Components designed to mitigate engine noise and aftermarket enhancements tailored for pickup vehicles utilized in agricultural or rural environments represent a specialized market segment. These products often prioritize durability and functionality over purely aesthetic considerations, serving a practical need for vehicle owners in demanding work conditions.

The adoption of these sound-dampening and enhancement devices is significant due to its impact on operational efficiency, vehicle longevity, and regulatory compliance. Historically, these enhancements have evolved from basic noise reduction solutions to sophisticated systems offering performance upgrades, increased storage capacity, and enhanced protection against environmental hazards. The rugged build quality reflects the harsh conditions under which these vehicles operate, requiring robust construction and resistance to corrosion.

The subsequent sections will delve into specific types of exhaust system modifications, various categories of aftermarket parts designed for truck customization, and considerations for selecting the optimal equipment based on operational requirements and budget.

Essential Considerations for Ranch Vehicle Exhaust and Customization

Selecting appropriate exhaust modifications and aftermarket enhancements for ranch vehicles requires careful evaluation of performance needs, environmental conditions, and budget constraints. Prioritizing durability and functionality is crucial for ensuring reliable operation and extended vehicle lifespan.

Tip 1: Assess Operational Requirements: Evaluate the primary uses of the vehicle, including hauling frequency, terrain type, and typical load weight, to determine necessary performance enhancements.

Tip 2: Consider Environmental Factors: Select materials and coatings resistant to corrosion and degradation from exposure to moisture, dust, and agricultural chemicals.

Tip 3: Prioritize Durability and Build Quality: Opt for components manufactured from high-grade steel or alloys designed to withstand rigorous use and impact.

Tip 4: Research Noise Reduction Technologies: Investigate muffler options that effectively minimize engine noise without compromising performance, ensuring compliance with local noise ordinances and reducing operator fatigue.

Tip 5: Evaluate Storage Solutions: Assess cargo-carrying needs and choose bed covers, toolboxes, or storage racks that provide secure and weather-resistant storage for equipment and supplies.

Tip 6: Inspect Suspension Upgrades: Determine if suspension modifications are necessary to improve handling and stability under heavy loads or on uneven terrain.

Tip 7: Verify Compatibility: Ensure all selected components are compatible with the vehicle’s make, model, and year to prevent installation issues or performance compromises.

Adhering to these recommendations facilitates the selection of appropriate vehicle enhancements, thereby maximizing performance, extending service life, and ensuring operational efficiency in demanding ranching environments.

The following sections will address common installation procedures and maintenance practices to optimize the performance and longevity of these automotive systems.

1. Noise Mitigation

Effective noise mitigation is a fundamental requirement for vehicles operating in agricultural environments. Excessive noise emissions can lead to operator fatigue, communication challenges, and potential violations of local noise ordinances. Addressing these concerns necessitates the selection of specialized exhaust systems and sound-dampening components designed to reduce decibel levels without compromising engine performance.

- Muffler Design and Functionality

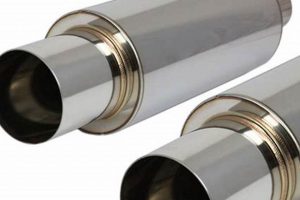

Muffler design plays a critical role in noise reduction. Baffled and chambered mufflers are commonly employed to disrupt and absorb sound waves generated by the engine’s combustion process. The internal structure of the muffler dictates its effectiveness in attenuating specific frequency ranges, and the selection should be tailored to the engine characteristics and operational demands. Aftermarket muffler options often incorporate advanced materials and designs to achieve superior noise reduction compared to stock systems.

- Resonator Integration

Resonators are supplemental components used in conjunction with mufflers to further dampen exhaust noise. These devices are tuned to specific frequencies, effectively canceling out unwanted sound waves. Integrating a resonator into the exhaust system can provide additional noise reduction without significantly impacting exhaust flow or engine performance. The positioning of the resonator within the exhaust system is crucial for optimal effectiveness.

- Exhaust Pipe Insulation

The radiation of noise from exhaust pipes themselves can contribute significantly to overall noise levels. Wrapping exhaust pipes with thermal insulation not only reduces heat radiation but also dampens vibrational noise. High-temperature wraps designed for exhaust systems can withstand extreme temperatures and provide a durable and effective means of noise mitigation. Proper installation is essential to prevent moisture accumulation and corrosion.

- Cab Soundproofing

While exhaust system modifications address noise at the source, supplementing these measures with cab soundproofing can further reduce noise levels experienced by the vehicle operator. Applying sound-deadening materials to the cab floor, doors, and firewall can minimize the transmission of noise into the cabin. This approach enhances operator comfort and reduces fatigue during extended periods of operation.

The integration of these noise mitigation strategies is essential for creating a more comfortable and productive work environment for ranch vehicle operators. The selection of specific components and techniques should be based on a comprehensive assessment of noise levels, engine characteristics, and operational requirements. Prioritizing noise mitigation not only enhances operator well-being but also promotes regulatory compliance and responsible environmental stewardship.

2. Durability Enhancement

Durability enhancement, in the context of ranch muffler and truck accessories, refers to the augmentation of component resilience to withstand the rigorous demands of agricultural environments. This extends beyond mere product lifespan to encompass resistance to corrosion, impact, and operational stressors.

- Material Selection for Exhaust Systems

The choice of materials directly impacts the longevity of exhaust systems. Aluminized steel provides a moderate level of corrosion resistance suitable for some environments, while stainless steel offers superior protection against rust and degradation caused by exposure to moisture, chemicals, and road salts. Heavy-gauge steel is crucial for mufflers and exhaust pipes to withstand impacts from rocks and debris commonly encountered on ranch terrain.

- Protective Coatings for Truck Accessories

Aftermarket accessories, such as bumpers, bed liners, and running boards, benefit from protective coatings that shield against abrasion, UV exposure, and chemical damage. Powder coating provides a durable, impact-resistant finish, while spray-on bed liners offer robust protection against scratches, dents, and corrosion in truck beds. Regular application of protective coatings can significantly extend the lifespan of these components.

- Reinforced Construction Techniques

Welding quality and structural reinforcement are critical factors in the durability of both exhaust systems and truck accessories. Robust welds ensure the integrity of exhaust pipes and muffler assemblies, preventing leaks and premature failure. Reinforced construction techniques, such as gussets and bracing, enhance the strength and stability of bumpers, racks, and other accessories, enabling them to withstand heavy loads and impacts.

- Design Considerations for Harsh Environments

The design of ranch truck accessories should account for the unique challenges posed by agricultural settings. Components should be engineered to minimize the accumulation of mud, dirt, and debris, which can accelerate corrosion and wear. Sealed electrical connectors and corrosion-resistant hardware are essential for preventing malfunctions caused by exposure to moisture and contaminants. Streamlined designs that minimize snagging on vegetation or obstacles can further enhance durability.

The incorporation of durable materials, protective coatings, reinforced construction, and thoughtful design is essential for maximizing the lifespan and reliability of ranch muffler and truck accessories. Investing in components with enhanced durability translates to reduced maintenance costs, increased operational efficiency, and improved vehicle performance in demanding agricultural environments.

3. Performance Optimization

The objective of performance optimization, when coupled with exhaust and vehicular enhancements commonly employed in ranching, directly relates to enhancing the functional efficacy of the vehicle. This involves addressing factors that impede operational capabilities, particularly in terms of power delivery, fuel efficiency, and handling. The application of aftermarket components is not merely aesthetic; it represents a strategic effort to refine the vehicle’s response to the rigors of agricultural work. An upgraded exhaust system, for example, facilitates improved engine breathing, potentially leading to increased horsepower and torque, which are critical for hauling heavy loads or navigating challenging terrain. Furthermore, performance optimization may encompass enhancements to the vehicle’s suspension, addressing stability and control, especially when traversing uneven ground or carrying substantial payloads.

The practical application of performance optimization is observed through several key modifications. High-flow exhaust systems can reduce backpressure, allowing the engine to operate more efficiently, thereby improving fuel economy and overall power output. Air intake systems, designed to deliver a greater volume of air to the engine, can further contribute to these improvements. Electronic control unit (ECU) tuning, often implemented in conjunction with exhaust and intake upgrades, allows for recalibration of engine parameters to maximize performance gains. Additionally, heavier-duty suspension components, such as upgraded shocks and springs, can enhance stability and load-carrying capacity, ensuring safe and effective operation under demanding conditions.

In conclusion, the integration of ranch-specific exhaust systems and vehicular accessories is intrinsically linked to the goal of performance optimization. This pursuit translates directly into improved operational capabilities, enhanced reliability, and increased efficiency. While challenges may arise in selecting the appropriate components and ensuring proper installation, the resultant gains in performance and longevity justify the investment. This synergy ultimately contributes to the overall productivity and effectiveness of ranching operations.

4. Load Capacity

Load capacity represents a critical consideration in the selection and application of truck accessories for ranching operations. The ability to safely and efficiently transport heavy loads of equipment, supplies, and livestock directly impacts productivity and operational effectiveness. Aftermarket enhancements play a significant role in optimizing a vehicle’s load-carrying capabilities while maintaining safety and performance.

- Suspension Upgrades and Load Support

Upgrading suspension components, such as heavy-duty springs, air suspension systems, or helper springs, directly increases a truck’s load-carrying capacity. These enhancements provide additional support to the vehicle’s chassis, preventing sagging and improving stability when hauling heavy loads. Examples include installing air bags to level the vehicle under load or replacing stock springs with higher-rated alternatives. These modifications ensure safe handling and prevent premature wear on other vehicle components.

- Towing Capacity and Hitch Systems

For ranches requiring frequent towing, upgrading the hitch system is essential for maximizing towing capacity. Selecting a Class IV or V hitch, along with appropriate ball mounts and safety chains, ensures a secure connection between the vehicle and trailer. Reinforcing the vehicle’s frame with additional bracing can further enhance towing stability and prevent damage under heavy loads. Proper hitch selection and installation are crucial for safe and compliant towing operations.

- Bed Accessories and Cargo Management

Bed accessories, such as bed liners, tonneau covers, and cargo management systems, contribute to safe and efficient load carrying. Bed liners protect the truck bed from damage caused by heavy equipment and supplies, while tonneau covers secure cargo and improve aerodynamics. Cargo management systems, including tie-down points, cargo nets, and bed dividers, prevent shifting and ensure the secure transport of various items. These accessories optimize the use of available bed space and enhance cargo security.

- Wheel and Tire Selection for Load Demands

The selection of appropriate wheels and tires is paramount for supporting heavy loads. Load-rated tires with adequate sidewall strength are crucial for maintaining stability and preventing blowouts under pressure. Upgrading to larger diameter wheels with higher load ratings can further enhance load-carrying capacity and improve handling characteristics. Matching wheel and tire specifications to the vehicle’s load demands ensures safe and reliable performance in demanding ranching environments.

The integration of these load-enhancing accessories directly impacts the operational efficiency and safety of ranch vehicles. Careful consideration of load requirements and the selection of appropriate aftermarket enhancements are essential for maximizing the vehicle’s utility and ensuring the safe and effective transport of equipment and supplies. Investment in these accessories is often offset by reduced maintenance costs, improved productivity, and enhanced safety during demanding ranching operations.

5. Vehicle Protection

In the context of ranch operations, vehicle protection assumes paramount importance, necessitating the strategic integration of specialized components. Ranch vehicles are exposed to environmental and operational hazards that significantly accelerate wear and tear, potentially leading to premature failure and increased maintenance costs. The application of specific aftermarket enhancements directly mitigates these risks, safeguarding the vehicle’s structural integrity and extending its operational lifespan.

- Underbody Armor and Shielding

Underbody armor and shielding constitute a critical line of defense against damage from rocks, debris, and uneven terrain commonly encountered in ranch environments. These components, typically constructed from heavy-gauge steel or aluminum, protect vulnerable undercarriage components such as the oil pan, transmission, and fuel tank. Real-world applications include navigating rocky pastures or traversing unpaved roads where impacts from debris are unavoidable. The implementation of underbody protection directly reduces the risk of mechanical damage and potential fluid leaks, minimizing downtime and repair expenses.

- Brush Guards and Front-End Protection

Brush guards and front-end protection devices shield the vehicle’s front fascia from damage caused by collisions with vegetation, livestock, or other obstacles. These components, often constructed from steel tubing or reinforced polymer, provide a robust barrier against impacts that can damage headlights, grilles, and radiators. Ranch vehicles operating in areas with dense brush or livestock presence benefit significantly from this added layer of protection. The installation of a brush guard minimizes the risk of cosmetic damage and potential mechanical failures, maintaining the vehicle’s aesthetic appeal and operational readiness.

- Wheel Well Liners and Mud Flaps

Wheel well liners and mud flaps mitigate the accumulation of mud, dirt, and debris within the wheel wells, preventing corrosion and damage to brake lines and suspension components. These components, typically constructed from durable plastic or rubber, deflect projectiles and minimize the build-up of corrosive materials that can accelerate wear and tear. Ranch vehicles operating in muddy or dusty conditions benefit substantially from the implementation of these protective measures. The installation of wheel well liners and mud flaps reduces the risk of corrosion, extends the lifespan of suspension and brake components, and maintains the vehicle’s overall structural integrity.

- Protective Coatings and Bed Liners

Protective coatings, such as spray-on bed liners and rust inhibitors, safeguard the vehicle’s body from corrosion, scratches, and dents. These coatings create a durable barrier against the elements, preventing moisture and chemicals from penetrating the underlying metal. Bed liners protect the truck bed from damage caused by heavy equipment and supplies, while rust inhibitors prevent corrosion from spreading to other areas of the vehicle. Ranch vehicles operating in harsh environments benefit significantly from the application of these protective measures. The implementation of protective coatings and bed liners maintains the vehicle’s aesthetic appeal, extends its lifespan, and reduces the need for costly repairs.

The strategic application of these protective components represents a proactive approach to vehicle maintenance in demanding ranching environments. By mitigating the risks associated with environmental and operational hazards, these enhancements contribute to increased vehicle longevity, reduced maintenance costs, and enhanced operational reliability. The selection of specific protective measures should be tailored to the unique challenges posed by the ranch’s operating conditions, ensuring optimal performance and safeguarding the vehicle’s long-term value.

Frequently Asked Questions

This section addresses common inquiries regarding exhaust systems and aftermarket enhancements suitable for trucks operating in agricultural environments. The information provided aims to clarify technical aspects and inform decision-making related to equipment selection and maintenance.

Question 1: What constitutes a “ranch muffler” and how does it differ from standard mufflers?

A “ranch muffler” typically refers to a heavy-duty muffler designed for enhanced durability and noise reduction in demanding agricultural settings. These mufflers often feature thicker steel construction and more robust internal baffling to withstand impacts and prolonged use in harsh conditions compared to standard mufflers.

Question 2: Are there specific legal restrictions regarding muffler modifications on ranch trucks?

Vehicle exhaust systems are subject to federal, state, and local regulations regarding noise emissions. Modifications that increase noise levels beyond permissible limits may result in fines or require remediation. It is imperative to verify compliance with all applicable regulations prior to undertaking any exhaust system modifications.

Question 3: Which truck accessories are most beneficial for enhancing load capacity in ranching operations?

Heavy-duty suspension upgrades, reinforced trailer hitches, and load-leveling kits are among the most effective accessories for increasing load capacity. Additionally, installing bed liners and cargo management systems can improve cargo security and prevent damage during transport.

Question 4: How frequently should ranch truck accessories be inspected and maintained?

A comprehensive inspection of truck accessories, including hitches, suspension components, and protective coatings, should be conducted at least every six months, or more frequently under severe operating conditions. Regular maintenance, such as lubricating moving parts and addressing corrosion, is crucial for ensuring continued performance and longevity.

Question 5: What are the key considerations when selecting protective coatings for ranch truck accessories?

Protective coatings should exhibit high resistance to abrasion, impact, corrosion, and UV degradation. Powder coating, spray-on bed liners, and specialized rust inhibitors are viable options depending on the specific application and environmental conditions.

Question 6: Can aftermarket exhaust systems and accessories improve fuel efficiency in ranch trucks?

Certain aftermarket exhaust systems, when coupled with appropriate engine tuning, can improve fuel efficiency by reducing backpressure and optimizing engine performance. Aerodynamic accessories, such as tonneau covers, can also contribute to minor fuel savings by reducing drag. However, the actual impact on fuel economy depends on driving habits and operating conditions.

The information presented aims to provide a concise overview of frequently encountered questions related to vehicle exhaust and accessory options for ranching environments. Adherence to proper maintenance practices and regulatory guidelines is paramount for ensuring optimal performance and safety.

The subsequent section will explore specific product recommendations based on operational needs and budgetary considerations.

Ranch Muffler & Truck Accessories

This exploration of “ranch muffler & truck accessories” has illuminated the multifaceted considerations inherent in optimizing vehicles for agricultural use. The discussion spanned noise mitigation strategies, durability enhancements, performance optimization techniques, load capacity augmentation, and protective measures against environmental hazards. It highlighted that the selection and implementation of appropriate components is not merely a matter of customization, but rather a strategic investment in operational efficiency and vehicle longevity.

The demanding nature of ranching necessitates a proactive approach to vehicle maintenance and enhancement. Informed decision-making, based on a thorough understanding of operational requirements and the capabilities of available products, is crucial for achieving optimal performance and safeguarding valuable assets. Continued vigilance in monitoring vehicle condition and adherence to recommended maintenance schedules remain essential for ensuring sustained operational readiness in the face of challenging environmental conditions. The proper utilization of appropriate aftermarket solutions contributes significantly to the overall productivity and sustainability of ranching endeavors.

![Sheldon's Custom Muffler: Performance & Sound [Shop Now] Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades Sheldon's Custom Muffler: Performance & Sound [Shop Now] | Best Mufflers for Cars & Trucks | Performance, Sound & Durability Upgrades](https://dnamufflers.com/wp-content/uploads/2026/02/th-208-300x200.jpg)