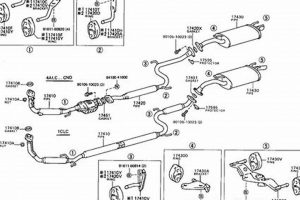

A device designed to reduce the noise generated by an internal combustion engine while simultaneously enhancing the vehicle’s operational capabilities is the focal point. This component is typically installed as part of the exhaust system and is engineered to optimize gas flow. An example would be the installation of a specialized unit to improve horsepower and torque in a modified vehicle.

The significance of such a component lies in its ability to balance acoustic control with enhanced engine output. Historically, these units were primarily focused on noise reduction. However, modern designs also prioritize improvements in engine efficiency and power. Benefits can include increased fuel economy, improved throttle response, and a more aggressive sound profile.

The following sections will delve into the specific materials used in manufacturing, the various design types available, and the critical factors to consider when selecting the most appropriate unit for a given application. Furthermore, maintenance procedures and potential performance gains will be addressed in detail.

Essential Guidance

The following guidance focuses on optimizing the utilization of aftermarket exhaust components. Proper selection and installation are crucial for realizing the intended performance enhancements and ensuring longevity.

Tip 1: Material Selection: Prioritize stainless steel construction. This material offers superior corrosion resistance, essential for withstanding the harsh conditions within an exhaust system. For example, vehicles operating in regions with salted roads benefit significantly from stainless steel components.

Tip 2: Diameter Considerations: Ensure the diameter of the aftermarket component is appropriately matched to the engine displacement and intended power output. An undersized diameter can restrict exhaust flow, negating potential gains. Conversely, an excessively large diameter can reduce exhaust velocity, impacting low-end torque.

Tip 3: Professional Installation: Consider professional installation for complex exhaust systems. Improper welding or mounting can lead to leaks, vibrations, and structural failures. A qualified technician possesses the necessary tools and expertise to ensure proper fitment.

Tip 4: Sound Level Monitoring: Be cognizant of local noise ordinances. While performance enhancements are desirable, exceeding permissible sound levels can result in fines or vehicle restrictions. Investigate components that offer adjustable sound levels or integrated resonators.

Tip 5: Regular Inspection: Periodically inspect the exhaust system for signs of damage, corrosion, or leaks. Address minor issues promptly to prevent them from escalating into more significant problems. Pay particular attention to welds and mounting points.

Tip 6: Matching Components: Consider matching the aftermarket component with other compatible performance upgrades, such as headers or catalytic converters. A synergistic approach can maximize overall performance gains.

Adhering to these guidelines ensures that the intended performance enhancements are realized, while simultaneously preserving the integrity and longevity of the exhaust system. Consistent maintenance and careful selection contribute significantly to the overall effectiveness.

The subsequent section will provide an in-depth analysis of troubleshooting common issues and maximizing the lifespan of aftermarket exhaust systems.

1. Enhanced Exhaust Flow

Enhanced exhaust flow is a primary objective in the design and selection of performance exhaust components. Its direct influence on engine efficiency and power output renders it a critical consideration for enthusiasts and professionals alike. The subsequent points delineate key facets of this characteristic in relation to such exhaust system enhancements.

- Reduced Backpressure

Backpressure, the resistance to exhaust gases exiting the engine, directly hinders performance. By minimizing this resistance, the engine expends less energy pushing out exhaust, thereby freeing up power for propulsion. Modified systems achieve this through larger diameter piping and smoother bends, facilitating a more efficient evacuation of exhaust gases.

- Optimized Piping Diameter

Selection of an appropriate piping diameter is crucial. While intuitively, larger diameter piping might seem universally beneficial, excessively large diameters can reduce exhaust gas velocity, negatively impacting scavenging effects and low-end torque. Properly sized piping maintains adequate gas velocity while minimizing backpressure.

- Smooth Mandrel Bends

Traditional exhaust systems often employ crush bends, which constrict the internal diameter of the pipe at the bend. Mandrel bending utilizes specialized tooling to maintain a consistent diameter throughout the bend, eliminating flow restrictions and minimizing turbulence. This ensures a smooth, uninterrupted path for exhaust gases.

- High-Flow Catalytic Converters (if applicable)

While designed to reduce emissions, factory catalytic converters can introduce significant backpressure. High-flow catalytic converters utilize less restrictive internal designs, allowing for improved exhaust flow while still meeting emissions standards (where required). Replacing a restrictive factory converter with a high-flow alternative can further enhance performance.

These factors collectively contribute to improved engine breathing, resulting in increased horsepower and torque. The proper implementation of these design elements is crucial for realizing the full potential of a performance exhaust system. The integration of these features is essential for achieving measurable gains in vehicle performance.

2. Reduced Backpressure

The efficiency of an internal combustion engine is intrinsically linked to its ability to expel exhaust gases effectively. Reduced backpressure, a key characteristic often associated with performance-oriented exhaust systems, plays a critical role in this process. Specific components are engineered to minimize restrictions, thereby optimizing engine output. Understanding this relationship is fundamental when evaluating the functionality of specialized exhaust solutions.

- Core Functionality

The primary role of a performance-oriented exhaust system is to facilitate the rapid evacuation of exhaust gases from the combustion chamber. By decreasing resistance within the exhaust pathway, the engine experiences less impedance during its exhaust stroke. This reduced burden translates directly into increased power and torque output.

- Material and Design Considerations

The materials used in manufacturing such units contribute significantly to backpressure reduction. Smoother internal surfaces and optimized flow paths minimize turbulence and resistance. For instance, stainless steel, due to its inherent smoothness and durability, is often employed in performance applications.

- Impact on Engine Performance

The effect of reduced backpressure is particularly noticeable at higher engine speeds. As the engine RPM increases, the volume of exhaust gases generated rises proportionally. A restrictive exhaust system can become a significant bottleneck, limiting peak power. Minimizing backpressure allows the engine to breathe more freely, resulting in improved horsepower and torque across the rev range.

- Application-Specific Optimization

The optimal level of backpressure reduction is often application-specific. Factors such as engine displacement, camshaft profile, and intended usage influence the ideal exhaust system design. While significantly reducing backpressure is generally desirable, excessively large exhaust diameters can, in some cases, negatively impact low-end torque due to reduced exhaust gas velocity.

In summary, the reduction of backpressure is a pivotal element in the design and functionality of performance exhaust solutions. Its impact extends beyond mere noise reduction, directly influencing engine efficiency and overall vehicle performance. Careful consideration of the factors outlined above is crucial when selecting and implementing these systems for optimal results.

3. Sound Level Management

Effective sound level management is a critical aspect of performance exhaust systems. It encompasses strategies to control and modify the auditory output of a vehicle, balancing performance enhancements with regulatory compliance and driver preferences. Specialized exhaust components play a vital role in achieving optimal sound characteristics.

- Muffler Design and Functionality

Mufflers are integral components designed to attenuate sound waves generated by the engine. Different muffler designs, such as chambered, baffled, or absorption types, offer varying degrees of sound reduction. A chambered muffler, for example, uses internal chambers to reflect and cancel out sound waves, while an absorption muffler employs sound-absorbing materials like fiberglass to dampen noise. The design directly impacts the overall sound level and tone of the exhaust.

- Resonator Integration

Resonators are additional components strategically placed within the exhaust system to target specific frequencies and reduce unwanted noise. They operate by creating destructive interference patterns that cancel out certain sound waves. Resonators can be tuned to address droning or harsh frequencies, resulting in a more refined and pleasant exhaust note. Their effectiveness depends on precise placement and tuning relative to the engine’s exhaust characteristics.

- Sound Level Regulations and Compliance

Many jurisdictions have established regulations regarding permissible vehicle noise levels. Performance exhaust systems must comply with these standards to avoid legal penalties. Sound level meters are used to measure the decibel output of a vehicle at specific RPMs and distances. Manufacturers often design their products to meet these regulations while still delivering performance benefits. Compliance is essential for street legality.

- Driver Preference and Customization

Beyond regulatory compliance, driver preference plays a significant role in sound level management. Some drivers prefer a loud, aggressive exhaust note, while others prioritize a quieter and more refined sound. Aftermarket exhaust systems offer a range of options to cater to different preferences, including adjustable mufflers and resonators that allow drivers to customize the sound output. This personalization enhances the driving experience.

The integration of effective sound level management techniques within performance exhaust systems is essential for achieving a balance between performance gains, regulatory compliance, and driver satisfaction. Components are engineered to deliver the desired sound characteristics while meeting legal requirements and personal preferences. The careful selection and tuning are crucial for optimal results.

4. Durable material construction

Durable material construction is a cornerstone of performance exhaust systems, directly influencing longevity, reliability, and overall value. The specific materials selected for exhaust components dictate their resistance to corrosion, thermal stress, and physical damage, ultimately impacting operational lifespan. For a high-performance exhaust system, material selection is not merely an aesthetic consideration but a critical determinant of its ability to withstand the harsh operating environment.

- Stainless Steel Alloys

Stainless steel is a prevalent material in exhaust construction due to its inherent corrosion resistance. Different grades of stainless steel, such as 304 and 409, offer varying levels of protection against oxidation and degradation. For example, a 304 stainless steel exhaust system will typically exhibit greater resistance to corrosion in coastal environments compared to a 409 stainless steel system. The selection of the appropriate alloy is paramount for maximizing lifespan in specific operating conditions.

- Titanium Alloys

Titanium alloys represent a premium material choice, offering exceptional strength-to-weight ratios and superior corrosion resistance compared to stainless steel. The use of titanium results in a lighter exhaust system, potentially improving vehicle handling and fuel efficiency. However, titanium alloys are significantly more expensive than stainless steel, limiting their application to high-end performance vehicles and racing applications.

- Welding Techniques and Integrity

The integrity of welds is crucial for the overall durability of an exhaust system. Improper welding techniques can create weak points that are susceptible to cracking and failure. TIG (Tungsten Inert Gas) welding is often preferred for performance exhaust systems due to its ability to create strong, clean welds with minimal porosity. The quality of the welds directly impacts the system’s ability to withstand thermal stress and vibrations.

- Coatings and Surface Treatments

Protective coatings and surface treatments can further enhance the durability of exhaust components. Ceramic coatings, for example, provide a thermal barrier that reduces heat radiation and protects surrounding components from excessive temperatures. These coatings also offer additional corrosion resistance. Similarly, specialized paints and sealants can be applied to welds and joints to prevent oxidation and extend lifespan. The application of appropriate coatings represents a proactive measure to mitigate environmental degradation.

These material considerations are inextricably linked. The selection of a durable material, coupled with proper welding techniques and protective coatings, directly translates to a longer-lasting and more reliable exhaust system. Neglecting these aspects can result in premature failure, necessitating costly repairs or replacements. Therefore, careful attention to material construction is essential for realizing the full potential and value of any exhaust system.

5. Precise Fitment

Precise fitment is a critical determinant of the performance, longevity, and overall satisfaction derived from any aftermarket exhaust system, including the A&A Performance Muffler. Inadequate fitment can negate performance gains, introduce mechanical stresses, and compromise the structural integrity of the entire exhaust system.

- Direct Bolt-On Compatibility

A core element of precise fitment is direct bolt-on compatibility. This implies that the A&A Performance Muffler is designed to seamlessly integrate with the vehicle’s existing exhaust mounting points and hangers without requiring modifications. An example would be a muffler designed specifically for a 2015 Ford Mustang GT, which should align precisely with the factory exhaust hangers and utilize the original mounting hardware. Deviations from this direct compatibility necessitate modifications, potentially compromising structural integrity and introducing exhaust leaks.

- Exhaust Leak Prevention

Precise fitment is paramount for preventing exhaust leaks. Mismatched flange surfaces, misaligned connections, or gaps between components can lead to the escape of exhaust gases. Even minor leaks can negatively impact engine performance, fuel economy, and emissions compliance. The A&A Performance Muffler must be engineered to create a tight, leak-free seal with the adjacent exhaust components. An ill-fitting muffler can cause backpressure reduction to be nullified due to leaks.

- Structural Integrity and Reduced Vibration

Proper fitment ensures the structural integrity of the exhaust system and minimizes vibration-induced stress. When the muffler is securely and properly supported, it is less susceptible to excessive movement and strain. This, in turn, reduces the risk of cracks, breaks, and premature failure. A muffler that is not precisely fitted may vibrate excessively against the vehicle’s undercarriage, generating unwanted noise and potentially damaging surrounding components. A proper installation ensures minimal stress on the system.

- Optimized Exhaust Flow Dynamics

Precise fitment indirectly contributes to optimized exhaust flow dynamics. A properly aligned exhaust system, free from leaks and misalignments, ensures that exhaust gases flow smoothly and efficiently. This minimizes turbulence and backpressure, maximizing engine performance. A misaligned muffler can disrupt the intended exhaust flow path, negating some of the performance benefits offered by the A&A Performance Muffler. Each system has specific design in order to achieve the flow results for its intended effect.

In conclusion, the A&A Performance Muffler’s efficacy is inextricably linked to precise fitment. Without it, potential gains in performance, durability, and sound characteristics are compromised, leading to diminished returns and potential long-term issues. The selection and installation process must prioritize dimensional accuracy and compatibility to ensure optimal performance and customer satisfaction. The overall benefit of the component is greatly reduced by lacking proper installation.

6. Power output improvement

The core objective of integrating an A&A Performance Muffler into a vehicle’s exhaust system often centers on enhancing power output. This improvement is not solely a result of noise reduction; rather, it stems from optimized exhaust gas flow. A stock muffler typically presents a restrictive pathway for exhaust gases, creating backpressure that impedes the engine’s ability to expel spent combustion products efficiently. By minimizing backpressure, the A&A Performance Muffler facilitates faster and more complete evacuation of exhaust gases, allowing the engine to draw in a greater volume of air and fuel during the intake stroke. This, in turn, leads to a more powerful combustion cycle and an increase in horsepower and torque.

Practical examples demonstrate this effect clearly. A dynamometer test conducted on a vehicle before and after installing an A&A Performance Muffler will typically reveal a measurable increase in both horsepower and torque figures. The magnitude of the improvement depends on several factors, including the engine’s initial state of tune, the design of the A&A Performance Muffler, and any other modifications made to the vehicle. For instance, a naturally aspirated engine may exhibit a more pronounced gain compared to a turbocharged engine, where the turbocharger already mitigates some of the backpressure inherent in the stock exhaust system. Further, coupling the muffler with high-flow catalytic converters and headers will further maximize the system’s flow potential and increase power gains.

Understanding the connection between power output improvement and the A&A Performance Muffler is crucial for consumers seeking to enhance their vehicle’s performance. While the muffler may contribute to an improved sound profile, its primary function is to optimize exhaust flow and reduce backpressure, ultimately unlocking the engine’s potential for increased power. The challenge lies in selecting the appropriate muffler design and size for a given application, ensuring that the reduction in backpressure does not compromise exhaust gas velocity at lower engine speeds. Therefore, a thorough understanding of the vehicle’s characteristics and the muffler’s specifications is essential for achieving optimal power output gains. Selecting the correct system can improve horsepower while decreasing engine strain.

7. Improved Thermal Efficiency

Enhanced thermal efficiency, a crucial aspect of internal combustion engine performance, is significantly influenced by the exhaust system, including the A&A Performance Muffler. The capability of the exhaust system to manage and dissipate heat effectively directly impacts engine longevity, overall performance, and fuel economy.

- Reduced Exhaust Gas Temperature

The A&A Performance Muffler can contribute to improved thermal efficiency by reducing exhaust gas temperature (EGT). A less restrictive muffler allows for a more rapid evacuation of exhaust gases from the combustion chamber. This reduces the time spent within the exhaust manifold and system, leading to less heat soaking into the engine components. Lower EGTs can reduce the risk of detonation, allowing for optimized engine tuning and increased power output. For example, on a turbocharged engine, a reduction in EGTs can allow for increased boost levels without exceeding thermal limits.

- Enhanced Heat Dissipation

The design and materials employed in the A&A Performance Muffler can enhance heat dissipation. Certain muffler designs utilize larger surface areas or incorporate cooling fins to promote heat transfer to the surrounding air. Furthermore, materials with high thermal conductivity, such as stainless steel, can facilitate more efficient heat dissipation compared to mild steel. Improved heat dissipation can protect sensitive components, such as the catalytic converter and fuel lines, from excessive heat exposure, extending their lifespan.

- Minimizing Thermal Stress on Engine Components

Efficient management of exhaust gas temperature minimizes thermal stress on critical engine components, including the exhaust valves, cylinder head, and turbocharger (if applicable). Excessive heat can lead to premature wear and failure of these components. The A&A Performance Muffler, by reducing backpressure and facilitating quicker exhaust gas evacuation, can help to mitigate thermal stress and prolong the lifespan of these critical components. A reduction in backpressure helps the engine breathe more efficiently reducing the stress that causes wear.

- Optimized Combustion Efficiency

Improved thermal efficiency can indirectly contribute to optimized combustion efficiency. By reducing backpressure and allowing for more efficient exhaust gas scavenging, the A&A Performance Muffler can help to create a more favorable environment for combustion. This can lead to a more complete burning of the air-fuel mixture, resulting in increased power output, improved fuel economy, and reduced emissions. An engine operating at optimal thermal efficiency is more likely to achieve its peak performance potential.

The A&A Performance Muffler, therefore, plays a critical role in managing thermal dynamics within the exhaust system. By optimizing exhaust flow, reducing backpressure, and enhancing heat dissipation, it contributes to improved thermal efficiency, leading to enhanced engine performance, increased component lifespan, and optimized fuel economy. These factors collectively contribute to the overall value and efficacy of the component.

Frequently Asked Questions

The following section addresses common inquiries regarding the A&A Performance Muffler, providing clear and concise information to facilitate informed decision-making.

Question 1: What discernible performance gains can be expected from an A&A Performance Muffler installation?

Performance gains are contingent upon specific vehicle configurations and existing modifications. Typically, an A&A Performance Muffler installation results in a measurable increase in both horsepower and torque, primarily due to reduced backpressure and improved exhaust gas flow. Dynometer testing is recommended to quantify specific improvements.

Question 2: Does the installation of an A&A Performance Muffler void a vehicle’s factory warranty?

The impact on a factory warranty depends on jurisdictional regulations and the manufacturer’s policies. The Magnuson-Moss Warranty Act generally protects consumers from blanket warranty voidances due to aftermarket parts. However, if the A&A Performance Muffler directly causes a component failure, the warranty claim may be denied for that specific component.

Question 3: What is the expected lifespan of an A&A Performance Muffler, and what maintenance procedures are recommended?

The lifespan is heavily influenced by environmental factors and material composition. Stainless steel A&A Performance Mufflers generally offer superior longevity compared to aluminized steel options. Periodic inspections for corrosion, leaks, and structural damage are recommended. Promptly addressing any detected issues will extend the muffler’s operational lifespan.

Question 4: Are there specific A&A Performance Muffler models designed for particular engine types or vehicle applications?

Yes, A&A Performance Mufflers are available in various configurations tailored to specific engine types and vehicle applications. These designs consider factors such as engine displacement, exhaust gas flow requirements, and sound level preferences. Consulting product specifications and expert recommendations is crucial for selecting the most appropriate model.

Question 5: How does the A&A Performance Muffler contribute to sound level management and regulatory compliance?

A&A Performance Mufflers incorporate various sound attenuation technologies, such as chambered designs and sound-absorbing materials, to manage exhaust noise levels. Compliance with local noise ordinances is paramount. Consumers should verify that the selected A&A Performance Muffler meets applicable sound level regulations in their jurisdiction.

Question 6: What are the primary factors to consider when selecting an A&A Performance Muffler for optimal performance and longevity?

Key factors include the muffler’s material construction (stainless steel is preferred), diameter, internal design, and compatibility with the vehicle’s existing exhaust system. Precise fitment is essential for preventing leaks and ensuring optimal performance. Professional installation is recommended for complex systems.

In summary, the A&A Performance Muffler is a complex component requiring careful consideration of various factors to ensure optimal performance, longevity, and regulatory compliance.

The following section will explore detailed case studies highlighting the practical applications of the A&A Performance Muffler across diverse vehicle types.

Conclusion

The preceding analysis has illuminated the multifaceted aspects of the A&A Performance Muffler, ranging from its fundamental design principles to its practical applications and potential benefits. The core tenets of enhanced exhaust flow, reduced backpressure, sound level management, durable material construction, precise fitment, power output improvement, and improved thermal efficiency have been thoroughly examined. These attributes underscore the component’s critical role in optimizing engine performance and overall vehicle operation.

The selection and implementation of an A&A Performance Muffler necessitate a comprehensive understanding of both the vehicle’s specifications and the muffler’s characteristics. Prudent decision-making, coupled with professional installation and diligent maintenance, will ensure the realization of the intended performance enhancements and the preservation of the exhaust system’s integrity. Further research and consultation with automotive professionals are encouraged to maximize the potential of this technology.