle maintenance. More frequent inspections are advisable in regions with high road salt usage or where the vehicle is subjected to harsh driving conditions.

Question 3: What are the common materials used in the construction of these components, and how do they differ?

Common materials include standard steel, aluminized steel, and stainless steel. Standard steel is the least expensive but most susceptible to corrosion. Aluminized steel offers improved corrosion resistance. Stainless steel provides the highest level of durability and resistance to rust.

Question 4: Is it possible to replace only the faulty component, or is a complete exhaust system replacement required?

In many cases, the faulty exhaust component can be replaced independently. However, if other components of the exhaust system are significantly corroded or damaged, a complete system replacement may be more cost-effective in the long run.

Question 5: Are there performance advantages associated with aftermarket replacement options?

Some aftermarket systems claim to offer performance gains, such as increased horsepower or improved fuel economy. However, these claims should be carefully evaluated, as modifications to the exhaust system can potentially impact emissions compliance and vehicle reliability. It’s important to ensure that any aftermarket component meets or exceeds OEM specifications.

Question 6: Does replacing this component require specialized tools or expertise?

While some individuals with mechanical aptitude may be able to perform the replacement, professional installation is generally recommended. Specialized tools may be required, and improper installation can lead to exhaust leaks, reduced performance, or safety hazards.

In summary, routine inspection, informed material selection, and adherence to proper installation procedures are essential for maintaining the effectiveness and longevity of the vehicle’s exhaust noise reduction component.

This concludes the FAQ section. The next section will explore potential upgrades and enhancements to the exhaust system.

In Summary

This exploration of the ford explorer muffler has emphasized its multifaceted role beyond mere noise reduction. The analysis encompassed material durability, exhaust backpressure implications, proper fitment requirements, and adherence to regulatory mandates. Proper maintenance, component selection, and installation techniques directly influence vehicle performance, emissions compliance, and overall operational costs.

The longevity and effectiveness of the described exhaust component are dependent upon informed decision-making. Careful attention to these factors ensures a vehicle that operates efficiently, minimizes environmental impact, and adheres to established standards. Further research into specific applications and individual vehicle needs is encouraged for optimal exhaust system management.