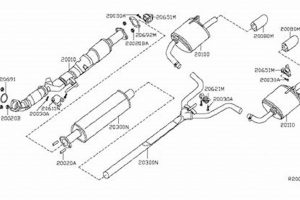

The component in question, specifically designed for a vehicle manufactured by Ford in 2007 under the Focus model name, serves as a critical part of the exhaust system. This device is engineered to reduce the noise produced by the engine’s combustion process as exhaust gases are expelled. An example of its function involves diminishing the loud roaring or hissing sounds emanating from the tailpipe during vehicle operation.

The device offers several significant advantages. Noise reduction contributes to a more comfortable driving experience for both the operator and passengers. Furthermore, many jurisdictions have regulations concerning vehicle noise levels, and this part helps ensure compliance. Historically, such components have evolved from simple, baffled designs to more sophisticated chambers that utilize principles of acoustics to attenuate specific frequencies. Early versions prioritized basic silencing, while modern iterations often balance noise reduction with exhaust flow efficiency.

Understanding the function and maintenance of this exhaust system component is paramount for ensuring optimal vehicle performance, longevity, and regulatory compliance. Subsequent sections will delve into common issues, replacement procedures, and factors to consider when selecting a suitable replacement unit for the specified automobile.

Guidance on Maintaining and Replacing the Exhaust System Component

The following information provides advice for proper maintenance and replacement procedures related to the exhaust component designed for the specified vehicle. Adherence to these guidelines can extend the lifespan of the system and maintain optimal vehicle performance.

Tip 1: Routine Inspection is Essential. Regularly examine the component for signs of corrosion, rust, or physical damage. Visual inspection, ideally during oil changes or scheduled maintenance, can identify problems early before they escalate.

Tip 2: Address Unusual Noises Promptly. Changes in exhaust sound, such as increased loudness or rattling, can indicate internal damage or leaks. Ignoring these symptoms can lead to decreased engine efficiency and potential emissions violations.

Tip 3: Consider Material Quality. When selecting a replacement, opt for components constructed from durable materials like stainless steel or aluminized steel. These materials offer superior resistance to corrosion compared to standard steel, especially in regions with harsh weather conditions.

Tip 4: Ensure Proper Installation. Incorrect installation can lead to premature failure or leaks. Use appropriate hardware and torque specifications when securing the replacement. A qualified mechanic is recommended if the installer lacks experience.

Tip 5: Check Exhaust Hangers. The hangers that support the exhaust system are susceptible to wear and tear. Replace any damaged or deteriorated hangers to prevent excessive stress on the component and the exhaust piping.

Tip 6: Understand Emission Standards. Ensure the replacement part meets or exceeds the original equipment manufacturer’s (OEM) specifications and relevant emissions standards for the vehicle’s model year. Failure to do so can result in failed emissions tests.

Tip 7: Protect Against Corrosion. Applying a rust preventative coating to the exterior of the component can extend its lifespan, particularly in areas prone to road salt or coastal environments.

Consistent monitoring, timely repairs, and the selection of quality replacements are vital for maintaining the exhaust system’s integrity and performance. Neglecting these aspects can lead to increased noise pollution, reduced fuel efficiency, and potential regulatory issues.

The following sections will provide a more in-depth examination of potential problems associated with this system and methods for ensuring long-term reliability.

1. Corrosion Resistance

Corrosion resistance is a critical attribute for the specified exhaust system component, impacting its operational lifespan and overall performance. The exhaust system, situated beneath the vehicle, is consistently exposed to environmental elements such as moisture, road salts (particularly in colder climates), and extreme temperature fluctuations. These factors contribute significantly to accelerated corrosion. Failure to address the issue of corrosion can lead to structural weakening of the component, resulting in exhaust leaks, increased noise levels, and potential degradation of engine performance. For instance, prolonged exposure to road salt can initiate rust formation, weakening the metal and eventually creating holes, thereby diminishing the muffler’s sound dampening effectiveness.

The choice of materials plays a pivotal role in determining the device’s ability to resist corrosion. Original equipment often utilized aluminized steel, offering a reasonable degree of protection. However, aftermarket replacements are available in stainless steel, which provides superior corrosion resistance. The cost of the material typically reflects its protective capabilities. Installation practices also have an indirect impact. Proper sealing of joints and the use of corrosion-resistant fasteners can prevent moisture ingress and minimize the potential for localized corrosion. Furthermore, routine maintenance, such as washing the undercarriage of the vehicle, can help remove accumulated road salts and other corrosive agents.

Ultimately, the degree of corrosion resistance directly correlates with the longevity and reliability of the exhaust system component. Selecting a component constructed from a corrosion-resistant material, combined with appropriate installation and maintenance practices, is paramount for maximizing its lifespan and ensuring continued adherence to noise emission standards. Neglecting this aspect can result in premature failure, increased repair costs, and potentially, environmental concerns related to increased noise pollution.

2. Sound Attenuation

Sound attenuation, in the context of the specified vehicle’s exhaust system component, is the process of reducing the noise generated by the engine’s combustion and exhaust expulsion. This reduction is achieved primarily through the design and construction of the component, which incorporates internal chambers and baffles. These elements are engineered to disrupt and absorb sound waves, thereby decreasing the overall noise level emitted from the vehicle’s tailpipe. Ineffective sound attenuation can manifest as excessive engine noise, potentially leading to driver discomfort, regulatory violations, and negative public perception.

The effectiveness of sound attenuation is directly linked to the internal structure of the device. A worn or damaged unit experiences diminished sound-dampening capabilities, resulting in increased exhaust noise. For instance, corrosion or internal structural failure can compromise the internal chambers, allowing sound waves to propagate more freely. This is particularly pertinent in older vehicles like the 2007 model, where the cumulative effects of environmental exposure and operational stresses can degrade the component’s sound attenuation properties over time. Replacements must adhere to or exceed original equipment specifications to maintain adequate sound dampening. Aftermarket options often advertise their sound attenuation characteristics, indicating the decibel reduction achieved.

In summary, sound attenuation is a critical functional attribute. Its degradation directly impacts the vehicle’s noise profile and compliance with noise regulations. The design and condition of the specified component are key determinants of effective sound attenuation. Regular inspection and timely replacement are necessary to preserve this critical function and ensure the vehicle operates within acceptable noise parameters. Therefore, maintenance or replacement of this exhaust system part will affect sound attenuation and noise level of the 2007 Ford Focus.

3. Exhaust Flow

Exhaust flow is a critical parameter influencing the performance of the 2007 Ford Focus and is intrinsically linked to the functionality of its muffler. The muffler, while designed to reduce noise, also has the potential to impede the efficient expulsion of exhaust gases from the engine. This section explores key facets of exhaust flow in relation to the specified vehicle component.

- Restriction and Backpressure

A primary concern is the restriction of exhaust flow, which can lead to increased backpressure within the exhaust system. Excessive backpressure reduces engine efficiency, diminishes power output, and can potentially increase fuel consumption. The design of the internal baffling within the device significantly influences backpressure. A clogged or poorly designed component creates more resistance to gas flow. As an example, a heavily corroded internal structure restricts the free movement of exhaust gases, forcing the engine to work harder to expel them.

- Muffler Design and Flow Dynamics

Different muffler designs offer varying levels of flow efficiency. Chambered designs, while effective at noise reduction, often create more backpressure compared to straight-through designs. The 2007 Ford Focus, depending on the specific trim level and original equipment, may have been fitted with different muffler configurations. Consequently, replacing the original unit with an aftermarket option that significantly alters the flow dynamics can impact engine performance.

- Impact on Engine Performance Metrics

Changes in exhaust flow directly affect key engine performance indicators such as horsepower, torque, and fuel economy. A restricted exhaust system diminishes the engine’s ability to “breathe” effectively, resulting in reduced power output, particularly at higher RPMs. This effect may be noticeable in the form of sluggish acceleration or a general lack of responsiveness. Conversely, an overly free-flowing exhaust system, while reducing backpressure, can potentially compromise low-end torque.

- Exhaust System Diameter and Flow Capacity

The diameter of the exhaust piping, including the inlet and outlet of the component, influences the overall flow capacity. A smaller diameter restricts flow, while a larger diameter allows for greater flow volume. However, simply increasing the diameter without considering other factors, such as engine displacement and intended usage, can lead to inefficiencies. Matching the diameter of the replacement part to the original specification is crucial for maintaining optimal performance.

The interplay between exhaust flow and the specified vehicle component is a critical consideration for maintaining optimal engine performance. Selecting a replacement part that balances noise reduction with flow efficiency is paramount. Ignoring the impact of the component on exhaust flow can lead to diminished power, reduced fuel economy, and potential long-term engine damage. Therefore, assessing exhaust flow characteristics when selecting a 2007 Ford Focus muffler replacement is essential.

4. Component Lifespan

The lifespan of an exhaust system component on a 2007 Ford Focus is a function of several interrelated factors. Understanding these factors is crucial for vehicle owners seeking to optimize maintenance schedules and minimize repair costs. The duration of operational effectiveness is not solely determined by manufacturing quality but is also significantly influenced by environmental conditions and driving habits.

- Material Composition and Environmental Exposure

The materials used in the construction of the muffler directly impact its longevity. While original equipment often utilized aluminized steel, providing some corrosion resistance, exposure to road salts, moisture, and temperature fluctuations accelerates degradation. For instance, in regions with harsh winters where road salt is prevalent, a standard aluminized steel component may exhibit signs of significant corrosion within five years, while a stainless-steel aftermarket replacement could potentially last twice as long. This underscores the importance of material selection in determining the component’s service life.

- Driving Conditions and Usage Patterns

Driving patterns and usage conditions contribute significantly to the wear and tear experienced by the exhaust system. Frequent short trips, where the exhaust system does not reach optimal operating temperature, can lead to the accumulation of condensation within the muffler, promoting internal corrosion. Conversely, long-distance highway driving allows the system to fully heat up, evaporating moisture and potentially extending its lifespan. Aggressive driving habits, involving rapid acceleration and deceleration, can also subject the system to increased stress, potentially shortening its lifespan.

- Maintenance Practices and Preventive Measures

Regular maintenance and the implementation of preventive measures can substantially extend the service life of the specified exhaust component. Periodic visual inspections can identify early signs of corrosion or damage, allowing for timely repairs and preventing more extensive deterioration. Applying rust-inhibiting coatings to the exterior of the muffler can provide an additional layer of protection against environmental elements. Furthermore, ensuring proper drainage of accumulated condensation through weep holes, if present in the design, is essential for minimizing internal corrosion.

- Aftermarket Replacements and Quality Considerations

When the original equipment part requires replacement, the quality and specifications of the aftermarket component are crucial factors affecting its lifespan. Selecting a replacement that meets or exceeds OEM standards is essential for ensuring comparable or improved durability. Opting for a lower-quality, less expensive replacement may result in a shorter service life, potentially negating any initial cost savings due to the need for more frequent replacements. Therefore, a comprehensive evaluation of material quality, design, and warranty terms is vital when choosing an aftermarket replacement.

In summary, the lifespan of the exhaust system component on a 2007 Ford Focus is a complex interplay of material composition, environmental factors, driving conditions, maintenance practices, and replacement part quality. Vehicle owners who proactively address these factors can significantly extend the service life of the component, reduce maintenance costs, and ensure the continued operational integrity of the vehicle’s exhaust system.

5. OEM Specification

The term “OEM specification,” when applied to a 2007 Ford Focus muffler, refers to the precise design, material, and performance parameters established by Ford Motor Company for the original component installed during vehicle assembly. Adherence to these specifications is paramount for ensuring proper fitment, functionality, and compliance with emissions and noise regulations. A component not meeting the original equipment manufacturer’s standards can lead to a range of issues, from reduced engine performance to failed emissions tests. For instance, a non-OEM muffler might have inadequate sound dampening capabilities, resulting in increased noise pollution, or it may create excessive backpressure, negatively impacting fuel economy and horsepower.

The importance of adhering to the OEM specification extends beyond basic functionality. The original muffler was engineered to work in harmony with the vehicle’s entire exhaust system, including the catalytic converter and oxygen sensors. Deviations from the OEM design can disrupt this carefully calibrated balance. A practical example lies in the potential for altered exhaust gas flow. If a replacement muffler significantly restricts or enhances exhaust flow compared to the original, it can affect the catalytic converter’s efficiency and potentially trigger diagnostic trouble codes, illuminating the check engine light. Moreover, using a non-OEM muffler may void the vehicle’s warranty in certain cases, particularly if the component is directly linked to a system failure.

In conclusion, understanding and respecting the OEM specification for a 2007 Ford Focus muffler is critical for maintaining the vehicle’s performance, reliability, and regulatory compliance. While aftermarket options offer a range of prices and features, opting for a component that closely aligns with the original manufacturer’s standards minimizes the risk of adverse effects and ensures the vehicle operates as intended. Neglecting the significance of OEM specification can lead to unforeseen complications, increased maintenance costs, and potential environmental concerns. Therefore, making informed decisions based on OEM specifications is the cornerstone of responsible vehicle maintenance.

6. Installation Integrity

Installation integrity is paramount to the proper functioning and longevity of a 2007 Ford Focus muffler. A correctly installed component ensures optimal performance, compliance with noise regulations, and prevents premature failure of the exhaust system. The following points detail key aspects of installation integrity concerning this specific vehicle component.

- Correct Mounting and Alignment

Proper mounting of the muffler is essential for preventing stress on the exhaust system. Misalignment can cause undue strain on the exhaust piping and hangers, leading to cracks or breaks. Real-world examples include improperly tightened clamps or misaligned hangers, resulting in vibrations and eventual detachment of the muffler. Such failures can lead to increased noise levels and potential damage to other vehicle components.

- Secure Fastening and Torque Specifications

The fasteners used to secure the muffler must be properly tightened to the manufacturer’s specified torque. Under-tightening can result in exhaust leaks, reducing engine efficiency and increasing noise. Over-tightening, conversely, can damage the fasteners or mounting points, leading to premature failure. Incorrect torque settings often manifest as hissing sounds near the connection points, indicating escaping exhaust gases.

- Proper Sealing of Joints

The joints between the muffler and the exhaust piping must be properly sealed to prevent leaks. Gaskets, sealants, or welding are commonly used to achieve this. Inadequate sealing can result in exhaust leaks, reducing engine performance and potentially exposing vehicle occupants to harmful exhaust gases. A telltale sign of inadequate sealing is a sooty residue around the joint, indicating escaping exhaust fumes.

- Compatibility of Components

Ensuring compatibility between the muffler and the existing exhaust system is critical. Using incompatible components, such as a muffler with incorrect inlet/outlet diameters, can compromise installation integrity. Adapting mismatched parts can lead to leaks, increased backpressure, and reduced engine performance. Specifically, using a muffler not designed for the 2007 Ford Focus can affect its mounting points, creating stress and potential failures.

In summation, installation integrity is not merely a procedural step but a critical determinant of the 2007 Ford Focus muffler’s functionality and lifespan. Adhering to correct mounting procedures, torque specifications, joint sealing, and component compatibility is essential for maximizing performance, minimizing environmental impact, and ensuring the long-term reliability of the vehicle’s exhaust system.

7. Material Durability

The longevity and effectiveness of a 2007 Ford Focus muffler are intrinsically linked to material durability. The muffler’s operational environment is characterized by exposure to corrosive elements, thermal stress, and mechanical vibration. Consequently, the material composition directly dictates the component’s resistance to degradation and its ability to maintain structural integrity over time. Inadequate material durability results in premature failure, leading to increased noise pollution, reduced engine performance, and the necessity for frequent replacements. For example, a muffler constructed from low-grade steel will rapidly corrode in regions with significant road salt usage, potentially failing within a few years. Such failures necessitate costly repairs and increase the vehicle’s overall operational expenses.

The selection of materials for the 2007 Ford Focus muffler often involves a trade-off between cost and performance. Original equipment mufflers typically utilized aluminized steel, which offers a moderate level of corrosion resistance at a reasonable price point. However, aftermarket replacements are available in more durable materials, such as stainless steel, which provide significantly enhanced resistance to corrosion and thermal degradation. The increased cost of stainless steel is often justified by its extended lifespan and reduced maintenance requirements. Furthermore, the design of the muffler, including the thickness of the metal and the presence of reinforcing features, also contributes to its overall durability. These design considerations are crucial for withstanding the mechanical stresses encountered during vehicle operation, such as vibration and impact from road debris.

In conclusion, material durability is a fundamental consideration in the context of a 2007 Ford Focus muffler. The choice of materials directly impacts the component’s lifespan, its ability to maintain performance standards, and the overall cost of vehicle ownership. Selecting a muffler constructed from durable materials, such as stainless steel, combined with proper installation and maintenance practices, is essential for maximizing its longevity and ensuring the continued reliable operation of the vehicle’s exhaust system. Therefore, the material durability of the exhaust system part is a critical factor that need to consider.

Frequently Asked Questions

The following section addresses common inquiries regarding the exhaust system component specific to the stated vehicle model. The information aims to provide clarity on performance, maintenance, and replacement considerations.

Question 1: What is the expected lifespan of the component?

The operational lifespan varies depending on material composition, environmental conditions, and driving habits. Aluminized steel components typically last 5-7 years, while stainless steel replacements can extend to 10 years or more.

Question 2: How does a malfunctioning component affect vehicle performance?

A deteriorated component can lead to increased noise, reduced fuel efficiency, diminished horsepower, and potential emissions test failures. Exhaust leaks and increased backpressure negatively impact engine operation.

Question 3: What are the key signs indicating a need for replacement?

Key indicators include excessive exhaust noise, visible corrosion or damage, rattling sounds emanating from the exhaust system, and a noticeable decrease in fuel economy or engine performance.

Question 4: Are there specific OEM specifications to consider when replacing the component?

Yes, adhering to OEM specifications regarding dimensions, material, and flow characteristics is crucial. Deviations can result in improper fitment, compromised performance, and potential regulatory non-compliance.

Question 5: What are the primary benefits of upgrading to a stainless-steel replacement?

Stainless steel offers superior corrosion resistance compared to aluminized steel, resulting in a longer lifespan and reduced maintenance requirements, particularly in regions with harsh weather conditions.

Question 6: Is professional installation recommended for this component?

While DIY installation is possible, professional installation is generally recommended to ensure proper fitment, sealing, and torque specifications are met. Incorrect installation can lead to premature failure and potential safety hazards.

Understanding these aspects is essential for maintaining the optimal performance and longevity of the specified vehicle’s exhaust system. Regular inspections and timely replacements are key to preventing more extensive and costly repairs.

The subsequent section will delve into troubleshooting common issues associated with the component and effective resolution strategies.

Conclusion

The preceding analysis has explored the multifaceted role of the 2007 Ford Focus muffler within the vehicle’s exhaust system. The examination encompassed material durability, sound attenuation properties, exhaust flow dynamics, adherence to OEM specifications, the critical importance of proper installation, and the expected lifespan of the component. Each of these elements contributes significantly to the overall performance, regulatory compliance, and longevity of the exhaust system.

A thorough understanding of these factors empowers vehicle owners to make informed decisions regarding maintenance and replacement strategies. The selection of appropriate replacement parts, coupled with diligent monitoring and proactive maintenance, will ensure continued optimal operation and prevent costly repairs. Future advancements in material science and exhaust system design may further enhance the efficiency and durability of components, reinforcing the importance of staying informed about best practices in vehicle maintenance.