A component designed to reduce the noise output of diesel engines, specifically those utilizing a 4-inch exhaust piping system. This device operates by dampening sound waves generated during the engine’s combustion process and their expulsion through the exhaust system. Examples include aftermarket replacements designed for improved performance and reduced noise levels in trucks and heavy equipment.

The significance of this lies in its ability to mitigate environmental noise pollution and improve operator comfort. Historically, these were often basic, restrictive designs. Modern iterations, however, often incorporate advanced baffling and flow-through technologies to minimize backpressure, contributing to improved engine efficiency alongside noise reduction. Benefits extend to compliance with noise regulations in various operating environments.

Further exploration will detail the construction materials, performance considerations, installation procedures, and common maintenance requirements associated with these noise reduction devices.

Essential Considerations

Selecting the appropriate component requires careful evaluation of several factors. These considerations ensure optimal performance, longevity, and compliance with operational requirements.

Tip 1: Material Selection: Stainless steel construction offers superior corrosion resistance, crucial for longevity, particularly in environments with frequent exposure to road salts or other corrosive agents. Aluminized steel represents a cost-effective alternative, providing adequate protection in less demanding conditions.

Tip 2: Internal Design: Baffled designs offer effective noise reduction but can increase backpressure. Straight-through designs minimize backpressure, potentially improving engine performance, but may offer less noise attenuation. Evaluate the trade-offs based on operational priorities.

Tip 3: Diameter Compatibility: Ensure precise matching of inlet and outlet diameters with the existing exhaust system (4-inch in this case) to avoid flow restrictions or the need for adapters. Incorrect sizing can negatively impact engine performance and exhaust system integrity.

Tip 4: Regulatory Compliance: Verify adherence to local noise regulations, particularly if operating within noise-sensitive areas. Select a model certified to meet or exceed applicable standards to avoid potential fines or operational restrictions.

Tip 5: Installation Procedures: Proper installation is critical. Ensure secure mounting to prevent vibrations and stress fractures. Utilize appropriate clamps and hangers to maintain structural integrity over time.

Tip 6: Welding Considerations: If welding is required, employ proper welding techniques and materials compatible with the component’s composition to ensure a robust and leak-free connection.

Tip 7: Measurement Accuracy: Confirm the exact outer diameter to prevent misalignment with other exhaust components, especially during clamp fitting

Tip 8: Periodic Inspection: Regularly inspect for signs of corrosion, damage, or leaks. Address any issues promptly to prevent further degradation and maintain optimal performance.

Careful attention to these considerations during the selection and installation process will contribute to a quieter, more efficient, and compliant operation.

The subsequent sections will delve into specific applications and troubleshooting techniques.

1. Noise Reduction Levels

Noise reduction capabilities are a primary characteristic differentiating models and influencing their suitability for specific diesel engine applications, particularly within the 4-inch exhaust system category. Achieving the desired level of sound attenuation necessitates a careful consideration of design features and operating environments.

- Insertion Loss Measurement

Insertion loss, measured in decibels (dB), quantifies the noise reduction performance. This measurement represents the difference in sound pressure level before and after the muffler is installed. Higher insertion loss values indicate greater noise attenuation. Examples include models marketed for residential areas, often engineered for insertion loss exceeding 20 dB.

- Frequency-Specific Attenuation

Diesel engines generate noise across a broad frequency spectrum. Some models are designed for optimal attenuation at specific frequencies, often targeting the dominant low-frequency rumble. Specialized designs may incorporate resonators or tuned chambers to effectively dampen these targeted frequencies, improving overall sound quality.

- Backpressure Considerations

While maximizing noise reduction is desirable, it must be balanced against potential increases in backpressure. Excessive backpressure can negatively impact engine performance, reducing fuel efficiency and power output. Design features such as straight-through cores and optimized baffling aim to minimize backpressure while maintaining adequate noise control.

- Construction Materials and Longevity

The effectiveness of noise reduction can degrade over time due to corrosion or material fatigue. Stainless steel construction offers superior corrosion resistance, ensuring consistent performance in harsh environments. Regular inspections and maintenance are essential to identify and address any deterioration that could compromise noise attenuation capabilities.

The selection of a suitable noise reduction component requires a careful evaluation of insertion loss specifications, frequency-specific attenuation characteristics, backpressure considerations, and material durability. Aligning these factors with the intended application ensures both effective noise control and sustained engine performance within the 4-inch diesel exhaust system.

2. Exhaust Flow Dynamics

Exhaust flow dynamics are critically important when selecting and implementing a noise reduction component for a 4-inch diesel exhaust system. The internal design directly influences the movement of exhaust gases, affecting engine backpressure, overall performance, and the effectiveness of sound attenuation.

- Internal Geometry and Backpressure

The internal structure, whether utilizing baffles, chambers, or straight-through designs, dictates the resistance encountered by exhaust gases. Baffled systems generally offer higher noise reduction but can create greater backpressure, impeding exhaust flow. Conversely, straight-through designs minimize backpressure, promoting efficient flow, but may provide less effective sound dampening. The goal is to achieve a balance that optimizes both noise reduction and engine performance within acceptable parameters. For example, a highly restrictive silencer can lead to reduced horsepower and increased fuel consumption.

- Gas Velocity and Scavenging

The velocity of exhaust gases within the system influences the scavenging process the removal of spent combustion gases from the cylinders. An efficient exhaust system promotes effective scavenging, improving combustion efficiency and overall engine performance. The internal design should facilitate smooth and consistent gas flow to minimize turbulence and maximize scavenging. An inappropriately sized or designed component can disrupt gas velocity and negatively impact the engine’s breathing capacity.

- Resonance and Wave Propagation

The internal chambers and pathways within the component affect the propagation of sound waves. Some designs utilize resonance principles to cancel out specific frequencies, enhancing sound attenuation. The precise configuration of these chambers and pathways is crucial for achieving optimal performance. Improper design can lead to amplification of certain frequencies, resulting in an undesirable exhaust note.

- Turbulence and Flow Resistance

Sharp bends, constrictions, or rough surfaces within the internal structure can create turbulence, increasing flow resistance and backpressure. Smooth, gradual transitions and optimized internal pathways minimize turbulence, promoting efficient exhaust flow and reducing energy losses. Careful attention to these details is essential for maximizing performance and minimizing fuel consumption.

Understanding these exhaust flow dynamics is essential when choosing a 4-inch diesel exhaust silencer. A properly selected and installed component will not only reduce noise levels but also maintain or even improve engine performance by optimizing exhaust gas flow and minimizing backpressure.

3. Material Corrosion Resistance

The selection of materials with high corrosion resistance is paramount in the design and longevity of a component integrated into a 4-inch diesel exhaust system. Given the harsh operating environment, characterized by high temperatures, exposure to corrosive gases, and potential contact with road salts, material integrity directly impacts the lifespan and performance of the entire system.

- Stainless Steel Grades

Specific grades of stainless steel, such as 304 and 409, are frequently employed due to their elevated chromium content, which forms a passive oxide layer, inhibiting rust formation. Grade 304 offers superior resistance to chloride-induced corrosion, prevalent in coastal regions, while Grade 409 provides a more cost-effective solution with adequate corrosion resistance for less demanding environments. The choice hinges on the balance between cost and anticipated exposure to corrosive elements. A 4 inch component constructed from 304 stainless steel is expected to outlast one made of aluminized steel in environments with high salt exposure.

- Aluminized Steel Composition

Aluminized steel provides a layer of aluminum alloy bonded to the steel substrate. This aluminum coating acts as a sacrificial anode, corroding preferentially to protect the underlying steel. While offering enhanced corrosion protection compared to bare steel, aluminized steel is more susceptible to degradation in highly acidic or alkaline conditions. Surface scratches exposing the steel beneath can initiate localized corrosion. A 4 inch aluminized model provides a good balance of cost-effectiveness and increased longevity.

- Weld Integrity and Corrosion Prevention

Welding processes can compromise corrosion resistance if not properly executed. The heat-affected zone near welds can experience changes in microstructure, rendering it more susceptible to corrosion. Employing appropriate welding techniques, such as using compatible filler metals and post-weld heat treatment, is essential to maintain corrosion resistance in welded joints. A poorly welded 4 inch component can fail prematurely due to corrosion at the weld site.

- Protective Coatings and Treatments

In addition to base material selection, supplemental protective coatings can further enhance corrosion resistance. Ceramic coatings, for example, provide a barrier against high temperatures and corrosive gases. Regular application of rust inhibitors can also prolong the lifespan of components exposed to harsh environments. A 4 inch exhaust silencer with a ceramic coating offers additional protection against degradation in extreme conditions.

The interconnectedness of material selection, welding practices, and protective coatings dictates the overall corrosion resistance of a 4-inch diesel exhaust component. Careful consideration of these factors ensures prolonged operational life, reduced maintenance costs, and sustained performance within the challenging environment of a diesel exhaust system.

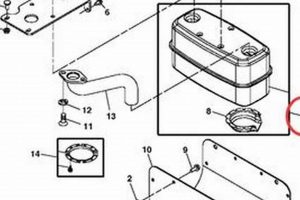

4. Dimensional Accuracy

Dimensional accuracy is a critical factor in the selection and installation of a “diesel muffler 4 inch.” It directly impacts the fit, function, and overall performance of the exhaust system. Deviations from specified dimensions can lead to leaks, reduced noise attenuation, increased backpressure, and potential damage to other exhaust components. The “4 inch” designation refers to the nominal diameter of the inlet and outlet, intended to match the existing exhaust piping. However, manufacturing tolerances and variations can result in discrepancies, necessitating careful measurement and verification during installation. For instance, a muffler with an inlet slightly smaller than 4 inches will create a bottleneck, increasing backpressure and potentially reducing engine efficiency. Conversely, an oversized inlet may lead to exhaust leaks, compromising noise reduction and creating a safety hazard.

The importance of dimensional accuracy extends beyond the inlet and outlet diameters. The overall length and body diameter must also be within acceptable limits to ensure proper clearance within the vehicle’s chassis and prevent interference with other components. A muffler that is too long or too wide may require modifications to the exhaust system or even the vehicle itself, increasing installation costs and complexity. Consider a situation where the body diameter is larger than specified, interfering with the vehicle’s frame; this could necessitate costly modifications or the selection of an alternative model. Accurate measurements and adherence to manufacturer specifications are essential to avoid such complications.

In summary, dimensional accuracy is not merely a technical detail but a fundamental requirement for the proper functioning of a “diesel muffler 4 inch.” Inaccuracies can lead to performance degradation, safety concerns, and increased installation costs. Therefore, careful attention to dimensional specifications and verification during installation are crucial for ensuring optimal performance and longevity of the exhaust system. Challenges remain in maintaining consistent manufacturing tolerances across different brands and models, highlighting the need for thorough inspection and, when necessary, professional installation assistance.

5. Installation Compatibility

Installation compatibility represents a crucial consideration when integrating a noise-reduction component into a 4-inch diesel exhaust system. Variances in vehicle design, exhaust system configurations, and the specific dimensions of the chosen component necessitate careful attention to ensure seamless integration. Compatibility issues can lead to installation difficulties, compromised performance, and potential damage to both the muffler and surrounding components.

- Exhaust Pipe Diameter and Alignment

The inlet and outlet diameters of the muffler must precisely match the existing 4-inch exhaust piping to ensure a secure and leak-free connection. Misalignment or dimensional discrepancies can necessitate the use of adapters or modifications, increasing installation complexity and potentially introducing flow restrictions. For example, a slight mismatch in diameter may require welding, potentially compromising the structural integrity or corrosion resistance of the joint. Correct alignment is crucial to avoid stress on the exhaust hangers and prevent premature failure.

- Mounting Configuration and Chassis Clearance

The mounting points and overall dimensions of the muffler must be compatible with the vehicle’s chassis and exhaust system hangers. Insufficient clearance can lead to vibrations, noise, and potential damage to the muffler or surrounding components. Universal mufflers often require modifications to the exhaust hangers to ensure proper fitment. Some vehicle models may have limited space, requiring a compact muffler design to avoid interference with other undercarriage components.

- Sensor Placement and Accessibility

The installation should not obstruct or interfere with the placement or accessibility of any existing exhaust sensors, such as oxygen sensors or temperature probes. Relocating or disabling these sensors can negatively impact engine performance and emissions control. Some aftermarket mufflers may require sensor extensions or modifications to the exhaust piping to accommodate sensor placement. Ensuring proper sensor function is essential for maintaining optimal engine operation and regulatory compliance.

- Welding Requirements and Material Compatibility

If welding is required to connect the muffler to the existing exhaust system, the welding process must be performed by a qualified technician using appropriate techniques and materials. Incompatible welding rods or improper welding procedures can compromise the structural integrity and corrosion resistance of the joint. The materials of the muffler and exhaust piping must also be compatible to prevent galvanic corrosion. For instance, welding a stainless steel muffler to a mild steel exhaust system can lead to accelerated corrosion of the mild steel components.

Effective integration of a “diesel muffler 4 inch” requires a thorough understanding of the vehicle’s exhaust system configuration and careful selection of a muffler with compatible dimensions, mounting points, and sensor placement. Addressing potential compatibility issues during the planning stages can prevent costly modifications, ensure optimal performance, and prolong the lifespan of both the muffler and the exhaust system.

Frequently Asked Questions

The following addresses common inquiries regarding the selection, application, and maintenance of a 4-inch diesel exhaust silencer. Understanding these aspects is crucial for ensuring optimal performance and longevity.

Question 1: What constitutes a “4-inch” diesel muffler?

The designation “4-inch” refers to the nominal outer diameter of the inlet and outlet connections designed to interface with a 4-inch exhaust piping system. Exact outer dimensions may vary slightly due to manufacturing tolerances, but the component is intended for direct connection to a 4-inch exhaust pipe.

Question 2: What are the primary benefits of installing a noise reduction component on a diesel engine?

The primary benefit is a reduction in exhaust noise, contributing to a more comfortable operating environment and potential compliance with noise regulations. Secondary benefits can include optimized exhaust flow (depending on the internal design) and improved engine performance. A quality component decreases noise without significantly impeding performance.

Question 3: How does the internal design affect performance?

Internal design, typically baffled or straight-through, directly impacts backpressure and noise attenuation. Baffled designs generally offer greater noise reduction at the expense of increased backpressure. Straight-through designs prioritize minimal backpressure but may offer less noise attenuation. Selecting a design appropriate for the specific engine and operating conditions is important.

Question 4: What materials are commonly used in construction, and what are their advantages?

Common materials include aluminized steel and stainless steel. Aluminized steel provides adequate corrosion resistance at a lower cost. Stainless steel offers superior corrosion resistance, particularly in harsh environments, contributing to a longer lifespan. The choice depends on budget and anticipated environmental exposure.

Question 5: How critical is proper installation?

Proper installation is essential for achieving optimal performance and preventing exhaust leaks. Secure mounting is necessary to avoid vibrations and potential damage. Adherence to manufacturer instructions and the use of appropriate clamps or welding techniques are crucial. Improper installation can negatively impact both noise reduction and engine performance.

Question 6: What maintenance is required?

Periodic inspection for corrosion, leaks, and damage is recommended. Addressing any issues promptly will prevent further degradation and maintain optimal performance. Depending on operating conditions, occasional cleaning may also be necessary to remove accumulated debris.

Careful consideration of these factors will facilitate informed decisions regarding the selection, installation, and maintenance of a 4-inch diesel exhaust silencer.

The subsequent section will address troubleshooting common problems.

In Summary

This exploration has detailed the critical aspects of the 4-inch diesel muffler, encompassing material selection, internal design variations, installation procedures, and ongoing maintenance. Understanding these elements is crucial for effective noise reduction, optimized exhaust flow, and long-term system integrity. Proper selection and installation mitigate noise pollution, enhance engine efficiency, and ensure regulatory compliance.

The informed application of this knowledge is paramount. Continued adherence to best practices in selection, installation, and maintenance guarantees a quieter, more efficient operational environment, contributing to both environmental responsibility and enhanced equipment performance.

![Sheldon's Custom Muffler: Performance & Sound [Shop Now] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Sheldon's Custom Muffler: Performance & Sound [Shop Now] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-208-300x200.jpg)