A specific type of exhaust component utilizes fiberglass packing material within its structure to attenuate sound. This design often results in a distinctive, performance-oriented exhaust note, particularly noticeable during acceleration. These components are commonly found in aftermarket applications designed to enhance both the sound and performance characteristics of a vehicle’s exhaust system. They can vary in size, shape, and the specific grade of fiberglass used, influencing the resulting sound profile and longevity.

The appeal of these units lies in their ability to provide a noticeable increase in exhaust volume and a more aggressive tone compared to stock systems. Historically, these components gained popularity among automotive enthusiasts seeking improved performance and a more pronounced auditory experience. The effectiveness of sound damping is influenced by factors such as the density and quality of the fiberglass packing, as well as the internal design of the unit itself. Over time, the packing material can degrade due to heat and exhaust gas exposure, leading to a change in sound characteristics and potentially reduced effectiveness.

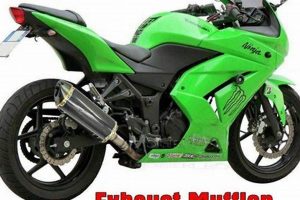

The following sections will delve into the construction details of these components, the factors affecting their performance and lifespan, and a comparison with alternative sound attenuation methods used in exhaust systems.

Guidance on Utilization

The following recommendations address key considerations for selection, maintenance, and optimal performance of aftermarket exhaust components employing fiberglass packing for sound attenuation. Careful adherence to these guidelines can maximize lifespan and ensure continued acoustic performance.

Tip 1: Material Quality Assessment: Prior to purchase, scrutinize the manufacturer’s specifications regarding the fiberglass packing. High-temperature resistant materials exhibit prolonged durability and consistent sound characteristics. Inquire about the density and composition of the packing material.

Tip 2: Weld Integrity Inspection: Thoroughly examine all welds on the unit. Inadequate weld penetration or porosity can lead to premature failure and exhaust leaks, compromising performance and sound quality. A visual inspection is essential before installation.

Tip 3: Proper Installation Techniques: Adhere strictly to the manufacturer’s installation instructions. Incorrect mounting or improper exhaust system alignment can induce stress and shorten the component’s lifespan. Use appropriate mounting hardware and gaskets.

Tip 4: Periodic Acoustic Evaluation: Regularly monitor the exhaust note for changes indicating degradation of the fiberglass packing. A noticeable increase in volume or a shift in tone suggests that the packing material may require replacement or repacking.

Tip 5: Exhaust System Backpressure Management: Ensure the exhaust system is designed to minimize backpressure. Excessive backpressure can increase operating temperatures, accelerating the deterioration of the fiberglass packing and reducing overall performance.

Tip 6: Avoidance of Chemical Contamination: Prevent exposure to harsh chemicals, road salts, and abrasive materials. These substances can corrode the exterior of the component and potentially degrade the packing material. Regular cleaning with appropriate products is advised.

Tip 7: Evaluate Internal Design: Before purchasing, if possible, evaluate the internal design elements such as the baffle structure or core design. Some internal designs promote better flow and sound wave disruption, improving longevity and performance.

Implementing these tips promotes responsible utilization, extends the product’s functional lifespan, and maintains the desired performance characteristics over extended use.

The next section will offer a comparative analysis with alternative exhaust system technologies.

1. Sound Attenuation Design

Sound attenuation design is fundamental to the function of a glass-packed muffler. The specific arrangement of internal components, particularly the perforated core surrounded by fiberglass packing, directly dictates the level and character of sound reduction achieved. The interaction between the exhaust gases and the packing material results in the dissipation of sound energy. A poorly designed internal structure can lead to inadequate sound attenuation or premature degradation of the fiberglass, diminishing the muffler’s effectiveness over time. For example, a restrictive core design can increase backpressure, leading to elevated temperatures that accelerate the breakdown of the fiberglass. Conversely, an overly open design may fail to adequately dampen sound waves.

The effectiveness of the sound attenuation design is contingent upon several factors. These include the thickness and density of the fiberglass packing, the size and spacing of perforations in the core, and the overall volume of the muffler canister. A well-engineered design optimizes the balance between sound reduction, exhaust flow, and durability. For instance, some designs incorporate multiple layers of fiberglass with varying densities to target specific frequencies, while others utilize internal baffles to further disrupt sound waves. This strategic approach allows for customization of the exhaust note while maintaining acceptable noise levels. Failures in the structural integrity or material choice of any component within the design can compromise overall effectiveness, demonstrating the critical importance of each design element.

In summary, the sound attenuation design constitutes the core operational principle of a glass-packed muffler. The interrelationship between the core perforations, fiberglass packing, and overall muffler volume determines the system’s capacity to diminish exhaust noise while preserving appropriate exhaust flow. Design shortcomings inevitably lead to decreased sound reduction, accelerated component degradation, or increased backpressure. A thorough understanding of these design principles is vital for selecting or manufacturing exhaust components that achieve optimal acoustic performance and longevity.

2. Fiberglass Packing Density

Fiberglass packing density is a critical parameter governing the performance and longevity of exhaust components employing fiberglass for sound attenuation. The quantity of fiberglass packed within the muffler canister significantly influences sound absorption, exhaust flow, and the overall lifespan of the unit.

- Sound Attenuation Efficiency

Higher packing densities generally lead to more effective sound dampening. The increased mass of fiberglass provides a greater surface area for sound waves to interact with, resulting in more energy dissipation. However, excessively dense packing can restrict exhaust flow, potentially reducing engine performance.

- Exhaust Backpressure

Increased packing density directly correlates with increased exhaust backpressure. This backpressure can negatively impact engine efficiency and power output, particularly at higher engine speeds. The trade-off between sound attenuation and backpressure must be carefully considered when selecting or designing such exhaust components.

- Heat Dissipation

Fiberglass packing acts as an insulator, trapping heat within the muffler. Higher densities can exacerbate this issue, leading to elevated operating temperatures that accelerate the degradation of the fiberglass material itself. Effective heat management strategies, such as external heat shields or strategically placed air gaps, become increasingly important with denser packing.

- Packing Material Lifespan

The lifespan of the fiberglass packing is inversely related to its density and the operating temperature. Higher densities can accelerate breakdown due to increased internal temperatures and restricted airflow. The choice of high-temperature resistant fiberglass materials becomes crucial to mitigate this effect and extend the usable lifespan of the muffler.

The optimal fiberglass packing density represents a compromise between sound attenuation effectiveness, acceptable backpressure levels, efficient heat dissipation, and prolonged material lifespan. Careful consideration of these factors is paramount in achieving the desired performance characteristics and durability within a glass-packed muffler system.

3. Exhaust Flow Dynamics

Exhaust flow dynamics fundamentally influence the performance and acoustic characteristics of a glass-packed muffler. The interaction between the exhaust gases and the internal structure of the muffler, particularly the perforated core and fiberglass packing, dictates the flow patterns and pressure gradients, directly affecting both sound attenuation and engine efficiency.

- Core Perforation Design and Backpressure

The size, density, and pattern of perforations in the muffler core directly impact exhaust flow resistance. Smaller or fewer perforations increase backpressure, potentially reducing engine horsepower and fuel economy. Conversely, larger or more numerous perforations reduce backpressure but may compromise sound attenuation effectiveness. Optimal core design balances these competing factors.

- Fiberglass Packing Density and Flow Restriction

The density of the fiberglass packing surrounding the core influences exhaust gas permeability. Denser packing materials offer greater sound dampening but also present a higher resistance to flow. This increased resistance can lead to elevated exhaust temperatures and accelerated degradation of the fiberglass packing due to restricted airflow. The selection of appropriate packing density is therefore crucial for long-term performance.

- Internal Baffle Configuration and Flow Turbulence

Some designs incorporate internal baffles to redirect exhaust flow and enhance sound wave cancellation. While effective for sound attenuation, baffles also introduce turbulence, increasing flow resistance and potentially generating unwanted pressure fluctuations. Careful baffle placement and design are necessary to minimize negative impacts on exhaust flow dynamics.

- Muffler Volume and Gas Expansion

The overall volume of the muffler canister affects the expansion and cooling of exhaust gases. A larger volume provides greater opportunity for gas expansion, reducing exhaust velocity and temperature. This, in turn, can improve the lifespan of the fiberglass packing. However, excessively large muffler volumes may lead to a less aggressive exhaust note due to the diminished exhaust pulse energy.

These interconnected aspects of exhaust flow dynamics collectively determine the efficiency and effectiveness of a glass-packed muffler. A comprehensive understanding of these relationships is essential for optimizing muffler design and selecting components that deliver the desired balance of sound attenuation, performance, and durability. Variations in engine type, vehicle application, and performance goals will necessitate tailored approaches to exhaust flow management within the muffler system.

4. Heat Resistance Threshold

The heat resistance threshold of the fiberglass packing material is a defining characteristic in the performance and longevity of glass-packed mufflers. This threshold represents the maximum temperature the material can withstand before undergoing significant degradation, impacting its sound-dampening properties and structural integrity. Exceeding this threshold leads to premature failure and diminished muffler effectiveness.

- Material Composition and Degradation Rate

The specific composition of the fiberglass packing directly determines its heat resistance. Materials composed of higher-grade silica and specialized binders exhibit superior thermal stability compared to standard fiberglass. Elevated temperatures cause the binders to break down, leading to a loss of structural integrity and a reduction in sound-absorbing capacity. This degradation accelerates exponentially as the temperature exceeds the material’s specified threshold. Consequently, selecting fiberglass with a higher heat resistance is crucial for mufflers operating in high-temperature environments, such as those found in turbocharged or high-performance vehicles.

- Exhaust Gas Temperature and Operational Environment

Exhaust gas temperature (EGT) varies considerably depending on engine type, operating conditions, and exhaust system design. Vehicles subjected to frequent high-load operation, such as towing or track racing, experience significantly higher EGTs than those used for typical commuting. Therefore, the heat resistance threshold of the muffler must be carefully matched to the anticipated EGT range. Installing a muffler with an inadequate heat resistance threshold in a high-temperature application will inevitably result in premature failure of the packing material and a rapid increase in exhaust noise.

- Muffler Design and Heat Dissipation

The design of the muffler itself can influence the operating temperature of the fiberglass packing. Designs that promote efficient heat dissipation, such as those with larger surface areas or integrated heat shields, can help to keep the packing material within its acceptable temperature range. Conversely, poorly designed mufflers that trap heat within the canister can accelerate the degradation of the fiberglass, even if the exhaust gas temperature is nominally within the material’s specified limits. The internal geometry and airflow characteristics of the muffler therefore play a critical role in managing the thermal load on the packing material.

- Acoustic Performance and Material Degradation

The acoustic performance of a glass-packed muffler is directly linked to the integrity of the fiberglass packing. As the material degrades due to excessive heat exposure, its ability to absorb sound waves diminishes. This results in a progressive increase in exhaust noise and a change in the muffler’s tonal characteristics. Monitoring the exhaust note for changes in volume or tone can provide an indication of the packing material’s condition and the proximity to its heat resistance threshold. Regular inspection and timely replacement of the muffler are essential to maintain desired acoustic performance and prevent excessive noise pollution.

In conclusion, the heat resistance threshold of the fiberglass packing is a pivotal factor determining the long-term effectiveness of glass-packed mufflers. Careful consideration of material composition, exhaust gas temperature, muffler design, and acoustic performance is essential to ensure the selection of a muffler suitable for the intended application and operating environment. Exceeding the heat resistance threshold leads to premature degradation, increased noise levels, and reduced overall muffler lifespan.

5. Acoustic Performance Lifespan

The acoustic performance lifespan of a glass-packed muffler is directly contingent upon the degradation rate of its fiberglass packing material. Several factors contribute to this degradation, including exposure to high exhaust gas temperatures, chemical corrosion from exhaust byproducts, and physical breakdown due to vibration and pressure fluctuations. The initial sound-dampening characteristics are defined by the packing’s density, composition, and installation method. As the fiberglass degrades, its ability to absorb sound waves diminishes, resulting in a gradual increase in exhaust noise and a shift in tonal quality. A performance-oriented vehicle, for example, subjected to frequent high-RPM operation, will experience significantly shortened muffler lifespan due to elevated exhaust temperatures that accelerate the breakdown of the fiberglass.

Practical implications of understanding the acoustic performance lifespan are considerable. Regular monitoring of exhaust noise levels can provide an indication of the muffler’s condition. A noticeable increase in volume or a change in tone often signals the need for replacement or repacking. Ignoring these signs can lead to non-compliance with noise regulations and a deterioration of the vehicle’s overall performance. Furthermore, selecting a muffler with higher-quality, heat-resistant fiberglass packing can extend the acoustic performance lifespan, reducing the frequency of replacements and minimizing long-term maintenance costs. A properly maintained exhaust system not only ensures optimal acoustic performance but also contributes to the vehicle’s overall reliability and longevity. Consider municipal transit buses, where a commitment to regular exhaust system maintenance directly improves community relations by reducing noise pollution.

In summary, the acoustic performance lifespan of a glass-packed muffler is a critical consideration for vehicle owners and operators. The longevity of acoustic performance is influenced primarily by the gradual decay of the packing material through thermal, chemical and physical exposure. Proactive monitoring, informed material selection, and regular maintenance are crucial for maximizing the lifespan and ensuring continued compliance with noise regulations. Challenges remain in predicting the precise lifespan due to the variability in driving conditions and environmental factors, yet an understanding of the underlying degradation mechanisms enables more effective management and mitigation strategies.

6. Corrosion Protection Measures

Corrosion poses a significant threat to the operational lifespan of glass-packed mufflers. These exhaust components are frequently exposed to harsh environmental conditions, including road salts, moisture, and corrosive chemicals present in exhaust gases. Consequently, the implementation of effective corrosion protection measures is essential to mitigate material degradation and ensure long-term functionality. The interaction between corrosive elements and the muffler’s metallic components initiates electrochemical reactions, leading to rust formation and structural weakening. If left unaddressed, corrosion can compromise the muffler’s integrity, resulting in exhaust leaks, diminished performance, and eventual component failure. For example, in regions with high levels of road salt application during winter months, vehicles lacking adequate corrosion protection on their exhaust systems exhibit significantly shorter muffler lifespans compared to vehicles operating in less corrosive environments. The practical significance of this understanding lies in the direct correlation between corrosion protection and the overall cost of ownership, as frequent muffler replacements due to corrosion-related damage can be a substantial financial burden.

Various corrosion protection strategies are employed in the manufacturing and maintenance of glass-packed mufflers. These measures include the use of corrosion-resistant materials, such as stainless steel or aluminized steel, for the muffler’s outer shell and internal components. Protective coatings, such as ceramic coatings or paint formulated with corrosion inhibitors, are also applied to create a barrier against corrosive elements. Furthermore, regular cleaning and inspection of the muffler can help to identify and address early signs of corrosion before significant damage occurs. In industrial applications, such as heavy-duty trucks operating in chemically harsh environments, specialized corrosion-resistant alloys and coatings are often utilized to ensure the mufflers can withstand prolonged exposure to corrosive substances. These examples illustrate the diverse approaches available for mitigating corrosion and extending the service life of glass-packed mufflers across a range of operational contexts.

Effective corrosion protection measures are indispensable for ensuring the durability and performance of glass-packed mufflers. The selection of appropriate materials, application of protective coatings, and implementation of regular maintenance procedures are crucial for minimizing corrosion-related damage and maximizing the muffler’s lifespan. While the initial cost of corrosion-resistant materials or coatings may be higher, the long-term benefits, including reduced replacement frequency and improved vehicle reliability, far outweigh the initial investment. Challenges remain in developing cost-effective corrosion protection solutions that can withstand the extreme conditions encountered in certain operating environments. However, ongoing research and development efforts are continuously improving the effectiveness and affordability of corrosion protection technologies, contributing to the continued advancement of glass-packed muffler design and performance.

7. Vehicle Application Suitability

The correlation between vehicle application suitability and glass-packed muffler performance is paramount. A mismatch between muffler characteristics and the intended vehicle can lead to suboptimal engine performance, excessive noise levels, and reduced component lifespan. The selection of a glass-packed muffler should therefore be predicated on a comprehensive understanding of the vehicle’s engine specifications, intended use, and regulatory noise restrictions. Engine displacement, horsepower output, and operating RPM range influence the required exhaust flow capacity. A muffler with insufficient flow capacity can create excessive backpressure, reducing engine efficiency and potentially causing damage. Conversely, a muffler with excessive flow can result in inadequate sound attenuation, exceeding noise limits and potentially impacting vehicle drivability due to diminished low-end torque. For example, installing a high-flow glass-packed muffler designed for a performance sports car on a fuel-efficient compact car may result in a significant increase in exhaust noise without a corresponding improvement in performance, while potentially reducing fuel economy. Therefore, careful consideration of vehicle-specific parameters is essential for optimal integration.

Practical application requires a detailed evaluation of several factors. Noise regulations vary significantly across jurisdictions; compliance necessitates selecting a muffler that meets the applicable sound level limits. Vehicle modifications, such as aftermarket headers or catalytic converters, can alter exhaust flow characteristics, requiring adjustments to muffler selection. The intended use of the vehicle also plays a crucial role. A vehicle primarily used for highway driving will benefit from a muffler that minimizes drone at cruising speeds, while a vehicle used for off-road applications may require a more durable muffler capable of withstanding impacts and exposure to harsh environments. Furthermore, the vehicle’s exhaust system layout and mounting points must be compatible with the muffler’s dimensions and configuration. Failing to account for these factors can result in installation difficulties, performance compromises, or even damage to the vehicle. Consider a classic car restoration, where maintaining the original exhaust note and appearance is paramount. A modern, high-performance glass-packed muffler would be entirely unsuitable, whereas a reproduction muffler designed to replicate the original’s sound and aesthetics would be the appropriate choice.

In conclusion, vehicle application suitability is a non-negotiable aspect of glass-packed muffler selection. The complex interplay between engine characteristics, regulatory requirements, intended use, and installation constraints dictates the optimal muffler choice. A thorough assessment of these factors ensures not only compliance with noise regulations and satisfactory performance but also maximizes the muffler’s lifespan and minimizes potential damage to the vehicle. While challenges remain in predicting long-term performance due to variations in driving conditions and environmental factors, a systematic approach to vehicle application suitability provides the best possible assurance of a successful and satisfactory outcome. Ongoing research into muffler design and materials continues to refine the options available, further emphasizing the importance of staying informed about the latest advancements in exhaust system technology.

Frequently Asked Questions

The following section addresses common inquiries and concerns regarding the selection, operation, and maintenance of exhaust components utilizing fiberglass packing for sound attenuation. The information presented aims to provide a clear and objective understanding of these devices.

Question 1: What defines a glass packed muffler and what distinguishes it from other muffler types?

A glass packed muffler employs fiberglass material surrounding a perforated core to dampen sound waves. Unlike chambered mufflers that rely on internal baffles and resonance, these components utilize absorption to reduce noise. The distinct characteristic lies in its ability to produce a unique exhaust note often described as aggressive or throaty.

Question 2: What is the expected lifespan of a glass packed muffler and what factors influence its durability?

Lifespan varies depending on operating conditions, material quality, and design. High exhaust gas temperatures, exposure to corrosive elements, and vibration contribute to the degradation of the fiberglass packing. The use of high-temperature resistant packing materials and robust construction methods can extend the unit’s service life. Expect a range from 2 to 5 years under normal use, shorter in performance applications.

Question 3: Does the installation of a glass packed muffler affect vehicle emissions or compliance with environmental regulations?

If the original catalytic converter is removed or modified, emissions compliance may be compromised. Altering the exhaust system before the catalytic converter can affect engine performance and potentially trigger diagnostic trouble codes. Confirm compliance with local emissions standards before installation.

Question 4: How does fiberglass packing density influence sound attenuation and exhaust flow characteristics?

Higher packing density generally provides greater sound attenuation but can increase backpressure, potentially reducing engine performance. Lower density reduces backpressure but may result in a louder exhaust note. An optimal balance is required to achieve desired acoustic and performance characteristics.

Question 5: What maintenance procedures are recommended to maximize the lifespan and performance of a glass packed muffler?

Regular inspection for signs of corrosion, exhaust leaks, or packing degradation is advisable. Avoidance of harsh chemicals and excessive exhaust temperatures can prolong the packing material’s lifespan. Replacement of the unit is necessary when the packing material deteriorates significantly, resulting in increased exhaust noise.

Question 6: What are the potential performance benefits and drawbacks of using a glass packed muffler compared to other aftermarket exhaust options?

Potential benefits include a distinctive exhaust note and potentially improved exhaust flow compared to stock systems. Drawbacks may include increased noise levels, potential drone at certain engine speeds, and a shorter lifespan compared to some chambered mufflers. A careful evaluation of these factors is essential before making a decision.

Glass packed mufflers present a specific set of acoustic and performance trade-offs. Understanding these nuances is essential for informed decision-making and responsible utilization.

The following section will provide a glossary of terms related to exhaust systems and sound attenuation.

Glass Packed Muffler

This exploration has illuminated the operational principles, performance characteristics, and maintenance requirements associated with glass packed mufflers. The interplay between fiberglass packing density, exhaust flow dynamics, heat resistance, and corrosion protection significantly influences both the acoustic signature and the longevity of these components. Furthermore, the critical importance of selecting a muffler appropriate for the specific vehicle application has been underscored, highlighting the necessity of balancing performance aspirations with regulatory compliance.

The decision to incorporate a glass packed muffler into an exhaust system requires careful deliberation. A comprehensive understanding of the trade-offs between sound attenuation, performance enhancement, and component durability is essential for informed decision-making. Continued advancements in materials science and muffler design promise to further refine the capabilities and extend the service life of these components, demanding ongoing vigilance from both manufacturers and end-users.