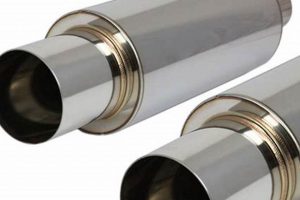

This component, commonly associated with automotive exhaust systems, functions to reduce engine noise and emissions. It is typically installed as part of the exhaust piping, often toward the rear of the vehicle. An example would be its utilization in classic car restoration projects, where maintaining the original sound characteristics is desired alongside emission control.

Its significance lies in its dual role of mitigating environmental impact through decreased emissions and enhancing the driving experience by minimizing unwanted engine sounds. Historically, such components have evolved from simple noise reduction devices to sophisticated systems incorporating catalytic converters and other technologies. This has improved vehicle efficiency and met increasingly stringent environmental regulations.

The subsequent sections will delve into the specific design considerations, material science aspects, and technological advancements related to these vital elements of vehicle engineering, exploring their impact on performance, longevity, and environmental sustainability.

Maintenance and Longevity Strategies

Effective strategies can significantly prolong the service life of exhaust system components. Implementing preventative measures minimizes potential performance degradation and the need for premature replacements.

Tip 1: Regular Visual Inspections: Conduct routine examinations for signs of corrosion, physical damage, or leaks. Early detection allows for timely repairs, preventing escalation of issues.

Tip 2: Proper Exhaust System Alignment: Ensure that the exhaust system is correctly aligned and securely mounted. Misalignment can induce stress points, leading to premature wear and potential failure.

Tip 3: Address Unusual Noises Promptly: Investigate any unusual sounds emanating from the exhaust system. Rattling, hissing, or droning noises can indicate loose components, exhaust leaks, or internal damage that require immediate attention.

Tip 4: Minimize Short Trip Driving: Short trips prevent the exhaust system from reaching optimal operating temperature, leading to moisture accumulation and accelerated corrosion. When possible, combine errands to allow for longer driving periods.

Tip 5: Salt and De-icing Chemical Exposure Mitigation: In regions with road salt application, regularly wash the vehicle undercarriage to remove corrosive salt residue. Consider applying corrosion-resistant coatings to vulnerable exhaust components.

Tip 6: Professional Exhaust System Servicing: Schedule periodic inspections and servicing by qualified technicians. Professional evaluation can identify potential issues not readily apparent during visual inspections.

Tip 7: Consider Material Upgrades: When replacement becomes necessary, consider upgrading to exhaust system components constructed from more corrosion-resistant materials, such as stainless steel.

By adhering to these preventative measures, one can maximize the lifespan, ensuring sustained performance and operational efficiency. This proactive approach reduces the likelihood of unexpected repairs and associated expenses.

The following segments will transition towards exploring advancements in materials science and design optimizations, further illustrating avenues for enhancing exhaust system robustness and extending its service life.

1. Noise Reduction Capability

The ability to attenuate engine exhaust noise is a primary function inherent in the design of most exhaust components. The degree to which a specific component achieves noise reduction is a critical performance metric, directly influencing vehicle sound characteristics and compliance with noise regulations.

- Internal Baffle Design

The internal structure dictates noise attenuation effectiveness. Baffles create tortuous paths for exhaust gases, causing sound waves to interfere destructively, reducing their amplitude. An example is the use of Helmholtz resonators tuned to specific frequencies to cancel dominant noise components. Poor baffle design compromises noise reduction and affects backpressure.

- Material Acoustics

The physical properties of the materials used in construction impact noise transmission. Denser materials, or those incorporating sound-dampening layers, provide greater noise attenuation. Steel and stainless steel are common, but layering with materials possessing higher damping coefficients further reduces noise. Material selection directly affects the component’s capacity to absorb and dissipate sound energy.

- Chamber Volume and Configuration

Internal chamber volumes and their arrangement influence noise reduction characteristics. Larger volumes typically provide more effective noise attenuation. Multi-chamber designs, with carefully calculated volume ratios and connecting passages, achieve broader frequency range noise reduction. Incorrect chamber design diminishes noise reduction performance and potentially increases backpressure.

- Exhaust Gas Velocity and Temperature

These operational parameters affect sound propagation within the system. Higher exhaust gas velocities can generate broadband noise, requiring more sophisticated attenuation strategies. Elevated temperatures can alter material properties, impacting their noise-dampening capabilities. Effective designs account for anticipated exhaust gas conditions to maintain consistent performance.

These facets collectively define the sound-deadening qualities. Design choices in these domains determine sound characteristics and regulatory conformity. The cumulative effect dictates the overall sonic signature of a vehicle and its acceptance within noise-sensitive environments.

2. Exhaust Flow Optimization

Exhaust flow optimization is intrinsically linked to the performance characteristics of exhaust components. The component’s internal design critically influences the efficient evacuation of exhaust gases from the engine. Impediments to this flow manifest as increased backpressure, reducing engine power and fuel efficiency. Therefore, optimizing the internal architecture is essential for realizing the component’s full potential. Poorly optimized component designs will impede flow and adversely impact engine performance. An example of a beneficial design is a straight-through design with minimal restrictions to promote rapid exhaust removal. Conversely, a component with excessive baffling or a constricted internal diameter will impede exhaust flow.

A direct consequence of optimizing exhaust flow is improved engine responsiveness and increased power output. Reduced backpressure allows the engine to breathe more freely, enabling it to operate more efficiently across the RPM range. Performance vehicles often employ carefully designed exhaust components to minimize flow restrictions and maximize horsepower. Another benefit of optimizing exhaust flow is reduced operating temperatures, which increases component lifespan. Poorly designed components cause higher temperatures, causing premature wear or degradation of materials. As component design becomes refined in concert with modern technology, flow rates have been optimized to new peak levels.

In summary, the relationship between exhaust flow optimization and exhaust components is one of cause and effect: optimal design facilitates efficient exhaust gas evacuation, while poor design inhibits it. Understanding this principle is vital for selecting and maintaining components that enhance engine performance and longevity. This insight can be utilized to achieve optimal function within the exhaust system.

3. Material Corrosion Resistance

The longevity and operational effectiveness of exhaust components are profoundly influenced by the material’s inherent resistance to corrosion. This is particularly relevant, as these components are routinely exposed to harsh environmental conditions, fluctuating temperatures, and corrosive byproducts of combustion.

- Environmental Exposure

Exhaust components are constantly subjected to external elements, including road salt, moisture, and debris. These substances accelerate corrosion, particularly in areas with harsh winter climates. The material must withstand these challenges to prevent premature degradation. For example, the application of de-icing salts on roads can rapidly corrode exhaust systems not constructed of corrosion-resistant materials.

- Combustion Byproducts

The combustion process generates acidic gases and water vapor that condense within the exhaust system, creating a corrosive environment from the inside. The material must resist the effects of these byproducts to prevent internal damage. Systems utilizing catalytic converters experience even harsher internal conditions, necessitating superior corrosion resistance.

- Temperature Fluctuations

Exhaust components undergo significant temperature cycling, expanding and contracting during operation. This thermal stress can compromise the protective layers of the material, making it more susceptible to corrosion. Materials with high thermal stability and resistance to thermal fatigue are therefore preferred. Rapid heating and cooling exacerbate any existing corrosion damage.

- Material Selection Implications

The choice of material directly impacts the service life and maintenance requirements. Materials like stainless steel offer superior corrosion resistance compared to mild steel, but at a higher cost. Careful consideration of the vehicle’s intended operating environment and budget is essential in selecting the appropriate material. Using inferior materials will shorten the service life.

Material corrosion resistance is a paramount consideration. Its importance extends beyond mere aesthetics, influencing the component’s structural integrity, performance, and overall environmental impact. Optimal material selection strikes a balance between cost, durability, and the intended operating environment.

4. Dimensional Compatibility

Dimensional compatibility represents a crucial aspect in the successful integration and function of any exhaust component within a vehicle’s exhaust system. In the context of a “tom cherry muffler”, ensuring precise dimensional matching is paramount. Variations, even minor ones, can lead to improper fitment, exhaust leaks, compromised performance, and potential damage to surrounding components. The physical dimensions of the replacement component, including length, diameter, inlet/outlet sizes, and mounting point locations, must precisely correspond to the vehicle’s original specifications. A real-world example lies in aftermarket part installations, where incorrect dimensional specifications could render a component unusable, requiring rework or a return, which results in increased costs and delays. Incompatibility also elevates stress points, reducing the longevity.

Further analysis reveals practical applications. Automotive manufacturers design exhaust systems with specific dimensional tolerances to ensure optimal performance and compliance with emissions standards. Utilizing a “tom cherry muffler” that deviates dimensionally can disrupt the carefully engineered flow dynamics of the exhaust system, increasing backpressure and negatively impacting engine efficiency. Moreover, dimensional discrepancies can complicate installation procedures, demanding modifications to existing exhaust piping or mounting points, adding to labor costs and potentially compromising the structural integrity of the overall system. Properly aligned replacement components will minimize any modifications to ensure stability.

In summary, dimensional compatibility is not merely a matter of physical fit but a fundamental requirement for ensuring the intended performance, longevity, and safety of the vehicle’s exhaust system. Adherence to dimensional specifications prevents a cascade of potential issues, ranging from performance degradation to increased maintenance costs. Challenges arise from manufacturing tolerances and inaccurate product listings, highlighting the necessity for rigorous quality control and meticulous product verification prior to installation. This focus on dimensional accuracy is vital for preserving the integrity of the exhaust system and its role in vehicle operation.

5. Thermal Management Efficiency

Thermal management efficiency, the capability to regulate and dissipate heat, directly impacts the performance and lifespan of exhaust components, notably including the “tom cherry muffler.” Effective heat management prevents thermal degradation of materials, reduces the risk of fire hazards, and optimizes the performance of catalytic converters, if present. Poor thermal control causes component failure and environmental risk.

- Heat Dissipation Mechanisms

Heat dissipation mechanisms in the “tom cherry muffler” facilitate the transfer of thermal energy away from the component. These mechanisms encompass both conductive and convective heat transfer. Conductive heat transfer relies on the material’s thermal conductivity, while convective heat transfer involves the movement of air around the component. Effective heat dissipation minimizes the temperature gradient within the component, mitigating thermal stress and material fatigue. A practical example is the use of external heat shields or fins to enhance convective heat transfer. The efficiency dictates component integrity.

- Material Selection and Thermal Properties

The selection of materials plays a central role in determining the “tom cherry muffler’s” thermal management efficiency. Materials with high thermal conductivity, such as certain grades of stainless steel, facilitate efficient heat transfer. Furthermore, the material’s thermal expansion coefficient must be carefully considered to prevent thermal stress-induced cracking or deformation. In instances where weight reduction is paramount, alternative materials with lower density but comparable thermal properties may be employed. Materials are selected based on function and cost.

- Insulation and Heat Shielding Strategies

Insulation and heat shielding techniques are employed to minimize heat transfer from the “tom cherry muffler” to surrounding components or the vehicle’s chassis. Heat shields, typically constructed from reflective materials like aluminum, redirect radiant heat away from sensitive areas. Insulating wraps, often made from ceramic fibers, reduce conductive heat transfer. The strategic placement of these thermal barriers prevents overheating of adjacent components, improving overall system reliability. This is especially important near fuel lines.

- Impact on Catalytic Converter Performance

In vehicles equipped with catalytic converters, the thermal management efficiency of the exhaust system directly affects the converter’s performance. Catalytic converters require a specific operating temperature range to function optimally. Excessive heat can damage the catalyst, reducing its effectiveness in converting harmful emissions. Conversely, insufficient heat can prevent the catalyst from reaching its light-off temperature. Effective thermal management ensures the catalytic converter operates within its optimal temperature window, maximizing emissions reduction. These elements are crucial to system viability.

In summary, thermal management efficiency is an integral aspect of the “tom cherry muffler’s” design and operation. The interplay between heat dissipation mechanisms, material selection, insulation strategies, and the catalytic converter’s thermal requirements significantly impacts the component’s performance, lifespan, and environmental impact. Optimizing thermal management ensures system reliability and environmental compliance. Component engineering is crucial.

Frequently Asked Questions

This section addresses common inquiries and misconceptions surrounding the function, maintenance, and selection of components, focusing on clarifying their role within the exhaust system.

Question 1: What is the primary function of an exhaust component?

The primary function is to mitigate engine noise and facilitate the efficient removal of exhaust gases. Secondary functions may include emission control and optimization of engine performance.

Question 2: How does the internal design of an exhaust component affect its performance?

The internal design, encompassing baffle configuration and chamber volume, directly influences noise attenuation, exhaust flow, and backpressure. Suboptimal designs can compromise performance and fuel efficiency.

Question 3: What materials are commonly used in the construction of exhaust components, and what are their respective advantages?

Common materials include mild steel, aluminized steel, and stainless steel. Stainless steel offers superior corrosion resistance, while mild steel represents a more economical option. Aluminized steel provides a compromise between cost and corrosion protection.

Question 4: How can the service life of an exhaust component be extended?

Regular inspections, proper alignment, addressing unusual noises promptly, minimizing short trips, mitigating salt exposure, and professional servicing are effective strategies for extending service life.

Question 5: What are the symptoms of a failing exhaust component?

Symptoms of failure may include increased engine noise, reduced fuel efficiency, noticeable exhaust leaks, and the presence of rust or physical damage.

Question 6: Does the size and style of an exhaust component have implications for its sound characteristics?

The size and style profoundly impact sound characteristics. Larger components typically offer greater noise attenuation. Straight-through designs tend to produce a more aggressive sound, while baffled designs prioritize noise reduction.

These answers should provide a better understanding of exhaust components and their role in vehicle function.

The subsequent section will transition to exploring specific applications and case studies.

Conclusion

The preceding analysis has detailed key attributes, material considerations, and operational aspects of components, exemplified by the “tom cherry muffler.” The discussion encompassed noise reduction, flow optimization, corrosion resistance, dimensional compatibility, and thermal management. Each factor contributes to the device’s overall performance and longevity within an exhaust system.

Understanding these technical intricacies is crucial for informed decision-making regarding vehicle maintenance, performance modifications, and environmental responsibility. Further research and technological advancements will continue to shape the evolution of these systems, emphasizing the importance of staying abreast of the latest developments in this field.