The feasibility of reinstalling a muffler following its removal from a vehicle’s exhaust system is a common inquiry. This action addresses situations where a vehicle owner wishes to revert to a quieter exhaust note, comply with noise regulations, or mitigate potential performance drawbacks associated with a muffler-less system. The underlying question is whether the original, or a similar, muffler can be effectively reattached to the exhaust pipe after a section has been modified for its removal. The ease and success of this process hinge on several factors, including the method of the original deletion, the condition of the remaining exhaust components, and the availability of necessary hardware or replacement parts.

Reverting to a muffled exhaust offers several advantages. It reduces noise pollution, potentially avoiding legal repercussions in areas with strict noise ordinances. Furthermore, some vehicle owners observe improved low-end torque and fuel efficiency when a muffler is present. Historically, mufflers were primarily designed to reduce exhaust noise, but modern iterations also play a role in optimizing exhaust flow and overall engine performance. The decision to reinstate a muffler reflects a desire for a balance between performance, sound, and regulatory compliance.

The subsequent discussion will delve into the practical steps involved in muffler reinstallation, focusing on identifying necessary components, preparing the exhaust system for reattachment, and addressing potential challenges, such as corrosion or improper previous modifications. Different reinstallation methods, including welding, clamping, and the use of specialized connectors, will be explored. Furthermore, the importance of ensuring a secure and leak-free connection to prevent exhaust leaks and optimize performance will be examined.

Reinstalling a Muffler After its Removal

Reattaching a muffler after its deletion requires careful planning and execution to ensure proper functionality and prevent future issues. This section outlines essential considerations for a successful reinstallation.

Tip 1: Assess the Exhaust System’s Condition: Before commencing the reinstallation, thoroughly inspect the remaining exhaust components for rust, corrosion, or damage. Address any pre-existing issues, as they can compromise the integrity of the new connection and lead to leaks.

Tip 2: Identify the Original Deletion Method: Understanding how the muffler was initially removed is crucial. If the exhaust pipe was cut, measure the gap and select an appropriate connecting pipe or adapter to bridge the distance. If flanges were used, ensure they are in good condition and properly aligned.

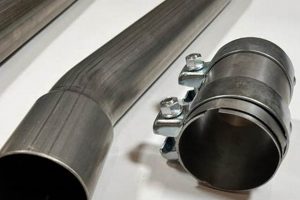

Tip 3: Select the Appropriate Muffler and Connection Method: Choose a muffler that is compatible with the vehicle’s make and model. Determine the most suitable connection method: welding provides a permanent and robust bond, while clamping offers a less invasive and more adjustable solution. Exhaust couplers can also be used.

Tip 4: Clean and Prepare the Connection Surfaces: Before welding or clamping, thoroughly clean the surfaces of the exhaust pipes and muffler inlets/outlets. Remove any rust, dirt, or debris to ensure a tight and leak-free seal. Using a wire brush or sandpaper can improve adhesion.

Tip 5: Ensure Proper Alignment: Correct alignment is critical to prevent stress on the exhaust system and premature failure. Use supports or hangers to maintain the proper position of the muffler and exhaust pipes during installation. Misalignment can result in leaks and vibrations.

Tip 6: Use High-Quality Clamps or Welding Techniques: If using clamps, select heavy-duty stainless steel clamps designed for exhaust systems. Tighten the clamps evenly to the manufacturer’s specified torque. If welding, employ proper welding techniques and use appropriate welding rods for exhaust pipe material.

Tip 7: Check for Exhaust Leaks: After reinstallation, start the engine and carefully listen for exhaust leaks. Pay attention to the connections between the muffler and the exhaust pipes. Applying soapy water to the joints can help identify leaks by creating bubbles.

Reinstalling a muffler is a task that demands precision and attention to detail. By carefully assessing the exhaust system, selecting the correct components and methods, and ensuring proper alignment and sealing, it is possible to effectively restore the original exhaust configuration.

The subsequent sections will explore potential performance changes after reinstallation and regulatory factors related to exhaust modifications.

1. Reversibility

Reversibility, in the context of exhaust system modifications, directly addresses the question of whether one can put muffler back on after delete. It refers to the ease and practicality with which an altered system can be restored to its original, factory-specified configuration. The initial method of muffler removal significantly influences this reversibility. For instance, a muffler deleted via a simple bolt-on connection offers substantially higher reversibility compared to one removed through welding and subsequent pipe cutting. The less destructive the initial removal process, the more readily the system can be returned to its original state. A high degree of reversibility provides vehicle owners with the flexibility to adapt the exhaust system based on changing preferences, noise regulations, or performance goals.

Consider a scenario where a vehicle owner removes the muffler to achieve a more aggressive exhaust sound for track days. If the muffler was initially attached using flanges and bolts, reverting to the stock configuration for daily driving is a straightforward process. Conversely, if the muffler was removed by cutting the exhaust pipe and welding in a straight pipe section, reinstallation requires either welding the original muffler back in place or using exhaust clamps and adapter pipes to bridge the gap. This not only increases the complexity of the process but also potentially introduces points of weakness or potential leaks in the exhaust system. Preserving as much of the original exhaust system as possible during the initial modification is crucial for maximizing reversibility.

In summation, reversibility is a paramount consideration when contemplating muffler removal. The initial method of removal dictates the complexity and cost associated with reinstating the muffler. Preserving the integrity of the original exhaust system during modification directly impacts the ability to effectively return the vehicle to its factory-specified configuration, fulfilling the core principle of whether one can put muffler back on after delete without undue difficulty or compromise to the system’s overall performance and reliability.

2. Component Compatibility

Component compatibility forms a foundational aspect of determining whether it’s feasible to reinstall a muffler after its deletion. The seamless integration of a replacement muffler with the existing exhaust system hinges on understanding various compatibility facets. The selection process must consider dimensions, materials, and connection types to ensure a proper fit and functionality.

- Inlet/Outlet Diameter

The diameter of the muffler’s inlet and outlet must precisely match the existing exhaust pipe’s diameter. Mismatched diameters necessitate adapters, which can introduce potential leak points and increase the complexity of the reinstallation process. Selecting a muffler with the correct diameter streamlines installation and reduces the risk of exhaust leaks.

- Muffler Body Dimensions

The physical dimensions of the muffler body must be considered to ensure adequate space within the vehicle’s undercarriage. A muffler that is too large may not fit, while one that is too small may not provide the desired level of sound reduction. Careful measurement and consideration of available space are crucial for successful reinstallation.

- Material Compatibility

Ideally, the replacement muffler’s material should match the existing exhaust system’s material (e.g., stainless steel to stainless steel, aluminized steel to aluminized steel). Mixing materials can lead to accelerated corrosion due to galvanic reactions. Using compatible materials extends the lifespan of the exhaust system and minimizes maintenance requirements.

- Connection Type

The connection type (e.g., flanged, slip-fit, welded) must be compatible with the existing exhaust system. If the original muffler was welded, reinstallation might require welding skills or the use of adapters to convert to a slip-fit connection. Choosing a muffler with a compatible connection type simplifies the reinstallation process and reduces the need for specialized tools or expertise.

The successful reinstallation of a muffler after its deletion critically depends on the precise matching of components. Addressing dimensional, material, and connection compatibility is paramount. A properly chosen muffler, matched to the existing exhaust system, ensures effective sound reduction, long-term durability, and minimizes complications during the reinstallation process. The more closely the replacement muffler aligns with the original specifications, the greater the likelihood of a seamless and effective return to the factory exhaust configuration.

3. Connection Integrity

Connection integrity is paramount when considering the feasibility of muffler reinstallation following its removal. A robust, leak-free connection is essential for achieving intended noise reduction, preventing exhaust leaks, and maintaining optimal engine performance. Any compromise in connection integrity directly undermines the success of the reinstallation.

- Weld Quality/Clamp Strength

Whether welding or clamping is employed, the quality of the weld or the strength of the clamp significantly impacts connection integrity. A poorly executed weld can crack or develop pinholes, allowing exhaust gases to escape. Similarly, a weak or improperly tightened clamp can loosen over time, leading to leaks. High-quality welding techniques and durable, corrosion-resistant clamps are vital for establishing and maintaining a secure connection.

- Surface Preparation

Thorough surface preparation of the exhaust pipes and muffler inlets/outlets is critical for ensuring a proper seal. Removing rust, scale, and other contaminants creates a clean surface for welding or clamping. A rough or contaminated surface can prevent a tight seal, resulting in exhaust leaks and reduced performance. Wire brushing or sanding the surfaces before connection enhances adhesion and promotes a leak-free joint.

- Alignment and Support

Proper alignment of the muffler and exhaust pipes, coupled with adequate support, is essential for preventing stress on the connection. Misalignment can cause undue strain on the weld or clamp, leading to premature failure. Properly positioned hangers and supports distribute the weight of the exhaust system, reducing the likelihood of leaks and component damage.

- Gasket or Sealant Application

In certain applications, gaskets or exhaust sealant may be necessary to ensure a leak-free connection. These materials fill any minor imperfections in the mating surfaces, creating a tighter seal. Using the appropriate gasket or sealant, according to the manufacturer’s recommendations, enhances connection integrity and prevents exhaust leaks.

Achieving satisfactory results when considering whether can you put muffler back on after delete hinges on attention to connection integrity. By prioritizing weld quality or clamp strength, meticulous surface preparation, proper alignment and support, and the judicious use of gaskets or sealants, a secure, leak-free connection can be established, ensuring that the reinstalled muffler effectively reduces exhaust noise and maintains engine performance.

4. Regulatory Compliance

Regulatory compliance exerts a substantial influence on the decision to reinstate a muffler following its removal. Noise regulations, enforced at the federal, state, and local levels, dictate permissible exhaust noise levels for vehicles operating on public roads. The removal of a muffler often leads to non-compliance with these regulations, exposing vehicle owners to potential fines, citations, or mandatory vehicle inspections. Consequently, the desire to adhere to legal requirements is a primary driver for reinstalling a muffler, particularly in regions with stringent noise enforcement. The feasibility of reinstating a muffler therefore directly intersects with the practical necessity of meeting regulatory standards.

Consider, for example, jurisdictions with established decibel limits for vehicle exhaust. A vehicle modified with a muffler delete may significantly exceed these limits, resulting in a legal violation. Reinstalling the muffler serves as a corrective action, bringing the vehicle back into compliance and avoiding legal penalties. In some areas, vehicles are subject to periodic inspections that include noise level testing. Failure to pass these inspections necessitates the reinstatement of a muffler to obtain vehicle registration or certification. The act of reinstating, therefore, isn’t solely a matter of personal preference but a legal imperative for operating the vehicle lawfully on public roadways.

Ultimately, the consideration of whether one can put muffler back on after delete is often overshadowed by the more pressing concern of whether one must put the muffler back on to comply with applicable laws. Regulatory compliance serves as a crucial determinant, transforming the decision from a matter of choice to one of legal obligation. Understanding and adhering to these regulations is paramount for vehicle owners who have modified their exhaust systems, ensuring they can operate their vehicles legally and responsibly within their respective jurisdictions.

5. Performance Impact

The reinstatement of a muffler following its removal invariably affects a vehicle’s performance characteristics. The degree and nature of this impact depend on several factors, including the vehicle’s engine type, the design of the exhaust system, and the characteristics of the replacement muffler. A muffler’s primary function is to attenuate exhaust noise, but it also introduces backpressure into the exhaust system. This backpressure can influence engine torque and horsepower, particularly at different engine speeds. Removing the muffler often results in reduced backpressure, potentially leading to increased horsepower at higher RPMs, but at the possible expense of low-end torque. Reinstalling the muffler reverses this effect, potentially restoring low-end torque but potentially reducing peak horsepower. The specific magnitude of these changes varies greatly depending on the vehicle and the particular muffler used. For instance, a high-performance aftermarket muffler may provide a better balance between noise reduction and exhaust flow compared to the original factory muffler. This illustrates the necessity of considering performance implications when addressing the question of can you put muffler back on after delete.

The relationship between exhaust backpressure and engine performance is complex. Too little backpressure can reduce cylinder scavenging efficiency at lower engine speeds, leading to decreased low-end torque. Conversely, excessive backpressure can restrict exhaust flow at higher engine speeds, limiting peak horsepower. Modern engine designs often incorporate sophisticated exhaust systems that carefully manage backpressure to optimize performance across the entire RPM range. Reinstalling a muffler that closely matches the original factory specifications is typically the safest approach for maintaining the intended performance characteristics. However, experimenting with different muffler designs and exhaust configurations can potentially yield improved results, provided that careful attention is paid to engine tuning and performance monitoring. For example, the installation of a free-flowing catalytic converter in conjunction with a higher-performance muffler may mitigate some of the performance losses associated with increased backpressure.

In summary, the decision to reinstall a muffler should not be made without careful consideration of its potential impact on engine performance. While reinstallation typically restores the vehicle to its original operating parameters, it may also introduce subtle changes in torque and horsepower. Evaluating the specific characteristics of the replacement muffler, understanding the engine’s sensitivity to backpressure, and potentially adjusting engine tuning can help to optimize performance following the muffler’s reinstatement. Therefore, the question of whether can you put muffler back on after delete must be viewed within the broader context of its influence on overall vehicle performance and drivability.

Frequently Asked Questions

This section addresses common inquiries regarding the reinstallation of a muffler after its removal. These questions aim to clarify practical considerations and dispel potential misconceptions surrounding this process.

Question 1: Is it always possible to reinstall a muffler after it has been removed?

The feasibility of muffler reinstallation depends on the method used for the initial removal. If the muffler was unbolted, reinstallation is generally straightforward. However, if the exhaust pipe was cut, additional steps, such as welding or using exhaust clamps and adapter pipes, may be necessary.

Question 2: What are the potential legal ramifications of operating a vehicle without a muffler?

Operating a vehicle without a muffler may violate local noise ordinances, potentially resulting in fines or citations. Many jurisdictions have established decibel limits for vehicle exhaust, and removing the muffler often leads to non-compliance.

Question 3: Will reinstalling a muffler restore lost low-end torque?

Reinstalling a muffler typically increases backpressure in the exhaust system, which can improve low-end torque. The extent of this improvement depends on the vehicle’s engine and the design of the muffler.

Question 4: What tools are required for muffler reinstallation?

The necessary tools vary depending on the reinstallation method. Common tools include wrenches, sockets, a hacksaw or exhaust pipe cutter (if pipes were cut), a welding machine (if welding is required), exhaust clamps, and safety glasses.

Question 5: Is it necessary to use a new muffler for reinstallation?

Using a new muffler is not always necessary. The original muffler can be reinstalled if it is in good condition. However, if the original muffler is damaged or corroded, a new muffler should be used.

Question 6: How can exhaust leaks be detected after muffler reinstallation?

Exhaust leaks can be detected by listening for hissing sounds near the connections. Applying soapy water to the joints can also reveal leaks by producing bubbles. Any detected leaks should be promptly addressed to ensure optimal performance and prevent potential health hazards.

The successful reinstallation of a muffler depends on careful planning, proper tools, and attention to detail. Addressing potential challenges and complying with local regulations ensures a smooth and effective reinstallation process.

The following section will summarize the key considerations discussed throughout this article.

Conclusion

The preceding exploration of “can you put muffler back on after delete” reveals a multi-faceted undertaking. The feasibility of this action is contingent upon the original removal method, the compatibility of replacement components, and the integrity of the subsequent connections. Furthermore, regulatory compliance and potential performance impacts must be carefully considered. A successful reinstallation necessitates meticulous planning and execution.

Ultimately, the decision to reinstate a muffler following its removal should be guided by a comprehensive understanding of its implications. Vehicle owners must weigh the benefits of noise reduction and regulatory adherence against potential performance alterations. Informed decision-making is paramount to ensure a satisfactory outcome that aligns with both legal requirements and individual preferences. A proactive approach, encompassing thorough research and careful execution, is recommended for those contemplating the reinstatement of a muffler.