A device designed to attenuate sound emanating from a conical acoustic horn is commonly employed in scenarios where directed audio projection is necessary but excessive noise levels are undesirable. These sound-dampening components typically utilize absorptive materials and/or strategic baffling to reduce the amplitude of the emitted sound wave. For example, these accessories are often attached to public address systems used in crowded environments to mitigate noise pollution while maintaining speech intelligibility.

The utilization of these acoustic modifications offers several advantages. They contribute to a more controlled auditory environment, reducing listener fatigue and minimizing disturbance to surrounding areas. Historically, methods of sonic control have been implemented alongside acoustic amplification technologies to balance the need for communication with considerations for environmental noise management. This balance is crucial in maintaining order and clarity in various public and industrial settings.

Understanding the principles of sound attenuation and the design considerations behind these devices allows for a more informed approach to optimizing audio communication systems. Subsequent sections will delve into the specific types, construction materials, and applications where these noise-reducing elements are most effectively employed. The objective is to provide a detailed exploration of methods for controlling sound propagation from amplified sources.

Tips for Effective Sound Management with Acoustic Horn Dampeners

Effective deployment of devices for attenuating sound projection from conical acoustic horns requires careful consideration of several factors. The following tips offer guidance for optimal performance and noise reduction.

Tip 1: Material Selection: Choose absorptive materials based on the frequency range of the projected sound. Denser materials are generally more effective at attenuating lower frequencies, while porous materials are better suited for higher frequencies. Consider testing different materials to determine the optimal composition for the specific application.

Tip 2: Proper Installation: Ensure a secure and airtight fit to the acoustic horn. Gaps or loose connections can compromise the device’s effectiveness and introduce unwanted noise artifacts. Follow manufacturer guidelines for installation procedures meticulously.

Tip 3: Environmental Considerations: Account for environmental factors such as temperature and humidity, which can affect the performance of certain sound-dampening materials. Select materials that are resistant to degradation under the anticipated environmental conditions.

Tip 4: Strategic Placement: Consider the placement of the audio projection system in relation to surrounding structures and reflective surfaces. Positioning the system to minimize reflections can further reduce overall noise levels in the surrounding environment.

Tip 5: Regular Maintenance: Inspect the device periodically for signs of wear, damage, or material degradation. Replace or repair components as needed to maintain optimal performance. A preventative maintenance schedule can extend the lifespan of the device.

Tip 6: Sound Level Monitoring: Implement a system for monitoring sound levels in the surrounding environment. This allows for objective assessment of the device’s effectiveness and identification of potential areas for improvement.

Tip 7: Compliance with Regulations: Ensure compliance with local noise ordinances and regulations. This may require adjusting the projection volume or implementing additional sound-dampening measures to meet established standards.

Effective sound management with acoustic horn dampeners involves a comprehensive approach that addresses material selection, installation, environmental factors, and ongoing monitoring. By implementing these tips, users can achieve optimal noise reduction while maintaining clear and effective audio communication.

The following sections will provide further insights into advanced techniques and troubleshooting strategies for maximizing the performance of audio projection systems and their associated dampening components.

1. Material Composition

The effectiveness of a sound-dampening device affixed to an acoustic horn is inextricably linked to its material composition. The chosen materials directly dictate the degree to which sound waves are absorbed, reflected, or transmitted, thereby influencing the overall noise reduction achieved. Porous materials, such as open-cell foams and fibrous composites, are commonly employed due to their ability to convert sound energy into heat through frictional losses within their internal structure. Denser materials, conversely, may reflect or block sound waves, offering an alternative mechanism for attenuation. The specific material or combination of materials selected must align with the frequency range of the sound being emitted from the acoustic horn to ensure optimal performance. For example, a dampener designed for a low-frequency audio system may utilize a dense rubber or layered composite, whereas a system projecting higher frequencies might rely on a more porous and lightweight foam.

The structural integrity and durability of these materials also warrant consideration. Outdoor applications, for instance, necessitate materials resistant to ultraviolet radiation, moisture, and temperature fluctuations. A dampener constructed from a material susceptible to degradation could experience diminished performance over time, rendering it ineffective and potentially requiring premature replacement. Real-world examples include the use of weather-resistant polymers in dampeners designed for stadium public address systems and the application of antimicrobial treatments to materials used in healthcare facilities to prevent the growth of mold or bacteria. This demonstrates the interconnectedness of material choice, environmental context, and long-term functionality.

In conclusion, material composition is a paramount determinant of sound-dampening efficacy and longevity in these devices. Understanding the acoustic properties, structural characteristics, and environmental limitations of different materials is essential for selecting the appropriate components and maximizing noise reduction in a given application. The selection challenges involve balancing acoustic performance with durability, cost-effectiveness, and environmental impact. Further research into novel materials and composite structures promises to advance the field of acoustic horn noise control and provide solutions tailored to diverse operational requirements.

2. Acoustic Absorption

Acoustic absorption is a fundamental property governing the effectiveness of a noise-reducing attachment for a conical acoustic horn. It dictates the extent to which sound energy is dissipated rather than reflected or transmitted, directly impacting the device’s ability to attenuate sound projection.

- Material Porosity and Fiber Density

The porosity and fiber density of the materials employed within the dampener significantly affect its absorptive capabilities. Higher porosity and optimized fiber density create more surface area for sound waves to interact with, facilitating the conversion of acoustic energy into heat through friction. For example, open-cell foams with controlled pore sizes are frequently utilized. Their efficiency is dependent on the pore size being appropriately matched to the wavelengths of the sounds being attenuated. Inefficient pore matching leads to reduced noise control.

- Surface Treatment and Geometry

The surface treatment and overall geometry of the dampener influence how sound waves interact with the absorptive materials. Textured or convoluted surfaces increase the effective surface area, promoting greater acoustic absorption. In contrast, smooth surfaces may reflect sound waves, reducing the dampener’s effectiveness. Examples of surface treatments include the application of acoustic coatings or the incorporation of strategically placed baffles that redirect sound waves towards absorptive materials, leading to a reduction in the sound that’s propagating towards to outside environment.

- Frequency-Dependent Absorption

Different materials exhibit varying degrees of acoustic absorption at different frequencies. A dampener designed for broadband noise reduction often incorporates a combination of materials with complementary absorption characteristics. For instance, a layered construction might include a dense material to attenuate low frequencies and a porous material to absorb high frequencies. This ensures a more uniform reduction in noise across a wider spectrum, leading to a more effective sound management solutions, applicable to a range of sonic environments.

- Impedance Matching

Effective acoustic absorption relies on impedance matching between the dampener and the surrounding air. An impedance mismatch can result in sound waves being reflected rather than absorbed. To mitigate this, dampeners are often designed with a gradual transition in impedance, facilitating a smoother transfer of sound energy into the absorptive material. For example, a dampener might incorporate a tapered design or a series of layers with progressively increasing density to minimize reflections and maximize sound absorption. The more balanced the impedance the less echoing and more sound that’s effectively absorbed.

The interplay of material properties, surface treatments, frequency-dependent absorption, and impedance matching determines the overall effectiveness of an acoustic horn noise dampener. Optimizing these factors allows for the creation of devices that significantly reduce noise pollution while preserving the clarity and intelligibility of the intended audio signal. The effectiveness of sound reduction solutions are a result of the impedance matching, frequency and other physical properties used in its construction and design.

3. Frequency Range

The efficacy of a sound-dampening device attached to an acoustic horn is critically dependent on its ability to attenuate sound waves within a specific frequency range. The design and material composition of such a device must be tailored to address the frequencies produced by the audio source using the acoustic horn. If the frequency range of the audio overlaps poorly with the dampener’s effective range, the device’s ability to mitigate sound propagation will be compromised. A public address system utilized for voice announcements, for instance, typically operates within the speech frequency range (approximately 300 Hz to 3 kHz). A dampener intended for this application must exhibit high attenuation within this range to effectively reduce noise pollution while maintaining speech intelligibility. Conversely, a dampener designed for a system projecting music may need to address a broader frequency spectrum, requiring a more complex design or multiple layers of different materials.

Failure to account for frequency range can lead to ineffective noise reduction or, paradoxically, distortion of the intended audio signal. A dampener that excessively attenuates high frequencies may result in muffled or unclear audio, while one that fails to address low frequencies may allow undesirable rumbling or booming sounds to propagate. Consider the example of emergency sirens, which often incorporate frequencies designed to penetrate ambient noise. A dampener that indiscriminately reduces all frequencies could render the siren less effective in alerting the public. Therefore, careful consideration of the intended audio signal’s spectral characteristics is essential when selecting or designing a sound-dampening device for an acoustic horn. Advanced designs may incorporate tunable elements that allow the device’s effective frequency range to be adjusted to suit different audio sources.

In summary, the frequency range constitutes a vital parameter in determining the performance of a sound-dampening component for an acoustic horn. Matching the dampener’s attenuation characteristics to the intended audio signal’s frequency spectrum is crucial for achieving effective noise reduction without compromising audio clarity or intelligibility. Challenges remain in developing devices that offer broad bandwidth attenuation while maintaining compact size and cost-effectiveness. Future advancements in materials science and acoustic engineering will likely focus on addressing these challenges, leading to more versatile and efficient sound-dampening solutions.

4. Attenuation Level

Attenuation level, in the context of sound-dampening devices designed for acoustic horns, represents the degree to which the device reduces the intensity of the sound waves emitted. This parameter is crucial in determining the effectiveness of the dampening solution and its suitability for specific applications.

- Decibel Reduction and Perceived Loudness

Attenuation level is typically quantified in decibels (dB), representing the logarithmic reduction in sound pressure level. A higher dB reduction corresponds to a greater decrease in perceived loudness. For example, a dampener with a 10 dB attenuation level will reduce the perceived loudness of the sound by approximately half. In scenarios where strict noise regulations are enforced, a dampener with a high attenuation level is essential. The measured attenuation level must consistently comply with the relevant standards to avoid penalties and maintain a safe and comfortable acoustic environment.

- Frequency Dependence of Attenuation

The attenuation level of a dampening device is rarely uniform across all frequencies. Most devices exhibit frequency-dependent attenuation, meaning they are more effective at reducing sound intensity within certain frequency ranges. This characteristic must be considered when selecting a dampener for a specific application. For instance, a dampener designed for speech reinforcement should exhibit high attenuation within the speech frequency range (300 Hz to 3 kHz). A dampener with poor attenuation at these frequencies would be ineffective in reducing noise pollution from voice announcements. This means the frequency range and attenuation must be balanced according to the specific use for the amplification of sound.

- Impact on Audio Clarity and Intelligibility

While a high attenuation level is desirable for noise reduction, excessive attenuation can negatively impact the clarity and intelligibility of the intended audio signal. A dampener that excessively attenuates high frequencies, for example, may result in muffled or unclear audio. Careful design and material selection are necessary to achieve a balance between noise reduction and audio quality. Advanced dampening designs may incorporate tunable elements that allow the attenuation level to be adjusted to suit different audio sources. This allows the dampener to be optimized for different sonic needs, maximizing the output from the amplification device.

- Measurement and Verification Methods

The attenuation level of a dampening device should be determined through standardized measurement methods, such as those defined by ANSI or ISO. These methods involve measuring the sound pressure level with and without the dampener in place under controlled conditions. The resulting difference in sound pressure level represents the attenuation level. Independent verification of the attenuation level by a certified testing laboratory provides assurance of the device’s performance. Measurement, verification and control should all be part of the attenuation plan.

In conclusion, the attenuation level is a critical performance parameter of sound-dampening devices used with acoustic horns. Achieving the appropriate attenuation level, while maintaining audio quality and complying with relevant regulations, requires careful consideration of frequency dependence, design, and measurement methods. These combined strategies will optimize performance of the sound management plan for any megaphone or acoustic horn set up.

5. Physical Dimensions

The physical dimensions of a sound-dampening device designed for use with an acoustic horn directly influence its acoustic performance and practical applicability. These dimensions, including length, diameter, and internal volume, dictate the device’s ability to attenuate sound waves of specific frequencies. A larger internal volume, for example, may be necessary to effectively dampen lower frequencies, while a longer device may provide a greater path length for sound absorption. Conversely, overly large dimensions can render the dampener unwieldy and impractical for certain applications, particularly in portable or space-constrained environments. Therefore, a balance between acoustic performance and physical size is a critical design consideration. For example, dampeners used in crowd control megaphones must be compact and lightweight to maintain ease of use, while those intended for stationary public address systems may prioritize acoustic performance over portability.

The method of attachment to the acoustic horn is also heavily influenced by the dampener’s physical dimensions. A secure and airtight fit is essential to prevent sound leakage and maintain optimal attenuation. The dimensions of the attachment interface must precisely match those of the acoustic horn to ensure a proper seal. Furthermore, the overall weight of the dampener, determined by its dimensions and material composition, must be considered to avoid placing undue stress on the acoustic horn. Real-world examples illustrate this principle: lightweight foam dampeners are commonly used with plastic megaphones to minimize stress, while more robust metal dampeners may require reinforced attachments when used with larger, more powerful acoustic horns. Incorrect physical dimensions may not only render the dampener ineffective but can also damage the acoustic horn itself.

In summary, the physical dimensions of a sound-dampening device for an acoustic horn are inextricably linked to its acoustic performance, ease of use, and compatibility with the horn. Careful consideration of these dimensions is essential for selecting or designing a dampening solution that effectively reduces noise pollution while maintaining practicality and avoiding potential damage. The challenge lies in optimizing dimensions to achieve the desired acoustic characteristics within the constraints of the intended application. Future advancements may involve the development of novel materials and designs that allow for smaller, more efficient dampeners without sacrificing performance.

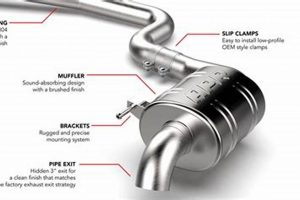

6. Attachment Method

The attachment method is a critical determinant of the efficacy of any sound-dampening device employed on a conical acoustic horn. The secure and stable affixation of the dampener directly influences its ability to effectively attenuate sound waves emanating from the horn. A poorly executed attachment can result in sound leakage, vibrational resonances, and ultimately, a significant reduction in the dampener’s intended noise-reducing capabilities. For example, a slip-on dampener lacking a tight seal around the horn’s perimeter allows sound waves to escape, negating the absorptive properties of the dampening material. Similarly, a dampener secured with inadequate fastening mechanisms may vibrate in response to the sound waves, generating additional noise and further diminishing the overall attenuation level. The attachment method, therefore, functions as an integral component of the sound-dampening system, impacting performance as significantly as the materials used in its construction.

Diverse attachment methods are employed depending on the design of the acoustic horn and the sound-dampening device. These can range from simple friction fits and clamp systems to more elaborate threaded connections and adhesive bonding. Each method offers distinct advantages and disadvantages in terms of ease of installation, security of attachment, and potential for long-term degradation. For instance, threaded connections provide a highly secure and stable attachment, but may be impractical for quick installation or removal. Adhesive bonding, while offering a clean and permanent solution, may be susceptible to degradation from environmental factors such as temperature and humidity. Clamping mechanisms offer a balance between security and ease of use, but must be carefully designed to avoid creating stress points on the acoustic horn. The selection of an appropriate attachment method requires careful consideration of these factors to ensure both effective sound dampening and the longevity of the system.

In conclusion, the attachment method represents a crucial aspect of the sound-dampening system integrated with acoustic horns. Its selection directly impacts the system’s overall effectiveness in reducing noise pollution and maintaining audio clarity. A robust and well-engineered attachment mechanism ensures optimal performance by minimizing sound leakage, preventing vibrational resonances, and providing long-term stability. Further advancements in attachment technologies, focusing on ease of installation, secure fixation, and resistance to environmental degradation, are crucial for enhancing the overall performance and reliability of sound-dampening solutions for acoustic horns. The successful integration between sound dampening systems and acoustic horns is largely dependent on an equally well designed and executed attachment method.

7. Environmental Resistance

Environmental resistance, in the context of sound-dampening devices attached to acoustic horns, refers to the ability of the device to maintain its structural integrity and acoustic performance when exposed to various environmental conditions. The longevity and effectiveness of these noise-reducing components are directly dependent on their capacity to withstand factors such as temperature variations, humidity, ultraviolet radiation, and physical impacts. Failure to adequately address environmental resistance can lead to premature degradation of the dampening materials, compromising their ability to attenuate sound and potentially requiring costly replacements.

- UV Radiation Degradation

Prolonged exposure to ultraviolet (UV) radiation from sunlight can cause significant degradation in certain materials commonly used in these sound-dampening components. Polymers, foams, and fabrics are particularly susceptible to UV-induced chain scission, leading to embrittlement, discoloration, and loss of structural integrity. For instance, a dampener installed on an outdoor public address system may experience a gradual decline in its acoustic performance due to UV degradation of its foam lining. Selecting UV-resistant materials or applying protective coatings can mitigate these effects, ensuring the dampener maintains its effectiveness over time.

- Temperature and Humidity Effects

Fluctuations in temperature and humidity can also impact the performance and durability of these noise-reducing attachments. Extreme temperatures can cause materials to expand or contract, potentially leading to dimensional changes that compromise the fit and seal of the dampener. High humidity can promote the growth of mold and mildew within porous materials, further degrading their acoustic properties and posing potential health hazards. Dampeners designed for use in harsh climates should incorporate materials that are resistant to these effects, such as closed-cell foams and hydrophobic coatings. For example, in tropical environments, dampeners used in outdoor event spaces require materials designed to resist high temperature and high levels of humidity.

- Physical Impact and Abrasion

Sound-dampening devices are often subjected to physical impacts and abrasion during transportation, installation, and use. This is particularly relevant in portable applications, such as megaphones used by emergency responders or construction workers. The materials used in these dampeners must be robust enough to withstand these stresses without sustaining significant damage. Protective outer layers, reinforced construction, and impact-resistant materials can enhance the dampener’s ability to withstand physical abuse. For instance, a megaphone used in a construction environment benefits from a robust outer shell that protects internal components from accidental impacts and abrasion from job-site materials.

- Chemical Exposure and Corrosion

In certain industrial environments, sound-dampening devices may be exposed to corrosive chemicals or solvents that can degrade their materials. Selecting chemically resistant materials, such as fluoropolymers or specialized coatings, is crucial for ensuring long-term performance in these settings. For instance, a dampener used in a manufacturing facility may require protection against exposure to cutting fluids, lubricants, or cleaning agents. Using the appropriate shielding will help mitigate degradation from chemical exposure or corrosion.

In conclusion, environmental resistance is a critical factor in the design and selection of sound-dampening devices for acoustic horns. Addressing the potential impacts of UV radiation, temperature, humidity, physical impacts, and chemical exposure is essential for ensuring the long-term performance and reliability of these noise-reducing components. Utilizing durable, environmentally resistant materials extends the lifespan of the overall design.

Frequently Asked Questions

The following questions address common inquiries regarding devices designed to attenuate sound projection from acoustic horns, often referred to as megaphone mufflers. This section aims to provide clarity on their functionality, applications, and limitations.

Question 1: What is the primary function of a device marketed as a “megaphone muffler”?

The primary function is to reduce the sound pressure level emanating from a conical acoustic horn, commonly used in megaphones and public address systems. It mitigates noise pollution while maintaining a degree of speech intelligibility within a targeted area.

Question 2: How does a “megaphone muffler” achieve sound attenuation?

These devices typically employ absorptive materials, baffling techniques, or a combination thereof to dissipate sound energy. The specific mechanism depends on the design and the frequency range targeted for attenuation.

Question 3: Are there different types of “megaphone mufflers”?

Yes, variations exist based on materials, construction, and intended application. Some are designed for specific frequency ranges, while others offer broadband attenuation. The choice depends on the characteristics of the audio source and the surrounding environment.

Question 4: Does using a “megaphone muffler” affect the clarity of the projected sound?

Improperly designed mufflers can negatively impact audio clarity, particularly by attenuating high frequencies. Careful design and material selection are necessary to balance noise reduction with speech intelligibility. Sound clarity is a balance between frequency and output level which will optimize intelligibility.

Question 5: Are “megaphone mufflers” universally compatible with all megaphones?

No, compatibility depends on the physical dimensions and attachment method of both the megaphone and the muffler. It is essential to ensure a proper fit and secure connection to avoid sound leakage and maintain optimal performance. The fit between the components is a key aspect of performance.

Question 6: What are the key factors to consider when selecting a “megaphone muffler”?

Key considerations include the frequency range of the audio source, the desired attenuation level, the environmental conditions, the compatibility with the megaphone, and the impact on audio clarity. All must be balanced between them.

In summary, a “megaphone muffler” is a tool for managing sound output, balancing noise reduction with the need for clear communication. Careful selection and proper installation are paramount to achieving the desired results.

The following section will explore case studies of effective “megaphone muffler” applications in diverse settings.

Conclusion

The preceding exploration has elucidated the multifaceted aspects of the “megaphone muffler,” a critical component for managing sound propagation from acoustic horns. Key points addressed encompass material composition, acoustic absorption, frequency range considerations, attenuation levels, physical dimensions, attachment methodologies, and environmental resistance. Understanding these elements is paramount for effectively mitigating noise pollution while preserving the intelligibility of the intended audio signal.

Continued research and development in advanced materials and acoustic engineering are essential to optimize the performance and broaden the applicability of the “megaphone muffler.” Future endeavors should prioritize the creation of versatile, durable, and cost-effective solutions that address the diverse acoustic challenges encountered in various operational settings. The responsible deployment of this technology remains crucial for fostering environments conducive to both effective communication and noise mitigation.