A component integral to vehicle exhaust systems, it plays a pivotal role in diminishing the noise generated by the engine’s combustion process. Functionally, it employs a series of chambers and tubes designed to reflect and absorb sound waves. For instance, a typical passenger vehicle will utilize one to mitigate the high-decibel sounds produced during operation, ensuring compliance with noise pollution regulations.

The significance of this device lies in its contribution to environmental and public health. By reducing exhaust noise, it minimizes noise pollution in urban and residential areas. Furthermore, its development has been influenced by evolving environmental standards and the increasing demand for quieter vehicles. Early iterations were relatively simple, but modern designs incorporate sophisticated acoustic engineering principles for enhanced noise reduction and optimal engine performance.

The following discussion will delve into specific aspects of exhaust system components, examining their construction, functionality, maintenance requirements, and the potential consequences of system failure.

Maintenance and Longevity Guidance

Optimizing the performance and extending the lifespan of an exhaust system requires adherence to specific maintenance practices and an understanding of potential vulnerabilities.

Tip 1: Conduct Regular Visual Inspections: Periodically examine the exhaust system for signs of corrosion, rust, or physical damage. Pay close attention to welded seams and connection points, as these areas are particularly susceptible to failure.

Tip 2: Address Minor Issues Promptly: Small cracks or holes can rapidly expand, leading to more significant problems. Addressing these issues early can prevent costly repairs or replacements.

Tip 3: Be Mindful of Driving Conditions: Frequent short trips can lead to moisture buildup within the exhaust system, accelerating corrosion. Similarly, driving on salted roads can contribute to rust formation.

Tip 4: Ensure Proper Mounting and Support: Inspect the exhaust system’s hangers and supports to ensure they are intact and properly positioned. Loose or damaged supports can cause excessive vibration and stress on the system.

Tip 5: Monitor Engine Performance: Unusual noises, reduced fuel efficiency, or a decrease in engine power can indicate an exhaust system problem. These symptoms should be investigated promptly.

Tip 6: Consider Protective Coatings: Applying a heat-resistant, corrosion-resistant coating to the exhaust system can provide an additional layer of protection against environmental factors.

Tip 7: Consult Qualified Technicians: For complex repairs or concerns, seeking professional assistance is crucial. Experienced technicians can accurately diagnose issues and perform necessary repairs to ensure optimal system performance.

Implementing these strategies will contribute to the long-term health and efficiency of the exhaust system, mitigating the risk of premature failure and maintaining optimal vehicle operation.

The subsequent section will address the consequences of neglecting these maintenance practices and the potential impact on vehicle performance and environmental compliance.

1. Noise Reduction Effectiveness

Noise reduction effectiveness is a primary design consideration and functional outcome of a muffler. Its capacity to attenuate exhaust noise directly impacts vehicle comfort, regulatory compliance, and environmental impact. The following examines critical facets that determine this effectiveness.

- Internal Chamber Design and Acoustic Baffling

The internal architecture of a muffler, encompassing chamber size, shape, and the placement of acoustic baffles, dictates its ability to dissipate sound energy. Complex designs redirect sound waves, causing them to interfere destructively and reduce amplitude. Examples include resonance chambers tuned to specific frequencies and perforated tubes that diffuse sound energy. Ineffective baffling leads to increased exhaust noise and potential regulatory violations.

- Material Properties and Sound Absorption

The materials used in muffler construction influence their ability to absorb and dampen sound waves. Dense materials like steel provide a barrier to sound transmission, while internal packing materials like fiberglass or mineral wool absorb sound energy. Degradation of these materials over time reduces noise reduction effectiveness and necessitates replacement.

- Exhaust Flow Restriction and Backpressure

Muffler designs must balance noise reduction with minimal exhaust flow restriction. Excessive backpressure, caused by overly restrictive designs, can negatively impact engine performance, reducing power and fuel efficiency. Effective mufflers optimize internal flow paths to minimize backpressure while maximizing noise attenuation.

- Helmholtz Resonance and Frequency Attenuation

Some mufflers incorporate Helmholtz resonators, which are chambers designed to cancel specific frequencies of sound. These resonators target dominant noise frequencies generated by the engine. Precise tuning of these resonators is crucial for achieving effective noise reduction at the targeted frequencies; however, their effectiveness may be limited for other noise frequencies.

The integration of these facets determines the overall noise reduction effectiveness. By addressing each element meticulously, manufacturers strive to deliver products that minimize noise pollution, enhance vehicle drivability, and ensure compliance with stringent environmental regulations.

2. Material durability demands

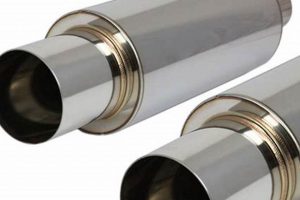

The operational environment of a vehicle exhaust system subjects its components, including the muffler, to considerable stress. Material selection is, therefore, paramount to ensure longevity and consistent performance. The material durability demands placed on a muffler directly influence its ability to withstand thermal stress, corrosive substances, and physical impacts encountered during typical vehicle operation.

- Thermal Cycling Resistance

Exhaust systems experience rapid and significant temperature fluctuations. Materials must resist degradation from repeated expansion and contraction. For example, stainless steel alloys are chosen for their ability to maintain structural integrity at high temperatures and their resistance to thermal fatigue. Inadequate thermal cycling resistance can lead to cracking and eventual failure of the muffler.

- Corrosion Resistance to Exhaust Gases

Exhaust gases contain corrosive compounds, including water vapor, sulfur oxides, and nitrogen oxides. Materials must withstand prolonged exposure to these substances without significant degradation. Aluminized steel offers a cost-effective compromise, providing a protective layer against corrosion, although it may not be as durable as stainless steel under severe conditions. Failure to resist corrosion leads to thinning of the material and eventual exhaust leaks.

- Resistance to Road Debris and Physical Impacts

Mufflers are exposed to potential impacts from road debris, such as rocks and salt. Materials must possess sufficient strength and impact resistance to prevent damage. Thicker gauge materials and protective coatings can mitigate the risk of physical damage. Insufficient resistance to physical impacts can result in dents, punctures, and compromised structural integrity.

- Weld Integrity and Joint Strength

The quality of welds and the strength of joints are critical to overall durability. Welds must withstand thermal stress, vibration, and corrosive environments without cracking or separating. High-quality welding techniques and appropriate filler metals are essential for ensuring joint integrity. Weak welds can lead to exhaust leaks, increased noise, and premature failure of the muffler.

The fulfillment of material durability demands directly affects the functional lifespan of a muffler. Selecting materials that can withstand the harsh operating conditions is crucial for minimizing maintenance requirements, ensuring optimal vehicle performance, and reducing the environmental impact associated with frequent replacements.

3. Installation precision impact

Installation precision directly and significantly affects the performance, longevity, and overall effectiveness of a muffler within a vehicle’s exhaust system. Deviations from specified installation procedures can compromise the muffler’s intended functionality, potentially leading to reduced noise attenuation, increased emissions, and premature component failure. The following outlines critical facets influenced by installation accuracy.

- Exhaust Leak Prevention

Proper alignment and secure connection of the muffler to the exhaust pipe are paramount for preventing exhaust leaks. Inadequate tightening of clamps, misaligned flanges, or damaged gaskets can create pathways for exhaust gases to escape. Exhaust leaks not only increase noise levels but also pose a safety hazard due to the potential for carbon monoxide intrusion into the vehicle cabin. Furthermore, leaks can disrupt the intended exhaust flow, impacting engine performance and emissions control.

- Stress Reduction and Component Alignment

Correct muffler positioning and support are essential for minimizing stress on the exhaust system. Improper alignment can induce strain on mounting points, exhaust pipes, and the muffler itself. This stress can lead to premature cracking, corrosion, and eventual failure of system components. Proper support hangers and brackets should be used to maintain the correct alignment and distribute the weight of the muffler evenly.

- Clearance and Thermal Isolation

Adequate clearance between the muffler and surrounding vehicle components is necessary to prevent heat transfer and potential damage. Insufficient clearance can lead to overheating of adjacent components, such as fuel lines or wiring harnesses, increasing the risk of fire or component malfunction. Additionally, proper thermal isolation helps to maintain optimal operating temperatures for the catalytic converter and other emission control devices.

- Sensor Functionality and Feedback Loops

In modern vehicles, the exhaust system often incorporates sensors, such as oxygen sensors, that provide feedback to the engine control unit (ECU). Incorrect muffler installation can affect the accuracy of these sensors, leading to inaccurate readings and potentially triggering diagnostic trouble codes (DTCs). Compromised sensor data can negatively impact engine performance, fuel efficiency, and emissions control effectiveness.

The cumulative effect of these facets underscores the critical importance of precise installation procedures. Adhering to manufacturer specifications and employing qualified technicians are essential for ensuring the optimal performance, longevity, and safety of the muffler and the overall exhaust system.

4. Corrosion resistance value

The operational environment exposes a “safeway muffler,” or any automotive muffler, to corrosive elements, predominantly water, road salt, and acidic compounds present in exhaust gases. The inherent resistance of the materials used in its construction dictates the muffler’s service life and overall performance. Lower corrosion resistance precipitates premature failure, necessitating replacement and increasing vehicle maintenance costs. Conversely, a higher corrosion resistance value translates to extended durability and sustained functionality under harsh conditions.

Stainless steel mufflers exemplify high corrosion resistance. Their chromium content forms a passive oxide layer, preventing rust formation and protecting the underlying metal. Aluminized steel also provides corrosion protection, though its performance degrades under prolonged exposure to extreme conditions. Neglecting corrosion resistance in muffler design can result in exhaust leaks, reduced noise suppression effectiveness, and increased emissions due to system breaches. For instance, vehicles operated in regions with heavy winter salting on roads experience accelerated muffler corrosion, emphasizing the critical importance of material selection.

Ultimately, the corrosion resistance value is a key determinant of a “safeway muffler’s” lifecycle cost and environmental impact. Prioritizing materials with superior corrosion resistance minimizes the need for frequent replacements, reducing waste and contributing to sustainable vehicle operation. The engineering choice in material for muffler construction directly addresses both the economic concerns of the consumer and the environmental considerations of reduced material consumption.

5. Emissions control interaction

The integration of the “safeway muffler” within the vehicle’s exhaust system is intrinsically linked to emissions control. While the primary function of the muffler is noise reduction, its design and condition directly influence the efficiency and effectiveness of the overall emissions control system. Factors such as backpressure, exhaust flow, and the integrity of the muffler’s structure all play a role in maintaining optimal emissions levels.

- Backpressure Effects on Catalytic Converter Performance

An improperly designed or deteriorated muffler can create excessive backpressure in the exhaust system. This elevated backpressure can negatively impact the catalytic converter’s ability to function efficiently. Increased backpressure raises exhaust gas temperatures, potentially leading to converter overheating and reduced effectiveness in converting harmful pollutants into less harmful substances. For example, a clogged muffler significantly hinders exhaust flow, raising backpressure and diminishing the catalytic converter’s efficiency, ultimately increasing tailpipe emissions.

- Exhaust Leakage and Sensor Accuracy

A compromised muffler, exhibiting corrosion or physical damage, can result in exhaust leaks. These leaks disrupt the intended exhaust flow and can impact the accuracy of oxygen sensors located upstream or downstream of the muffler. Inaccurate sensor readings can lead to incorrect fuel-air mixture adjustments by the engine control unit (ECU), resulting in increased emissions and reduced fuel economy. For instance, an exhaust leak near an oxygen sensor can introduce ambient air, skewing the sensor readings and prompting the ECU to enrich the fuel mixture, leading to higher hydrocarbon emissions.

- Muffler Material Composition and Hydrocarbon Adsorption

The material composition of the “safeway muffler” itself can influence emissions, particularly with respect to hydrocarbon (HC) adsorption. Some muffler materials, especially those with porous surfaces, can temporarily trap HC molecules during cold starts. As the muffler heats up, these adsorbed HCs are released, contributing to a spike in emissions. While the effect is generally small, it highlights the potential for material selection to influence emissions characteristics. Advanced materials and coatings can minimize this effect.

- Resonance Effects and Exhaust Gas Mixing

The internal design of a “safeway muffler” can influence the mixing and flow characteristics of exhaust gases. Certain designs may create resonance effects that improve the mixing of exhaust gases, leading to more complete combustion within the catalytic converter. Enhanced mixing promotes better contact between the exhaust gases and the catalytic converter’s active materials, increasing its efficiency. Conversely, a poorly designed muffler could impede exhaust gas mixing, reducing the converter’s effectiveness.

In conclusion, the “safeway muffler’s” role extends beyond noise reduction. Its design, condition, and material composition exert a noticeable influence on emissions control. Maintaining the muffler’s structural integrity, optimizing its design for minimal backpressure, and selecting appropriate materials are all essential for ensuring that the overall emissions control system operates at peak efficiency and maintains compliance with stringent environmental regulations. The interplay between the muffler and other emission control components underscores the importance of a holistic approach to vehicle emissions management.

Frequently Asked Questions

This section addresses common inquiries regarding the “safeway muffler,” providing factual information to enhance understanding of its function, maintenance, and related aspects.

Question 1: What constitutes a “safeway muffler” and its primary function within a vehicle?

A “safeway muffler” is a key component of the vehicle exhaust system designed to reduce the noise generated by the engine’s combustion process. It achieves this through a series of internal chambers and baffles that attenuate sound waves.

Question 2: What are the indications of a failing “safeway muffler” and what actions should be taken?

Indications of a failing muffler include increased exhaust noise, reduced fuel efficiency, and visible signs of corrosion or physical damage. Addressing these issues promptly by consulting a qualified technician is advised to prevent further system damage and maintain optimal vehicle performance.

Question 3: How does the material composition of a “safeway muffler” affect its durability and longevity?

The material composition significantly impacts durability. Stainless steel offers superior corrosion resistance and longevity, while aluminized steel provides a cost-effective alternative with moderate corrosion protection. Selecting a muffler constructed from durable materials is essential for withstanding the harsh operating conditions within the exhaust system.

Question 4: Does the design of a “safeway muffler” impact engine performance, and if so, how?

The design influences engine performance primarily through its effect on backpressure. A poorly designed muffler can create excessive backpressure, reducing engine power and fuel efficiency. Optimizing the internal flow paths to minimize backpressure is crucial for maintaining optimal engine performance.

Question 5: What routine maintenance is recommended to prolong the lifespan of a “safeway muffler”?

Routine maintenance includes regular visual inspections for corrosion, rust, and physical damage, as well as ensuring proper mounting and support. Addressing minor issues promptly and applying protective coatings can also extend the muffler’s lifespan.

Question 6: Can a faulty “safeway muffler” affect a vehicle’s emissions, and if so, how?

A faulty muffler can indeed affect emissions. Exhaust leaks resulting from a compromised muffler can disrupt the accuracy of oxygen sensors, leading to incorrect fuel-air mixture adjustments and increased emissions. Additionally, excessive backpressure can negatively impact catalytic converter performance.

In summary, the “safeway muffler” plays a crucial role in noise reduction, and its condition affects both vehicle performance and environmental impact. Regular maintenance and prompt attention to any signs of failure are essential for maintaining optimal vehicle operation.

The subsequent section will delve into specific types of mufflers, examining their construction, functionality, and application in various vehicle models.

Safeway Muffler

The preceding discussion has elucidated the critical role of the “safeway muffler” within the broader context of automotive exhaust systems. Its primary function in noise attenuation has been detailed, alongside the significant influence of material selection, design considerations, and installation precision on its overall effectiveness and longevity. The intricate interplay between the “safeway muffler” and emissions control systems has also been examined, emphasizing its contribution to environmental compliance.

Ultimately, the responsible selection, maintenance, and timely replacement of the “safeway muffler” are paramount. Vehicle owners and technicians must recognize the implications of a compromised system component and prioritize actions that ensure optimal performance, minimize environmental impact, and uphold regulatory standards. Continued research and development in muffler technology remain essential to address evolving noise pollution concerns and meet increasingly stringent emissions requirements, ensuring a quieter and cleaner transportation landscape for the future.

![Sheldon's Custom Muffler: Performance & Sound [Shop Now] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Sheldon's Custom Muffler: Performance & Sound [Shop Now] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-208-300x200.jpg)