This automotive component, situated downstream from the catalytic converter, constitutes a specific section of an exhaust system. It typically encompasses the piping from the converter’s outlet to the vehicle’s exhaust tip, often including a muffler. A common modification involves replacing the factory-installed system with an aftermarket version, typically constructed from materials like stainless steel.

Upgrading this exhaust section can offer various advantages. Potential benefits include improved exhaust flow, which may contribute to increased engine horsepower and torque. Furthermore, an aftermarket component may produce a more aggressive exhaust note, enhancing the vehicle’s auditory profile. Historically, modifications to the exhaust system were driven by performance aspirations; modern iterations often balance performance gains with regulatory compliance.

The following sections will explore the factors involved in selecting such a system, detailing installation considerations and providing insight into performance implications. An objective evaluation of aftermarket options will assist in making an informed purchasing decision.

Muffler Catback

Optimizing exhaust performance requires careful attention to component selection and installation practices. The following guidelines aim to provide clarity and direction throughout the process.

Tip 1: Material Selection: Prioritize stainless steel construction for enhanced durability and corrosion resistance. Aluminized steel represents a more economical option, but its lifespan may be reduced in harsh environmental conditions.

Tip 2: Diameter Optimization: Select a pipe diameter commensurate with the engine’s output characteristics. Overly large diameters can reduce exhaust gas velocity, potentially diminishing low-end torque.

Tip 3: Muffler Design Assessment: Evaluate muffler design based on desired sound characteristics and performance goals. Chambered mufflers often provide a deeper tone, while straight-through designs may offer greater flow potential.

Tip 4: Welding Quality Inspection: Thoroughly inspect all welds for integrity and penetration. Poorly executed welds represent a potential failure point, compromising system longevity.

Tip 5: Hanger Alignment Verification: Ensure proper alignment of mounting hangers prior to final installation. Misaligned hangers can induce stress on the system, potentially leading to premature wear or damage.

Tip 6: Hardware Torque Specification Adherence: Adhere strictly to manufacturer-recommended torque specifications for all fasteners. Over-tightening can result in component damage, while under-tightening may lead to leaks or loosening.

Tip 7: Professional Installation Consideration: For complex installations or when lacking requisite expertise, consider engaging a qualified automotive technician to ensure proper fitment and functionality.

Adherence to these guidelines will promote optimal performance, longevity, and satisfaction. Proper attention to detail throughout the selection and installation process will contribute to a well-integrated and reliable exhaust system upgrade.

The subsequent sections will delve into performance metrics and potential performance enhancements related to the component described. Thorough analysis and objective judgement will be required to provide clarity in the exhaust selection.

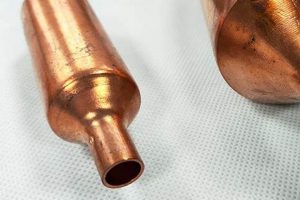

1. Material Composition

The material composition of this component directly influences its durability, longevity, and performance characteristics. The selection of materials has a cascading effect, impacting resistance to corrosion, thermal stability, and overall system weight. For instance, systems constructed from austenitic stainless steel alloys, such as 304 or 316, exhibit superior resistance to oxidation and corrosive elements encountered in exhaust environments. This contrasts with aluminized steel, which offers lower upfront cost but diminished resistance to corrosion, particularly in regions with harsh winters or high road salt usage.

The correlation between material and performance stems from the exhaust system’s operating conditions. Exhaust gases, often containing moisture and acidic byproducts, can aggressively corrode less resistant materials. This corrosion not only compromises the system’s structural integrity but also degrades its ability to effectively manage exhaust flow. A corroded system may develop leaks, causing a reduction in engine efficiency and an increase in noise. Conversely, premium materials contribute to a longer service life and consistent performance, thus justifying the higher initial investment.

Ultimately, the choice of material represents a trade-off between cost and longevity. While stainless steel offers the most robust protection against corrosion, aluminized steel may serve as a viable option for budget-conscious consumers operating in environments with less exposure to corrosive agents. However, acknowledging the direct link between material and performance ensures an informed decision and optimal system functionality over its lifespan. Prioritizing high-quality materials enhances system durability.

2. Pipe Diameter

Pipe diameter constitutes a critical parameter influencing the performance characteristics of an exhaust system modification. It directly affects exhaust gas velocity, backpressure, and ultimately, engine power output. Appropriate sizing is paramount for optimizing engine efficiency and achieving desired performance gains.

- Exhaust Gas Velocity

A smaller diameter pipe increases exhaust gas velocity, potentially improving scavenging at lower engine speeds. However, an excessively small diameter creates undue backpressure, hindering high-RPM performance. Conversely, a larger diameter reduces gas velocity, which can diminish low-end torque. Therefore, selecting the appropriate diameter involves balancing these opposing effects.

- Backpressure Management

Backpressure, the resistance to exhaust flow, directly influences engine efficiency. Excessive backpressure reduces the engine’s ability to expel exhaust gases effectively, resulting in decreased power and fuel economy. An exhaust modification with an appropriately sized pipe is designed to minimize backpressure without sacrificing exhaust gas velocity.

- Engine Performance Characteristics

The optimal pipe diameter is contingent upon the engine’s displacement, intended operating range, and modifications. Smaller displacement engines generally benefit from smaller diameter systems, while larger, more powerful engines require larger diameters to accommodate increased exhaust gas volume. Forced induction engines often necessitate larger diameters to minimize backpressure and maximize power output.

- Aftermarket Considerations

Aftermarket systems offer various diameter options, catering to different performance goals. Systems designed for street use typically prioritize a balance between low-end torque and high-RPM power, while systems optimized for racing applications often prioritize maximum flow at the expense of low-end responsiveness. Careful consideration of the vehicle’s intended use is crucial when selecting a system.

The selection of an appropriate pipe diameter involves a comprehensive understanding of its effects on exhaust gas velocity, backpressure, and engine performance characteristics. Choosing the correct diameter enables the modification to effectively enhance performance across the engine’s operating range, optimizing both power and efficiency. Consideration of all these factors guarantees an informed decision.

3. Muffler Design

The muffler constitutes a critical component within an exhaust system modification, directly influencing sound characteristics and exhaust flow dynamics. Its design profoundly affects the overall performance and auditory profile of a vehicle equipped with a catback system.

- Chambered Mufflers

Chambered mufflers utilize a series of internal baffles and chambers to attenuate sound waves. This design effectively reduces noise levels but may introduce greater backpressure compared to other configurations. In the context of a catback system, a chambered muffler can provide a more refined and subdued exhaust note, suitable for daily driving while maintaining acceptable performance levels.

- Straight-Through Mufflers

Straight-through mufflers feature a perforated core surrounded by sound-absorbing material, allowing exhaust gases to flow with minimal restriction. This design maximizes exhaust flow and often results in a louder, more aggressive exhaust note. When integrated into a catback system, a straight-through muffler can enhance engine performance, particularly at higher RPMs, at the expense of increased sound levels.

- Baffled Mufflers

Baffled mufflers strike a balance between noise reduction and exhaust flow by incorporating strategically placed baffles that deflect and redirect sound waves. This design can provide a compromise between the sound attenuation of chambered mufflers and the flow characteristics of straight-through designs. In a catback configuration, baffled mufflers can offer a noticeable improvement in both sound and performance compared to the factory system.

- Resonator Integration

Resonators, often incorporated within catback systems, function to eliminate specific sound frequencies and reduce overall noise levels. A resonator’s design can significantly affect the final sound produced by the system. They can be designed to target specific frequencies that cause drone, resulting in a smoother more pleasant sound inside the vehicle.

The integration of these different muffler designs within a catback system allows for a wide range of customization, enabling vehicle owners to tailor the exhaust sound and performance characteristics to their specific preferences. Careful consideration of the muffler design ensures that the catback system delivers the desired balance of sound, performance, and driving experience. The various designs each offer unique qualities in terms of performance and sound.

4. Sound characteristics

The sound characteristics of a vehicle are substantially altered by the installation of an aftermarket exhaust system modification. The exhaust modification, which replaces the factory exhaust components downstream of the catalytic converter, often results in a change to the volume, tone, and overall quality of the exhaust note. This change occurs primarily due to differences in muffler design, pipe diameter, and the absence or presence of resonators. The sound produced becomes a defining characteristic of the modification, significantly impacting the driver’s and bystanders’ perception of the vehicle.

The impact of an exhaust modification on sound is multifaceted. For instance, a system employing a straight-through muffler design and larger diameter piping typically produces a louder and more aggressive exhaust note than the factory system. This is directly attributable to the reduced restriction to exhaust flow, enabling sound waves to propagate more freely. Conversely, a system incorporating a chambered muffler and strategically placed resonators aims to attenuate specific frequencies, resulting in a more refined and controlled sound. Real-world examples abound, such as a sports car equipped with a performance exhaust exhibiting a throaty roar, or a truck fitted with a system designed for reduced drone on long highway drives. Understanding this connection enables consumers to select a system that aligns with their individual preferences and noise regulations.

In summary, the sound characteristics are an inseparable element of this exhaust modification. The design choices made during the system’s development directly dictate the auditory experience. While achieving a desired sound profile often involves trade-offs with performance or noise compliance, recognizing the underlying principles allows for informed decision-making. Consequently, the sound produced by an exhaust system serves as a critical factor in the overall ownership experience and warrants careful consideration during the selection process.

5. Installation Complexity

The installation process associated with an exhaust modification represents a significant consideration for both experienced mechanics and vehicle owners. The level of complexity involved directly impacts the time required for installation, the tools needed, and the potential for professional assistance.

- Direct Bolt-On Systems

Direct bolt-on systems are engineered for simplified installation, typically utilizing existing mounting points and hardware. These systems generally require basic hand tools and minimal modifications to the vehicle. For example, a system designed for a specific make and model might directly replace the factory exhaust section without requiring welding or fabrication. The implication is a reduced installation time and the potential for successful completion by individuals with limited mechanical experience.

- Systems Requiring Modification

Some aftermarket offerings necessitate modifications to the vehicle’s exhaust system or chassis. This can include cutting, welding, or relocating exhaust hangers. An example would be a universal system adapted to a specific vehicle, where the installer must fabricate custom mounting points. The complexity increases significantly, often requiring specialized tools and skills, making professional installation advisable.

- Potential for Component Interference

Physical interferences with other vehicle components, such as the fuel tank, suspension components, or underbody panels, can significantly complicate the installation process. This situation might arise when the exhaust system design deviates substantially from the original equipment configuration. Addressing such interferences often necessitates adjustments to either the exhaust system or the interfering component, increasing installation time and expertise needed.

- Hardware and Fastener Considerations

The condition of existing hardware and fasteners plays a role in determining installation complexity. Corroded or damaged fasteners may require specialized tools or techniques for removal, potentially adding time and difficulty to the installation. In some cases, replacement hardware might be necessary, necessitating additional procurement efforts.

The multifaceted nature of installation complexity underscores the importance of carefully evaluating the system’s design and fitment prior to purchase. A realistic assessment of one’s mechanical skills and available resources is crucial in determining whether professional installation is warranted. The chosen system should align with available resources.

6. Performance enhancement

Aftermarket exhaust systems, specifically those of the catback configuration, are frequently implemented to achieve performance gains. This arises from the premise that factory exhaust systems are often designed with compromises, balancing performance, noise reduction, cost, and regulatory compliance. These compromises frequently restrict exhaust flow, thereby limiting engine output. Replacing the factory exhaust section with a less restrictive aftermarket component can reduce backpressure, enabling the engine to expel exhaust gases more efficiently. This reduction in backpressure can translate to measurable increases in horsepower and torque, particularly at higher engine speeds. Real-world examples include dyno-tested performance gains reported by automotive enthusiasts and documented by aftermarket parts manufacturers, often demonstrating improvements ranging from 5 to 15 horsepower on naturally aspirated engines.

The magnitude of performance enhancement varies depending on several factors, including engine configuration, existing modifications, and the design characteristics of the exhaust component itself. Engines with forced induction, such as turbochargers or superchargers, generally exhibit more pronounced gains from reduced exhaust restriction. Furthermore, the pipe diameter, muffler design, and material composition influence overall exhaust flow characteristics. For instance, a straight-through muffler design with larger diameter piping will typically yield greater performance gains compared to a chambered muffler with smaller diameter piping. The practical application of this understanding lies in selecting an exhaust system that is appropriately matched to the engine’s capabilities and intended use. A system optimized for high-RPM power might compromise low-end torque, while a system designed for balanced performance provides more usable power across the engine’s operating range.

While aftermarket exhaust components can offer performance enhancements, it is crucial to acknowledge potential challenges. Improper installation, incompatibility with existing engine modifications, or failure to account for regulatory compliance can negate any potential gains. Furthermore, advertised performance figures should be regarded critically, as they are often obtained under controlled conditions and may not accurately reflect real-world results. Ultimately, achieving meaningful performance enhancement with an aftermarket exhaust system requires a comprehensive understanding of its design principles, the engine’s characteristics, and potential limitations. It necessitates informed selection and proper installation, as well as compliance to regulations.

Frequently Asked Questions

This section addresses common inquiries and clarifies misconceptions related to exhaust system upgrades, specifically focusing on the component downstream of the catalytic converter.

Question 1: Does this modification automatically increase horsepower?

Performance gains are contingent upon several factors, including engine design, existing modifications, and the exhaust system’s design. While potential gains exist, they are not guaranteed and should be assessed based on specific vehicle and component characteristics.

Question 2: Will this modification void the vehicle’s warranty?

The impact on the vehicle’s warranty depends on the specific warranty terms and applicable laws. Modifications directly causing a component failure may not be covered. Consult the vehicle’s warranty documentation and relevant legal provisions for clarification.

Question 3: Is professional installation required?

The necessity of professional installation depends on the installer’s experience and the complexity of the installation process. Direct bolt-on systems may be suitable for experienced individuals, while systems requiring modification or welding necessitate professional expertise.

Question 4: How does pipe diameter affect performance?

Pipe diameter influences exhaust gas velocity and backpressure. Smaller diameters increase velocity, potentially improving low-end torque, while larger diameters reduce backpressure, potentially enhancing high-RPM power. Optimal diameter depends on the engine’s characteristics and intended use.

Question 5: What material is most suitable for longevity?

Stainless steel alloys, such as 304 or 316, exhibit superior corrosion resistance and are generally recommended for maximizing system longevity, particularly in environments exposed to harsh conditions.

Question 6: How does muffler design influence sound?

Muffler design directly impacts the exhaust note. Chambered mufflers tend to produce a deeper tone, while straight-through designs often result in a louder, more aggressive sound. Resonators further shape the sound profile by attenuating specific frequencies.

This FAQ section underscores the importance of informed decision-making and thorough research when considering exhaust system modifications. Understanding the relevant factors contributes to a satisfactory outcome.

The subsequent section will provide a buyer’s guide, offering practical advice for selecting an appropriate exhaust system modification based on individual needs and preferences.

Muffler Catback

This exploration has illuminated the multifaceted considerations inherent in selecting and installing a system downstream of the catalytic converter. The discussion encompassed material selection, pipe diameter optimization, muffler design evaluation, and installation complexity assessment. A comprehensive understanding of these variables facilitates informed decision-making. Performance enhancements, while potentially attainable, are subject to the engine’s characteristics and the system’s design. Regulatory compliance and warranty implications warrant careful scrutiny.

The information presented herein serves as a foundational resource for individuals contemplating such modifications. Prioritizing informed selection and adherence to established installation guidelines ensures a satisfactory outcome. Future developments in exhaust technology may offer refined performance characteristics and enhanced sound management capabilities. Continuous assessment of evolving technologies remains paramount.