This establishment specializes in vehicular exhaust systems and stopping mechanisms. It offers services ranging from the replacement of sound dampening components to the repair and maintenance of devices responsible for deceleration and halting motion. Its core function centers around ensuring vehicles operate quietly and safely.

Proper functioning of these systems is critical for both environmental protection and driver safety. Malfunctioning exhaust components can lead to increased emissions, while brake issues directly impact a vehicle’s ability to stop effectively, potentially causing accidents. Historically, dedicated shops specializing in these areas have played a significant role in maintaining vehicle roadworthiness and compliance with safety regulations.

The following sections will elaborate on the specific aspects of exhaust system maintenance and brake repair, exploring common problems, diagnostic procedures, and recommended service intervals to ensure optimal vehicle performance and safety.

Vehicle Maintenance Guidance

Maintaining optimal vehicle performance requires consistent attention to critical systems. Prioritizing preventative measures minimizes the risk of costly repairs and ensures driver safety.

Tip 1: Regular Brake Inspections: Schedule routine inspections to assess brake pad thickness, rotor condition, and hydraulic line integrity. Early detection of wear prevents brake failure.

Tip 2: Prompt Brake Noise Evaluation: Investigate any unusual noises emanating from the braking system. Squealing, grinding, or clicking sounds often indicate worn components requiring immediate attention.

Tip 3: Exhaust System Examination: Conduct periodic visual inspections of the exhaust system for signs of rust, corrosion, or leaks. Addressing minor issues early prevents significant damage and ensures regulatory compliance.

Tip 4: Muffler Condition Monitoring: Listen for changes in exhaust noise levels. A louder or more aggressive sound may signal a muffler breach, reducing noise dampening efficiency and potentially impacting emissions.

Tip 5: Timely Brake Fluid Replacement: Adhere to manufacturer-recommended intervals for brake fluid replacement. Old or contaminated fluid compromises braking performance and increases the risk of system failure.

Tip 6: Catalytic Converter Awareness: Be vigilant for symptoms of catalytic converter failure, such as reduced engine performance, increased emissions, or a sulfur-like odor. A malfunctioning converter requires prompt replacement to ensure emissions compliance.

Tip 7: Suspension Component Review: Examine suspension components regularly, including shocks, struts, and springs, to maintain stability and control. Worn suspension parts can negatively impact braking effectiveness and overall handling.

Implementing these preventative maintenance measures contributes significantly to extending vehicle lifespan, enhancing driver safety, and reducing the likelihood of unexpected breakdowns. Prioritizing system checks mitigates potential hazards and ensures continued operational efficiency.

The subsequent sections will provide more detailed information on specific repair procedures and advanced diagnostic techniques for maintaining both the exhaust and braking systems.

1. Exhaust Noise Reduction

Exhaust noise reduction is a critical function addressed by automotive service providers specializing in exhaust systems. This function impacts vehicle operation, environmental regulations, and overall driving experience. The integrity of the exhaust system directly correlates with the level of noise emitted, necessitating professional attention when irregularities arise.

- Muffler Functionality

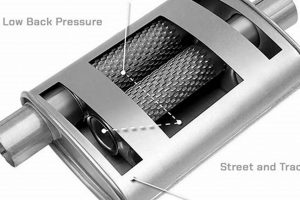

The muffler is a primary component designed to attenuate exhaust noise. Its internal chambers and baffles are engineered to reduce sound waves emanating from the engine. Damage or corrosion to the muffler compromises its sound-dampening capabilities, leading to increased noise levels and potential regulatory violations.

- Exhaust System Leaks

Leaks within the exhaust system, including those around connections or within the pipes themselves, create pathways for pressurized exhaust gases to escape prematurely. This results in elevated noise levels and can also lead to potential safety hazards due to the introduction of exhaust fumes into the vehicle cabin.

- Resonator Performance

The resonator, often positioned upstream of the muffler, further refines exhaust sound. It targets specific frequencies to reduce drone and unwanted noise characteristics. Degradation of the resonator affects the overall sound quality and can contribute to increased noise pollution.

- Catalytic Converter Impact

While primarily responsible for emissions control, the catalytic converter also contributes to noise reduction by altering the flow and composition of exhaust gases. A failing catalytic converter can lead to changes in exhaust sound and potentially amplify noise due to increased backpressure or internal damage.

These interconnected aspects of exhaust noise reduction are central to the services provided. Addressing these issues requires specialized diagnostic equipment and expertise to ensure optimal performance, regulatory compliance, and a comfortable driving environment.

2. Braking System Efficiency

Braking system efficiency directly relates to the operational integrity of vehicles serviced. Effective braking is paramount for safety, influencing stopping distances, vehicle control, and accident avoidance. This efficiency is a key element in assessing overall vehicle roadworthiness and safety standards.

- Hydraulic System Integrity

The hydraulic system transmits force from the brake pedal to the brake calipers or drums. Leaks, air contamination, or component failures within this system reduce pressure, increasing stopping distances and compromising control. Routine inspections and maintenance of master cylinders, brake lines, and calipers are essential for maintaining hydraulic efficiency.

- Friction Material Condition

Brake pads and shoes generate friction against rotors or drums to decelerate the vehicle. Wear, glazing, or contamination of these friction materials reduce their coefficient of friction, diminishing braking power. Regular monitoring of pad/shoe thickness and rotor/drum surface condition is vital for optimal braking performance.

- Rotor and Drum Integrity

Rotors and drums serve as the friction surfaces for brake pads and shoes. Warping, cracking, or excessive wear on these components leads to uneven braking, vibrations, and increased stopping distances. Machining or replacement of damaged rotors/drums is crucial for restoring braking efficiency and safety.

- Anti-lock Braking System (ABS) Functionality

ABS modulates braking force to prevent wheel lockup during hard braking, maintaining steering control. Malfunctions in the ABS system compromise its ability to prevent skidding, particularly on slippery surfaces. Diagnostic testing and repair of ABS sensors, modules, and hydraulic components are essential for preserving ABS functionality and maximizing braking efficiency in emergency situations.

These facets of braking system efficiency are integral to the comprehensive vehicle services offered. Prioritizing the inspection, maintenance, and repair of these components ensures reliable stopping power and enhanced safety for both the driver and other road users. The optimization of these areas are significant factors contributing to its reputation and services provided.

3. Emissions Compliance

Adherence to emissions regulations constitutes a critical aspect of automotive maintenance, directly influencing vehicle legality and environmental responsibility. For a business specializing in exhaust and braking systems, emissions compliance represents a core service offering and a significant operational focus.

- Catalytic Converter Functionality

The catalytic converter reduces harmful pollutants in exhaust gases by facilitating chemical reactions. A malfunctioning catalytic converter leads to increased emissions of hydrocarbons, carbon monoxide, and nitrogen oxides, resulting in failed emissions tests and potential fines. Services focused on catalytic converter diagnostics, repair, and replacement are crucial for achieving emissions compliance.

- Exhaust System Integrity

Leaks within the exhaust system allow unburned hydrocarbons to escape into the atmosphere, contributing to air pollution. Maintaining a leak-free exhaust system, through welding repairs, component replacements, and seal maintenance, is essential for preventing excessive emissions and ensuring compliance with regulatory standards. Proper muffler functionality also plays a role in reducing certain emissions components.

- Oxygen Sensor Performance

Oxygen sensors monitor the oxygen content in the exhaust stream, providing feedback to the engine control unit (ECU) to optimize fuel-air mixture. Faulty oxygen sensors disrupt the feedback loop, leading to inefficient combustion and increased emissions. Accurate diagnosis and replacement of malfunctioning oxygen sensors are necessary for maintaining optimal engine performance and achieving emissions compliance.

- State and Local Regulations

Emissions standards vary by location, with specific requirements for vehicle testing and acceptable pollutant levels. Familiarity with and adherence to these regulations is essential for ensuring vehicles meet local requirements. Inspection services, repair recommendations aligned with specific regulations, and certification of compliance are critical aspects of emissions-related services.

The intersection of these elements underscores the importance of specialized services in ensuring vehicles meet stringent emissions criteria. Addressing these issues not only fulfills legal obligations but also contributes to improved air quality and environmental sustainability, key aspects of the services offered.

4. Component Longevity

Component longevity, in the context of exhaust and braking systems, directly impacts operational costs and vehicle safety. Premature failure of mufflers, brake pads, rotors, or related parts increases the frequency of repairs, raising the total cost of ownership. Substandard materials or improper installation practices contribute to accelerated degradation, necessitating more frequent replacements. For instance, low-quality brake pads may wear down rapidly, requiring replacement within a year, whereas durable, high-quality pads could last several years under similar driving conditions. Similarly, exhaust systems constructed from inferior steel are susceptible to corrosion, shortening their lifespan compared to those manufactured with stainless steel.

Optimal component longevity stems from a combination of quality parts and meticulous service procedures. Selecting components engineered for durability and resistance to environmental factors, such as salt and road debris, extends their operational lifespan. Proper installation techniques, including correct torque specifications and careful alignment, prevent premature stress and failure. Regular inspections and preventative maintenance, such as flushing brake fluid and addressing minor exhaust leaks promptly, mitigate wear and tear, maximizing the lifespan of critical system components.

The interplay between component quality, service practices, and preventative maintenance dictates the operational lifespan of exhaust and braking systems. Prioritizing durable components and adhering to rigorous service protocols minimizes long-term ownership costs and ensures consistent vehicle safety. Failure to address component longevity results in recurring repairs and increased financial burdens, highlighting the practical significance of proactive maintenance and quality part selection.

5. Driver Safety Assurance

Driver safety assurance is intrinsically linked to the proper functioning of vehicle exhaust and braking systems. The ability to safely decelerate and stop a vehicle, coupled with the mitigation of hazardous emissions, directly influences the safety of the driver, passengers, and surrounding environment. Deterioration or malfunction in either system compromises the vehicle’s operational integrity and elevates the risk of accidents or health hazards.

Consider, for instance, a scenario where a vehicle’s brake pads are excessively worn. The reduced friction coefficient increases stopping distances, potentially leading to a collision. Similarly, a compromised exhaust system emitting excessive carbon monoxide poses a significant health risk to vehicle occupants. Regular inspections, maintenance, and repairs of these systems are therefore essential preventative measures against accidents and health complications. A business specializing in these systems plays a crucial role in identifying and rectifying issues before they escalate into safety threats.

The practical significance of understanding this connection lies in proactive vehicle maintenance. Recognizing the importance of functional exhaust and braking systems encourages drivers to seek timely professional services. This proactive approach not only safeguards the driver and vehicle occupants but also contributes to a safer road environment for all users. Overlooking maintenance requirements creates a chain of potential consequences, culminating in preventable accidents and avoidable health risks, emphasizing the crucial role of businesses that prioritize these systems.

Frequently Asked Questions

The following represents responses to common inquiries regarding automotive exhaust and braking systems. The information presented is intended to provide clarity and promote informed decision-making concerning vehicle maintenance and repair.

Question 1: What factors contribute to premature muffler failure?

Muffler failure is often accelerated by internal corrosion resulting from condensation of exhaust gases. Exposure to road salt and physical damage from road debris also significantly reduce muffler lifespan. Regular inspections can identify early signs of deterioration.

Question 2: How frequently should brake pads be replaced?

Brake pad replacement intervals vary based on driving habits and vehicle type. However, a visual inspection of brake pad thickness should be conducted at least every six months or 6,000 miles. Replacement is indicated when pad thickness reaches a critical minimum.

Question 3: What are the potential consequences of neglecting exhaust system leaks?

Unrepaired exhaust leaks compromise emissions control, reduce fuel efficiency, and introduce potentially hazardous carbon monoxide into the vehicle cabin. Furthermore, exhaust leaks contribute to increased noise pollution.

Question 4: How does brake fluid condition impact braking performance?

Brake fluid is hygroscopic, meaning it absorbs moisture from the atmosphere. Contaminated brake fluid reduces its boiling point, leading to vapor lock and diminished braking effectiveness, particularly during heavy braking. Regular brake fluid flushes are essential for maintaining optimal braking performance.

Question 5: What are the warning signs of a failing catalytic converter?

Symptoms of catalytic converter failure include reduced engine performance, a sulfur-like odor emanating from the exhaust, and failed emissions tests. In some cases, a rattling sound from the converter housing may also be audible.

Question 6: Does the quality of brake rotors significantly affect braking performance?

Yes, the quality and composition of brake rotors directly influence heat dissipation, friction coefficient, and resistance to warping. High-quality rotors provide more consistent braking performance, reduced brake fade, and extended service life.

The answers provided offer insights into common exhaust and braking system concerns. Seeking professional evaluation remains crucial for accurate diagnosis and appropriate corrective action.

The following section will address advanced diagnostic techniques employed in assessing these critical vehicle systems.

Conclusion

This exploration has elucidated the critical role of exhaust and braking systems in vehicle operation and safety. Factors influencing component longevity, emissions compliance, and driver safety assurance have been examined in detail. Recognizing the interdependence of these systems is essential for responsible vehicle ownership.

Effective maintenance and timely repair are paramount. Neglecting these systems leads to compromised safety, increased environmental impact, and potential regulatory violations. Prioritizing professional evaluation and service ensures continued vehicle reliability and responsible road usage.