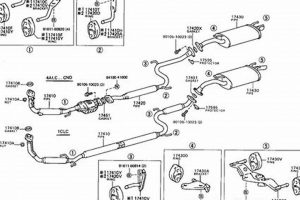

A specialized component integrated into exhaust systems, this device, typically constructed from durable materials, functions to reduce engine noise emanating from internal combustion processes. It relies on a system of chambers and baffles to attenuate sound waves, thereby decreasing the overall decibel level produced by the vehicle. Such components find application in a wide range of motorized equipment, from automobiles to industrial machinery, contributing to noise pollution mitigation.

The utilization of these noise-reducing devices yields multiple benefits. Environmentally, they contribute to quieter communities and decreased noise pollution, improving the quality of life for residents near roadways and industrial areas. Functionally, their presence ensures compliance with noise regulations imposed by various governing bodies, preventing legal repercussions for vehicle operators and manufacturers. Historically, the evolution of these devices has paralleled the increasing awareness of the detrimental effects of excessive noise and the subsequent implementation of stricter environmental standards.

Considering the functionalities described above, the subsequent analysis will delve into the specific construction materials, performance characteristics, and maintenance protocols associated with diverse models, ultimately focusing on aspects relevant to performance optimization and longevity within automotive applications.

Maintenance and Longevity Tips

Optimizing the lifespan and performance of exhaust noise reduction components requires adherence to specific maintenance and operational practices. Neglecting these can lead to diminished effectiveness and premature failure.

Tip 1: Regular Visual Inspection: Conduct routine visual checks for signs of corrosion, physical damage from road debris, or loose connections. Early detection of these issues prevents escalation into more significant problems.

Tip 2: Address Corrosion Promptly: Corrosion, particularly in regions with road salt exposure, is a primary cause of deterioration. Apply rust inhibitors and protective coatings to exposed surfaces to mitigate this effect.

Tip 3: Monitor Exhaust System Integrity: Leaks in the exhaust system upstream of the device can alter its performance characteristics. Ensure all connections are secure and free from exhaust gas escape.

Tip 4: Avoid Abrasive Cleaners: Refrain from using harsh chemicals or abrasive materials when cleaning the exterior. These substances can damage protective coatings and accelerate corrosion.

Tip 5: Check Mounting Hardware: Inspect mounting brackets and fasteners periodically for signs of wear or loosening. Loose or damaged hardware can lead to excessive vibration and premature failure.

Tip 6: Be Aware of Unusual Noises: Pay attention to any changes in exhaust sound. Rattling, hissing, or increased volume can indicate internal damage or deterioration requiring immediate attention.

These proactive maintenance measures are crucial for preserving the noise reduction capabilities and extending the service life of exhaust components, reducing the need for premature replacements and ensuring continued compliance with noise regulations.

Moving forward, the discussion will shift to identifying suitable replacement options and evaluating the performance characteristics of various aftermarket components.

1. Noise Attenuation

Noise attenuation is the core operational principle of a noise reduction component, and its effectiveness directly correlates to the overall performance and societal impact of the device. In essence, a device’s design is centered on achieving optimal noise attenuation, reducing the amplitude of sound waves generated by the internal combustion engine as they pass through the exhaust system. The practical implementation of noise attenuation techniques, such as reactive and absorptive methodologies, dictates the extent to which a component can mitigate noise pollution. For instance, a well-designed component effectively minimizes low-frequency rumble and high-frequency rasp, contributing to a more pleasant auditory environment. In contrast, a poorly designed or deteriorated device exhibits reduced attenuation, resulting in increased noise levels that violate regulatory standards and negatively impact public health.

The effectiveness of noise attenuation is quantified through decibel reduction measurements, which directly assess the impact on noise pollution. Consider the example of a vehicle operating without a functioning noise-reducing system; the resultant noise level might exceed 90 decibels at close proximity. With a properly functioning device that incorporates sophisticated noise attenuation strategies, this level can be reduced to below 75 decibels, a substantial improvement in both perceived loudness and adherence to legal requirements. Different methods of noise attenuation influence the frequency spectrum of the exhaust note. Reactive designs utilize carefully sized chambers to cancel specific frequencies, while absorptive designs employ sound-deadening materials to dampen a broader range of tones.

Therefore, the degree of noise attenuation achieved by a noise-reducing device is not merely a technical specification but a critical determinant of its environmental and societal value. A comprehensive understanding of the principles governing noise attenuation, coupled with diligent maintenance practices, ensures that these components continue to fulfill their intended purpose of minimizing noise pollution, promoting public well-being, and maintaining compliance with established noise regulations. Failure to address attenuation shortcomings leads to increased noise pollution and potential regulatory non-compliance.

2. Exhaust Backpressure

Exhaust backpressure is a critical parameter in internal combustion engine performance, directly influenced by the design of exhaust components, including noise reduction devices. Understanding the relationship between exhaust backpressure and such devices is essential for optimizing engine efficiency and ensuring regulatory compliance.

- Definition and Impact

Exhaust backpressure refers to the resistance encountered by exhaust gases as they flow through the exhaust system. Excessive backpressure impedes the expulsion of exhaust gases from the cylinders, reducing volumetric efficiency and consequently decreasing engine power output. Conversely, insufficient backpressure can negatively affect low-end torque and fuel economy. The design of a noise reduction device directly affects exhaust backpressure; intricate internal structures and restrictive passages create greater resistance.

- Design Considerations

The internal architecture of a noise reduction device must balance noise attenuation with exhaust flow characteristics. Baffles, chambers, and perforations within the device contribute to sound wave cancellation but also introduce flow restrictions. Optimizing these design elements is crucial to minimize backpressure while maintaining effective noise reduction. Manufacturers employ computational fluid dynamics (CFD) simulations and extensive testing to refine the internal geometry and achieve the desired performance balance.

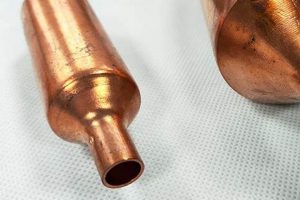

- Material Properties and Construction

The materials used in the construction of a noise reduction device influence its durability and flow characteristics. Corrosion-resistant materials, such as stainless steel, maintain structural integrity and prevent the buildup of rust or debris, which can further increase backpressure. The welding techniques and joint designs also impact flow efficiency. Smooth, continuous welds minimize turbulence and reduce flow resistance compared to rough or discontinuous welds.

- Performance Measurement and Monitoring

Exhaust backpressure can be measured using pressure sensors installed at various points in the exhaust system. Monitoring backpressure levels provides valuable insights into the health and performance of the system. Elevated backpressure readings may indicate a clogged device, a collapsed exhaust pipe, or other obstructions. Regular inspections and diagnostic testing can help identify and address these issues before they lead to significant performance degradation.

The optimal design and maintenance of a noise reduction device necessitates a careful consideration of exhaust backpressure to ensure efficient engine operation and sustained performance. Striking the right balance between noise attenuation and exhaust flow characteristics is crucial for maximizing engine power, minimizing fuel consumption, and adhering to environmental regulations. Continuous monitoring and proactive maintenance are essential for preventing excessive backpressure and preserving the long-term functionality of these critical exhaust system components.

3. Material Durability

The operational lifespan and performance of a noise-reducing component are intrinsically linked to the durability of its constituent materials. Premature failure due to material degradation results in increased noise emissions, reduced engine efficiency, and potential regulatory non-compliance. The selection of appropriate materials and manufacturing processes is, therefore, paramount to ensuring long-term functionality. The harsh operating environment, characterized by elevated temperatures, corrosive exhaust gases, and mechanical vibrations, places significant stress on component materials. Consequently, the selection criteria extend beyond mere cost considerations to encompass resistance to thermal fatigue, corrosion, and mechanical wear. For instance, a low-grade steel may exhibit rapid degradation due to oxidation and structural weakening, leading to premature failure of the device and a resultant increase in exhaust noise. In contrast, a high-grade stainless steel, appropriately treated and welded, offers superior resistance to these degradation mechanisms, thereby extending the component’s operational life and maintaining optimal noise reduction capabilities.

Consider the impact of road salt exposure on the material integrity of undercarriage-mounted devices. In regions where de-icing salts are heavily utilized, components fabricated from materials lacking adequate corrosion resistance are particularly susceptible to rapid deterioration. The ingress of salt-laden water promotes galvanic corrosion, leading to structural weakening and eventual failure. This phenomenon is frequently observed in components constructed from mild steel with inadequate protective coatings. Conversely, devices manufactured from austenitic stainless steels, known for their high chromium content, exhibit significantly enhanced resistance to corrosion, thereby minimizing the detrimental effects of road salt exposure. Furthermore, the welding processes employed in the fabrication of the component directly impact its overall durability. Poorly executed welds create stress concentrations and introduce points of vulnerability, increasing the likelihood of premature failure due to fatigue or corrosion. Proper welding techniques, such as tungsten inert gas (TIG) welding, ensure strong, uniform joints that resist cracking and provide enhanced corrosion protection.

In summation, the material durability of noise reduction components is a pivotal factor in determining their overall performance, longevity, and environmental impact. The selection of appropriate materials, coupled with robust manufacturing processes and proactive maintenance practices, is essential for ensuring long-term functionality and minimizing the risk of premature failure. Neglecting material durability considerations leads to increased noise emissions, reduced engine efficiency, and potential regulatory non-compliance, highlighting the critical importance of material selection in the design and fabrication of effective exhaust systems.

4. Component Longevity

Component longevity directly influences the operational lifespan and overall cost-effectiveness. The ability of the device to withstand prolonged exposure to harsh operating conditions is a primary determinant of its long-term value, affecting replacement frequency and associated maintenance expenses.

- Material Selection Impact

Material selection significantly affects the lifespan of noise reduction components. Corrosion-resistant materials, such as stainless steel and aluminized steel, extend component life by minimizing degradation from exposure to moisture, road salt, and exhaust gases. For example, a component constructed from low-carbon steel might require replacement within a few years due to corrosion, while a comparable component made from stainless steel could last for a decade or more.

- Weld Quality and Structural Integrity

The integrity of welds directly influences structural durability. High-quality welds prevent premature failure caused by stress concentrations and fatigue cracking. A component with poorly executed welds may experience cracking under thermal stress, leading to exhaust leaks and diminished noise reduction effectiveness, ultimately reducing its lifespan.

- Thermal Management Design

Effective thermal management minimizes heat-induced stress and degradation. Design features that promote heat dissipation, such as strategically placed heat shields and optimized internal flow paths, mitigate thermal fatigue. Components lacking adequate thermal management may experience accelerated material degradation due to excessive heat cycling, resulting in shortened lifespan.

- Environmental Exposure Considerations

Exposure to environmental factors, such as road debris, UV radiation, and extreme temperature variations, impacts component longevity. Protective coatings and robust mounting systems mitigate the effects of these factors. A component lacking adequate protection may suffer physical damage from road impacts or accelerated degradation from UV exposure, reducing its operational life.

The interrelation of these factors emphasizes that extended component lifespan is achievable through careful material selection, robust manufacturing processes, and designs that account for environmental and operational stresses. Optimizing these aspects ensures sustained performance and reduces the total cost of ownership.

5. Regulatory Compliance

Adherence to established noise emission standards is a fundamental aspect of exhaust system component design and functionality. Regulatory bodies worldwide impose restrictions on vehicle noise levels to mitigate noise pollution and protect public health. These regulations directly influence the design and performance characteristics of noise reduction devices.

- Noise Emission Standards

Governmental agencies establish maximum permissible noise levels for vehicles operating within their jurisdictions. These standards are often measured using standardized testing procedures, such as drive-by tests and stationary tests. Components must be designed to meet or exceed these requirements to ensure legal operation. Non-compliance can result in fines, vehicle recalls, and other penalties.

- Certification and Labeling

Many jurisdictions require noise reduction devices to undergo certification processes to verify compliance with established standards. Certified components are typically labeled or marked to indicate their compliance status. This labeling provides assurance to consumers and regulatory agencies that the device meets the required noise reduction performance criteria.

- Aftermarket Regulations

Regulations governing aftermarket components vary significantly by region. Some jurisdictions impose strict requirements on aftermarket noise reduction devices, mandating that they meet or exceed the performance of the original equipment manufacturer (OEM) components. Other jurisdictions have less stringent requirements, allowing for modifications that may alter noise emissions. Manufacturers and installers must be aware of the specific regulations in their target markets to ensure compliance.

- Enforcement and Penalties

Regulatory compliance is enforced through various mechanisms, including vehicle inspections, noise monitoring programs, and consumer complaints. Vehicles exceeding permissible noise levels may be subject to fines, repair orders, or even impoundment. Manufacturers and installers found to be in violation of noise regulations may face substantial penalties, including fines, license revocation, and legal action.

The stringent regulatory environment surrounding noise emissions necessitates careful consideration of noise reduction performance in the design and manufacturing of exhaust system components. Compliance with applicable regulations is not only a legal requirement but also a critical factor in protecting public health and mitigating noise pollution. Manufacturers must continually innovate and refine their designs to meet evolving regulatory standards and ensure the responsible operation of vehicles.

6. Acoustic Performance

Acoustic performance represents a primary attribute of noise reduction components, dictating the spectral characteristics and overall sound pressure levels emanating from vehicle exhaust systems. Optimization of acoustic properties requires a nuanced understanding of sound wave behavior within complex geometries and the application of specialized materials to achieve desired sonic outcomes.

- Frequency Response Shaping

A critical aspect of acoustic performance lies in the ability to shape the frequency response of the exhaust note. This involves attenuating undesirable frequencies, such as high-pitched rasp or low-frequency drone, while preserving or enhancing more desirable tonal qualities. Designs incorporating Helmholtz resonators and strategically placed baffles achieve targeted frequency attenuation. For example, a properly designed system can reduce the prominence of drone frequencies at cruising speeds, enhancing driver comfort and minimizing noise pollution. Conversely, poorly designed systems may exacerbate unwanted frequencies, resulting in an unpleasant and potentially non-compliant exhaust note.

- Sound Pressure Level Reduction

Beyond frequency response, acoustic performance is fundamentally linked to sound pressure level (SPL) reduction. The goal is to minimize the overall decibel level emitted by the exhaust system, ensuring compliance with regulatory noise limits. This requires efficient sound absorption and reflection mechanisms within the component. Internal chambers lined with sound-absorbing materials, such as fiberglass or mineral wool, effectively dampen sound waves, reducing SPL. Components lacking adequate sound absorption may fail to meet regulatory standards and contribute to noise pollution. Performance is directly related to the quality and quantity of materials used in the design and built.

- Material Acoustic Properties

The acoustic properties of construction materials play a pivotal role in determining performance characteristics. Materials with high sound absorption coefficients effectively dampen sound waves, minimizing reflections and reducing overall noise levels. Material selection considers factors such as density, porosity, and elasticity. For instance, stainless steel exhibits different acoustic properties than aluminized steel, influencing the sound characteristics of the exhaust system. The combination of the materials being used, and the design determine how successful the design is for acoustic performance.

- Flow-Induced Noise Considerations

Turbulent flow within the exhaust system can generate additional noise, negatively impacting overall acoustic performance. Optimizing internal flow paths to minimize turbulence and pressure drop is essential. Streamlined designs, smooth welds, and carefully sized perforations reduce flow-induced noise, contributing to a more refined and controlled exhaust note. Poorly designed systems may exhibit excessive turbulence, resulting in unwanted hissing or whistling sounds that detract from the acoustic experience.

These interconnected facets define acoustic performance, highlighting the importance of meticulous design and precise material selection in achieving optimal noise reduction and desired sonic characteristics. Maximizing noise reduction while addressing performance attributes can maximize consumer and performance desires. It exemplifies the complex challenges that must be addressed in crafting effective and aesthetically pleasing exhaust systems.

7. Installation Feasibility

The ease with which a noise reduction device can be installed significantly influences its market adoption and practical utility. Installation feasibility encompasses factors such as physical dimensions, mounting configurations, and compatibility with existing vehicle exhaust systems. Poor installation feasibility can lead to increased labor costs, potential damage to the vehicle, and reduced component lifespan. For example, a device designed without consideration for common vehicle undercarriage layouts may require extensive modifications to the exhaust system or vehicle chassis, rendering it impractical for many installations. This increased complexity deters both professional installers and do-it-yourself enthusiasts.

Compatibility with existing exhaust system designs is a crucial aspect of installation feasibility. A component intended as a direct replacement for an original equipment manufacturer (OEM) device should ideally utilize the same mounting points and connection methods. Deviations from these standards necessitate the use of adapters, custom fabrication, or specialized tools, increasing installation time and cost. Consider the case of a noise reduction device designed for a specific vehicle model that lacks precise dimensional accuracy. This discrepancy may require the installer to cut, weld, or bend exhaust pipes to achieve a proper fit, significantly increasing labor hours and potentially compromising the structural integrity of the exhaust system. Clear and comprehensive installation instructions are also paramount to installation feasibility. Instructions lacking detailed diagrams, torque specifications, or troubleshooting guidance can lead to errors, damage to the component, and increased frustration for the installer.

In summary, installation feasibility is an integral design consideration for noise reduction devices. Components that are easy to install, compatible with existing vehicle systems, and accompanied by clear instructions are more likely to be widely adopted and successfully implemented. Conversely, designs that prioritize performance or noise reduction at the expense of installation feasibility may face limited market acceptance and increased implementation challenges. Prioritizing ease of installation not only reduces costs and labor but also ensures the device functions as intended, maximizing its effectiveness and lifespan.

Frequently Asked Questions

This section addresses common inquiries regarding exhaust noise reduction components, providing factual information and clarifying prevalent misconceptions.

Question 1: What constitutes a failing noise reduction component, and what are the indicative symptoms?

A failing exhaust noise reduction component typically exhibits a progressive increase in exhaust noise levels, often accompanied by rattling sounds or visible signs of corrosion. Reduced engine performance and diminished fuel efficiency may also indicate a compromised component.

Question 2: What is the expected service life of a typical exhaust noise reduction component?

The service life of an exhaust noise reduction component varies based on material composition, operating conditions, and maintenance practices. Generally, components constructed from stainless steel can last 8-10 years, while those made from aluminized steel may require replacement within 5-7 years.

Question 3: Does the replacement of a noise reduction component necessitate recalibration of the engine control unit (ECU)?

The replacement of an exhaust noise reduction component typically does not require recalibration of the ECU, provided the replacement component maintains similar exhaust backpressure characteristics as the original equipment. However, modifications to the exhaust system upstream of the noise reduction component may necessitate ECU recalibration.

Question 4: What are the ramifications of operating a vehicle with a non-compliant exhaust system?

Operating a vehicle with a non-compliant exhaust system that exceeds permissible noise levels can result in fines, vehicle inspection failures, and potential impoundment, depending on local regulations and enforcement practices.

Question 5: What role does regular maintenance play in prolonging the lifespan of the exhaust noise reduction device?

Regular maintenance, including visual inspections for corrosion, prompt repairs of exhaust leaks, and avoidance of harsh chemicals, significantly prolongs the lifespan of the device. Application of rust inhibitors and protective coatings further mitigates the effects of environmental exposure.

Question 6: What criteria should guide the selection of a replacement exhaust noise reduction component?

The selection of a replacement device should prioritize material durability, noise attenuation performance, compatibility with the existing exhaust system, and compliance with relevant noise emission regulations. Consideration should also be given to the manufacturer’s reputation and warranty provisions.

In summary, exhaust noise reduction components are integral to maintaining vehicle compliance and mitigating noise pollution. Understanding their function, maintenance requirements, and regulatory implications is essential for responsible vehicle operation.

The following section will analyze various performance characteristics of different aftermarket exhaust systems.

Conclusion

The preceding analysis has illuminated the multifaceted characteristics of exhaust noise reduction components, encompassing design principles, material considerations, performance metrics, regulatory compliance, and installation dynamics. While diverse models exist, the core function remains consistent: the attenuation of engine noise to meet environmental standards and enhance the operational environment. A comprehensive understanding of these elements is vital for informed decision-making regarding system selection, maintenance, and optimization.

Ultimately, the responsible application and maintenance of effective noise reduction technology contributes to a more sustainable and harmonious coexistence between vehicular transportation and the human environment. Continued innovation and rigorous adherence to established standards will ensure the ongoing effectiveness of these critical components in mitigating noise pollution and promoting a quieter, healthier future.