A protective component designed to encase and shield a vehicle’s exhaust silencing device. This component serves as a barrier against environmental factors such as road debris, salt, and moisture. For instance, a stainless steel shell installed around the exhaust component safeguards it from premature corrosion and physical damage.

The implementation of this shield offers several advantages. It extends the lifespan of the underlying exhaust part by mitigating the impact of corrosive elements. This results in reduced maintenance costs and a prolonged period before replacement is necessary. Historically, these shields were often fabricated from materials less resistant to environmental degradation, but advancements in materials science have led to the utilization of more durable substances like stainless steel and heat-resistant polymers, increasing overall effectiveness and longevity.

The following sections will delve into the specific materials used in constructing these protective components, their installation procedures, and the measurable impact on vehicle performance and longevity, exploring the different types of materials, installation techniques, and overall effect on vehicle’s exhaust system and performance.

Optimizing Exhaust Silencer Protection

The following guidelines provide practical advice on maximizing the effectiveness and longevity of exhaust silencer protection systems.

Tip 1: Material Selection is Crucial: Opt for stainless steel or aluminized steel for enhanced resistance to corrosion, particularly in regions with harsh winter conditions or coastal environments. For example, a 304 stainless steel shield provides superior protection compared to standard steel.

Tip 2: Ensure Proper Fitment: A correctly installed shield minimizes gaps, preventing debris and moisture from accumulating between the shield and the exhaust component. Incorrect fitting can lead to accelerated corrosion, negating the protection offered.

Tip 3: Regularly Inspect for Damage: Conduct periodic visual inspections to identify any signs of damage, such as dents, cracks, or loose mounting hardware. Promptly address any issues to prevent further degradation of the protective barrier and the underlying exhaust component.

Tip 4: Consider Heat Management: In high-performance applications, heat-resistant coatings or materials can mitigate the transfer of excessive heat to surrounding components, preventing potential damage and maintaining optimal performance. A ceramic coating, for instance, can reduce radiant heat and improve efficiency.

Tip 5: Protect from Road Salt: In areas where road salt is prevalent, consider applying a corrosion-inhibiting spray to the exhaust component before installing the shield. This provides an additional layer of defense against salt-induced corrosion.

Tip 6: Prevent Internal Abrasion: In some designs, the shield can rub against the exhaust. Ensure that there is adequate spacing or use a heat-resistant padding to minimize abrasion, preventing both noise and premature wear.

Effective implementation of these tips can significantly extend the lifespan of the exhaust system, reducing maintenance costs and ensuring optimal vehicle performance.

The article’s conclusion will elaborate on the long-term cost benefits associated with investing in quality exhaust silencer protection solutions.

1. Corrosion Resistance

The capacity of a exhaust silencer shield to withstand degradation caused by chemical reactions with its environment is paramount to its functionality and longevity. Exhaust systems are inherently exposed to corrosive elements such as road salt, water, and exhaust gases, making corrosion resistance a critical attribute of an effective shield. The selection of materials with inherent corrosion resistance, such as stainless steel or aluminized steel, directly influences the lifespan of both the shield and the underlying exhaust silencer. For instance, a shield constructed from low-grade steel will rapidly corrode in regions with heavy road salt usage, negating its protective capabilities and potentially accelerating the corrosion of the exhaust silencer itself. By contrast, a stainless steel component can maintain its structural integrity and protective function for a significantly longer period.

The mechanism by which a shield prevents corrosion is multifaceted. It acts as a physical barrier, preventing direct contact between corrosive substances and the exhaust component. Furthermore, it can promote a more uniform temperature distribution, reducing localized condensation and the associated corrosion risks. The effectiveness of this protection is directly proportional to the quality of the materials used and the integrity of the shield’s construction. For example, poor welds or thin coatings can create points of vulnerability where corrosion can initiate and propagate, compromising the entire system. Similarly, inadequate ventilation can trap moisture and accelerate corrosion from the inside out. Therefore, proper design and manufacturing are essential to maximize the corrosion resistance of the shield.

In conclusion, corrosion resistance is an indispensable characteristic of an effective exhaust silencer shield. Its presence or absence directly impacts the lifespan of the exhaust system and the overall operational costs of the vehicle. Understanding the mechanisms by which shields provide corrosion protection, along with selecting appropriate materials and ensuring proper installation, are crucial for maximizing the benefits of this protective element. Ignoring corrosion resistance in the selection or maintenance of exhaust silencer shields results in premature failure and increased maintenance burdens.

2. Thermal Insulation

Thermal insulation, when integrated into the design or application of exhaust silencer shields, serves to mitigate heat transfer, influencing both vehicle performance and component longevity. Understanding the role of thermal insulation in this context necessitates a comprehensive examination of its specific facets.

- Heat Dissipation Management

The primary function of thermal insulation in this application is to control heat dissipation from the exhaust system. Excessive heat radiating from the exhaust can negatively impact nearby components, such as fuel lines, wiring harnesses, and even the vehicle’s body panels. A thermally insulating shield reduces radiant heat, preventing overheating and potential damage to these adjacent parts. For example, a shield with a ceramic coating can significantly decrease the surface temperature of the exhaust component, protecting surrounding elements from thermal degradation.

- Passenger Compartment Comfort

In certain vehicle configurations, the exhaust system may be located in close proximity to the passenger compartment. Thermal insulation integrated into the silencer shield can minimize heat intrusion into the cabin, improving occupant comfort, especially during extended periods of operation or in hot climates. A shield with an air gap or insulating material can act as a barrier, reducing the amount of heat radiated into the passenger space.

- Performance Optimization

Maintaining exhaust gas temperature within an optimal range can contribute to engine efficiency. Thermal insulation can help to prevent excessive cooling of exhaust gases, which can negatively impact catalytic converter performance and increase emissions. By retaining heat, the exhaust system operates more efficiently, leading to improved fuel economy and reduced pollution. This is particularly relevant in colder climates where rapid cooling of the exhaust can hinder the warm-up phase of the catalytic converter.

- Fire Prevention

In off-road or industrial applications where vehicles operate near combustible materials, thermal insulation plays a critical role in fire prevention. A hot exhaust system can easily ignite dry vegetation or flammable liquids. A shield with effective thermal insulation significantly reduces the risk of fire by lowering the surface temperature of the exhaust component and preventing direct contact with potential ignition sources. This is crucial for safety in environments where fire hazards are present.

These facets of thermal insulation demonstrate its multifaceted role in optimizing the performance, safety, and longevity of vehicles equipped with exhaust silencer shields. The selection of appropriate insulating materials and design considerations are paramount to maximizing the benefits of this technology.

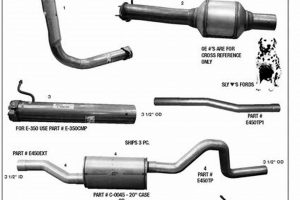

3. Physical Protection

The provision of physical protection is a fundamental function of an exhaust silencer shield. This shield acts as a barrier against impacts from road debris such as rocks, gravel, and other foreign objects encountered during vehicle operation. The consequences of neglecting this protection can range from superficial dents to significant structural damage to the exhaust silencer itself, leading to reduced performance, increased noise, and ultimately, premature failure. For instance, a vehicle operating on unpaved roads is significantly more susceptible to damage from flying stones; a properly designed shield can deflect these projectiles, preserving the integrity of the underlying exhaust component. Without this safeguard, the silencer’s thin metal walls are vulnerable to puncture or deformation, compromising its acoustic damping properties and potentially causing exhaust leaks.

The effectiveness of physical protection is contingent upon several factors, including the material composition, thickness, and mounting configuration of the shield. High-strength materials like heavy-gauge steel or reinforced polymers offer superior impact resistance compared to lighter, more flexible alternatives. Moreover, the shield’s design should incorporate adequate clearance to prevent direct contact with the exhaust silencer during normal operation, mitigating the risk of abrasion and localized stress concentrations. For example, some shields are equipped with internal baffles or vibration-damping mounts to further isolate the exhaust component from external forces. In commercial vehicles operating in demanding environments, reinforced shields are often a mandatory requirement to withstand the rigors of heavy-duty use and extend the lifespan of the exhaust system.

In summary, physical protection is an indispensable attribute of an effective exhaust silencer shield. Its role in safeguarding the exhaust system from external damage directly influences the vehicle’s reliability, performance, and overall maintenance costs. By mitigating the risk of impact-related failures, a well-designed and properly installed shield contributes significantly to the long-term operational efficiency of the vehicle. Failing to address this aspect can result in avoidable repairs, increased downtime, and compromised vehicle performance.

4. Acoustic Damping

Acoustic damping plays a significant role in the performance of an exhaust silencer system. It refers to the reduction of noise produced by the engine’s exhaust gases as they travel through the exhaust system. A silencer shield, while primarily designed for protection and thermal management, can also contribute to acoustic damping, albeit to a lesser extent than the internal components of the silencer itself. The interaction between these two elements can influence the overall noise characteristics of the vehicle.

- Vibration Reduction

One key aspect of acoustic damping in this context is the reduction of vibrations in the silencer’s outer shell. The shield, when properly installed, can dampen these vibrations, minimizing the amount of noise radiated from the silencer’s surface. For example, a shield made of a dense material, such as thick steel, can effectively absorb vibrational energy, converting it into heat and thereby reducing noise levels. Improper fitment of the shield, however, can create rattling or buzzing noises, negating any potential damping benefits.

- Airborne Noise Reduction

A silencer shield can also provide a barrier against airborne noise. By encasing the silencer, the shield can reduce the transmission of sound waves directly into the surrounding environment. This effect is more pronounced with shields that incorporate sound-absorbing materials, such as fiberglass or mineral wool. However, the shield’s effectiveness in reducing airborne noise is limited compared to the silencer’s internal baffling and absorption mechanisms.

- Shield Material and Design

The material and design of the shield significantly influence its acoustic damping capabilities. A rigid shield will tend to reflect sound waves, while a more flexible shield may absorb some energy. Perforations or slots in the shield can also affect its acoustic properties, potentially allowing more noise to escape. Therefore, the selection of materials and the shield’s design must be carefully considered to optimize its acoustic damping performance.

- System-Level Integration

The acoustic damping provided by a silencer shield is just one component of the overall exhaust system’s noise control strategy. The design and effectiveness of the silencer’s internal components, such as resonators and baffles, are far more critical in achieving desired noise levels. The shield should be viewed as a complementary element that can enhance the silencer’s performance, but it cannot compensate for deficiencies in the silencer’s design.

In conclusion, while a silencer shield primarily serves to protect the silencer from physical damage and thermal effects, it can also contribute to acoustic damping by reducing vibrations and blocking airborne noise. The extent of this contribution depends on the shield’s material, design, and integration with the overall exhaust system. Careful consideration of these factors can optimize the acoustic performance of the vehicle.

5. Extended Lifespan

The service life of an exhaust silencer is significantly influenced by its exposure to environmental stressors and physical damage. An appropriately designed and implemented protective component directly mitigates these factors, contributing to a tangible increase in the silencer’s operational duration. This extension of lifespan translates to reduced replacement frequency, decreased maintenance costs, and improved vehicle reliability.

- Corrosion Mitigation

Exhaust systems are constantly subjected to corrosive elements such as road salt, water, and exhaust byproducts. A protective component provides a barrier against these substances, preventing or slowing down the corrosion process. For example, a stainless steel shield surrounding the silencer offers superior resistance to rust compared to an unprotected carbon steel silencer, especially in regions where road salt is heavily used. This directly translates into a longer operational life for the silencer.

- Physical Damage Prevention

Road debris, such as rocks and gravel, can cause physical damage to the silencer, leading to dents, punctures, and compromised structural integrity. A robust protective component acts as a shield, absorbing impacts and preventing damage to the silencer’s thin metal walls. This is particularly important for vehicles operating on unpaved roads or in construction zones, where the risk of damage from flying debris is significantly higher.

- Thermal Stress Reduction

Exhaust systems undergo significant thermal stress due to extreme temperature fluctuations. A properly designed protective component can help to distribute heat more evenly, reducing localized hot spots and minimizing thermal fatigue. This, in turn, prevents premature cracking and failure of the silencer. Furthermore, some protective components incorporate insulating materials that reduce heat transfer to surrounding components, minimizing potential damage and improving overall system efficiency.

- Vibration Dampening

Engine vibrations can contribute to fatigue and failure of exhaust system components. A well-designed protective component can dampen these vibrations, reducing stress on the silencer’s welds and joints. This is particularly important for vehicles with high-performance engines or those subjected to frequent off-road use, where vibrations are more pronounced.

The synergistic effect of these protective mechanisms underscores the crucial role of a properly designed and installed component in extending the lifespan of an exhaust silencer. By mitigating corrosion, preventing physical damage, reducing thermal stress, and dampening vibrations, this protective element significantly contributes to the overall reliability and longevity of the vehicle’s exhaust system. Investment in a quality protective element represents a cost-effective strategy for minimizing maintenance expenses and maximizing vehicle uptime.

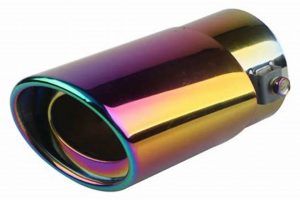

6. Aesthetic Improvement

The visual appearance of a vehicles exhaust system, though often overlooked, contributes to the overall aesthetic impression. A component designed to encase the exhaust silencer can serve not only a functional purpose but also enhance the vehicle’s visual appeal, transforming a utilitarian element into an integrated design feature.

- Concealment of Imperfections

The exhaust silencer, especially on older vehicles, may exhibit rust, dents, or discoloration due to prolonged exposure to the elements. A well-designed shield effectively conceals these imperfections, presenting a cleaner and more refined appearance. For instance, a polished stainless steel cover can mask a corroded silencer, restoring a sense of visual order to the undercarriage. This concealment contributes to an overall perception of meticulous maintenance and care.

- Customization and Styling

Protective components can be manufactured in a variety of materials, finishes, and designs, allowing for customization to match the vehicle’s overall styling. Options range from brushed aluminum to chrome-plated steel, each offering a distinct aesthetic. For example, a performance-oriented vehicle might benefit from a shield finished in carbon fiber, conveying a sense of technological sophistication. This level of customization allows owners to tailor the visual impact of the exhaust system to their personal preferences.

- Visual Integration

A protective component can visually integrate the exhaust system with other undercarriage elements, creating a more cohesive and harmonious appearance. By matching the colors and textures of surrounding components, the shield can seamlessly blend in, avoiding the appearance of an afterthought. This integration is particularly relevant for vehicles with exposed exhaust systems, where the silencer is readily visible. A well-integrated shield enhances the overall visual balance and symmetry of the vehicle.

- Enhancement of Perceived Value

The addition of a visually appealing protective component can increase the perceived value of the vehicle, suggesting attention to detail and a commitment to quality. A meticulously designed and installed shield communicates a sense of pride in ownership and enhances the vehicle’s overall image. This can be particularly important for vehicles intended for resale, where visual appeal plays a significant role in purchase decisions.

In conclusion, aesthetic improvement is a valuable, albeit often secondary, benefit derived from exhaust silencer shields. By concealing imperfections, allowing for customization, promoting visual integration, and enhancing perceived value, these components contribute to the overall aesthetic quality of the vehicle. The extent to which aesthetic considerations influence the selection and design of shields varies depending on the vehicle type and the owner’s preferences, but the potential for visual enhancement is undeniable.

Frequently Asked Questions

The following section addresses common inquiries regarding exhaust silencer shields, providing factual information and dispelling potential misconceptions.

Question 1: What is the primary function of an exhaust silencer shield?

The primary function is to protect the exhaust silencer from physical damage, corrosion, and thermal stress, thereby extending its lifespan. It acts as a barrier against road debris, corrosive substances, and extreme temperatures.

Question 2: Are all exhaust silencer shields made from the same material?

No. Materials vary depending on the application and desired performance characteristics. Common materials include stainless steel, aluminized steel, and heat-resistant polymers. Stainless steel offers superior corrosion resistance, while aluminized steel provides a more cost-effective alternative.

Question 3: Does a silencer shield affect vehicle performance?

A properly designed and installed shield should not negatively impact vehicle performance. In some cases, it may improve performance by maintaining optimal exhaust gas temperatures, leading to more efficient catalytic converter operation.

Question 4: Can a silencer shield reduce exhaust noise?

While the primary function is protection, a shield can contribute to acoustic damping by reducing vibrations and blocking airborne noise. However, its effect is typically less significant than the silencer’s internal components.

Question 5: Is professional installation required for exhaust silencer shields?

Professional installation is recommended to ensure proper fitment and avoid potential issues such as rattling, reduced ground clearance, or compromised heat dissipation. Improper installation can negate the benefits of the shield and potentially damage the exhaust system.

Question 6: How can the lifespan of a exhaust silencer shield be maximized?

Regular inspection for damage, proper cleaning to remove road salt and debris, and prompt repair of any issues are crucial for maximizing its lifespan. Selecting a shield made from high-quality materials and ensuring proper installation are also essential.

In summary, exhaust silencer shields offer significant benefits in terms of protection, longevity, and, to a lesser extent, noise reduction. Proper selection, installation, and maintenance are essential for maximizing their effectiveness.

The following section will provide a comparative analysis of different types of exhaust silencer shields available on the market.

Conclusion

This exploration of exhaust silencer shields, or cover muffler solutions, has elucidated their multifaceted role in vehicle maintenance. These components serve primarily to protect the exhaust system from corrosion, physical damage, and thermal stress, significantly extending the lifespan of the silencer. Secondary benefits include potential contributions to acoustic damping and aesthetic enhancement. The selection of appropriate materials, proper installation techniques, and diligent maintenance practices are crucial to realizing the full potential of these protective measures. The variety of materials and designs available allows for customization based on specific vehicle needs and environmental conditions.

The decision to implement a cover muffler system should be based on a comprehensive assessment of the vehicle’s operating environment, the potential for damage to the exhaust system, and the long-term cost benefits associated with reduced maintenance and replacement. Further research and technological advancements may lead to even more effective and integrated solutions for exhaust system protection. Investing in robust protective measures remains a prudent strategy for ensuring vehicle reliability and minimizing operational expenses.