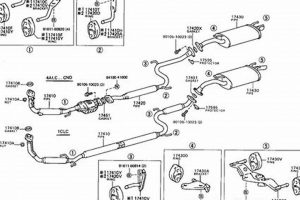

A vehicle exhaust system component designed for a specific make and model, it reduces engine noise and directs exhaust gases away from the vehicle occupants. This part plays a critical role in both vehicle performance and compliance with noise regulations. As an example, a specific model’s exhaust system may incorporate this component to manage backpressure and optimize engine efficiency.

The importance of this lies in its ability to lower noise pollution, enhance engine function, and maintain legal compliance. Historically, designs have evolved to improve flow characteristics and reduce weight, contributing to increased fuel economy and performance gains. Its proper functioning ensures a more comfortable and environmentally responsible driving experience.

Understanding the specifications, installation process, and available aftermarket options are essential for maintaining or upgrading a compatible vehicle’s exhaust system. Subsequent discussion will cover considerations for selecting the appropriate replacement, diagnosing potential issues, and exploring performance-enhancing alternatives for compatible exhaust systems.

Essential Considerations for Exhaust System Components

Maintaining optimal performance and addressing potential issues with exhaust systems require careful attention to detail and a thorough understanding of essential components. The following tips offer guidance on ensuring the longevity and efficiency of vehicle exhaust systems.

Tip 1: Routine Inspection is Paramount: Regularly examine the exhaust system for signs of corrosion, leaks, or physical damage. Early detection prevents minor issues from escalating into costly repairs. For instance, rust around the welds could indicate potential exhaust leaks.

Tip 2: Correct Sizing is Critical: Ensure the chosen component matches the vehicle’s make, model, and engine specifications. Using an improperly sized component can negatively impact engine performance and fuel efficiency. Refer to the vehicle’s manufacturer specifications or consult with a qualified mechanic.

Tip 3: Proper Installation Prevents Issues: Adhere to the manufacturer’s installation instructions during replacement or upgrade. Incorrect installation can lead to leaks, rattles, or premature wear. Tighten all connections to the specified torque values.

Tip 4: Material Selection Impacts Longevity: Consider the materials used in construction when selecting a component. Stainless steel typically offers greater resistance to corrosion than aluminized steel, extending the system’s lifespan, particularly in regions with harsh weather conditions.

Tip 5: Address Unusual Noises Promptly: Investigate any unusual noises emanating from the exhaust system immediately. Rattling, hissing, or droning sounds may indicate loose connections, exhaust leaks, or internal damage. Ignoring these symptoms can lead to more significant mechanical problems.

Tip 6: Understand Backpressure Effects: Recognize the role of backpressure in engine performance. While excessive backpressure can hinder performance, some level of backpressure is often necessary for optimal engine operation. Modifications that drastically reduce backpressure may require engine tuning.

Adhering to these recommendations will contribute to the reliable operation of the vehicle’s exhaust system, potentially minimizing repair expenses and improving overall vehicle performance.

Following these tips provides a foundation for understanding and maintaining the exhaust system. The ensuing discussion will delve into specific diagnostic procedures and common troubleshooting techniques.

1. Noise Reduction

The primary function of this exhaust system component is noise reduction. This aspect significantly impacts vehicle compliance with noise regulations and the overall driving experience. The following details the facets contributing to effective noise reduction.

- Internal Baffle Design

The internal configuration of baffles within the muffler dictates its ability to attenuate sound waves. Baffle design involves strategically placed partitions and chambers that redirect and dampen exhaust pulses, reducing their amplitude. Variations in baffle design include chambered, louvered, and perforated configurations, each offering distinct sound reduction characteristics. An example is the use of Helmholtz resonators within the design to cancel specific frequencies, further diminishing noise output.

- Acoustic Absorption Materials

Many designs incorporate acoustic absorption materials, such as fiberglass packing or ceramic wool, to absorb sound energy as exhaust gases pass through. These materials convert acoustic energy into thermal energy, reducing the overall sound level. The effectiveness of these materials depends on their density, thickness, and resistance to high temperatures and exhaust gas components. Regular inspection and replacement of these materials is often necessary to maintain optimal noise reduction performance.

- Chamber Volume and Geometry

The overall volume and geometric shape of the muffler’s internal chambers influence its noise reduction capabilities. Larger chamber volumes allow for greater expansion and dissipation of sound waves. Complex chamber geometries create multiple pathways for sound waves to travel, increasing the likelihood of attenuation through reflection and interference. The strategic arrangement of chambers, combined with carefully calculated volumes, contributes to targeted noise reduction across different frequency ranges.

- Shell Construction and Resonance Damping

The construction of the outer shell plays a role in minimizing noise radiation from the muffler itself. Thicker shell materials and strategically placed damping materials can reduce vibrations and resonance, preventing the shell from acting as a sound amplifier. Double-walled construction, with an air gap or damping material between the layers, is another method employed to reduce noise transmission through the shell.

The effectiveness of a component in reducing noise hinges on the integration of these facets. Variations in design and material selection allow for tailored sound characteristics, balancing noise reduction with performance considerations. Specific models utilize combinations of these techniques to achieve desired sound profiles, while adhering to mandated noise level restrictions.

2. Exhaust Flow

Exhaust flow directly influences the engine’s performance characteristics. A properly designed exhaust system, incorporating the specified component, minimizes backpressure, enabling efficient evacuation of exhaust gases from the combustion chambers. Reduced backpressure translates to improved volumetric efficiency, enhancing power output and fuel economy. Conversely, a restrictive component impedes exhaust flow, increasing backpressure and diminishing engine performance. A real-world example involves comparing two similar vehicles, one with an optimized system and one with a standard system; the former demonstrably exhibits superior acceleration and throttle response.

The internal architecture of the vehicle-specific component significantly dictates its flow characteristics. Straight-through designs, featuring minimal obstructions, facilitate maximum exhaust flow, typically favoring high-performance applications. Chambered designs, while effective at noise reduction, inherently introduce some degree of flow restriction. The choice between these designs necessitates a balance between performance and sound level requirements. Furthermore, the diameter of the component’s inlet and outlet pipes, as well as the smooth bending radii of any internal tubing, contribute to minimizing turbulence and maximizing flow. Aftermarket performance-oriented versions exemplify this by utilizing larger diameter tubing and mandrel bends to optimize exhaust gas velocity.

Understanding the relationship between exhaust flow and component design is critical for optimizing engine performance and ensuring regulatory compliance. Impediments to exhaust flow can not only reduce power but also elevate exhaust gas temperatures, potentially leading to component damage or increased emissions. Therefore, selecting an appropriate component, optimized for the vehicle’s engine specifications and intended use, is paramount. The integration of proper exhaust flow management constitutes a fundamental element in maintaining the vehicle’s efficiency and longevity.

3. Material Durability

Material durability constitutes a critical attribute of any exhaust system component. The service environment subjects these parts to extreme temperatures, corrosive elements, and mechanical stresses. Therefore, the choice of materials directly affects the component’s lifespan, performance, and overall value proposition. The selection of appropriate materials is pivotal in ensuring long-term reliability and functionality.

- Stainless Steel Grades

Various grades of stainless steel (e.g., 304, 409) offer different levels of corrosion resistance. 304 stainless steel, containing higher chromium and nickel content, exhibits superior resistance to rust and oxidation compared to 409 stainless steel. However, 409 stainless steel presents a more cost-effective option and possesses adequate corrosion resistance for many applications. The choice depends on the intended operating environment and budget constraints. For example, in regions with heavy road salting, 304 stainless steel may provide a substantially longer service life.

- Aluminized Steel Coatings

Aluminized steel represents a common material choice, particularly for original equipment manufacturer (OEM) components. The aluminum coating provides a barrier against corrosion, extending the life of the underlying steel. However, this coating can be compromised by scratches, impacts, or prolonged exposure to extreme heat, leading to eventual corrosion. While more affordable than stainless steel, aluminized steel typically exhibits a shorter lifespan, particularly in demanding operating conditions. Routine inspections for coating damage are recommended to mitigate potential corrosion issues.

- Weld Quality and Integrity

The quality of the welds joining the component’s sections significantly impacts its overall durability. Poorly executed welds introduce points of weakness and susceptibility to corrosion, leading to premature failure. Proper welding techniques, including the use of appropriate filler materials and shielding gases, are essential for creating strong, corrosion-resistant joints. Visual inspection of welds for porosity, cracks, and incomplete fusion provides an indication of their quality and long-term integrity.

- Thickness and Gauge of Material

The thickness, or gauge, of the material used in construction influences its ability to withstand mechanical stresses and resist deformation. Thicker materials offer greater resistance to impacts, vibration, and thermal expansion stresses. Conversely, thinner materials may be more prone to cracking, denting, or fatigue failure. Choosing the appropriate gauge of material depends on the intended application and the expected levels of stress. High-performance applications, subject to increased vibration and exhaust gas temperatures, typically benefit from thicker-gauge materials.

Ultimately, the durability hinges upon a holistic consideration of material selection, manufacturing processes, and environmental factors. Selecting a system constructed from high-quality materials and employing robust manufacturing techniques is crucial for ensuring longevity and reliable performance. The trade-offs between cost, performance, and durability should be carefully evaluated to determine the optimal solution for a given vehicle and operating environment.

4. Vehicle Compatibility

Vehicle compatibility represents a fundamental consideration when selecting an exhaust system component. Proper fitment and functionality are paramount for ensuring optimal engine performance, noise reduction, and regulatory compliance. Mismatched components can lead to reduced efficiency, potential damage to the vehicle, and failure to meet emission standards.

- Model-Specific Design

Specific vehicle models often require unique designs due to variations in chassis configuration, engine placement, and exhaust routing. Designs tailored for a specific vehicle ensure precise alignment with existing exhaust system components and mounting points. Deviations from the original specifications can result in improper fitment, requiring modifications or rendering the component unusable. For instance, a component designed for a model with a dual exhaust system will not be compatible with a model featuring a single exhaust configuration.

- Engine Displacement Matching

Engine displacement significantly influences exhaust gas volume and flow rate. Exhaust systems and their components must be appropriately sized to accommodate the engine’s specific exhaust output. Using a component designed for a smaller engine may create excessive backpressure, reducing power and potentially damaging the engine. Conversely, a component designed for a larger engine may not provide sufficient backpressure, leading to decreased low-end torque. For example, a vehicle equipped with a turbocharged engine requires a system capable of handling increased exhaust volume and temperatures compared to a naturally aspirated engine of the same displacement.

- Year-Specific Variations

Even within the same model line, year-to-year variations can necessitate modifications to exhaust system components. Changes in engine design, emission control systems, or chassis configuration can impact the compatibility of a particular component. It is crucial to verify that the selected component is specifically designed for the vehicle’s year of manufacture to ensure proper fitment and function. Examples include changes to catalytic converter placement or exhaust manifold design that may necessitate different component designs.

- Trim Level Considerations

Trim levels within a specific vehicle model may feature different engine options, exhaust system configurations, or aesthetic enhancements that affect component compatibility. High-performance trim levels may incorporate larger-diameter exhaust tubing or different muffling characteristics. Therefore, it is essential to confirm that the selected component aligns with the specific trim level of the vehicle. For example, an aftermarket component designed for a performance trim level may not be compatible with a base-level trim due to differences in exhaust routing or mounting points.

These considerations underscore the importance of meticulous verification when selecting a replacement or upgrade for a vehicle’s exhaust system. Consulting manufacturer specifications, utilizing compatibility charts, and seeking guidance from qualified automotive professionals can mitigate the risk of incompatibility. Correct selection and installation ensure optimal performance, longevity, and adherence to regulatory standards.

5. Backpressure Management

Backpressure management, within the context of exhaust systems, pertains to controlling the resistance encountered by exhaust gases as they exit the engine. A properly designed vehicle-specific component, such as a muffler, balances the need for adequate exhaust flow with the requirement for sufficient backpressure to maintain optimal engine performance. Excessive backpressure hinders exhaust scavenging, reducing engine power and fuel efficiency. Conversely, insufficient backpressure can lead to a loss of low-end torque and potentially damage engine components. The effect of the component on backpressure is therefore a critical design parameter.

The internal design of a vehicle exhaust component directly affects its backpressure characteristics. Chambered designs, employing baffles and partitions to attenuate sound, typically generate higher backpressure compared to straight-through designs. However, chambered designs offer superior noise reduction. Straight-through designs prioritize exhaust flow and minimize backpressure, often favored in performance applications where noise levels are less of a concern. Selecting the correct system, or component, therefore involves carefully considering the trade-offs between performance and sound attenuation. For example, an aftermarket system designed to increase horsepower may significantly reduce backpressure, resulting in a louder exhaust note and a potential loss of low-end torque if not properly matched to the engine’s characteristics.

Understanding the interplay between backpressure and the design of the exhaust component is essential for maintaining optimal engine performance and longevity. Modifications that drastically alter backpressure characteristics may necessitate engine tuning to compensate for changes in exhaust scavenging and fuel delivery. Furthermore, neglecting the effects of backpressure can lead to reduced engine life and increased emissions. By carefully selecting a properly designed component and considering the overall exhaust system characteristics, the detrimental effects of improper backpressure management can be mitigated, ensuring optimal engine performance and reliability.

6. Corrosion Resistance

Corrosion resistance constitutes a paramount attribute for exhaust system components, including the specific part under consideration, due to the harsh operating environment. Exposure to extreme temperatures, moisture, road salts, and corrosive combustion byproducts necessitates the utilization of materials and coatings that can withstand degradation and ensure long-term performance and reliability. Understanding the facets influencing corrosion resistance is essential for selecting an appropriate product.

- Material Composition and Grade

The base material’s composition significantly impacts its susceptibility to corrosion. Stainless steel alloys, such as 304 and 409, offer varying degrees of resistance. 304 stainless steel, containing higher chromium and nickel content, exhibits superior resistance to chloride-induced pitting and crevice corrosion, prevalent in regions with heavy road salt usage. 409 stainless steel, while more affordable, offers less corrosion resistance, especially in aggressive environments. The choice hinges on the vehicle’s operating location and expected exposure to corrosive elements. Using a system fabricated from higher-grade stainless steel can significantly extend the component’s service life.

- Protective Coatings and Surface Treatments

Coatings and surface treatments provide an additional layer of protection against corrosion. Aluminized coatings, commonly applied to steel, create a barrier that inhibits oxidation. Ceramic coatings offer enhanced thermal and chemical resistance, particularly at high temperatures. These coatings, however, are susceptible to damage from abrasion and impacts, potentially exposing the underlying material to corrosion. Regular inspection and maintenance of coated surfaces are crucial for preserving their protective properties. An example is the application of a high-temperature ceramic coating to minimize rust formation on a component exposed to extreme heat.

- Weld Integrity and Corrosion Protection

Welds represent potential weak points in terms of corrosion resistance. Improper welding techniques can create areas of increased susceptibility to rust and oxidation. Utilizing appropriate welding processes and filler materials that match the base metal’s corrosion resistance characteristics is crucial. Post-weld treatments, such as passivation, can enhance the corrosion resistance of weldments. Inspecting welds for porosity and incomplete fusion is also essential. A poorly executed weld on a system constructed from otherwise corrosion-resistant materials can compromise the entire system’s longevity.

- Environmental Factors and Operating Conditions

The severity of the operating environment plays a crucial role in determining the rate of corrosion. Vehicles operating in coastal regions, where exposure to saltwater is prevalent, or in areas with frequent road salting during winter months, require components with superior corrosion resistance. High exhaust gas temperatures can also accelerate corrosion processes. Regular washing of the vehicle, particularly the undercarriage, can help remove corrosive contaminants and extend the life of exhaust system components. For example, rinsing a vehicle after winter driving significantly reduces the accumulation of road salt, minimizing corrosion risk.

The integration of these facets into the design and material selection of a models muffler ensures its longevity and reliability. The effectiveness of strategies in mitigating corrosion is directly linked to the components long-term performance and its ability to maintain regulatory compliance. Continuous advancements in materials science and coating technologies are aimed at further improving corrosion resistance and extending the lifespan of these vital automotive components.

Frequently Asked Questions

The following addresses common inquiries and misconceptions regarding the function, selection, and maintenance of exhaust system components, specifically focusing on this make and model’s part.

Question 1: What is the primary function of the specific exhaust component under discussion?

The primary function of the mentioned component is to reduce engine noise generated by the combustion process. It also facilitates the efficient routing of exhaust gases away from the engine and vehicle occupants, contributing to vehicle emissions control and overall driving comfort.

Question 2: How does the design of the vehicle component affect its performance?

The internal design, including baffle configuration, chamber volume, and acoustic absorption materials, significantly influences its performance. A balance between noise reduction and exhaust flow is crucial. Chambered designs typically provide greater noise reduction, while straight-through designs prioritize exhaust flow and minimize backpressure.

Question 3: What materials are commonly used in the construction of an exhaust component, and how do they differ?

Common materials include aluminized steel and stainless steel (e.g., 409, 304). Aluminized steel offers a cost-effective solution with moderate corrosion resistance, while stainless steel provides superior durability and resistance to rust, particularly in harsh environments. The specific grade of stainless steel dictates its level of corrosion protection.

Question 4: How do I determine the correct exhaust system component for a particular vehicle?

Ensure compatibility by verifying the component is specifically designed for the vehicle’s make, model, year, and engine displacement. Consult manufacturer specifications, utilize compatibility charts, and, if necessary, seek guidance from qualified automotive professionals to avoid fitment issues and performance degradation.

Question 5: What are the signs of a failing exhaust component?

Common indicators of a failing exhaust include excessive noise, rattling sounds, reduced engine performance, decreased fuel efficiency, and visible corrosion or leaks. Promptly addressing these symptoms prevents further damage to the exhaust system and potential engine complications.

Question 6: Does modifying the exhaust system impact the vehicle’s emissions compliance?

Modifications to the exhaust system, including the replacement of the vehicle specific component, can affect emissions compliance. Ensure that any replacement component meets or exceeds original equipment manufacturer (OEM) specifications and adheres to applicable emissions regulations. Illegal modifications may result in fines and vehicle inspection failures.

Proper selection, installation, and maintenance of this exhaust system are crucial for optimizing vehicle performance, ensuring regulatory compliance, and preserving the environment.

The subsequent section will address common troubleshooting techniques for exhaust system related issues.

Conclusion

This exploration has detailed the essential characteristics of the component designed for a specific model’s exhaust system, emphasizing its roles in noise reduction, exhaust flow optimization, material durability, vehicle compatibility, backpressure management, and corrosion resistance. Understanding these critical aspects enables informed decision-making regarding selection, maintenance, and potential performance enhancements.

The continued advancement of exhaust system technology underscores its importance in meeting evolving emissions standards and performance expectations. Careful consideration of the factors outlined herein ensures responsible vehicle ownership and contributes to a more sustainable automotive future. The integrity of this component remains paramount for optimal vehicle operation and environmental stewardship.