The exhaust component specific to a high-performance motorcycle, the Suzuki Hayabusa, plays a crucial role in managing engine emissions and sound levels. This component is typically located at the end of the exhaust system and is engineered to meet both regulatory requirements and performance expectations for the motorcycle.

This motorcycle component significantly impacts the machine’s performance characteristics, including horsepower and torque output. Aftermarket options often prioritize weight reduction and improved exhaust flow, potentially resulting in enhanced acceleration and overall riding experience. Historically, modifications to this specific part have been a popular avenue for enthusiasts seeking to personalize and optimize the Hayabusa.

The following sections will delve into the various aspects of these components, including available materials, performance modifications, legal considerations, and maintenance procedures.

Enhancing the Suzuki Hayabusa Exhaust System

Maximizing performance and longevity requires careful attention to the exhaust system of a Suzuki Hayabusa. The following considerations provide valuable insights for owners and enthusiasts.

Tip 1: Material Selection: Consider the material composition of the exhaust system. Stainless steel offers a balance of durability and affordability, while titanium provides superior weight reduction and heat dissipation, albeit at a higher cost.

Tip 2: Exhaust Flow Optimization: Increased exhaust flow can improve engine performance. However, excessive flow without proper tuning can lead to decreased low-end torque. Consult with a qualified mechanic to ensure proper fuel mapping.

Tip 3: Noise Level Compliance: Modifications to the exhaust system can significantly alter the sound level. Ensure that any aftermarket system complies with local noise regulations to avoid penalties.

Tip 4: Regular Inspection: Periodically inspect the exhaust system for signs of corrosion, leaks, or damage. Addressing minor issues promptly can prevent more significant and costly repairs.

Tip 5: Proper Installation: Ensure that any aftermarket exhaust component is installed correctly. Improper installation can lead to exhaust leaks, reduced performance, and potential engine damage.

Tip 6: Heat Management: Consider the impact of exhaust heat on surrounding components. Heat shields or ceramic coatings can mitigate heat soak and protect sensitive areas.

Tip 7: Catalytic Converter Considerations: Removal of the catalytic converter can increase performance but may also violate emissions regulations. Weigh the performance benefits against legal and environmental considerations.

Prioritizing these aspects when maintaining or modifying the Suzuki Hayabusa exhaust system can lead to improved performance, reliability, and compliance with relevant regulations.

The subsequent sections will explore specific models and their impact on the motorcycle’s overall functionality.

1. Performance Enhancement

The connection between a Suzuki Hayabusa’s exhaust component and performance enhancement is direct and multifaceted. Replacing the factory component with an aftermarket alternative often aims to optimize engine output by reducing backpressure. This allows the engine to exhale more efficiently, translating to increased horsepower and torque, particularly at higher RPMs. The degree of performance gain depends on various factors, including the design of the replacement component, the engine’s state of tune, and the presence of other modifications. For example, a full exhaust system with a free-flowing muffler, coupled with a corresponding fuel map adjustment, can yield noticeable improvements in acceleration and top-end speed. However, improper matching of components or inadequate tuning can negate these benefits or even result in decreased performance.

Furthermore, the selection of materials plays a crucial role. Components crafted from lighter materials, such as titanium, contribute to weight reduction. This reduced mass not only improves acceleration but also enhances handling characteristics by lowering the motorcycle’s overall weight. The design of the internal baffling within the component is also critical, as it determines the balance between exhaust flow and sound attenuation. Racing versions often sacrifice sound reduction for maximum flow, while street-legal options prioritize noise control. Real-world examples often showcase dyno charts demonstrating significant horsepower gains after the installation of aftermarket systems, particularly when combined with professional tuning.

In summary, the practical significance of understanding this relationship lies in making informed decisions regarding modifications. Performance enhancement is a key driver for many Hayabusa owners, and the exhaust system represents a readily accessible avenue for achieving these gains. However, a thorough understanding of the interplay between the component, the engine, and the regulatory environment is essential to ensure that modifications yield the desired results without compromising reliability, legality, or overall riding experience. The challenge lies in selecting components that offer the optimal balance of performance, sound, and compliance, tailored to the rider’s specific needs and intended use.

2. Sound Modulation

The capacity of a Suzuki Hayabusa’s exhaust component to alter the vehicle’s sound characteristics is a critical factor for both regulatory compliance and rider preference. This modulation encompasses a range of parameters, influencing both the intensity and quality of the exhaust note.

- Internal Baffling Design

The internal structure of the component directly dictates the sound attenuation. Baffles redirect and disrupt sound waves, reducing their amplitude. Different baffle designs, such as perforated cores or chambered systems, produce distinct sound profiles. A denser baffle arrangement results in a quieter exhaust note, while a more open design yields a louder, more aggressive sound. Modifications to this internal structure are often undertaken to achieve a specific acoustic signature, balancing sound level with exhaust flow.

- Material Composition Impact

The material from which the exhaust component is constructed influences the sound’s tonal qualities. Stainless steel generally produces a brighter, more metallic sound, while titanium tends to generate a deeper, more resonant tone. Carbon fiber sleeves, often used for aesthetic purposes, can also slightly dampen the sound. The choice of material represents a trade-off between sound characteristics, weight, and cost.

- Resonator Integration

Resonators are specialized chambers designed to cancel out specific frequencies within the exhaust note, reducing drone or undesirable sounds. Integrating resonators into the exhaust system allows for fine-tuning of the sound profile, optimizing it for specific riding conditions or personal preferences. The placement and size of the resonator are critical factors in determining its effectiveness.

- Legal Sound Level Limits

Sound modulation is also heavily influenced by legal restrictions. Many jurisdictions impose limits on the maximum permissible sound level of motorcycles. Aftermarket exhaust components must comply with these regulations to be street legal. Sound testing is often conducted to ensure compliance, with penalties imposed for exceeding the prescribed limits. This regulatory framework necessitates a balance between performance and sound control.

These elements combine to determine the overall acoustic signature of a Suzuki Hayabusa. Understanding these factors enables owners to select or modify their exhaust components to achieve the desired sound characteristics while remaining compliant with relevant regulations. The interplay between these elements highlights the complex engineering considerations involved in sound modulation within exhaust systems.

3. Material Composition

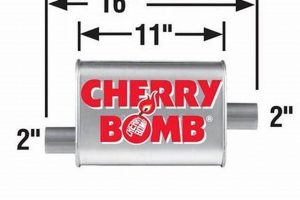

The material composition of a Suzuki Hayabusa muffler directly affects its performance, durability, weight, and aesthetic qualities. Choices in materials, therefore, represent a critical engineering decision. Stainless steel, titanium, and carbon fiber are common examples, each offering unique trade-offs. Stainless steel provides a balance of cost-effectiveness and corrosion resistance, making it a standard selection for many aftermarket components. This material withstands high temperatures and exposure to road debris effectively. Titanium, significantly lighter than steel, contributes to a reduction in overall vehicle weight, improving acceleration and handling. Its superior heat dissipation also minimizes heat soak to surrounding components. Carbon fiber is primarily used as an outer sleeve for aesthetic purposes but also offers minor weight savings and insulative properties. The selection of material influences not only the physical properties of the component but also its sound characteristics; titanium, for instance, produces a distinct resonant tone compared to steel.

Real-world examples illustrate the significance of material composition. A titanium exhaust system, while expensive, can significantly reduce the Hayabusa’s weight, resulting in improved track performance. Conversely, a stainless steel system offers a more budget-friendly option for street riders who prioritize durability and cost-effectiveness over ultimate performance gains. The longevity of the exhaust also depends on the quality of the material. Inferior stainless steel alloys are susceptible to corrosion, particularly in regions with harsh weather conditions or road salt usage. Therefore, material selection should align with the intended use and environmental factors. Furthermore, the welding process used to join the materials also influences the overall strength and lifespan of the component.

In summary, material composition is a crucial consideration when evaluating an exhaust for a Suzuki Hayabusa. The interplay of cost, weight, durability, performance, and aesthetics dictates the optimal choice. While titanium offers the highest performance potential, stainless steel remains a practical and affordable alternative. The challenge lies in striking the right balance to meet individual needs and budget constraints, ensuring long-term reliability and satisfaction. Neglecting this aspect can lead to premature failure, suboptimal performance, or aesthetic disappointment, ultimately detracting from the overall ownership experience.

4. Aesthetic Customization

Aesthetic customization, as it pertains to the Suzuki Hayabusa muffler, represents a significant driver in aftermarket modifications. The factory-installed component, while functional, often lacks the visual appeal desired by many owners. Consequently, the replacement of this component presents an opportunity to personalize the motorcycle’s appearance. Aftermarket manufacturers offer a diverse range of styles, finishes, and materials, enabling owners to tailor the muffler to match their individual tastes and the overall aesthetic theme of their Hayabusa. For example, a polished stainless steel muffler might complement a chrome-accented motorcycle, while a black ceramic-coated muffler could enhance a stealth-oriented design. The shape and size of the muffler also contribute to the aesthetic; shorty designs offer a more aggressive look, while longer, more traditional shapes provide a classic appearance. The addition of carbon fiber end caps or heat shields further enhances the visual customization possibilities. The effect of these aesthetic changes is a perceived increase in the motorcycle’s value and a heightened sense of ownership.

The importance of aesthetic customization extends beyond mere visual appeal; it often reflects the owner’s personal identity and their connection to the motorcycle. The chosen muffler becomes an extension of the owner’s style, a statement of individuality. Practical applications of this understanding include the careful selection of mufflers that complement existing modifications, such as custom paint jobs or aftermarket body kits. Additionally, some manufacturers offer customizable options, allowing owners to specify the finish, end cap design, and even laser-etch personalized logos onto the muffler. This level of customization allows for a truly unique and personalized aesthetic. However, it is crucial to ensure that aesthetic modifications do not compromise the muffler’s performance or structural integrity. A poorly designed or fabricated muffler, regardless of its visual appeal, can negatively impact engine performance or even pose a safety risk.

In summary, aesthetic customization is a crucial component of the Suzuki Hayabusa muffler aftermarket. It allows owners to personalize their motorcycles, reflecting their individual styles and preferences. The challenge lies in balancing aesthetic considerations with performance, durability, and safety. A well-chosen and properly installed muffler not only enhances the motorcycle’s visual appeal but also contributes to a positive ownership experience. Understanding the interplay between aesthetics and functionality is essential for making informed decisions and achieving the desired outcome.

5. Weight Reduction

Weight reduction, particularly concerning the Suzuki Hayabusa muffler, directly influences the motorcycle’s overall performance characteristics. A lighter muffler contributes to an improved power-to-weight ratio, impacting acceleration, braking, and handling capabilities.

- Material Selection’s Impact

The choice of materials significantly affects the muffler’s weight. Replacing a stock stainless steel component with a titanium or carbon fiber alternative can yield substantial weight savings. Titanium exhibits a superior strength-to-weight ratio compared to stainless steel, while carbon fiber offers exceptional lightness. Real-world examples demonstrate weight reductions of several pounds simply by swapping to an aftermarket titanium muffler. This reduction translates to a tangible improvement in the motorcycle’s responsiveness and agility.

- Design Optimization for Lightness

Beyond material selection, muffler design plays a crucial role in weight management. Compact, minimalist designs inherently weigh less than larger, more complex configurations. Manufacturers often employ advanced engineering techniques, such as thin-wall construction and strategically placed reinforcements, to minimize weight without compromising structural integrity. Aftermarket mufflers frequently prioritize weight reduction, resulting in more streamlined and efficient designs compared to stock components.

- Performance Implications of Reduced Weight

A lighter muffler contributes directly to enhanced performance. Decreased weight improves acceleration by reducing the motorcycle’s inertia, allowing it to reach higher speeds more quickly. Improved braking performance is also realized, as less mass needs to be decelerated. Furthermore, reduced weight enhances handling by lowering the motorcycle’s center of gravity and increasing its responsiveness to rider inputs. These performance benefits are particularly noticeable during aggressive riding or track use.

- The Cumulative Effect of Weight Savings

While the weight reduction achieved by replacing the muffler alone may seem modest, it contributes to the cumulative effect of other weight-saving measures. When combined with lighter wheels, tires, and other components, the overall weight reduction becomes substantial. This holistic approach to weight management yields the most significant performance gains, transforming the motorcycle’s handling and acceleration characteristics. Enthusiasts seeking to maximize their Hayabusa’s performance often prioritize weight reduction as a key modification strategy.

The connection between weight reduction and the Suzuki Hayabusa muffler is undeniable. A lighter muffler improves performance by contributing to a more favorable power-to-weight ratio and enhancing overall handling characteristics. Material selection and design optimization are critical factors in achieving significant weight savings, which, when combined with other modifications, can dramatically transform the motorcycle’s performance.

6. Legal Compliance

Legal compliance regarding Suzuki Hayabusa mufflers is a critical aspect for owners and manufacturers alike. Regulations govern noise emissions and, in some regions, exhaust emissions, demanding adherence to established standards. Failure to comply can result in fines, vehicle impoundment, or failure to pass inspections.

- Noise Emission Standards

Virtually all jurisdictions impose limits on the maximum permissible noise levels generated by motorcycles. These standards are often measured in decibels (dB) at a specified distance and engine speed. Mufflers must be designed to attenuate exhaust noise sufficiently to meet these limits. Aftermarket mufflers intended for street use must often be stamped or certified to indicate compliance with applicable noise regulations. Exceeding noise limits can result in fines or restrictions on vehicle operation. Certain locations may also have periodic noise testing procedures.

- Emissions Regulations

In certain regions, notably in Europe and California, emissions regulations apply to motorcycles, including the Hayabusa. These regulations govern the levels of pollutants emitted by the exhaust system, such as hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx). While the catalytic converter is the primary component addressing emissions, the muffler design can indirectly influence emissions performance. Removing or modifying the catalytic converter, or installing a poorly designed muffler, can result in increased emissions and non-compliance with applicable regulations. Fines and penalties may be applied.

- Type Approval and Certification

Manufacturers of aftermarket mufflers often seek type approval or certification from regulatory agencies to demonstrate compliance with applicable noise and/or emissions standards. This involves submitting the muffler to rigorous testing and documentation. Type approval provides assurance to consumers and enforcement agencies that the muffler meets the required standards. Using a non-approved or non-certified muffler can void the vehicle’s warranty and subject the owner to legal penalties. Compliance labels or markings on the muffler typically indicate type approval status.

- Street Legality vs. Off-Road Use

Many aftermarket mufflers are designed and marketed for off-road or closed-course use only. These mufflers often lack the noise-attenuating or emissions-reducing features necessary for street legality. Using such a muffler on public roads can result in legal consequences. It is the owner’s responsibility to ensure that any muffler installed on a Hayabusa is compliant with the applicable regulations for street use in their jurisdiction. Disclaimers on packaging or product descriptions often indicate the intended use of the muffler.

These considerations highlight the multifaceted nature of legal compliance as it relates to Suzuki Hayabusa mufflers. Navigating these regulations requires due diligence and a thorough understanding of applicable laws. Compliance is not merely a matter of avoiding penalties but also of contributing to a more environmentally responsible and socially conscious motorcycling community.

7. Heat Dissipation

The correlation between heat dissipation and the Suzuki Hayabusa muffler is a significant factor in maintaining engine performance and preventing component degradation. The high-performance engine of the Hayabusa generates substantial heat, which is channeled through the exhaust system. The muffler, as the terminal point of this system, plays a crucial role in dissipating this thermal energy into the surrounding environment. Inadequate heat dissipation can lead to overheating of the muffler, potentially damaging surrounding components, such as fairings or wiring harnesses. Furthermore, elevated temperatures within the muffler can reduce its lifespan and accelerate corrosion. Therefore, efficient heat dissipation is a critical design parameter for Suzuki Hayabusa mufflers.

Several factors influence the heat dissipation capabilities of a muffler. Material selection is paramount; for instance, titanium offers superior heat dissipation compared to stainless steel. The surface area of the muffler also affects heat transfer; larger mufflers generally dissipate heat more effectively. Design features, such as heat shields or cooling fins, can further enhance heat dissipation. Real-world examples demonstrate that aftermarket mufflers designed with enhanced heat dissipation capabilities often exhibit lower surface temperatures and reduced heat soak to surrounding components compared to stock mufflers. Moreover, proper exhaust system tuning ensures optimal engine performance and minimizes excessive heat generation. An improperly tuned engine can produce excessive exhaust gas temperatures, placing additional strain on the muffler’s heat dissipation capacity. Maintenance practices, such as ensuring proper airflow around the muffler and cleaning any accumulated debris, contribute to efficient heat dissipation.

In conclusion, heat dissipation is an integral function of the Suzuki Hayabusa muffler, influencing its performance, durability, and the overall health of the motorcycle. Material selection, design features, proper tuning, and maintenance practices all contribute to efficient heat dissipation. By understanding the practical significance of this relationship, owners can make informed decisions regarding muffler selection and maintenance, ensuring optimal performance and longevity. Ignoring this aspect can lead to component damage, reduced performance, and potential safety hazards. The design challenges involve balancing heat dissipation with other performance parameters, such as weight reduction and noise attenuation, highlighting the complex engineering considerations involved in developing high-performance mufflers.

Frequently Asked Questions

This section addresses common inquiries regarding the selection, maintenance, and performance aspects of the Suzuki Hayabusa muffler. The information provided aims to clarify prevailing misconceptions and offer data-driven insights.

Question 1: What constitutes a performance-enhancing Suzuki Hayabusa muffler?

A performance-enhancing component typically exhibits reduced backpressure relative to the factory-installed unit. This facilitates more efficient exhaust gas evacuation, potentially increasing horsepower and torque. However, optimal performance gains necessitate corresponding adjustments to the engine’s fuel mapping.

Question 2: How does muffler material impact the Suzuki Hayabusa’s exhaust note?

The material’s density and resonance characteristics influence the generated sound. Stainless steel generally produces a brighter tone, while titanium tends to generate a deeper, more resonant exhaust note. Carbon fiber sleeves primarily serve an aesthetic purpose, with a minor dampening effect on sound.

Question 3: What are the legal considerations when modifying the Suzuki Hayabusa exhaust system?

Most jurisdictions enforce noise emission standards for motorcycles. Aftermarket mufflers must comply with these regulations to be street legal. Furthermore, altering or removing catalytic converters may violate emissions regulations in certain regions. It is incumbent upon the owner to ensure compliance with all applicable laws.

Question 4: How does muffler weight reduction affect Suzuki Hayabusa performance?

Decreasing muffler weight improves the motorcycle’s power-to-weight ratio, leading to enhanced acceleration, braking, and handling. Lightweight materials such as titanium contribute to reduced overall mass and improved responsiveness. The degree of improvement is contingent upon the extent of weight reduction achieved.

Question 5: What maintenance procedures are recommended for Suzuki Hayabusa mufflers?

Regular inspection for corrosion, cracks, and leaks is essential. Cleaning the muffler periodically removes accumulated dirt and debris, maintaining its aesthetic appearance. Proper mounting and secure connections prevent vibrations and potential damage. Depending on the environment, anti-corrosion treatments may be beneficial.

Question 6: Is professional installation necessary for aftermarket Suzuki Hayabusa mufflers?

While some owners may possess the requisite mechanical skills, professional installation is generally recommended. Proper installation ensures secure mounting, leak-free connections, and accurate alignment. Improper installation can lead to performance degradation, damage, or safety hazards. A qualified technician can also advise on optimal tuning adjustments.

Understanding these key considerations facilitates informed decision-making regarding Suzuki Hayabusa muffler selection, modification, and maintenance.

The subsequent section will provide detailed guidance on selecting an appropriate Suzuki Hayabusa muffler based on individual needs and preferences.

Conclusion

The preceding discussion has elucidated the multifaceted nature of the component related to the Suzuki Hayabusa. The analysis encompassed performance enhancement, sound modulation, material considerations, aesthetic customization, weight reduction, legal compliance, and heat dissipation. These elements are intertwined, demanding a holistic understanding for informed decision-making.

Therefore, the selection, maintenance, or modification demands careful deliberation. The potential benefits are significant, ranging from improved performance to enhanced aesthetic appeal. Continued diligence in understanding advancements and regulatory changes remains crucial for all stakeholders. Prioritize informed choices.