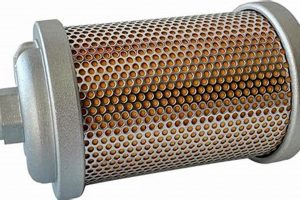

This component, commonly found in automotive exhaust systems, serves to reduce the acoustic intensity of engine emissions. Its function relies on principles of sound wave interference and absorption to achieve a quieter operational environment. For instance, a vehicle equipped with a properly functioning version of this part will produce significantly less noise pollution compared to one without.

Effective reduction of exhaust noise contributes to regulatory compliance regarding noise emission standards. It also enhances the comfort of vehicle occupants and minimizes disturbance to the surrounding environment. Historically, improvements in design and materials have led to increasingly efficient and durable iterations of this essential system element.

The following sections will delve into specific aspects of automotive exhaust systems, including material science considerations, performance metrics, and the impact of environmental factors on the longevity and efficiency of its sound-dampening capabilities. Subsequent discussion will focus on maintenance procedures and diagnostic techniques for identifying potential issues.

Maintenance and Longevity Tips

Proper maintenance and conscientious use are essential for maximizing the lifespan and effectiveness of noise reduction components within an automotive exhaust system. Neglecting regular inspections and preventative measures can lead to premature failure and diminished performance.

Tip 1: Routine Visual Inspections: Conduct regular visual inspections of the exhaust system, paying close attention to the muffler’s exterior. Examine for signs of rust, corrosion, physical damage (dents or punctures), or loose connections. Early detection of these issues allows for timely repairs and prevents further degradation.

Tip 2: Address Rust Promptly: Rust is a common enemy. If surface rust is observed, treat it immediately with a rust converter or inhibitor. This will help prevent it from spreading and weakening the material. For more severe rust, professional repair or replacement may be necessary.

Tip 3: Avoid Short Trips: Frequent short trips, especially in colder climates, can accelerate corrosion. Exhaust systems do not fully heat up during short drives, allowing condensation to accumulate and promote rust formation. Whenever possible, take longer trips to fully heat the exhaust system and evaporate moisture.

Tip 4: Mind the Road Conditions: Avoid driving through deep water or over debris that could damage the exhaust system. Impacts can dent or puncture the muffler, compromising its structural integrity and acoustic performance.

Tip 5: Check Exhaust System Mounts: Regularly inspect the rubber mounts that support the exhaust system. Deteriorated or broken mounts can cause excessive vibration, leading to stress cracks and premature failure. Replace worn mounts promptly.

Tip 6: Engine Performance Issues: Address any engine performance issues promptly. A poorly running engine can produce excessive backpressure or unburnt fuel, which can damage the muffler over time.

Tip 7: Professional Inspections: Schedule periodic professional inspections of the exhaust system. A qualified mechanic can identify potential problems that may not be readily apparent during visual inspections.

Adherence to these guidelines will significantly extend the service life and maintain the optimal performance of the exhaust system, ensuring continued compliance with noise regulations and a more comfortable driving experience.

The subsequent sections will address diagnostic procedures for identifying specific issues and the impact of different materials on overall system performance.

1. Noise Attenuation

Noise attenuation is the core functional objective achieved within an automotive exhaust system through the implementation of mufflers. Specifically, it is the degree to which sound pressure levels are reduced as exhaust gases flow through the device. The effectiveness of this process directly correlates to the design and condition of the muffler itself. A properly functioning unit drastically diminishes the decibel output of an engine, bringing vehicle operation within regulatory limits and improving overall environmental quality. A deteriorated unit, however, will fail to adequately dampen sound, resulting in increased noise pollution.

The design of internal components directly dictates noise attenuation capacity. Baffles and resonators within a muffler are engineered to disrupt sound waves, causing destructive interference and reducing their amplitude. Damage to these components, such as rust-induced perforations or physical deformation, reduces their ability to effectively cancel sound waves, leading to increased noise emissions. Furthermore, the materials employed in construction contribute significantly to noise attenuation capabilities. Certain materials are more effective at absorbing sound energy than others. For example, packing materials like fiberglass or steel wool are often used to absorb higher frequency sounds, but their degradation can compromise their noise-reducing effectiveness.

In summary, noise attenuation is not merely a byproduct but the central purpose of the muffler. Its effective operation is dependent on the design and materials of components and any degradation affects the entire system. Understanding the principles of noise attenuation and the role of the components is crucial for maintaining vehicle compliance with noise regulations and ensuring the environmental responsibility of automotive transportation.

2. Material Durability

Material durability is a critical factor influencing the performance and longevity of an automotive noise reduction component. The harsh operating environment, characterized by high temperatures, corrosive exhaust gases, and exposure to road debris, places significant stress on the materials used in its construction. A failure to withstand these conditions results in premature degradation, compromised noise attenuation, and ultimately, the need for replacement. For example, a component constructed from low-grade steel is susceptible to rapid corrosion, leading to leaks and a significant increase in exhaust noise within a relatively short period. Conversely, a component manufactured from stainless steel or aluminized steel demonstrates superior resistance to corrosion, extending its lifespan and maintaining its performance over a longer duration.

The impact of material choice extends beyond corrosion resistance. The ability to withstand thermal cyclingrepeated heating and coolingis also essential. Exhaust systems experience extreme temperature fluctuations during normal operation. Materials lacking sufficient thermal fatigue resistance can develop cracks and stress fractures, compromising structural integrity and acoustic performance. An example of this is the use of thin-walled materials which, while initially cost-effective, are prone to premature failure due to thermal stress. Furthermore, the composition of the material directly affects its ability to dampen vibrations and absorb sound energy. Materials with higher density and inherent damping properties contribute to improved noise attenuation, even as they age and are exposed to environmental factors.

In conclusion, material durability is not merely a desirable attribute but a fundamental requirement for reliable and long-lasting automotive exhaust noise reduction. Careful consideration of material properties, including corrosion resistance, thermal fatigue resistance, and acoustic damping characteristics, is essential to ensure optimal performance and minimize the environmental impact associated with frequent component replacement. The selection of appropriate materials represents a crucial engineering decision that directly influences the long-term cost-effectiveness and environmental sustainability of the exhaust system.

3. Exhaust Backpressure

Exhaust backpressure, a force opposing the expulsion of exhaust gases from an engine, is intrinsically linked to the design and condition of the muffler. Maintaining an optimal level is crucial for engine efficiency and overall vehicle performance. Excessive backpressure can negatively affect horsepower, fuel economy, and potentially engine longevity.

- Restriction and Flow Dynamics

The internal construction of a muffler, particularly the arrangement of baffles and chambers, directly influences exhaust flow. A highly restrictive design, while potentially effective at noise reduction, can impede exhaust flow and create excessive backpressure. Conversely, a design with minimal restriction may reduce backpressure but compromise noise attenuation capabilities. The balance between these two factors is a key design consideration.

- Impact on Engine Performance

Increased backpressure forces the engine to work harder to expel exhaust gases. This increased workload translates to reduced horsepower, particularly at higher engine speeds. Fuel economy also suffers as the engine requires more energy to overcome the resistance. In severe cases, excessive backpressure can lead to increased engine temperatures and potential damage to internal components, such as exhaust valves.

- Muffler Condition and Backpressure Increase

Over time, internal degradation within a muffler can exacerbate backpressure. Corrosion, carbon buildup, or damage to internal components can restrict exhaust flow, leading to a progressive increase in backpressure. Regular inspection and maintenance are crucial to identifying and addressing these issues before they significantly impact engine performance.

- Aftermarket Performance Considerations

Modifications to the exhaust system, including the installation of aftermarket components, can significantly alter backpressure characteristics. “Performance” mufflers are often designed to reduce backpressure, potentially increasing horsepower. However, it is essential to ensure that any modifications are compatible with the vehicle’s engine management system to avoid negative consequences.

The relationship between exhaust backpressure and muffler design highlights the complex engineering tradeoffs involved in creating an effective and efficient exhaust system. Managing backpressure within acceptable limits is crucial for optimizing engine performance, fuel economy, and longevity. Any significant alterations or maintenance neglecting can drastically alter the delicate balance, negatively impacting the vehicle’s system.

4. Acoustic Design

Acoustic design constitutes a core element in the functional efficacy of automotive exhaust noise reduction components. It dictates the component’s ability to attenuate sound waves generated by the engine. The configuration of internal chambers, baffles, and resonators within the muffler determines its acoustic properties, influencing the frequencies and amplitudes of sound that are either absorbed or cancelled. For example, a straight-through muffler design minimizes backpressure, but typically provides less noise attenuation than a baffled design. Careful manipulation of these design parameters allows engineers to tailor the acoustic signature of the exhaust system, addressing specific noise reduction requirements while minimizing undesirable side effects such as increased backpressure or reduced engine performance.

Practical application of acoustic design principles involves computational fluid dynamics (CFD) simulations and experimental testing. These techniques enable engineers to predict and optimize the acoustic behavior of different muffler designs before physical prototypes are constructed. Real-world examples include the development of Helmholtz resonators, which are specifically tuned to cancel out specific frequencies. These are often integrated into exhaust systems to address drone, a low-frequency booming sound that can be particularly annoying to vehicle occupants. Moreover, advancements in material science allow for the incorporation of sound-absorbing materials within the muffler structure, further enhancing acoustic performance.

In summary, acoustic design is not simply an aesthetic consideration, but rather a critical engineering discipline that governs the performance and acceptability of automotive exhaust noise reduction. Challenges remain in optimizing designs for both noise attenuation and backpressure minimization, as well as accounting for the long-term effects of heat, corrosion, and vibration on acoustic performance. Understanding the principles of acoustic design and their application in muffler technology is essential for achieving a balance between environmental responsibility, vehicle performance, and driver comfort.

5. Corrosion Resistance

Corrosion resistance is paramount to the durability and functional lifespan of an automotive noise reduction component. The components location within the exhaust system exposes it to a uniquely aggressive environment, including high temperatures, moisture, road salts, and acidic combustion byproducts. This combination promotes electrochemical reactions that degrade the metal structure. When the component’s material lacks adequate corrosion resistance, it’s structural integrity diminishes, compromising its noise attenuation capabilities and leading to eventual failure. For instance, a standard steel unit in regions with heavy road salting can exhibit significant rust within a few years, resulting in increased exhaust noise and requiring replacement.

The selection of corrosion-resistant materials, such as stainless steel or aluminized steel, represents a critical design consideration. These alloys form a protective oxide layer on the surface, inhibiting the progression of corrosion. Coatings, such as ceramic-based formulations, offer an additional barrier against environmental attack. Furthermore, design features that minimize the accumulation of moisture and debris can mitigate corrosion risks. As an example, drainage holes strategically placed in the muffler casing prevent the build-up of corrosive fluids. Understanding the specific corrosion mechanisms at play and implementing appropriate material selection and design strategies are vital for ensuring the long-term reliability of the exhaust system.

In summary, corrosion resistance directly dictates the performance and longevity of automotive noise reduction systems. Its consideration from the design phase is indispensable. The choice of robust materials, coupled with protective coatings and thoughtful design details, enhances component lifespan, decreases the need for frequent replacements, and lessens overall environmental impact. Neglecting corrosion resistance considerations inevitably leads to premature system failure, increased noise pollution, and elevated maintenance costs. This underscores the importance of corrosion resistance as a primary design objective, vital for the enduring function of this component.

6. Thermal Management

Thermal management, the control and dissipation of heat, plays a crucial role in the performance and longevity of automotive noise reduction components. Effective thermal management prevents overheating, reduces thermal stress, and maintains optimal operating temperatures, all of which contribute to component reliability and efficiency.

- Material Degradation and Thermal Stress

High operating temperatures exacerbate corrosion and material degradation. Repeated heating and cooling cycles induce thermal stress, leading to cracking and fatigue. Effective thermal management mitigates these effects by maintaining temperatures within material-specific tolerance ranges. For example, properly insulated components experience reduced temperature swings, minimizing thermal stress and extending the component’s lifespan.

- Catalytic Converter Integration

In integrated exhaust systems, the muffler is often located downstream of the catalytic converter, which generates significant heat. Proper thermal management prevents excessive heat transfer from the catalytic converter to the muffler, protecting the muffler’s sound-dampening materials and structural integrity. Heat shields, air gaps, and insulation are commonly employed to minimize heat transfer between these components.

- Engine Performance and Backpressure

Excessive temperatures increase exhaust gas volume, leading to increased backpressure. Conversely, insufficient heat can result in condensation and corrosion. Thermal management strategies that maintain optimal gas temperatures contribute to efficient engine performance and minimize the formation of corrosive byproducts. For example, strategically placed insulation can prevent excessive heat loss in colder climates, optimizing exhaust gas flow.

- Acoustic Performance

High temperatures can alter the acoustic properties of sound-dampening materials within the muffler. Certain materials, such as fiberglass packing, degrade at elevated temperatures, reducing their sound-absorbing capacity. Thermal management strategies that maintain these materials within their operational temperature ranges ensure consistent acoustic performance over the component’s lifespan. Proper thermal management ensures optimal long-term sound reduction.

Thermal management is an integral aspect of design, influencing material selection, component layout, and overall system performance. Effective thermal control mechanisms contributes to efficiency, durability, and consistent acoustic performance, critical factors in modern exhaust system design. Neglecting thermal management considerations will ultimately compromise performance and lifespan, underscoring its importance in achieving reliable and sustainable operation.

7. Vehicle Emissions

The effective operation of a muffler plays a pivotal role in the control of vehicle emissions, though the relationship is indirect. Mufflers themselves do not directly alter the chemical composition of exhaust gases. However, by ensuring proper engine function through the maintenance of optimal exhaust backpressure, mufflers contribute to the efficiency of the catalytic converter, a device specifically designed to reduce harmful emissions. For instance, a severely corroded or damaged muffler can create excessive backpressure, hindering the engine’s ability to operate at its designed stoichiometric ratio. This inefficiency can overload the catalytic converter, diminishing its effectiveness in converting pollutants such as hydrocarbons, carbon monoxide, and nitrogen oxides into less harmful substances.

A properly functioning noise reduction component also contributes to emissions control by maintaining the integrity of the entire exhaust system. Leaks within the exhaust system, often caused by a deteriorated muffler, can allow uncombusted hydrocarbons to escape into the atmosphere before reaching the catalytic converter. This not only increases harmful emissions but also creates a safety hazard. Furthermore, the noise generated by a damaged muffler can be indicative of underlying engine problems that contribute to elevated emissions. For example, an exhaust leak detected near a muffler could signal a larger issue with the engine’s combustion process, leading to higher levels of unburnt fuel in the exhaust stream. Addressing the muffler issue may then lead to identification and resolution of the root cause problem, indirectly improving vehicle emissions.

In conclusion, while the component primarily focuses on noise reduction, it is an integral part of a well-functioning exhaust system that supports effective emissions control. Maintaining this device’s optimal condition helps to preserve engine efficiency, preventing negative impacts on the catalytic converter’s performance and mitigating exhaust leaks. This understanding highlights the significance of regular inspection and maintenance, not just for noise compliance, but also for environmental responsibility. The vehicle emissions system underscores the interdependency of automotive components in achieving both performance and environmental goals.

Frequently Asked Questions

This section addresses common inquiries regarding automotive exhaust noise reduction components, providing detailed answers to ensure a clear understanding of their function, maintenance, and impact on vehicle performance.

Question 1: What are the primary indicators of a failing automotive noise reduction component?

Common symptoms include a noticeable increase in exhaust noise, rattling sounds emanating from the exhaust system, visible rust or physical damage, and a potential decrease in engine performance or fuel efficiency.

Question 2: How often should an automotive noise reduction component be inspected?

A visual inspection should be conducted at least annually, or more frequently in regions with harsh climates or poor road conditions. A professional inspection is recommended every two years or 24,000 miles, whichever comes first.

Question 3: Can a damaged automotive noise reduction component affect fuel economy?

Yes. A compromised unit can increase backpressure, forcing the engine to work harder. This increased workload translates to reduced fuel efficiency.

Question 4: Is it possible to repair a damaged automotive noise reduction component, or is replacement always necessary?

Minor rust or small holes may be repairable by a qualified technician. However, extensive damage, such as significant corrosion or structural failure, typically necessitates replacement for long-term reliability.

Question 5: Will replacing an automotive noise reduction component with an aftermarket performance unit void a vehicle’s warranty?

The impact on warranty depends on the specific terms of the warranty and the nature of the aftermarket component. It is crucial to consult with the vehicle manufacturer or warranty provider before making any modifications.

Question 6: What is the typical lifespan of an automotive noise reduction component?

Lifespan varies depending on material quality, driving conditions, and maintenance practices. However, a well-maintained unit constructed from durable materials can last for five to ten years.

The information provided offers important considerations for responsible vehicle ownership and maintenance. Attention to these details aids in extending the system’s life and performance.

The next section transitions to a brief conclusion summarizing the key points discussed throughout this article.

Conclusion

This exploration of automotive exhaust noise reduction components has underscored their importance in noise attenuation, material durability, exhaust backpressure management, acoustic design considerations, corrosion resistance, thermal management, and the influence on vehicle emissions. The interplay between these elements dictates both system performance and environmental impact.

Sustained operational effectiveness requires diligent maintenance practices and informed decision-making regarding component selection. Recognizing these components critical role promotes responsible vehicle ownership, contributing to quieter environments and improved air quality for future generations. Prioritizing quality and proper care ensures a lasting positive impact.